A simple Google search for ‘’top most dangerous industries in the world’’ will produce listicles and articles about the construction industry.

This is not a coincidence, since construction workers around the globe are injured or dying on their jobs every day.

Even annual statistics from reputable organizations and agencies support these facts.

So, to protect their workers and comply with OSHA regulations, companies are increasingly turning to construction technology.

Here is how construction technology is making construction sites safer for everyone involved.

In this article...

Wearables Help Protect Workers

Wearables can be any small, compact, and portable devices that keep workers safe.

In the construction industry, they’re typically smartwatches, smart clothing (vests, hard hats, boots), and sensors.

Their primary purpose is to collect relevant data about the workers’ health status and the environmental conditions they’re in, which helps eliminate fatalities and injuries on site.

For example, smartwatches can monitor vital signs in real-time, such as heart rate and temperature.

That way, they can detect if the worker is tired or at risk of heatstroke, and warn them on time.

Furthermore, sensors equipped with GPS locators can help you monitor the worker’s movement on site.

These insights are especially helpful in determining how often they move through hazardous areas.

But most importantly, if anything dangerous happens, the GPS feature can quickly locate the affected workers, so supervisors can begin emergency procedures.

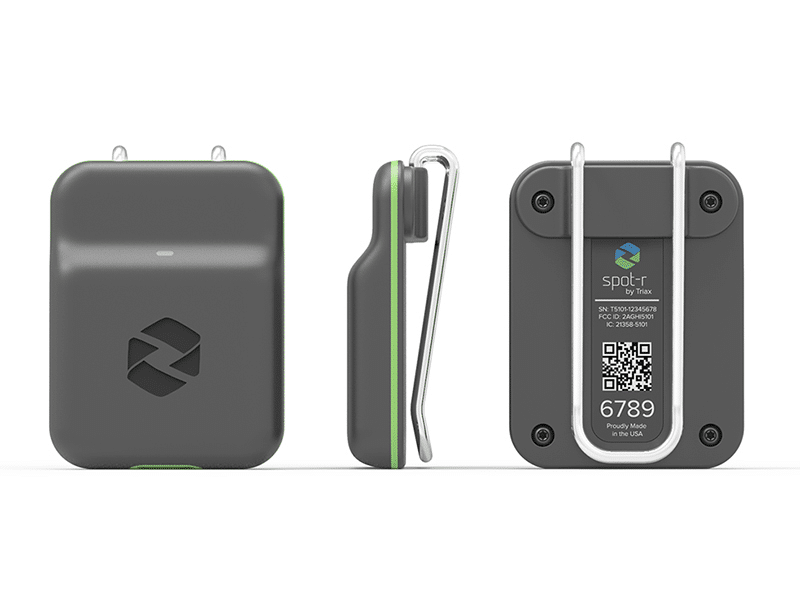

One device that offers this feature is the Spot-r Clip from Triax. This wearable construction tech only weighs two ounces but is invaluable for ensuring safety on construction sites.

The company claims Spot-r Clip can improve injury response time by 90% and detect worker falls.

Worker falls accounted for 34% of construction fatalities in 2020, so this wearable tech can help prevent potentially dangerous situations and save lives.

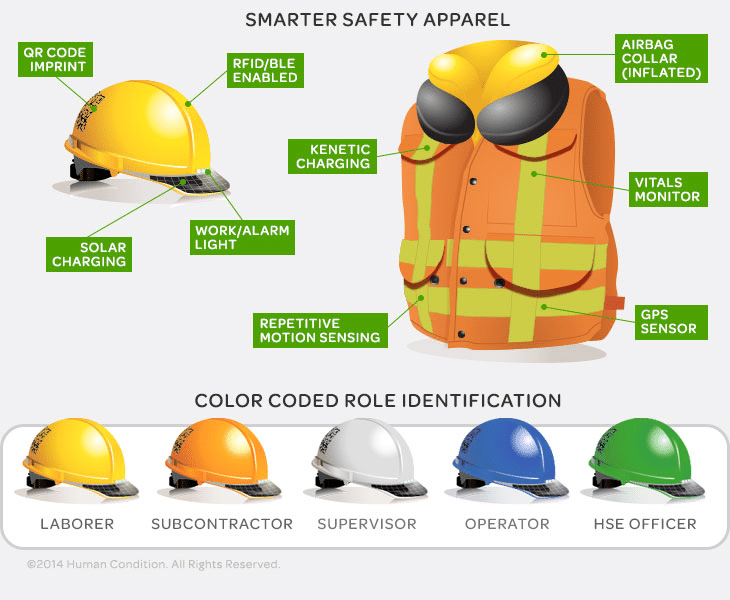

Even better, imagine if you could put an inflatable safety vest on your worker!

This sort of innovative tech can be seen in Human Condition, a think tank from New York that wanted to eliminate injuries and fatalities in the construction industry with wearable PPE.

To be more specific, the company designed a safety vest and a hard hat powered by computer tech, sensors, and GPS locating systems.

The tech has monitoring features similar to most wearable tech and smart clothing, such as monitoring vital signs and the worker’s posture and movements to determine if they’re tired or under the influence of drugs and alcohol.

But, the company also developed a safety vest with an inflatable airbag intended to protect workers if they fall.

Now, many are worried about the potential misuse of this tech, like limitless supervision and lack of privacy.

But it’s important to be transparent about data collection whenever you introduce any type of tracking device in a workplace.

Explaining to workers which data will be collected and how it will be used can help with the wider adoption of this tech on construction sites.

In the end, wearable tech helps everyone increase safety at a low cost.

Digitalization Streamlines Daily Activities

Implementing technology to increase safety doesn’t have to include new expensive equipment or the latest software.

Sometimes you can lean into solutions that are already there.

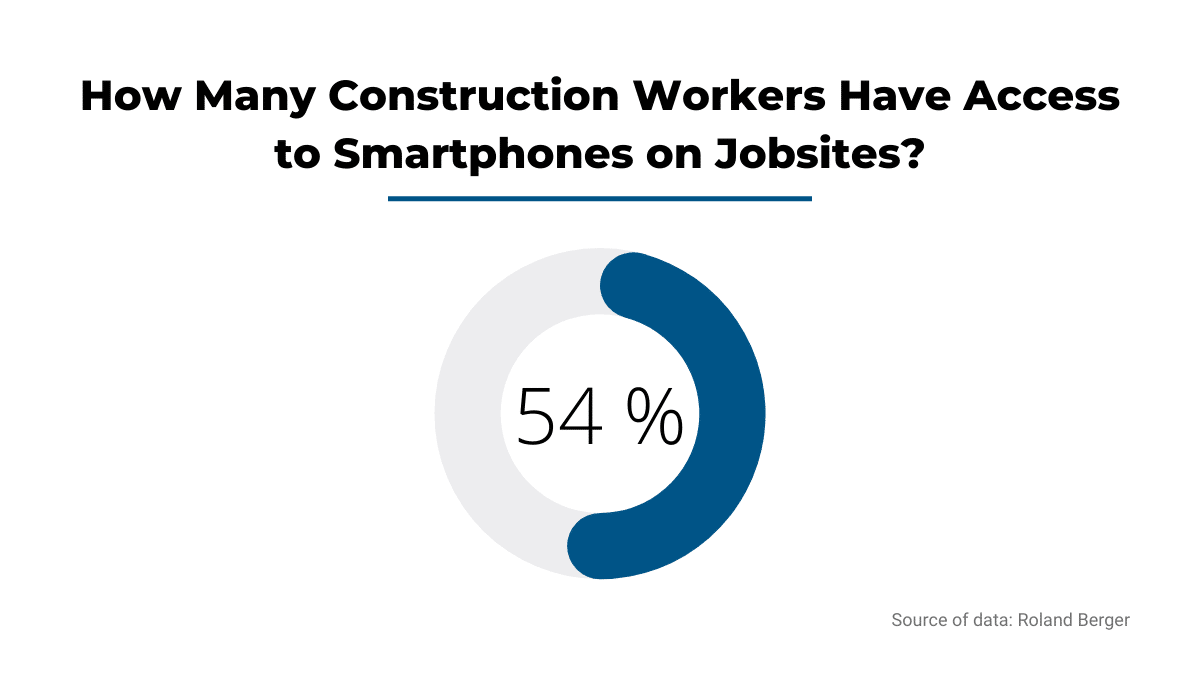

For example, according to recent research, more than half of construction workers have access to a smartphone at most construction companies.

This means they can use their mobile devices to record safety incidents and problems on the site as soon as they occur.

That way, workers don’t have to walk into the supervisor’s office after hours and file paper reports, which can make some people uncomfortable and reluctant to report issues.

You can also equip employees’ devices with GPS trackers to record precisely where the problem was detected and correct it for the future.

Moreover, it allows project managers and supervisors to better handle construction site safety without being physically present.

You can automatically share any report that your workers send you through mobile devices with other stakeholders and improve communication for the current project.

Not only are you more transparent in sharing potential issues onsite, but you’re also upholding an ongoing commitment to construction site safety.

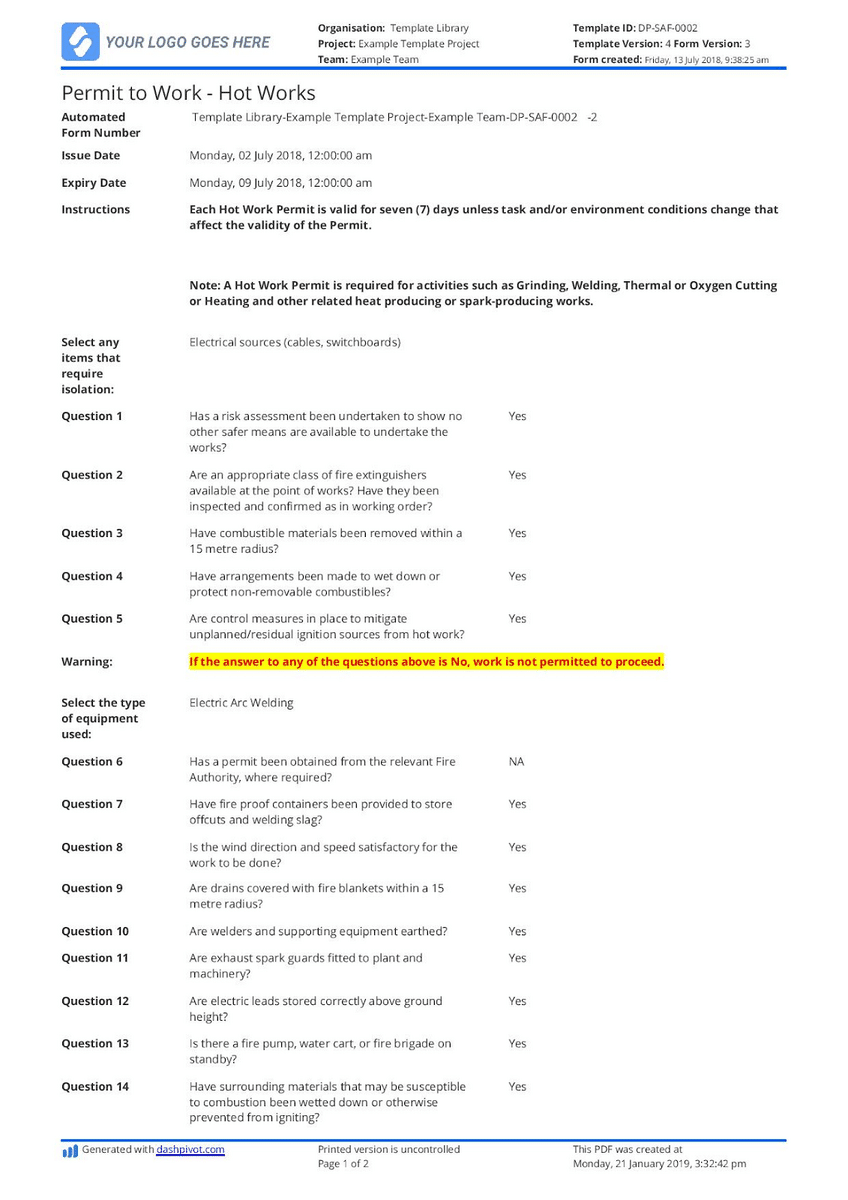

Here is what it looks like in practice. When workers are assigned high-risk tasks such as working at heights, lifting operations, or demolition, they have to file Permits to Work (PTWs).

This is mandatory by government authorities and ensures that work has been well-planned with all the necessary risks taken into account.

A worker can start their job only after the PTW Authority approves the permit. You can imagine how much time you would waste if you continued doing this manually!

Some reports say that workers waste on average 2-3 hours per week on manual reporting.

So by digitizing these permits and the filing process, you have higher levels of accuracy, reduced waiting times for approval, and greater accountability.

But most importantly, you have better visibility into the workers’ qualifications and permits for operating high-risk jobs.

Using mobile devices to monitor and report onsite safety can be a game-changer for construction companies looking to improve their processes without breaking the budget.

Drones Inspect Construction Sites

You might be familiar with drones for commercial use, but these devices are becoming a staple in the construction industry.

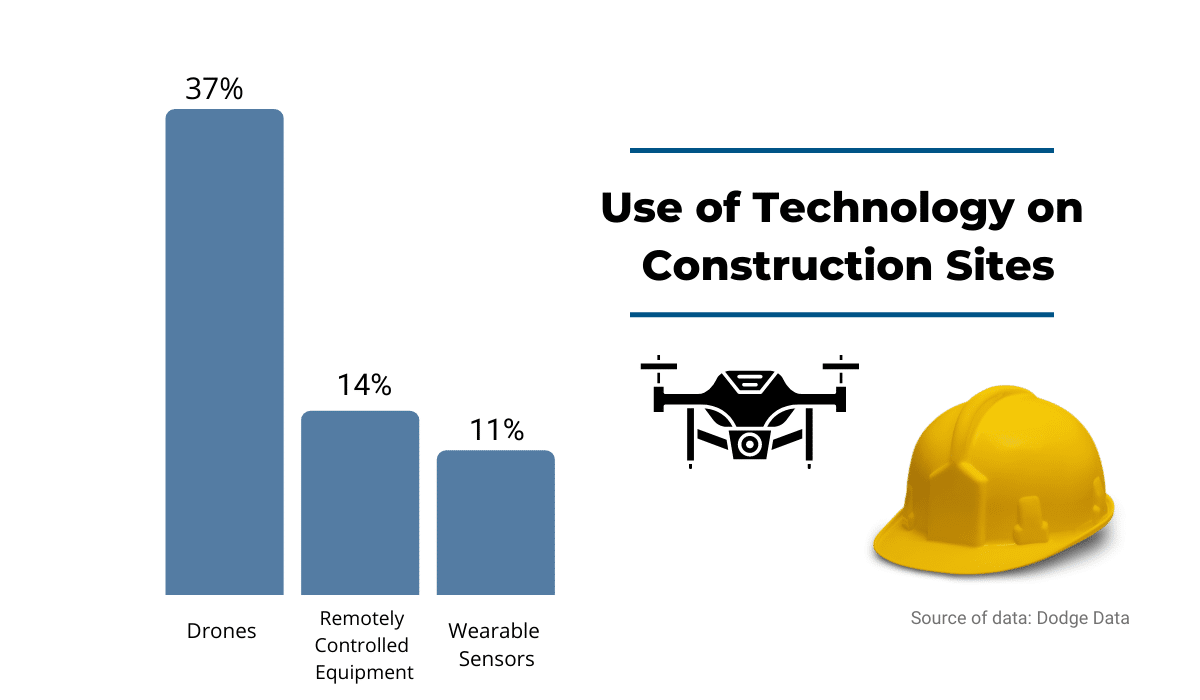

In fact, according to Dodge Data, with how many construction companies are using drones on construction sites nowadays, it can be considered an established technology.

Compared to other construction technologies, it’s safe to say drones are becoming as common as excavators on some construction sites.

One notable example is Balfour Beatty. The company currently has eleven trained drone pilots to do numerous activities on construction sites. Some of them include:

- Site surveying

- Stockpile measurement

- Visual inspections

- Monitoring progress

But according to Wayne Hughes, Principal UAS Pilot at Balfour Beatty, drones are exceptionally valuable when it comes to safety.

They can finish important construction tasks without putting people in dangerous situations to get the data and footage they need for the project.

Operators and supervisors are firmly on the ground while the drone does the heavy work, flying over the construction site.

Basically, looking at the construction site from a different perspective means safety managers can detect potential safety risks that aren’t visible from the ground.

The newest drone models can give accurate and high-quality footage of the construction site so contractors can understand the site conditions and adjust their daily work for maximum safety.

But there are other ways to use drones to ensure safety on site. Some companies monitor whether workers are using protective equipment or following safety protocols.

Or on the other hand, large and sturdy drones can be used to carry tools and equipment across the site to eliminate strains and back injuries due to excessive lifting.

As contractors realize the drone’s potential for safety in construction, this technology is becoming more commonplace on construction sites.

Site Sensors Inspect Construction Conditions

Dust, noise, high temperatures, and chemicals are almost synonymous with the construction industry. But they are also some of the main culprits that endanger workers’ health and safety.

Therefore, it’s necessary to monitor job site conditions for high chemical exposure, dust, or noise levels. Many companies use sensors to do that.

So, if the sensors detect dangerous levels of these hazardous environmental factors, the workers can be altered on time and evacuate the job site.

In a nutshell, during any sort of construction work, there will be small and invisible particles floating in the air, polluting the airways of your workers and anyone who finds themselves near the job site.

To demonstrate how important keeping the right air quality is, here’s an example of Integris Southwest Medical Center.

The health facility hired Nabholz Construction for renovations, but their main concern was protecting the health and wellness of their patients.

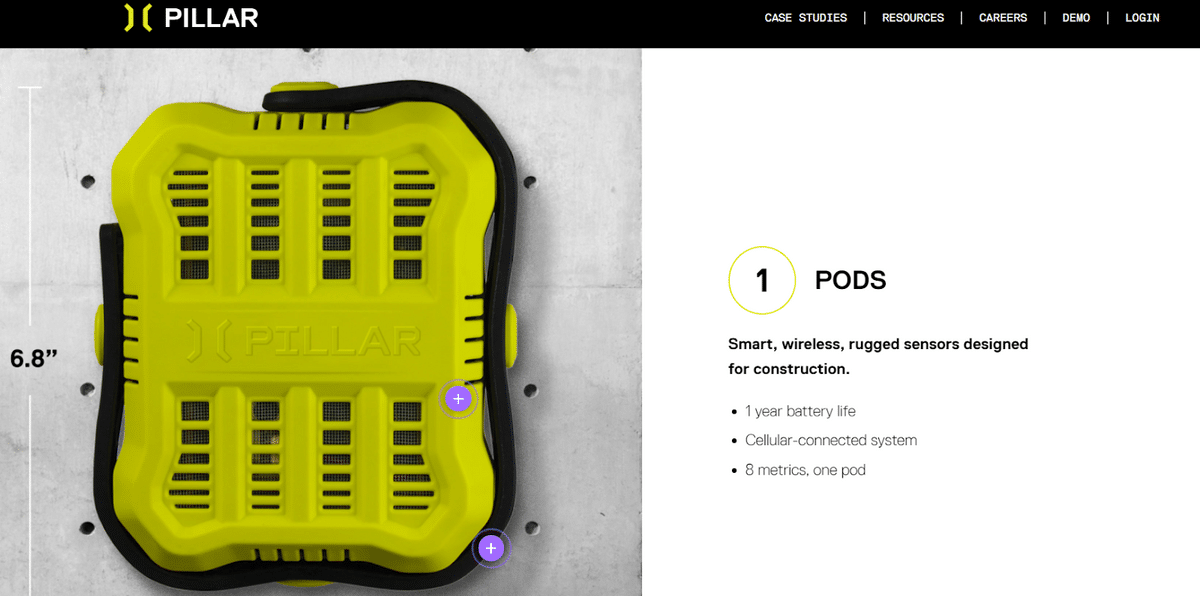

So, Nabholz and Integris decided to use Pods by Pillar Technology.

The tech company is producing smart sensors that detect eight different environmental metrics, like temperature, humidity, dust, noise vibration, and volatile organic compounds (from paint and varnish).

Furthermore, one sensor can cover 2,000 sq ft. of building space and give real-time alerts to contractors.

Pillar’s sensors were strategically placed inside and outside the renovation area and moved as each renovation phase was finished.

Additionally, the sensors were used to detect defective HEPA filters and gaps in exhaust ducts.

During this time, Nabholz and Integris got weekly reports on the levels of dust and noise inside the renovation area.

Integris also had its own hygienist to confirm the readings provided by Pillar were accurate, and dust didn’t move into other areas of the building.

In the end, Pillar sensors proved to be valuable for the health facility’s needs and helped protect their patients while undergoing necessary renovations.

What you can learn from this is that construction regularly produces toxic and dangerous airborne particles, some of which you can’t see.

So, to ensure maximum safety for everyone on the construction site, you need smart sensors that will alert workers if they’re at risk.

Virtual Reality Helps in Safety Training

What is your first thought when someone mentions safety training?

Probably a classroom-like lecture with an expert and a presentation covering basic safety procedures on most construction sites.

Now, a safety training program is different for every construction company, depending on their needs, available resources, and the worker’s learning styles, habits, and motivation.

But that doesn’t mean you can’t take it to another, more engaging level.

Jennifer Suerth, Vice President of Technical Services at Pepper Construction, says that their company leaned into new technologies to create a more unique and engaging experience, so employees are more excited and motivated to practice safety.

What are they doing differently?

They are using virtual reality to conduct safety training. To quote Suerth:

“With virtual reality, we can address any job-site risk without putting somebody in an unsafe environment.”

Which is the main premise of using virtual reality for safety in construction.

Basically, employees interact with computer-generated scenarios to learn the basics of operating machines safely, moving through a construction site, and conducting safety protocols.

They put on glasses or VR helmets which project real-life situations.

Then the user engages with the virtual world using controls, and their reactions produce different consequences in a safe environment.

So, no harm is done if a brick falls on their head in a virtual simulation.

But the visual impression combined with audio alerts can leave a lasting impact on the employee, who will be more diligent in using their hard hat when walking around the construction site.

In this way, you can create numerous scenarios to simulate dangerous on-site conditions so workers can learn in a safe environment about different practices and safety protocols.

But more importantly, inexperienced workers must learn how to operate dangerous heavy machinery before they sit in the cab of the actual machine.

Even people who have never operated heavy machinery can quickly learn the basics of safe operation with VR.

In this article by Eric Liga, he described his experience with operating a crane in virtual reality.

He spent an hour with Industrial Training International (ITI) VR’s crane simulator and applied what he learned on an actual machine.

As a complete novice, first, he had to get used to the crane’s controls, and he was put through several scenarios.

His first attempts were complete failures, with suspended loads swinging dangerously to other people and objects.

Even virtual supervisors reprimanded him for being too slow or setting his loads too hard.

But after completing the training, he sat in a real crane (under supervision, of course) and demonstrated what he learned.

He was now familiar with the crane’s controls and could perform basic functions with the machine.

According to him, the simulator was excellent in replicating the actual experience of operating a crane and thus is extremely valuable for any new crane operator that doesn’t have first-hand experience with the machine.

All in all, virtual reality is the next level in creating effective safety training programs which can incentivize employees to take safety protocols more seriously.

Conclusion

As you can see, technology can play a key role in monitoring and managing safety on construction sites.

From wearables that track the vital signs of your employees to sensors and drones that inspect the site and environmental conditions, there are numerous solutions that help you make the site safer for your workers.

Every bit counts in ensuring safety for construction workers, so severe injuries and fatalities become less common. Implementing tech solutions might be crucial in that endeavor.