It’s impossible for members of a workforce to perform their jobs correctly without the proper tools.

To avoid frustrating, time-wasting searches, it’s best to exercise strong tool control from the moment your organization acquires an asset until the end of its lifecycle.

Between these moments, the tool likely passes from one employee to another across multiple worksites.

Tool tracking with a dedicated app is a major aspect of effective tool control.

This post will discuss the consequences of poor tool control, particularly within industries where tool control and tool accountability matter the most.

Then, it will offer guidance and action items for effective improvement. The sooner your organization imposes sturdy tool control, the more efficient it will become.

In this article...

Industries Where Tool Control and Tool Accountability Matter

Employee and tool accountability is important in nearly every industry. However, certain economic sectors especially benefit from tool control.

Here is just a small sampling:

Education: Universities, high schools, grade schools, and even daycare centers benefit from tracking books, educational materials, projectors, playground equipment, chairs, desks, and maintenance materials

Military: Barcoded and tracked items help to enhance security and efficiency in addition to improving organization

Manufacturing: Machine tools, conveyor belts, small repair items such as bolts, boxes, shipping materials, and inventory

Retail: Inventory control, ease in restocking, accuracy in sales reports

Nonprofits: Donated items, gratitude rewards for donors, wholesale purchases

Healthcare: Medicine, sterilization items, patient beds, linens, test equipment, waiting room items

Office-Based Economy: Furniture, office supplies, printers, copy machines, employee break room items

Construction: Hand-used tools, vehicles, cement and wood, permit items, nails, trim, and siding

Aviation: Many aviation-connected businesses, such as repair shops and manufacturing stations, are governed by strict rules regarding cataloging, labeling, and ease of inspection

Hospitality: Stocking items for housekeeping, maintaining the flow of food items, tracking guest transport

When organizations in these industries exercise tool control and accountability, employees avoid mishaps more readily, and customer service improves.

Consequences of Poor Tool Control

While good tool control leads to many positive outcomes, the costs of neglecting it build and escalate quickly.

The most important goals a business seeks, such as profitability, client trust, employee satisfaction, and potential for growth, quickly become swallowed up by lax treatment of tools.

1. Poor Productivity

Productivity, prized from the smallest single-employee home office to the largest multinational corporation, is one of the first and most-lamented victims of substandard tool control.

Employees searching for misplaced tools, missing, stolen, or in maintenance are not completing important tasks.

They are also likely to grow frustrated and increasingly distracted.

In addition, such workers are forced to dedicate energy to checking places where they don’t usually go and even attempting to track down managers or other employees in an effort to find a single item.

When this happens, distractions lurk at every corner. Both time and space are used inefficiently.

Some tools are unique to a specific job or are extremely expensive. This can include scientific equipment, proprietary tools, or handmade items.

Such tools are irreplaceable, and often no work can take place without them.

This means that an entire operation can grind to a halt while employees search for a single item.

Even when multiple and identical tools are available for a job, smaller items still have a tendency to disappear.

Employees who don’t have the correct tools might turn to inefficient replacements or even use the wrong item for the job.

This affects task completion time, as well as the quality of the employee’s output. It has a disastrous domino effect on a company’s entire operation.

2. Unsafe Work Sites

Poor tool control hinders workplace safety. Safety standards, whether imposed by an industry or a government, are difficult to maintain when tool control is substandard.

According to EHSToday, construction accidents cause tragedies on a daily basis. Of all workplace fatalities, one in five are related to construction, and two deaths a day take place in the United States alone on such sites.

Proper maintenance helps avoid accidents and unsafe work conditions.

The same is true of regular inspections.

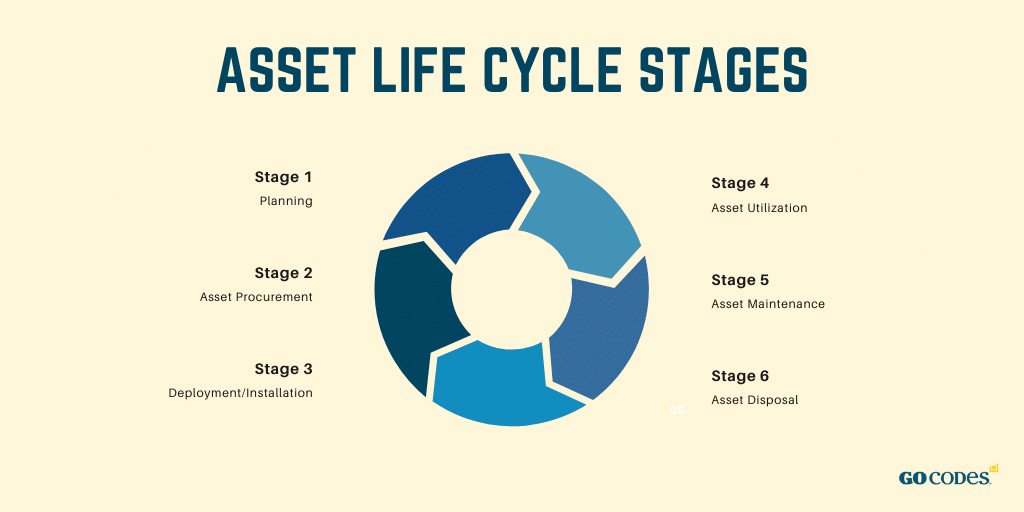

However, constant tool use causes erosion, and without strong tool control, it’s impossible to know where the assets are in their lifecycle.

That means the following can take place:

- The tool might develop cracks, dings, and weaknesses

- Since the tool has not undergone tracking, the damage goes unnoticed

- Further use exacerbates the damage

- Employees apply improper pressure to force the tool to perform

- The tool fails without warning, causing expensive damage or worker injury

This cycle is easily avoidable with proper tool control. In fact, several physical hazards await when companies do not oversee tools or care for them properly.

These include injuries from improperly maintained hand tools or dulled blades, as well as falls of all kinds.

For instance, workers can fall from compromised ladders or slip and fall on incorrectly maintained surfaces.

Safe worksites are well-organized ones. This begins with effective tool control.

3. Wasted Money

Financial losses are quick to follow inadequate tool control and this negative consequence quickly affects every other aspect of the business.

Tools, as well as equipment, are porous when companies don’t control them.

Before it instituted tool control, J&M Keystone, Inc. lost $30,000 a year to missing assets.

However, when decision makers began to track its assets, financial losses dropped to $1500.

Poor tool control can have an adverse effect on a variety of areas of business, from its output to its expenses.

Projects can remain stalled and uncompleted, frustrating clients and causing demoralization in employees.

Lost tools and assets that require unexpected replacements have to get rented or quickly purchased without comparison.

If there is vandalism, it can result in cleanup costs and unprofessional-looking job sites that damage your reputation.

Moreover, ineffective tracking facilitates theft, which can spread even to rented assets, such as portable toilets and contractor equipment.

This, in turn, prompts insurance companies to raise premiums after claims for lost or stolen assets.

In short, planning for the future or long-term projects becomes difficult or even impossible.

As you can see, turning tool control into a priority mitigates or solves many other financial problems—or even avoids them altogether.

The work of installing a system that is a good fit for your business leads not only to happier customers, better organization, and calmer employees, but also to a stronger bottom line.

4. Non-Scalable Operations

What are scalable operations?

While the term presents itself in many different ways, in this context, the term scalable operations refers to a business that is built to withstand natural expansion and contraction.

It does not collapse under the pressures applied by rapid or sustained growth.

Employees, communication, assets, systems, and structure are all easily adaptable to new demands.

Scaling up your business is an exciting prospect.

However, poor tool control can hinder growth quickly.

When businesses grow, contracts or jobs usually take place on multiple sites.

Failing to exert proper control over your assets quickly leads to chaos when multiple pieces of equipment become necessary on several job sites at once.

Additionally, it can lead to problems in communication that rapidly contribute to disagreements between managers and employees.

This is disastrous to morale and company culture.

Similarly, when contractions take place, a lack of oversight inhibits financial and physical restructuring.

Therefore, the best way to face the stresses of growth or controlled contraction is to implement strong tool control during calmer economic waters.

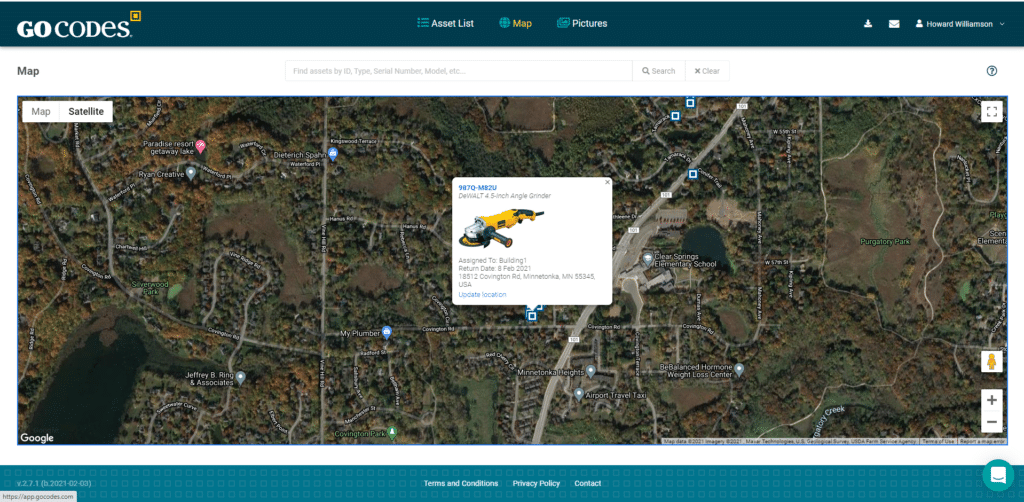

Systems such as GoCodes, which harnesses the power of a cloud-based operation, allows for remote scheduling and management.

Since there is no limit to the number of tools you can govern with a good tracking method, your system can expand with your business, tailored to what you need, when you need it.

How to Control Your Tools

Thinking of all the assets and tools your company might use might seem overwhelming at first. Where to start?

What is the best way to implement a user-friendly and scalable system? Here is some guidance for beginning your journey into more substantial control.

1. Implement QR Code Tool Tracking

Asset tracking takes a number of forms. For the purposes of tool control, however, consider the many benefits of QR codes.

A QR code takes the form of a square covered with a pattern of dark and light pixels.

While traditional barcode scanning provides valuable information about a product and its specifications, QR codes offer several benefits specific to tool tracking.

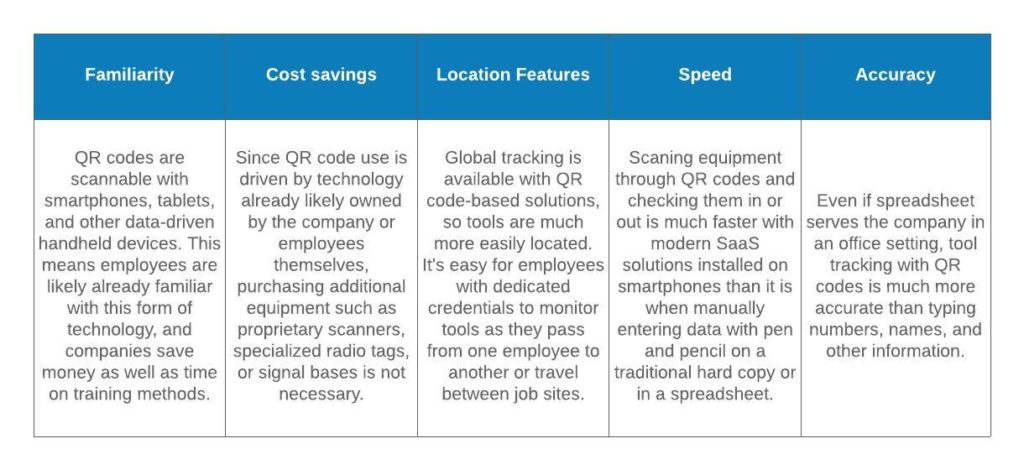

Familiarity: QR codes are scannable with smartphones, tablets, and other data-driven handheld devices. This means employees are likely already familiar with this form of technology, and companies save money as well as time on training methods.

Cost savings: Since QR code use is driven by technology already likely owned by the company or employees themselves, purchasing additional equipment such as proprietary scanners, specialized radio tags, or signal bases is not necessary.

GPS Features: Global tracking is available with QR code-based solutions, so tools are much more easily located in the event of loss or theft. In addition, it’s easy for employees with dedicated credentials to monitor tools as they pass from one employee to another or travel between job sites.

Speed: Using QR codes is much faster than manually entering data with pen and pencil on a traditional hard copy.

Accuracy: Even if spreadsheet software serves the company in an office setting, tool tracking with QR codes is much more accurate than typing numbers, names, and other information.

These benefits especially apply since employees typically use these assets in the field, far from a tool crib or headquarters.

Items that change hands regularly or are located in remote areas are still trackable with a QR-based system.

2. Use a Single System to Track Tools and Maintain Inventory

Trying to integrate several different systems leads to frustration and misunderstandings.

Using one method to schedule maintenance, another to track tools, and still another for record-keeping, limits business growth and often fails to capture important data.

Dedication to a single system is the best way to track and maintain tools and inventory, manage life cycles, as well as build a comprehensive view of asset health.

It also helps a business make data-based plans for the future.

GoCodes’ tool tracking software’s unique structure allows it to meet all of these challenges and more.

Not only does it offer user-friendly interfaces, it also makes workforce training comprehensive and efficient.

Furthermore, checking in and out is automatic and accomplished in seconds, while GPS fencing sets off alerts when someone removes tools from designated areas unauthorized.

Additionally, maintenance scheduling is automatic.

As such, it provides a wealth of information to contractors, technicians, and employees reporting breakdowns or condition concerns.

The software entails cloud-based access, which preserves, protects, and organizes tool-tracking data, an ideal solution for single-system control.

Storing data in the cloud—even scanned historical information—allows for instant recall, as well as significant savings in hard record storage.

It also allows for more precise and comprehensive information security.

The efficiency of single-system tool tracking and inventory maintenance offers a great many benefits over attempting to juggle many different methods at once.

3. Adhere to Standard Operating Procedures

Implementing standard operating procedures makes the company function in a more streamlined manner.

While it’s important to allow for flexibility and creativity in certain situations, such as emergencies or working in the aftermath of a natural disaster, standardization avoids disagreements between management teams and members of the workforce.

Standardized procedures help avoid potential legal entanglements.

Implementing them also ensures regulatory and warranty compliance.

When employees are presented with a list of standard operating procedures alongside an explanation of why they are important, they are more likely to perceive them as coherent and worthwhile.

As a result, they are more likely to prioritize adhering to them.

This is vital, especially when the guidelines apply to the tools they use regularly.

It is important to implement standard operating procedures that are simple, easily comprehended, and efficient.

They are of little to no assistance if they serve only to complicate or slow down any aspect of a job.

The length of a single page is a good aim for a standard operating procedure template.

When employees understand expectations, as well as the reason behind them, effective workflow and increased job satisfaction are more easily achieved.

Conclusion

The heavy burdens imposed by inadequate tool control hinder growth, impede communication, and quickly lead to disappointed clients.

Decision makers have to focus on exerting control over every aspect of an organization in order to achieve efficient movement of assets and employees.