Key Takeaways:

- The choice between passive and active RFID tags depends on your use case.

- Modern systems combine RFID with GPS and centralized databases for full asset and workforce visibility.

- RFID improves both site safety and security by monitoring worker locations and preventing unauthorized equipment use.

- Integrating RFID with construction management software reduces labor hours, inventory errors, and costly project delays.

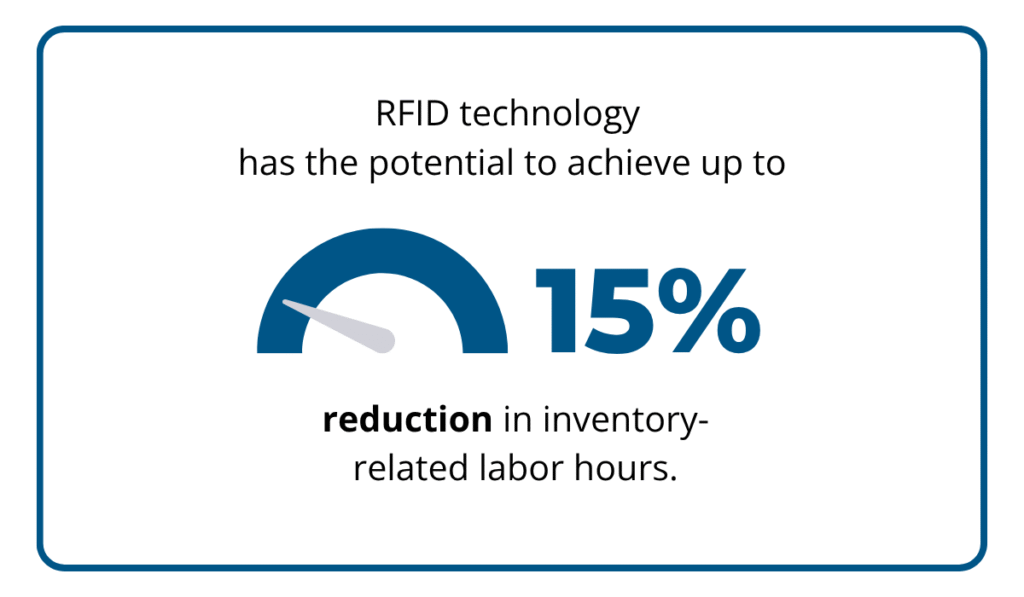

Did you know that some studies suggest RFID can reduce labor hours spent on inventory management by up to 15%?

And inventory management is just the start. RFID tracking technology also improves tool tracking, site safety, and more!

In this guide, we’ll unpack the essentials of RFID tracking and explore how it’s transforming construction job sites of every size.

In this article...

How Does RFID Tracking Work?

RFID tracking systems use wireless technology to identify, track, and monitor physical assets, overcoming the delays and limitations of manual processes at the same time.

The faster your managers can access reliable, real-time data, the better positioned your business will be to make swift, informed decisions on-site.

And that’s where RFID technology comes in.

The core components of an RFID system include tags, readers, and software that work together to deliver real-time location and status updates, as outlined in the video below.

Source: AXEM Technology on YouTube

Pretty neat, right?

Construction businesses benefit from this technology because it dramatically improves the accuracy, speed, and reliability of asset tracking across large, fast-moving job sites.

RFID tracking is associated with several well-known characteristics, such as instant bulk scanning and real-time tracking, but also relatively costly deployment.

Source: GoCodes Asset Tracking

This tracking technology is also frequently tied to controlled indoor environments like warehouses, although modern RFID systems are increasingly adapted for rugged outdoor settings like construction sites.

At the heart of it all are the RFID tags themselves.

These come in several types, each designed for different environments and operational needs:

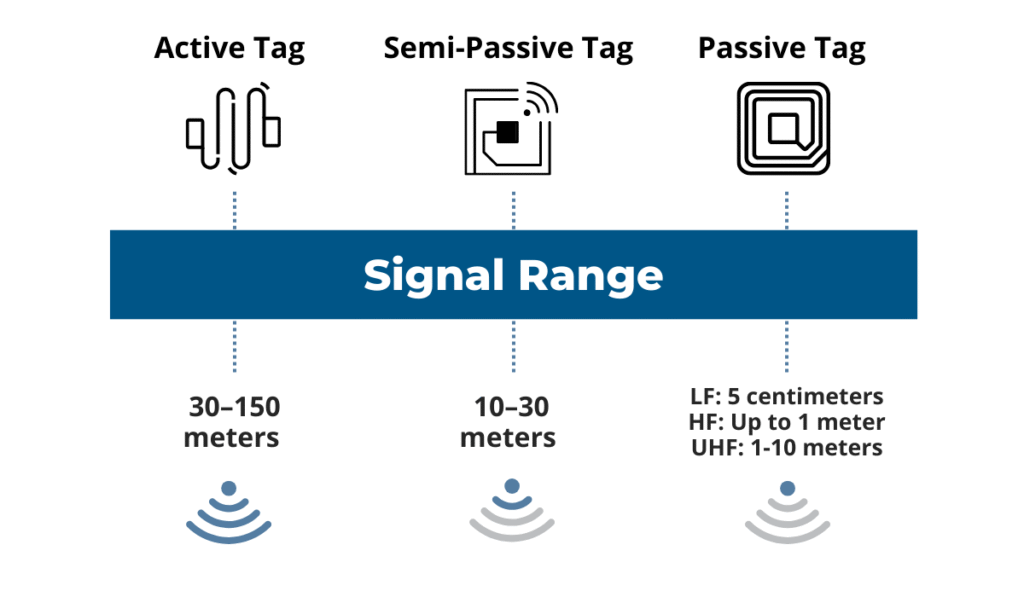

- Passive tags – require readers and have a shorter range, but are compact and cost-effective

- Active tags – use an internal battery for continuous broadcasting, enabling real-time monitoring over longer distances

- Semi-passive tags – offer extended range and environmental sensors, but sit somewhere in between

Key factors to consider include tag size, attachment method, and general durability, especially for equipment that’s exposed to harsh weather or heavy handling.

As shown below, there are also notable differences between passive, active, and semi-passive systems when it comes to reading range.

Source: GoCodes Asset Tracking

Keep in mind that while RFID performance has improved dramatically over the years, the physics behind the technology remains the same.

Namely, certain materials like metal and water can still cause unpredictable signal behavior, as explained by experts.

Illustration: GoCodes Asset Tracking / Quote: atlasRFIDstore on YouTube

In short, understanding how RFID works and choosing the right setup ensures your business gets the most from this system, no matter the conditions.

How Construction Teams Benefit from RFID Technology

Now that we’ve covered the RFID tracking essentials, let’s take a closer look at the key benefits this technology delivers for construction teams.

Improves Efficiency

Tracking technology directly enhances efficiency, one of the core construction necessities.

After all, the demands of tight deadlines, resource management, and site safety leave little room for wasted time or lost equipment.

The available data backs this up.

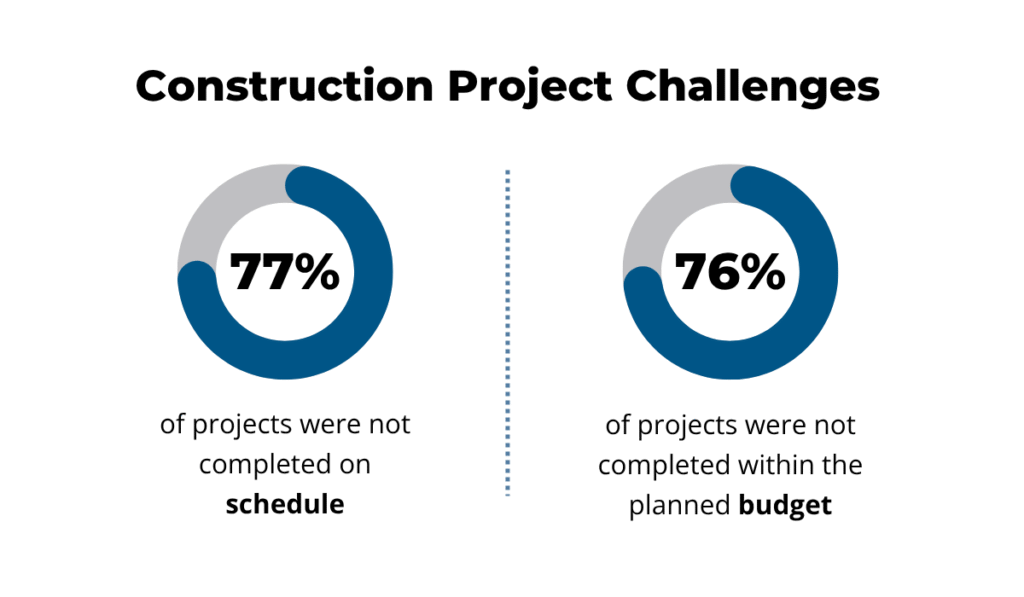

A Procore and IDC survey of North American construction firms revealed that nearly 80% of projects missed both their budget and schedule targets.

Illustration: GoCodes Asset Tracking / Data: Procore

On top of that, the average job experienced six budget changes, five scheduling changes, and a 15% increase in total costs.

It’s clear that to stay competitive, construction businesses need to rethink and automate wherever possible, with RFID tracking technology offering one of the fastest ways to get there.

RFID systems automate asset identification and data capture, drastically reducing the time spent on:

- Tool check-ins/check-outs

- Manual inventory counts

- Equipment locating

Fewer human errors mean smoother workflows and more time spent on productive, revenue-generating tasks.

And there’s no shortage of real-life examples.

For instance, one industrial-vehicle manufacturer used RFID to automatically track components moving through its assembly plant.

Eliminating manual part checks, enabling tag-scanning from forklifts in motion, and linking everything to ERP systems boosted throughput, cut loading times, and eliminated data entry errors.

Construction teams see similar benefits:

| Bulk and automated scanning | Multiple tools and materials can be tracked instantly as they move |

| Elimination of manual verification | Reducing idle equipment and saving hours of admin each week |

| Real-time location and process visibility | Knowing where tools and materials are, no matter the job size |

Ultimately, RFID helps your team spend less time chasing tools and paperwork and more time building.

Enhances Accountability

RFID technology is extremely valuable for cultivating a culture of accountability.

Construction sites are busy, unpredictable environments, which makes it surprisingly easy for tools and equipment to go missing or be mishandled.

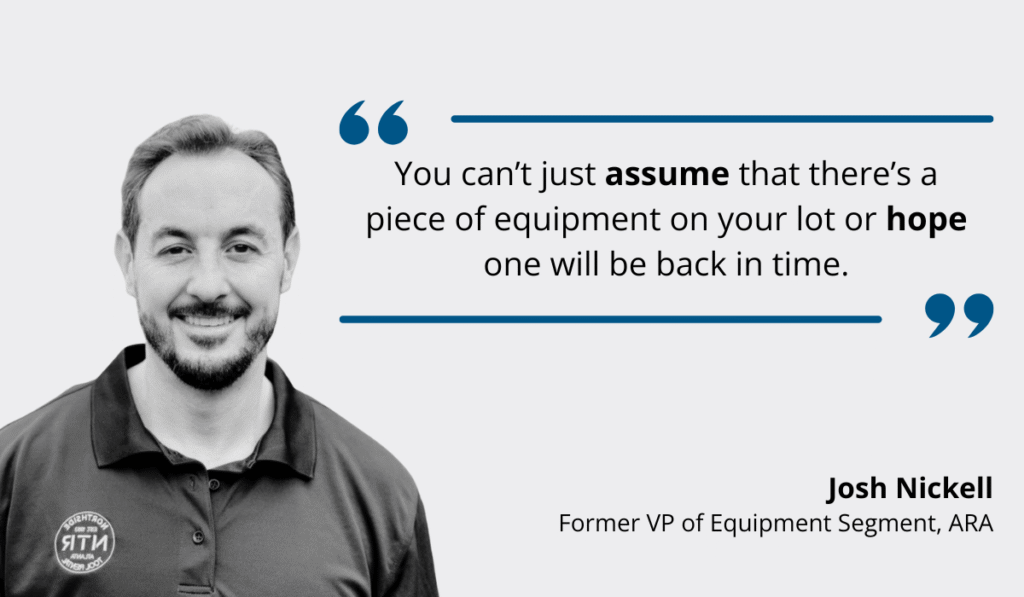

As Josh Nickell, former VP of Equipment for the American Rental Association, wisely put it:

Illustration: GoCodes Asset Tracking / Quote: For Construction Pros

With RFID, every tool or piece of equipment is tagged and connected to a central database, allowing you to track its entire lifecycle—from checkout to return. This real-time visibility means you’ll always know who has what, and where it’s supposed to be.

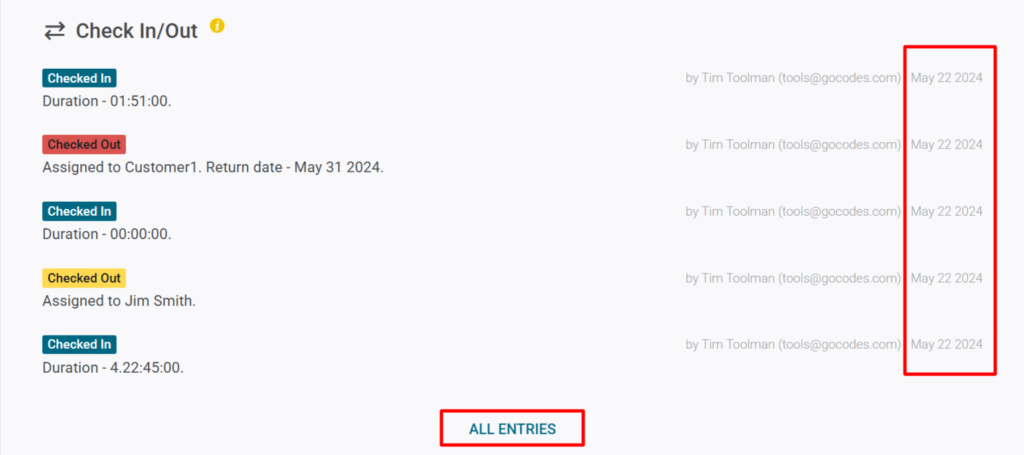

A proper check-in/check-out system is essential here.

By scanning RFID tags when tools leave and return to storage, your team gets instant, automated records of usage.

It’s not just about avoiding lost tools—it’s about encouraging responsible handling.

When staff know their usage is being tracked, they’re more likely to return equipment on time and report issues promptly.

Even if a tool goes missing or gets damaged within a single shift, checking the system allows you to quickly identify who handled it last and address the situation before it escalates.

Source: GoCodes Asset Tracking

To put it differently, you can trace patterns and determine whether there are some procedural gaps or if something is a case of misuse.

All in all, RFID replaces guesswork with facts, making it easier to get to the bottom of things and build a more accountable job site.

Prevents Asset Loss

RFID also plays an important role in preventing asset loss.

Losing equipment is one of the most frequent and expensive issues on construction sites, whether it’s through simple misplacement or outright theft.

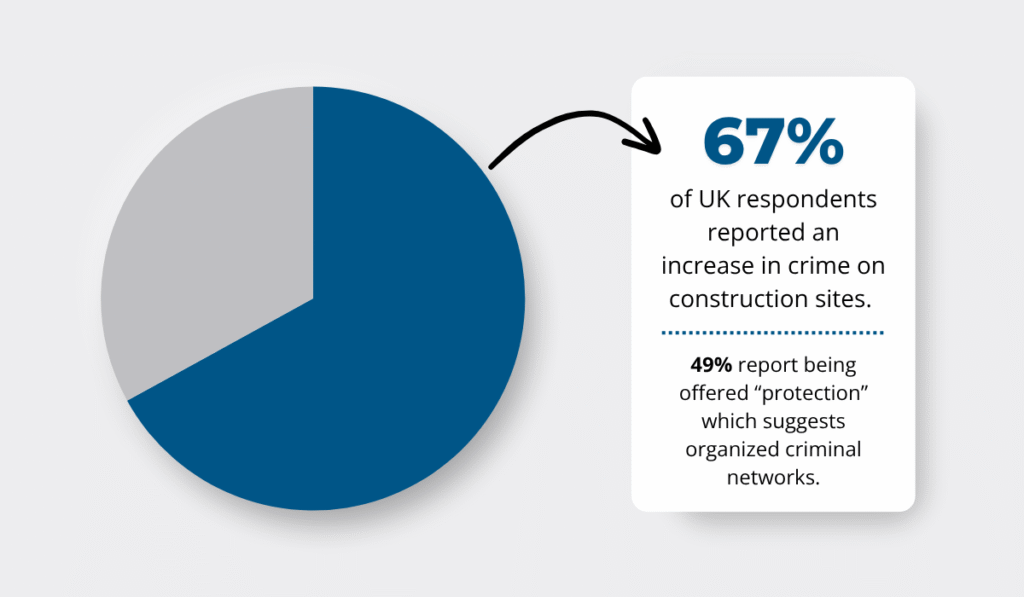

And the numbers show that the issue isn’t going away any time soon.

It’s quite the opposite, with a recent BauWatch survey revealing that 67% of UK construction professionals reported a rise in crime on their sites in 2024.

Illustration: GoCodes Asset Tracking / Data: BauWatch

These findings suggest a rise in organized crime, while some previous reports indicate that over 40% of tool theft cases can be attributed to either directly employed or subcontracted staff.

While the data mostly links to the UK, it’s much the same story in the US.

Fortunately, tracking technologies like RFID can make a measurable difference.

By providing real-time location data and automated alerts when tools or equipment move outside approved zones or storage areas, RFID helps your team detect missing or misplaced assets early, often before they’re gone for good.

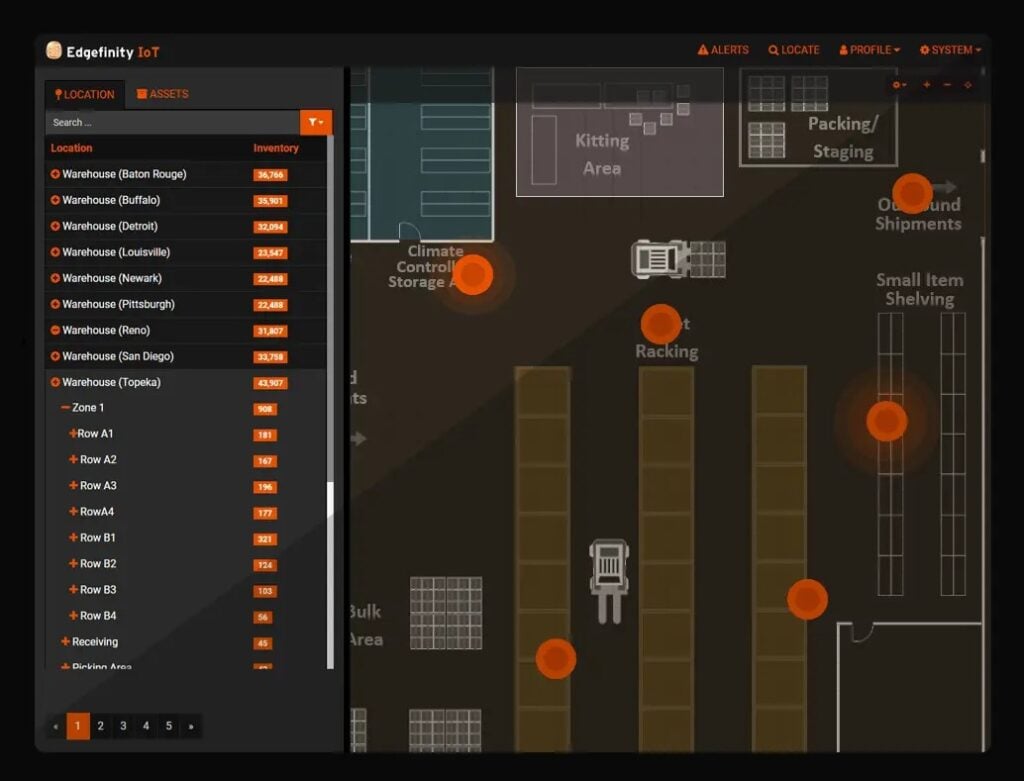

One practical example comes from Cybra, whose asset tracking software enables live, zone-based monitoring, as seen in this image.

Source: Cybra

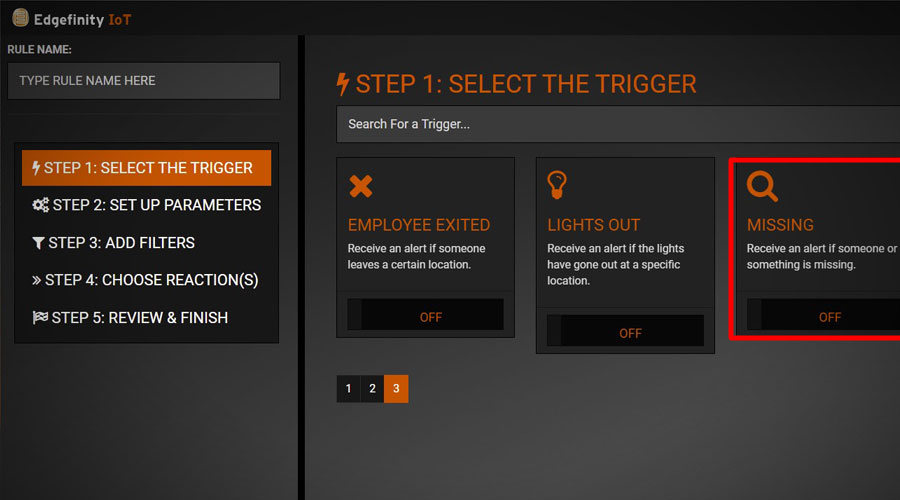

Users can assign zones, set up trigger events, and configure alerts to flag anything unusual, like a generator leaving the site perimeter after hours, or a tool moving to a restricted area.

Source: Cybra

A lot of software solutions allow you to tailor alerts by time of day, asset type, or zone location for even tighter control.

In short, better tracking with near-immediate response time enables construction companies to avoid costly delays, reduce replacement expenses, and strengthen site security.

Applications of RFID In Construction

RFID technology isn’t limited to warehouses and factories.

In the following sections, we’ll explore some of the most practical ways RFID systems are being used on modern job sites, improving site control, asset oversight, and workflow coordination.

Tool & Equipment Tracking

As we’ve already established, RFID makes it much easier to locate and manage tools, equipment, and vehicles across sprawling construction sites.

But it’s much more than just location tracking.

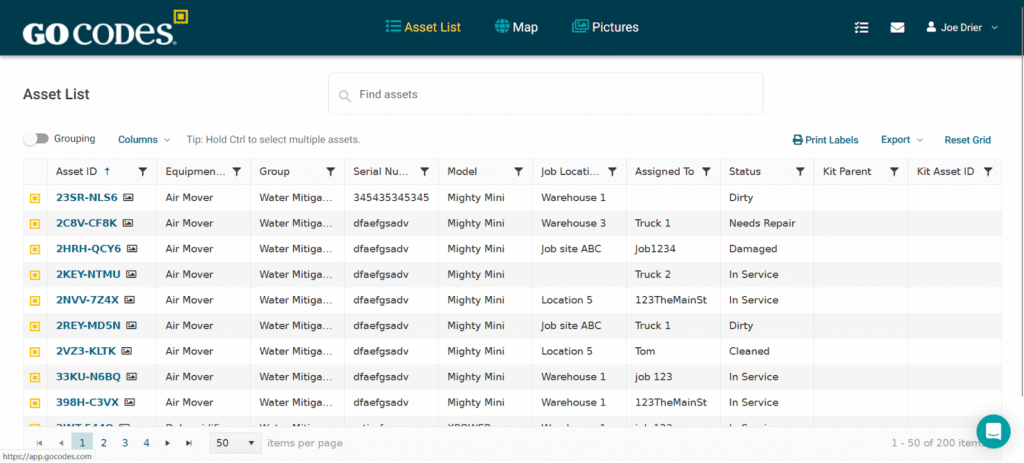

RFID systems can integrate with your asset management software to monitor maintenance cycles, availability status, depreciation, and usage logs in real time.

And you can access all that information from a single, intuitive dashboard.

Source: GoCodes Asset Tracking

In other words, smart asset management solutions like GoCodes Asset Tracking increase visibility and reduce manual errors while streamlining key on-site processes.

As noted by sales manager, Vishal Singh, RFID is highly effective for asset tracking and inventory management, but it performs best within defined zones, while GPS offers a more precise localization on wide-open outdoor sites.

Illustration: GoCodes Asset Tracking / Quote: LinkedIn

A good example is how some companies combine RFID readers on trucks with RFID-tagged dumpsters to significantly simplify the check-in/check-out process.

As a truck approaches, the reader automatically detects the tag and records the location, meaning that no manual scanning is needed.

In the end, it all boils down to efficiency. With RFID, you can streamline tool tracking to ensure critical equipment is where it should be when you need it, and in optimal condition.

Worker Safety Monitoring

RFID technology plays a growing role in protecting the people on your job site.

As construction remains one of the most dangerous industries worldwide, improving site safety monitoring is a critical consideration for owners and managers.

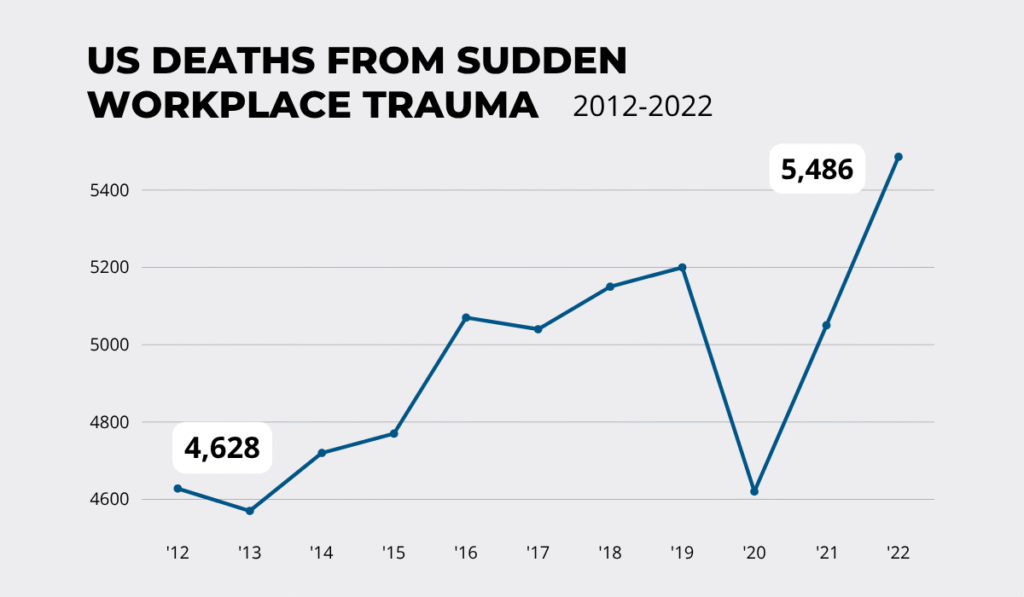

A comparison of 2012 and 2022 workplace trauma death statistics in the US reveals a troubling 18.5% increase in fatalities over the past decade.

Illustration: GoCodes Asset Tracking / Data: US Bureau of Labor Statistics

Construction accounted for a significant share of this, and given the latest Bureau of Labor Statistics (BLS) data that shows 1,075 fatalities in 2023, it is once again eclipsing other industries.

Many of these incidents result from equipment mismanagement, poor site visibility, or workers ending up in hazardous areas at the wrong time.

And that’s exactly where RFID worker tracking comes in.

By equipping workers with active RFID badges or tags, your safety managers can monitor real-time worker locations to ensure they stay within safe zones and comply with site protocols.

You can watch a real-time demo here.

Source: RICAL at Georgia Tech

The system also helps quickly identify anyone who has entered a restricted area or gone missing during emergencies, such as inclement weather episodes.

Beyond location tracking, RFID-based systems can store worker qualifications and training records.

That way, managers can scan a worker’s RFID badge to instantly confirm whether they’ve completed required safety training and can take on a specific task like operating an excavator.

While no technology can prevent every incident, RFID helps improve awareness, coordination, and emergency response, making job sites safer for everyone.

Inventory Management

RFID systems provide real-time, automated inventory updates while eliminating the need for manual counts.

Accurate, efficient inventory management is one of the toughest challenges on construction sites, with crucial materials and tools constantly moving between job zones, storage areas, and delivery points.

RFID technology transforms this by providing real-time, automated inventory updates without the need for manual counts.

According to McKinsey, using RFID readers and tags can cut labor hours spent on inventory management by up to 15%.

Illustration: GoCodes Asset Tracking / Data: McKinsey

This is not at all surprising.

In construction, poor inventory oversight often leads to material shortages, double orders, or stockouts at critical project stages.

RFID eliminates those risks by automating stock counts and capturing asset movements the moment they happen.

Still, the true potential of RFID can only be unlocked through system integration.

An SAP project manager, Khunal Bhat, highlights that such integration ensures you have accurate, live stock levels to support smarter demand forecasting and procurement decisions.

Illustration: GoCodes Asset Tracking / Quote: LinkedIn

One real-world example comes from TB International, which boosted logistics efficiency by 40% during the pandemic using RFID-equipped assets.

The system, which also integrates UWB technology, enables the company to handle high-volume demand in very unpredictable circumstances without losing track of inventory or slowing down operations.

Now, picture the same capability applied to a fast-paced construction project, where a single miscalculation in material availability can derail the entire schedule.

The bottom line? RFID gives your business the oversight and agility to minimize risks and stay ahead even in the face of adversity.

Project Progress Tracking

RFID technology plays a valuable role in monitoring the movement, delivery, and installation of materials and components across busy job sites.

This gives managers real-time visibility into project milestones and resource flow, helping keep complex schedules on track.

And it matters.

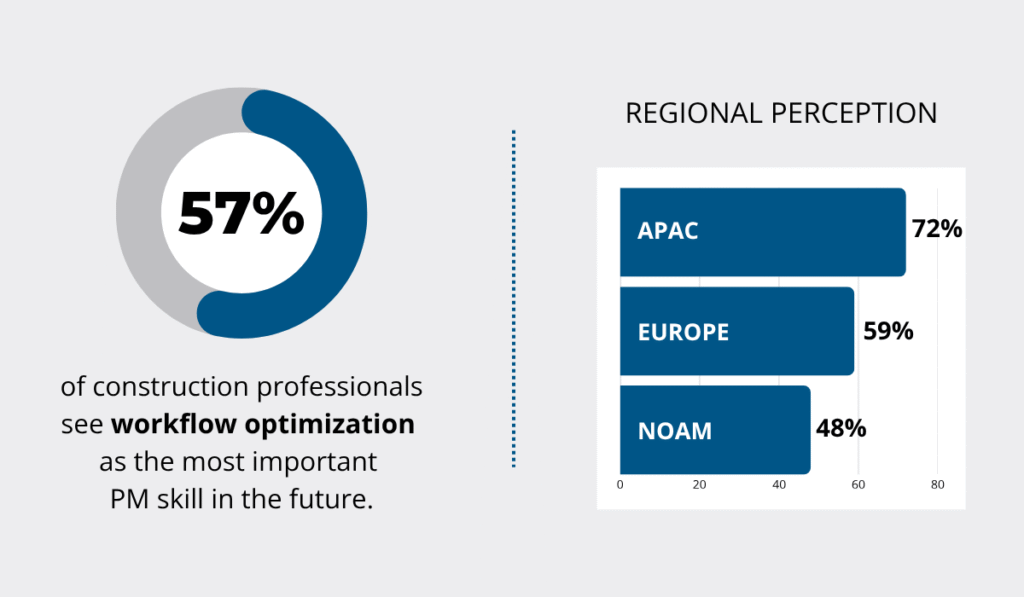

According to a 2022 report, 57% of surveyed construction professionals believe workflow optimization is the single most important project management skill for the future.

Illustration: GoCodes Asset Tracking / Data: FMI & Autodesk

So, how does RFID figure into this?

Digitalization is a notable trend in construction project management, with RFID systems enabling you to tag both materials and assets and gain real-time insights into their location, arrival times, and installation status.

This means that you can instantly spot delays or bottlenecks and adjust your planning before minor hiccups become major obstacles.

It also improves overall site logistics management, streamlining how equipment, materials, and crews move between different site zones.

With automated updates and alerts, your crew can also minimize the risk of overlooking tasks or misplacing deliveries, thereby ensuring smoother project execution.

Ultimately, RFID helps eliminate the guesswork and manual tracking that so often slow down builds, enabling teams to stay ahead of schedule and optimize workflows.

Conclusion

All in all, the applications of RFID technology may vary, but one thing is clear—it’s become one of the most valuable tools in modern construction management.

From preventing equipment loss to enhancing site safety, security, and resource coordination, RFID tracking delivers reliable, real-time data exactly when you need it.

If your business hasn’t explored RFID yet, now’s the time to invest in a comprehensive tracking solution and start building smarter, faster, and safer.