Key Takeaways:

- Strong perimeter security, access control, and surveillance form the first and often most effective line of defense.

- Asset tracking with QR codes or RFID ensures every tool and machine is accounted for.

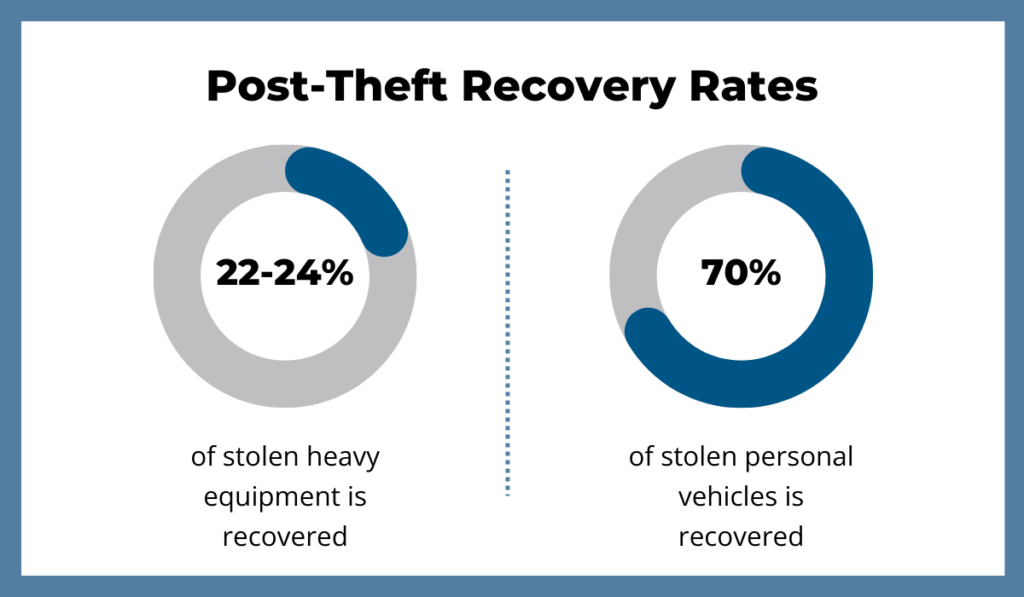

- GPS tracking and geofencing improve otherwise low recovery rates (22-24%) for heavy equipment.

- Training, accountability, and trust turn theft prevention into a shared team responsibility.

The recent surge in construction site thefts across the U.S. and Europe has put this long-standing problem back in the spotlight.

From small tools to heavy machinery, thieves target anything of value, leaving owners to deal with losses, costly delays, and budget overruns.

So, what can you do?

Put the right mix of standard security measures, smart planning, technology, and teamwork in place.

Let’s explore the most effective ways to keep your site secure.

In this article...

Establish Job Site Perimeter Security

Perimeter security is your first—and often most effective—barrier against theft on construction sites.

By locking down the site edge, you protect everything inside: tools, machinery, and materials.

The right signage, strong gate locks, and nighttime lighting further deter thieves.

But before putting up fences or installing gates, carry out a site-specific risk assessment.

That way, you can match perimeter security and other theft-prevention measures to the site’s size, layout, and unique risks.

In doing so, remember that small sites are also targeted, as Sarah Davies, Head of Construction Security at SecureIt UK, explains:

Illustration: GoCodes Asset Tracking / Quote: Viper Security

She adds that smaller construction sites also need robust security systems, but scaled and tailored to their needs.

This is where a thorough risk assessment becomes crucial.

It examines the site’s location, visibility from public roads, nearby crime rates, and the value of materials and equipment on-site.

It also flags weak spots, such as unlit corners or open storage areas, where thieves could slip in unnoticed.

Once you understand the site’s vulnerabilities, you can design the right perimeter, which usually means secure fencing, lockable gates, and clear warning signs.

Source: Wade Building Supplies

In high-risk areas, you can strengthen fencing with extra deterrents like anti-climb mesh, barbed wire toppers, or solid hoarding to block views of valuable equipment.

Gates should be just as strong—ideally steel-framed, with tamper-proof hinges, and secured with heavy-duty padlocks or coded entry systems.

Warning signs aimed at potential intruders work best when they’re clear and visible, such as “No Trespassing” or “CCTV in Operation,” even if no cameras are installed.

Source: My Safety Sign

Good lighting is another essential part of perimeter security.

Bright, motion-activated lights around fences, gates, and access points make it much harder for intruders to move unnoticed after dark.

Secure on-site storage is just as important.

Tools, small equipment, and materials should be locked in sturdy containers or dedicated storage units at the end of each shift, with heavy-duty padlocks or coded locks to keep opportunistic thieves out.

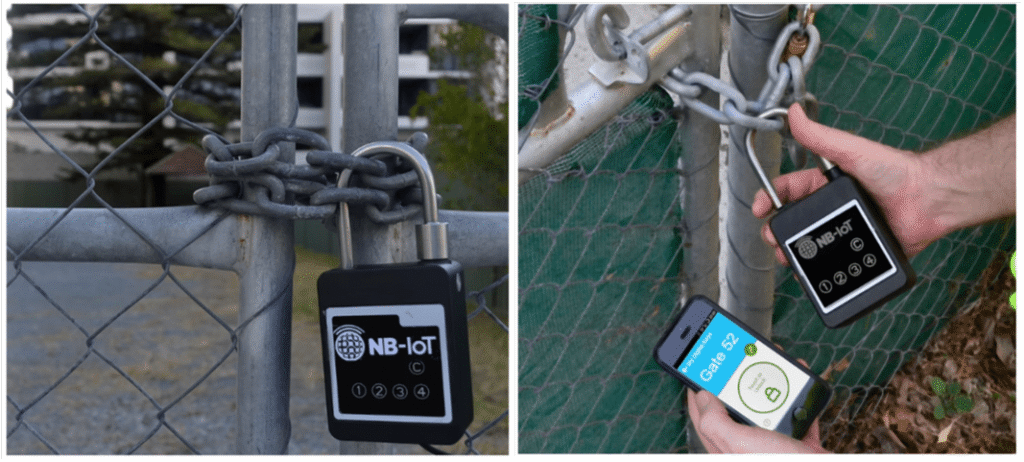

Here’s an example of a 5G IoT padlocks that use digital keys instead of metal ones.

Source: Digital Keys

These digital keys can be easily created, shared with authorized users, their usage tracked, and their validity revoked if foul play is suspected.

They also come with tampering alarms, which make them a hybrid between security, access control, and surveillance measures.

In summary, a detailed risk assessment, strong fencing, secure gates, visible signs, proper lighting, and lockable storage all work together to form a solid perimeter defense.

But perimeter security is only the first layer.

To truly protect your site, you need to control who gets in and out.

Ensure Access Control and Surveillance

Even the strongest fences and other perimeter security measures can only do so much if you don’t control who’s allowed inside.

That’s where access control and surveillance come in.

By managing entry and exit points, you know exactly which workers, vehicles, and deliveries are on-site at any given time.

For workers, there are several access control methods, ranging from traditional key cards and PIN codes to mobile passes or even facial recognition on high-value projects.

Source: VIS Systems

Vehicles and deliveries can be managed with barriers, license plate recognition, RFID checkpoints, or QR-coded delivery slips.

Regardless of the method, these systems ensure only authorized drivers and materials make it past the gate.

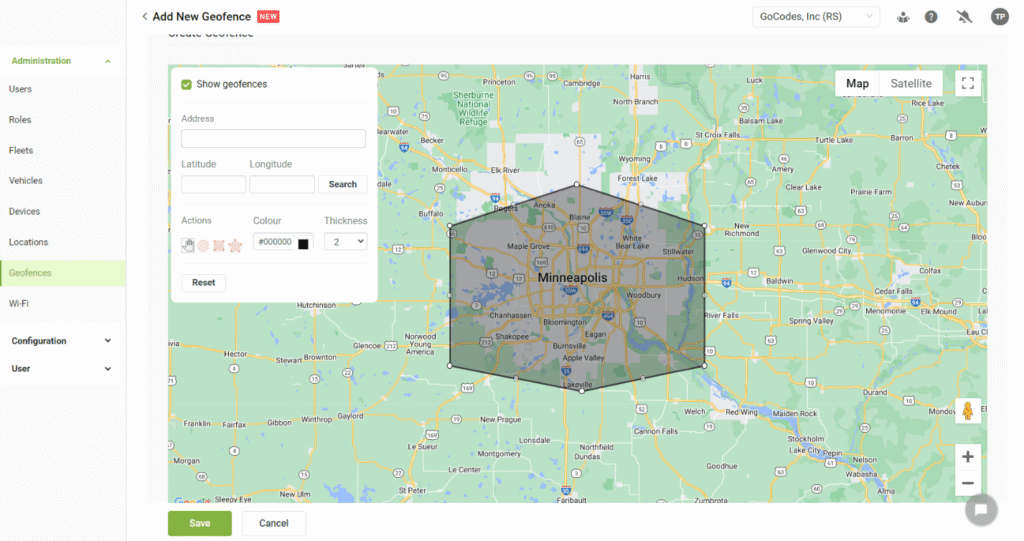

Geofencing adds another layer by creating a virtual boundary around the job site using GPS or, in shorter-range remote asset detection options, RFID or Bluetooth signals.

Source: GoCodes Asset Tracking

When vehicles or equipment cross this invisible line, the system can send instant alerts or automatically log the movement.

For example, it can flag a truck arriving after hours or warn if machinery is being moved off-site without approval.

This allows managers to respond immediately and, in the case of theft, alert authorities right away.

Rapid response is especially valuable for high-value heavy equipment or vehicles, where recovery rates are typically low, i.e., just 22–24% compared with 70% for personal vehicles, as shown below.

Illustration: GoCodes Asset Tracking / Source: Construction Briefing

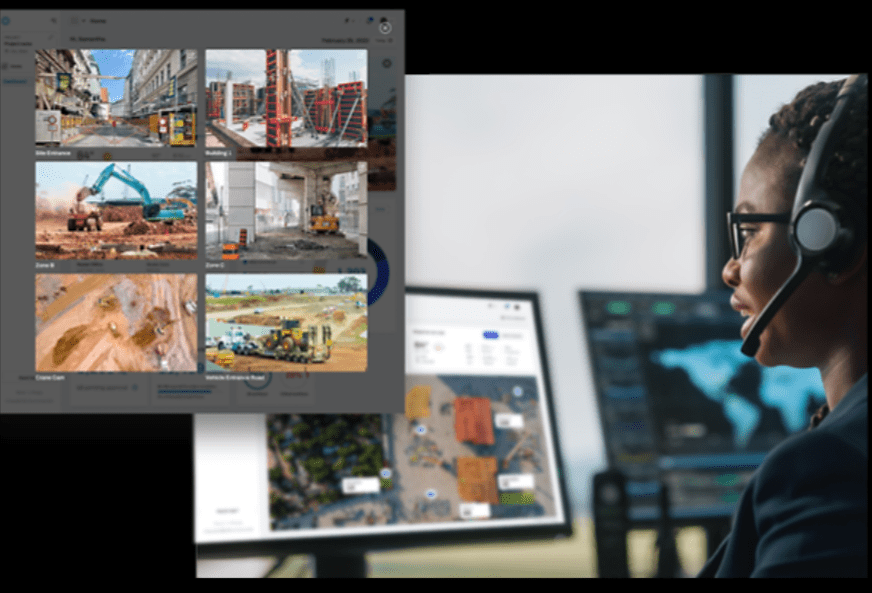

In addition to access control and geofencing, surveillance systems provide another layer of protection.

Security cameras, alarms, and even motion detectors allow staff to monitor activity across the site during and outside working hours.

Source: Eyrus

Nowadays, most camera surveillance systems can be accessed from a control center or remotely via any internet-connected device, such as a smartphone.

For higher-risk locations, manned security personnel can complement these systems, providing both a visible deterrent and the ability to intervene immediately.

Drones can further enhance security by patrolling large areas that are difficult to cover on foot, capturing live video, and automatically alerting staff to unusual activity.

Source: Titan Protection

Drones allow security teams to respond more quickly and extend surveillance beyond the limitations of fixed cameras.

Jack Wu, CEO of aerial security company Nightingale Security, explains that physical security is a team sport and drones can be a valuable addition:

Quote: Inside Unmanned Systems

Drones can also support another key aspect of access control and surveillance—regular site security inspections.

For instance, a quick daily walkaround at the end of a shift can help staff identify issues such as broken locks, cut fencing, or dark corners with burned-out bulbs.

Drones can make this process more efficient by quickly surveying the perimeter and highlighting potential vulnerabilities.

Together, all the methods and technologies create a layered security approach, controlling the movement of people, vehicles, and equipment on your site, day or night.

Track On-site Assets and Inventory

While strong perimeter security and access control protect your site, the tools, equipment, and materials inside it still need monitoring.

Tracking assets ensures every item, from high-value machinery and materials to everyday tools and PPE, is accounted for, both on-site and off-site.

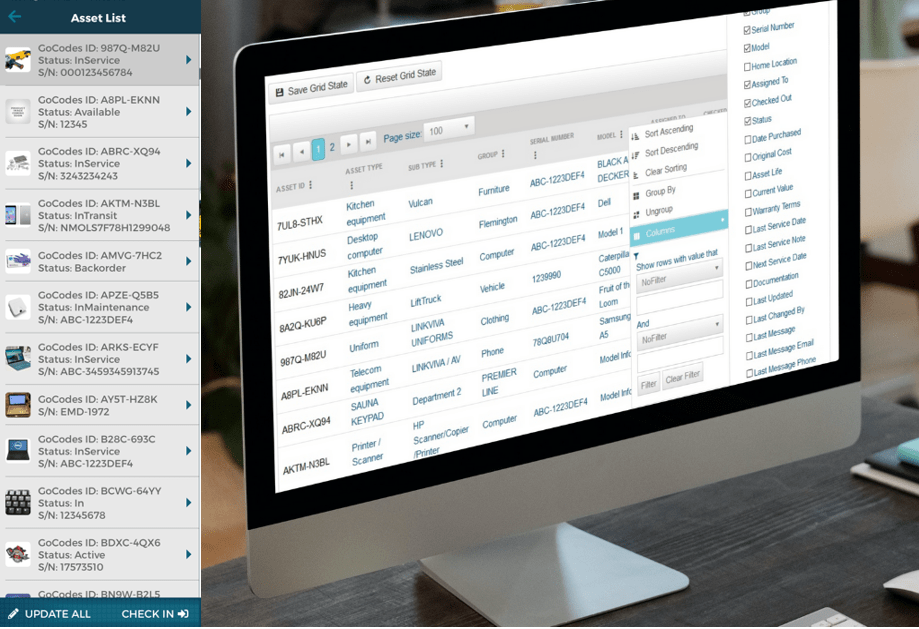

This begins with establishing a centralized database of all inventory.

Source: GoCodes Asset Tracking

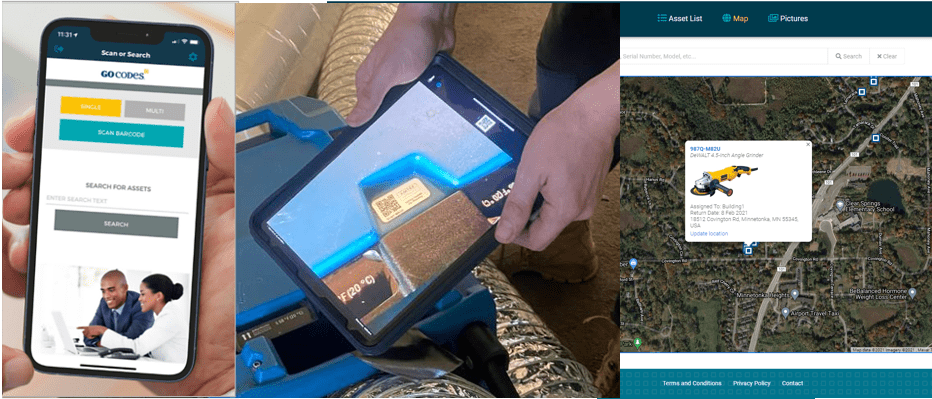

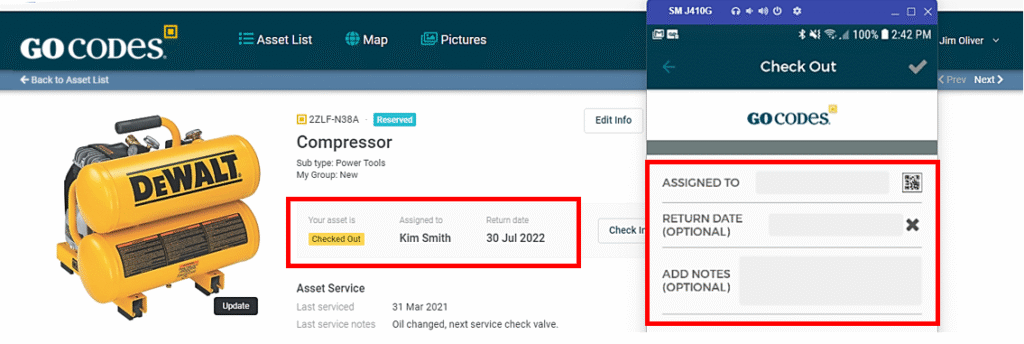

Using methods like barcodes, QR codes, or RFID tags, managers can log the usage and location of all items in near real time.

For example, QR code tags can be attached to assets, allowing workers to scan them with a smartphone for immediate access to asset details.

Source: GoCodes Asset Tracking

These asset tracking methods also let workers and managers easily check tools and equipment in and out, with all actions recorded in the software.

A clear chain of custody improves accountability, reduces internal theft, and supports theft investigations.

Some asset management systems also eliminate the need for workers to manually enter an item’s location.

Instead, the software uses the scanning device’s GPS location to automatically capture it and display it on a map.

Here’s how this simple process works:

Source: GoCodes Asset Tracking

This scan-based GPS tracking not only saves time but also reinforces worker accountability, preventing accidental or deliberate location errors.

With all assets and inventory items tagged, you now have a primary tracking system in place.

The next step is to protect high-value, movable equipment.

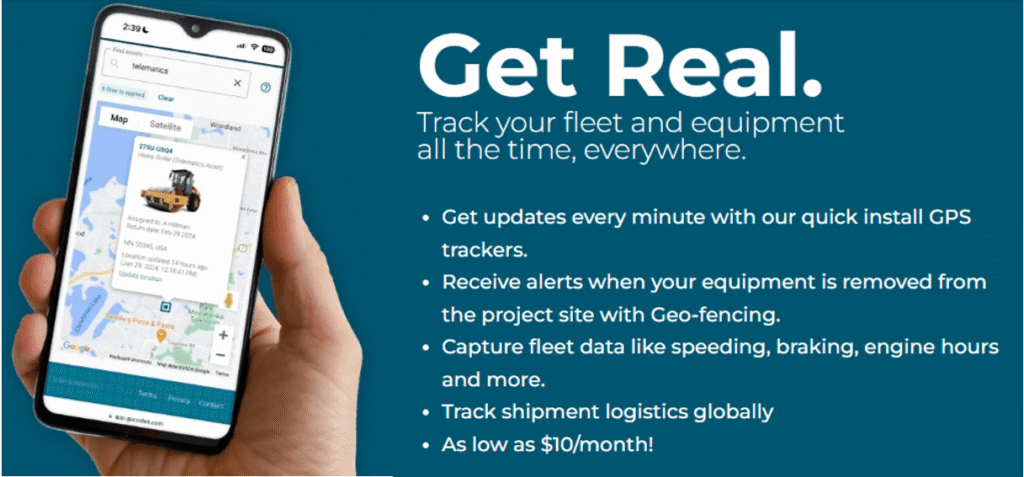

Real-time GPS trackers are particularly useful here, providing robust geofencing and continuous off-site monitoring.

While RFID and Bluetooth trackers can also support geofencing, these technologies are limited to short-range detection.

GPS trackers, in comparison, allow you to set geofences around large areas and provide minute-by-minute monitoring, whether the asset is on-site or off-site.

Here’s a quick overview of what you can achieve with GPS tracking:

Source: GoCodes Asset Tracking

The anti-theft benefits of GPS trackers are clear.

With geofencing enabled, you receive real-time alerts if unauthorized asset movement is detected.

If thieves haven’t removed the tracker—which can be firmly affixed, hidden, or even equipped with a decoy—you can follow the stolen asset and quickly alert the authorities.

For example, a single GPS tracker enabled the Alberta RCMP to recover not only the stolen vehicle but also uncover a larger operation at a chop shop.

Source: Edmonton Journal

To simplify the choice and installation of these tracking technologies, asset-tracking platforms like GoCodes Asset Tracking combine multiple methods, including QR codes, RFID, Bluetooth, and GPS, into one integrated system.

This flexibility lets owners or managers apply the most efficient option for each asset category:

- QR codes or RFID for everyday tools and consumables

- GPS or Bluetooth trackers for high-value or easily portable equipment

In practice, this creates a unified inventory system that supports theft prevention, improves accountability, and ensures every tool, material, or machine is traceable at all times.

Of course, even the best tracking systems are only as effective as the people using them, which brings us to the next section.

Invest in Employee Training and Culture

Even with advanced tracking systems and layered security in place, the human factor remains the most critical element of theft prevention.

More precisely, if workers aren’t trained to use anti-theft technologies and methods or don’t feel responsible for protecting company property, even the best security setups can fail.

That’s why investing in employee training and building a culture of accountability is essential, ensuring that every team member becomes an active participant in protecting assets.

This particularly applies to smaller tools and equipment, which are often underinsured and frequently targeted by thieves.

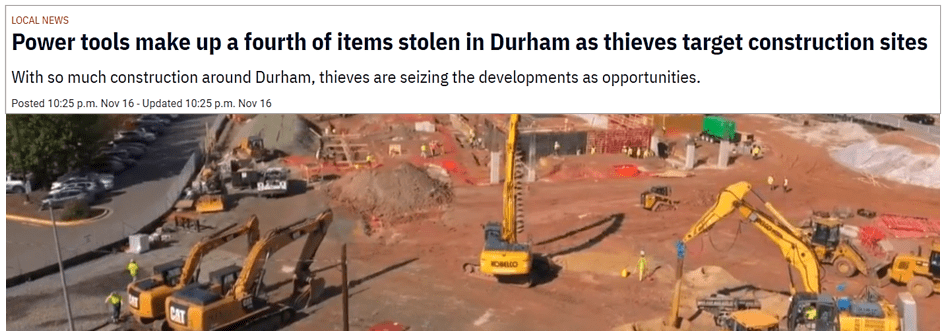

A recent case highlights just how widespread this problem has become.

Source: WRAL

Besides being easy to carry off-site and resell, smaller tools and equipment are also more vulnerable to internal theft.

In addition to offering fair pay and benefits, this risk can be reduced through regular toolbox talks that cover theft prevention, site security measures, and the importance of reporting suspicious activity.

Here, other anti-theft measures we’ve discussed, such as maintaining an up-to-date asset list and inventory system, matter as well, explains Dustin Jones, manager at insurer Ascott U.S.:

Illustration: GoCodes Asset Tracking / Quote: Axa

Establishing clear theft reporting procedures is just as important as tracking assets.

Workers should know exactly who to contact and how to report missing items without fear of retaliation.

Documented accountability policies, such as requiring every tool or piece of equipment to be checked in and out, create a transparent chain of custody.

Source: GoCodes Asset Tracking

This not only deters internal theft but also makes it much easier to identify when and where a loss occurred.

Another key step in strengthening accountability is fostering a culture of trust and shared responsibility.

Again, this can be achieved through security-focused toolbox talks, combined with open theft-reporting procedures and fair enforcement of rules.

Together, these measures help create a workplace where every team member feels responsible for maintaining site security.

Afnan Tajuddin, an experienced safety professional and founder of safetynotes.net, gives an example of how to start such talks with your employees:

Illustration: GoCodes Asset Tracking / Quote: Safety Notes

Clear communication about why theft prevention matters—whether it’s protecting jobs, maintaining project budgets, or keeping insurance premiums under control—helps employees see security as part of their role, not just a management directive.

Lastly, consider conducting background checks on employees and subcontractors as an additional layer of protection.

While these checks shouldn’t replace trust, they help ensure that everyone on-site has been properly vetted, reducing the likelihood of bad actors slipping through the cracks.

Overall, fair treatment, clear procedures, and a culture of trust work together to make theft prevention a shared responsibility and a team effort.

Conclusion

Construction site theft may be common, but it isn’t inevitable.

With the right mix of layered security, modern tracking technology, and a culture of accountability, you can protect your assets and keep projects on track.

So, evaluate your security measures, address site-specific risks, and put these strategies into action to create safer, more secure job sites.