Key Takeaways:

- QR codes can be scanned from any angle, store more data, and remain readable even if partially damaged.

- QR codes can be scanned using smartphones.

- QR code inventory software automates stock tracking, check-in/out processes, and log asset locations using GPS.

Keeping track of construction inventory—materials, equipment, and tools—can be challenging.

Are you still relying on spreadsheets or even pen and paper?

If so, you’re likely wasting time and money.

QR code-based management software offers a faster, more reliable way to track your inventory.

In this article, we’ll cover everything you need to know—from why QR codes are ideal for inventory tracking to how you can implement them for maximum efficiency.

In this article...

Why Use QR Codes for Inventory Tracking

QR codes have transformed how construction companies manage inventory.

Unlike traditional methods, they provide greater speed, accuracy, and ease of use.

Here are four key reasons why QR codes are the smarter choice for inventory tracking.

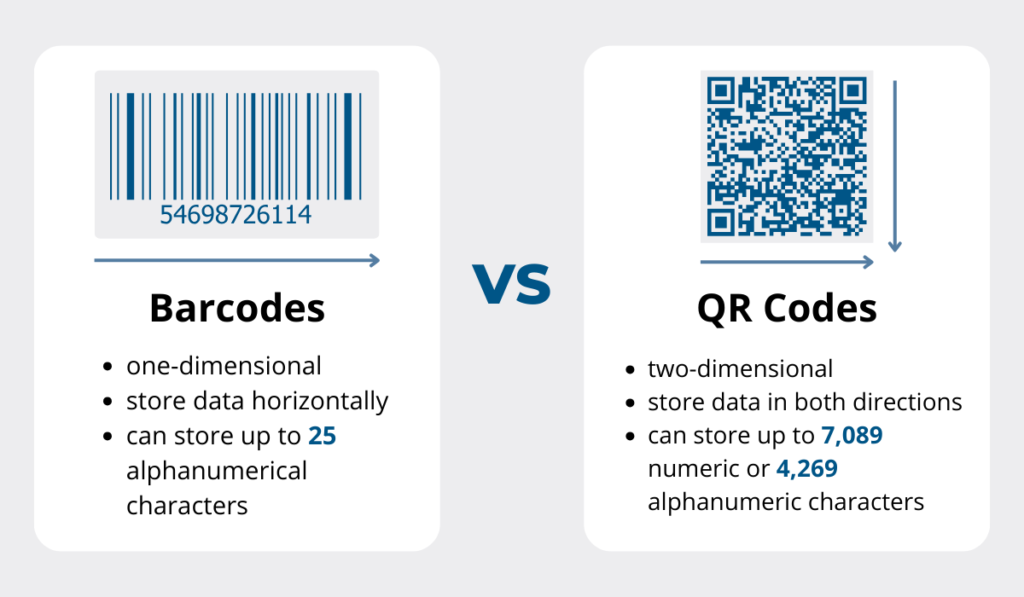

Better Than Barcodes

The first reason to use QR codes is simple: they’re better than barcodes.

While barcodes have been used for inventory tracking for decades, they come with several limitations.

Namely, barcodes:

- Need a perfectly aligned line of sight to scan

- Can’t store much data

- Are easily damaged

In a construction environment, where dirt, dust, and rough handling are common, barcode labels can easily fade, tear, or become unreadable.

QR codes address these issues more effectively.

Unlike barcodes, they can be scanned from any angle and still work, even if partially damaged.

Plus, QR codes can store significantly more data—you can see the comparison here.

Source: GoCodes Asset Tracking

The difference in data storage capacity only affects what information is stored directly in the barcode or QR code itself—it doesn’t change how the inventory management software processes the scan.

However, because QR codes can store more data within the code itself, you can access certain details directly—even without an internet connection.

Another advantage is their size—a QR code can be up to 10x smaller than a barcode while remaining readable.

Source: GoCodes Asset Tracking

This size difference allows you to print or order very small labels that can be affixed to even the tiniest items in your inventory.

Examples include small precision tools, hardware like nuts, bolts, and screws, or components that might otherwise be difficult to tag with a traditional barcode.

So, QR codes are more advanced, two-dimensional cousins of traditional barcodes that can be more easily scanned, hold more data, and come in any size.

This makes inventory tracking faster, more reliable, and better suited to the harsh conditions of construction sites.

When combined with the next reason, QR codes become even more powerful for inventory management.

No Scanning Devices Needed

Although barcodes can also be scanned with smartphones, barcode tracking systems often rely on specialized laser scanners.

These scanners add to the overall cost, as they can be expensive, fragile, and require regular maintenance or replacement.

QR codes, on the other hand, are designed to be scanned with a digital camera—now standard in smartphones and tablets.

Source: Sortly

This eliminates the need for dedicated scanning devices, making QR code inventory tracking more cost-effective.

It also means that anyone with a smartphone can scan a QR code, but only authorized users with the inventory management app installed can access the stored data.

Source: GoCodes Asset Tracking

Allowing workers to use their own or company-issued mobile devices instead of dedicated handheld scanners is a game-changer, especially on construction sites.

Now, employees can scan an item and update inventory records in real time, improving both operational efficiency and data accuracy.

When paired with a scanner-free software system, QR codes unlock even more benefits—leading us to the next advantage.

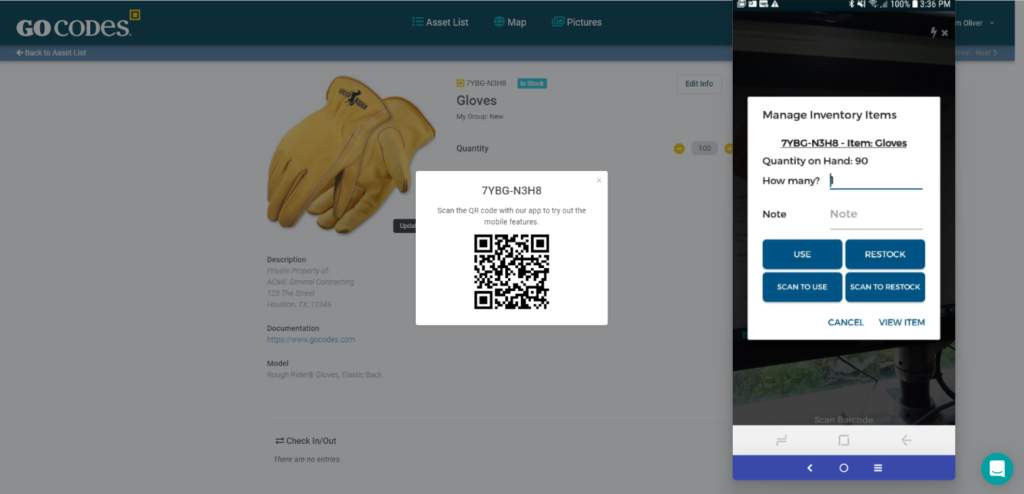

Automate Inventory Management Tasks

With QR code-based inventory management software, you can automate various tasks related to managing your equipment, tools, materials, spare parts, and other items.

Let’s start with how QR codes allow you to automate inventory-level tracking.

For instance, imagine you have a container of work gloves.

When a worker or manager wants to take a pair, they scan the QR tag attached to that container, which enables them to update the glove count in real time.

Source: GoCodes Asset Tracking

As the image shows, users have two options—they can enter the number of pairs they took (use) or the number they added back (restock).

Additionally, most QR code inventory solutions allow you to set predefined stock thresholds.

If an item’s count drops below this threshold, the system automatically sends a low-inventory alert.

This ensures your workers always have the necessary personal protective equipment (PPE), spare parts, and supplies to perform their jobs efficiently.

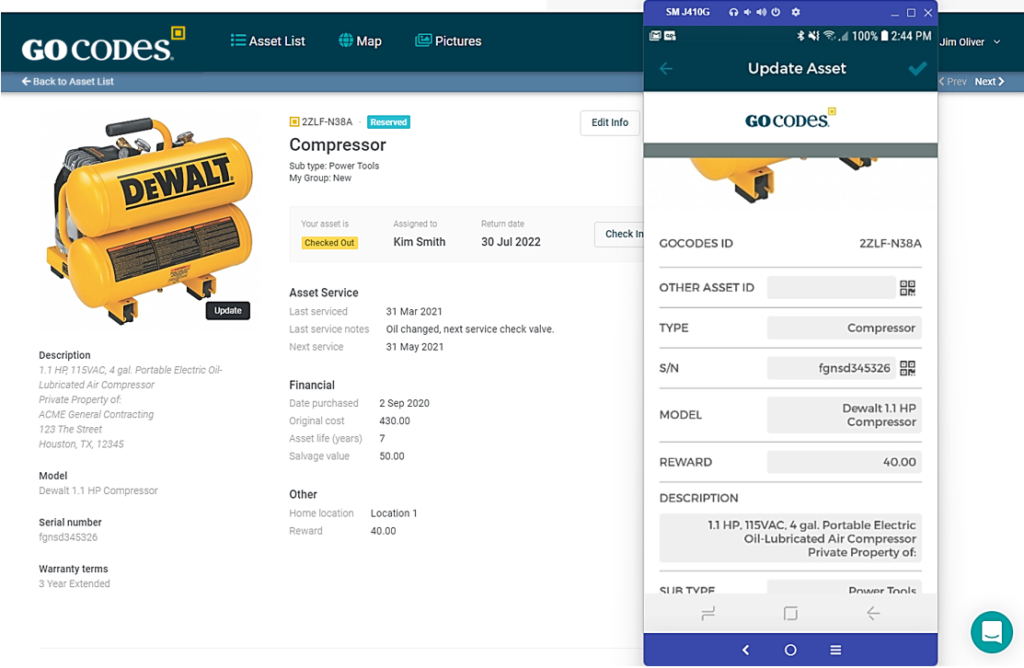

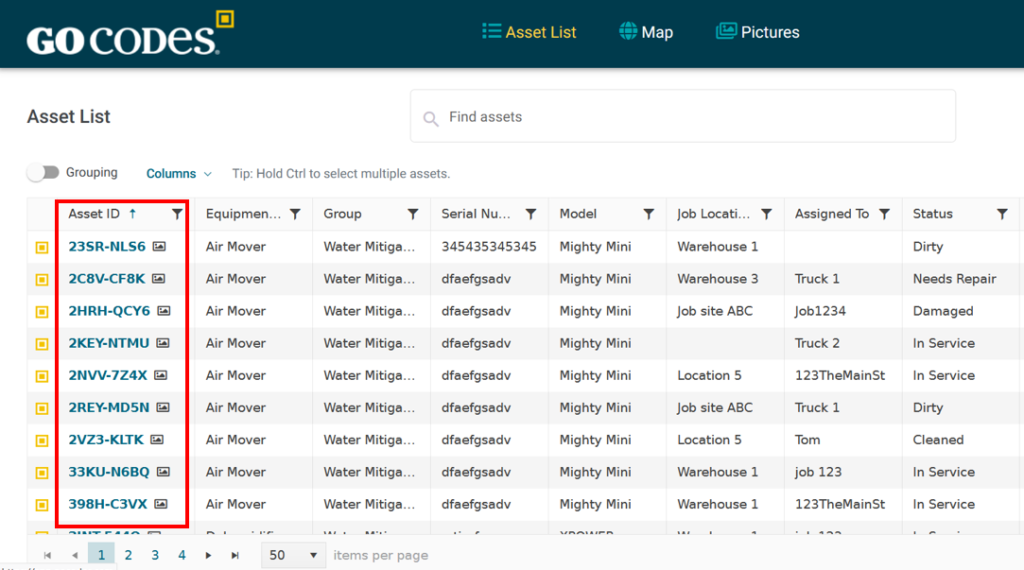

QR code-based software also automates asset tracking for individual equipment, vehicles, and tools.

When a user scans an asset’s QR tag, they’re instantly taken to that asset’s digital profile, as seen below.

Source: GoCodes Asset Tracking

This digital portal allows authorized users to view and update asset data on-site.

This automation streamlines tasks such as:

- Tracking asset condition and utilization

- Conducting inspections and scheduling maintenance

- Monitoring depreciation and lifecycle stages

And that’s just the beginning.

Most QR code-based solutions are highly customizable, allowing you to automate even more tasks based on your specific needs.

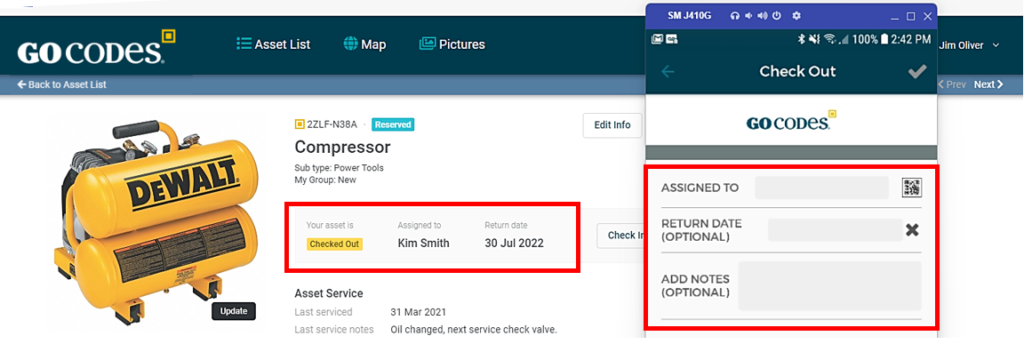

Another powerful automation enabled by QR codes and mobile apps is the check-in/check-out system.

When a worker takes a tool or piece of equipment from storage, they scan its QR tag to check it out.

The same process applies when returning the item.

Additionally, managers can also assign assets in advance, set return dates, and add notes within the software.

Source: GoCodes Asset Tracking

This automated check-in/check-out process enhances worker accountability, reducing the risk of lost or misplaced assets, negligent operation, and internal theft.

Workers always know which equipment is available, while managers can easily track who has what and when it’s due back.

While these task automations are impressive enough, the benefits of QR code software go even further.

Track Your Asset Movements

Most QR code inventory management solutions allow you to track asset movements by prompting the user who scanned the tag to manually enter its location.

While this functionality is useful, it has some drawbacks, such as entering the wrong location due to error or intentional record manipulation.

However, some solutions, like our GoCodes Asset Tracking, automate this function.

This means that, when a worker scans a QR code, the scanned asset’s location is automatically—not manually—captured by software.

How is this achieved?

The software uses the scanning device’s GPS locator to record the asset’s current location.

Here’s how this simple process works:

Source: GoCodes Asset Tracking

As shown, every time a QR tag is scanned, the GoCodes Asset Tracking app will automatically capture the asset’s GPS position and show it on a map.

The advantages of using these GPS-enabled QR codes start with managers and workers being able to search for assets in the central database to see their current location.

Since they can look up whether the assets are in storage or on-site, this saves time and boosts efficiency.

Additionally, together with the check-in/out system described earlier, this further enhances worker accountability and minimizes the risk of misplacement, negligence, or theft.

If a piece of equipment or a tool is misplaced, you can check its last-scanned location to help locate it or identify potential theft.

So, even though QR codes are not real-time GPS trackers, using scan-based automatic location updates gives you a reliable, cost-effective way to monitor your asset movements.

How to Integrate Inventory Management Software With QR Codes

Successful integration requires three key steps:

- Getting custom QR codes

- Properly attaching them to assets

- Connecting them with inventory management software

In the following sections, we’ll walk you through each step to ensure a smooth and effective setup.

Get Custom QR Codes

The first step is to obtain QR codes tailored to your needs—whether it’s their size, the material they’re printed on, or the information displayed on them.

For starters, you can generate and print QR code tags yourself.

This is practical for tracking the movement and usage of bundles, pallets, or bags of materials delivered from storage or vendors to your site.

While self-printed labels work well for consumable supplies, construction tools, and equipment usually require more durable, long-lasting tags.

These permanent tags ensure that QR codes remain scannable despite exposure to harsh jobsite conditions.

For example, QR tags made from metal offer high resistance to wear and tear.

Source: GoCodes Asset Tracking

These QR tags can be made from anodized aluminum foil or even annealed or intensified metal, making them durable in harsh conditions.

Other options include iron-on labels, high-temperature-resistant labels, industrial hang tags, and more.

Besides selecting materials and sizes for your asset tags, you can also customize their design.

For starters, ordering customized QR tags relieves you of having to come up with unique asset IDs that will act as primary identifiers in your tracking system.

Source: GoCodes Asset Tracking

In addition to automatically generated asset IDs, you can choose what other details appear on the tag.

Although label space is limited, you can typically include your company name and a “Scan for Details” message, signaling that the tag can be scanned for asset information.

This helps in two key ways:

- The tag acts as proof of ownership if an asset is lost or stolen.

- It allows good Samaritans to notify you if they find your missing equipment.

Additionally, using tamper-evident materials or affixing tags in a way that makes removal difficult without damage can help deter theft or make resale harder.

That’s why the next step is just as important.

Attach Codes to Your Assets

When ordering your custom QR code tags, you also decide how they’ll be attached to your assets.

You can choose adhesive backing, pre-drilled holes for mechanical fastening, or a combination of both.

Here are examples of tags securely attached using industry-grade adhesive, ensuring a permanent bond.

Source: GoCodes Asset Tracking

So, when your QR code labels arrive, it’s time to affix them to the respective assets using the method you selected.

If using adhesive, resist the temptation to test the bond strength until the prescribed curing period has passed.

Attach each QR code tag in a visible, easily accessible location that allows for quick scanning while offering some protection—such as a control panel.

Source: GoCodes Asset Tracking

With your QR tags securely attached to equipment, tools, and other items, the next step is linking them to your inventory management software.

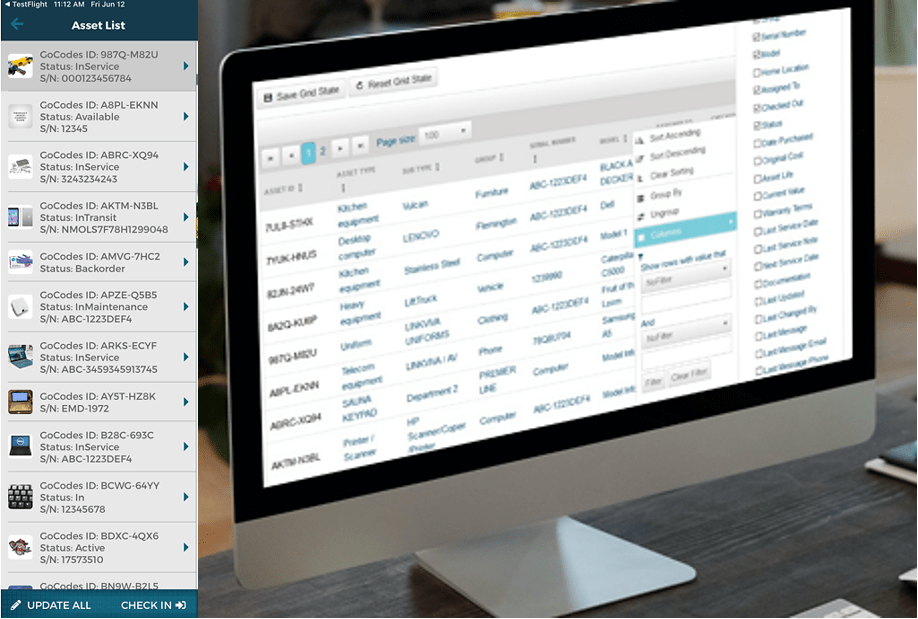

Connect With Inventory Management Software

This is a crucial step that enables QR code labels and software to work in tandem, resulting in a fully operational digital inventory management system.

First, choose a cloud-based, mobile-friendly software solution and install it on the necessary devices.

During setup, using several scanning-enabled smartphones or tablets alongside a desktop or laptop will speed up the process of connecting labels with the system.

Source: GoCodes Asset Tracking

Later, the mobile app can be downloaded to all other devices, such as workers’ personal or company-issued smartphones and tablets.

At this stage, however, the focus is on building the inventory database.

So, your team should enter data for each tagged item, either manually or by importing existing digital inventory records.

Either way, it’s important to ensure all information is accurate and up to date, whether it concerns asset data or stock counts.

While this may take time, it prevents errors that could cause management issues later, giving you a fresh start.

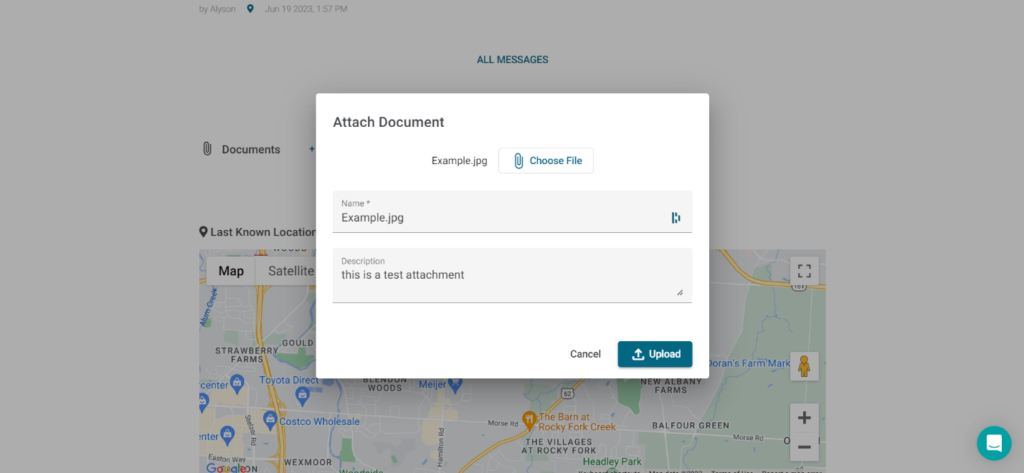

For both assets and materials, you can also attach relevant documents and images, such as specifications, warranties, maintenance logs, or user manuals.

Source: GoCodes Asset Tracking

By populating the database and attaching relevant documentation, you create a complete digital record for each tagged item.

Now, your inventory management system is fully set up and ready to streamline operations and automate the tasks we described earlier.

More precisely, users can now view, update, and search the inventory database by accessing the app on their smartphone or scanning a QR tag.

Managers can assign assets and tasks in advance, track asset users and locations, schedule usage and maintenance, monitor inventory counts, generate reports, and more.

Workers can search for assets and other inventory, check availability, attach reports, and receive in-app and email notifications and alerts.

With everything in place, your team can now manage inventory more efficiently, keeping projects on track and within budget.

Conclusion

A QR code system offers an easy-to-use and cost-effective solution for inventory management.

By eliminating manual record-keeping, automating tasks, and providing real-time location tracking, it helps you save time, reduce costs, and prevent inventory loss.

Given these and all the other benefits we covered, the right software will be more than worth the investment.