Key Takeaways:

- New equipment is less likely to suffer unexpected breakdowns.

- 67% of construction owners say giving workers access to better tech is key to retention.

- Modern machines depreciate more slowly and offer better trade-in or resale value.

Investing in new construction equipment can feel like a big leap, but over 60% of business owners are already doing it.

Why?

Well, because holding onto outdated machines can mean rising safety risks, lost productivity, and declining value.

This article breaks down the real, measurable benefits of upgrading and why it could be the smartest move for your business.

In this article...

Minimizes Unplanned Downtime

Procore’s 2021 report reveals just how volatile construction projects can be, with an average of six budget changes, five scheduling shifts, and a 15% increase in overall costs per job.

When you add unplanned downtime to the mix, it can throw your entire project off balance, halting work and eroding your margins.

And older tools and machines are the usual culprits.

Relying on unpredictable equipment means adding unnecessary risk to an already fragile setup, which is why you must carefully decide when to repair, rebuild, or replace assets.

Since new machines are less likely to suffer critical breakdowns, new replacements are a common answer.

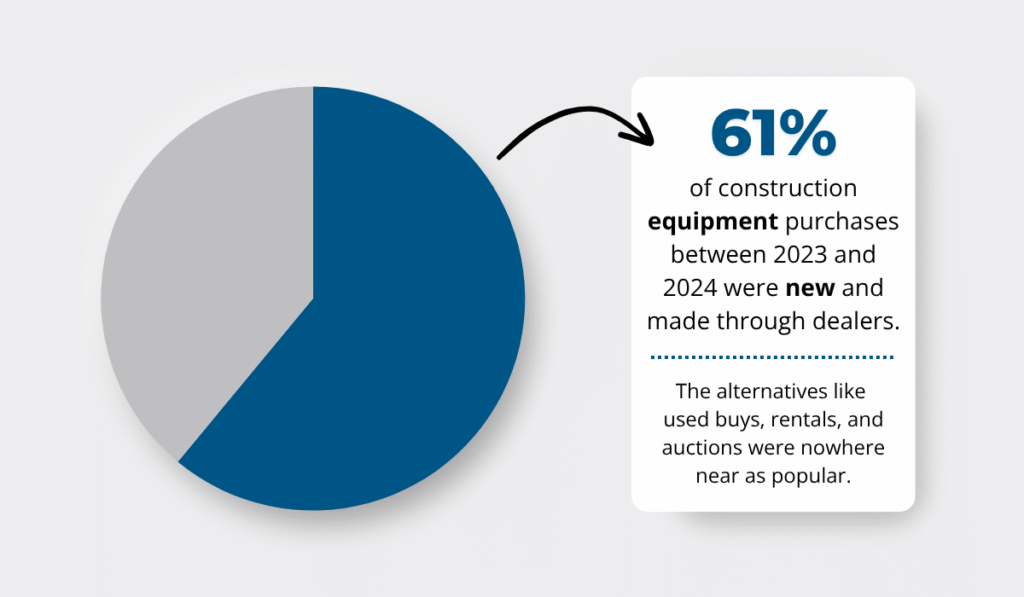

In fact, according to Equipment Watch, 61.2% of companies that acquired construction tools or machinery opted for new equipment directly from a dealer.

Illustration: GoCodes Asset Tracking / Data: Equipment Watch

Despite significant financial commitments, purchasing a new piece of equipment means you don’t have to worry about sudden breakdowns or deal with mounting maintenance costs.

As explained by Shawn Beinhower, CIO at E.K. Services, it’s never just the cost of repair.

You need to add up the time and money you lose while running diagnostics and fixing your asset.

Illustration: GoCodes Asset Tracking / Quote: For Construction Pros

Just imagine a scenario where an essential asset like a mini excavator keeps breaking down mid-task.

You’ve patched the fuel system and replaced the hydraulic lines twice, but every time it starts, something else gives out.

You decide to replace it after the fourth costly delay, and lo and behold, the new excavator runs better, and it eliminates the chaos.

No scrambling for backup. No reassigning workers. No more lost days.

New equipment also lets you start its lifecycle with a proper preventive maintenance program, rather than just trying to outrun problems.

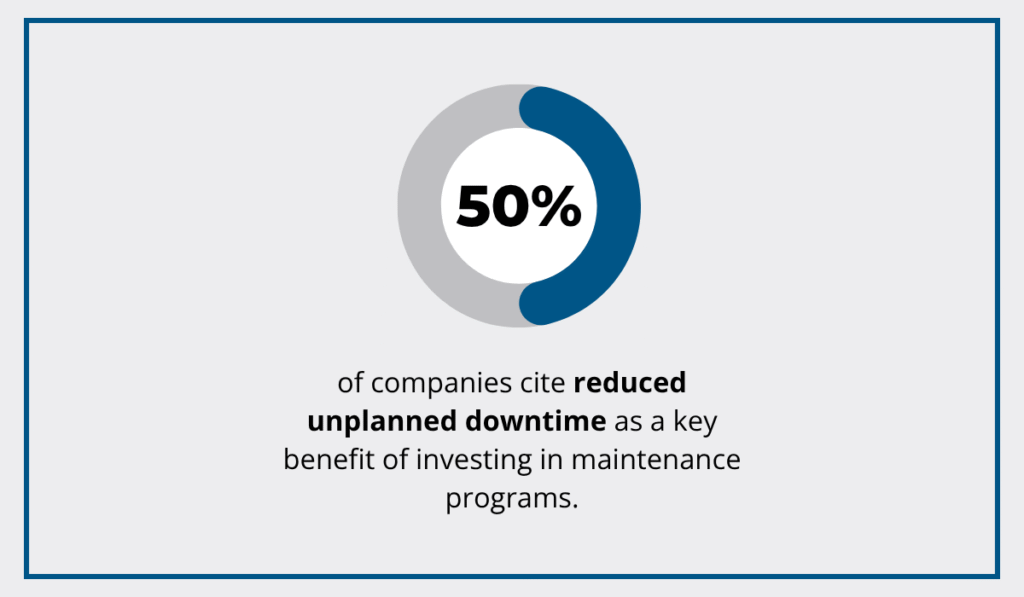

And companies across sectors agree.

In a recent ABB report, 50% of businesses identified reduced unplanned downtime as one of the top benefits of investing in maintenance programs.

Illustration: GoCodes Asset Tracking / Data: ABB

But even new machines aren’t immune to neglect.

On fast-moving job sites, small maintenance issues can easily slip through the cracks.

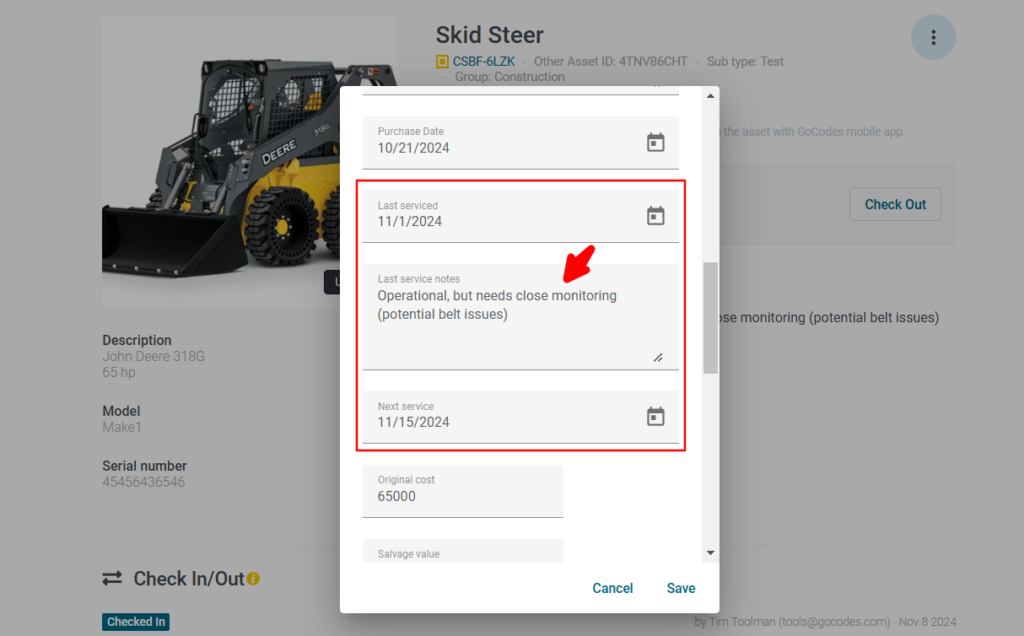

That’s why Beinhower’s team adopted an equipment management solution to simplify reporting and service coordination.

You can do the same and more with our comprehensive asset management solution, GoCodes.

A simple login on any device or an on-site scan of the asset in question gives you access to service history, lets you configure maintenance alerts, and makes it easy to share essential updates instantly.

Source: GoCodes Asset Tracking

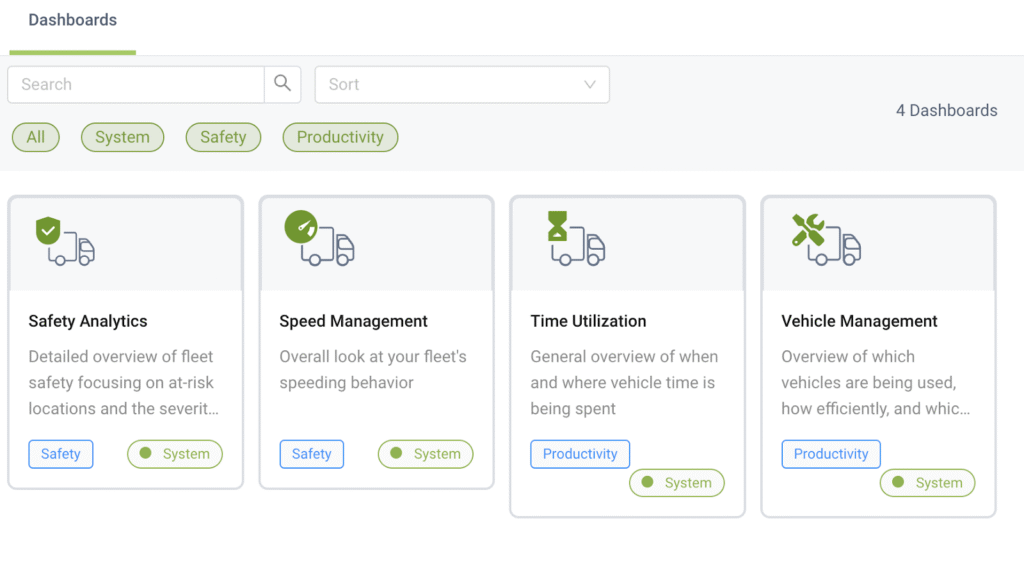

Thanks to GoCodes Asset Tracking’s robust analytics and reporting features, you get full visibility into how your equipment is being used, revealing essential insights into safety, downtime, and utilization.

Source: GoCodes Asset Tracking

Whether you’re managing a single site or coordinating a large fleet across multiple locations, software solutions like GoCodes Asset Tracking help you stay proactive and organized.

In the end, when you invest in reliable equipment and dedicated tools to keep it in peak condition, you can avoid unplanned downtime and build long-term project stability.

Mitigates Safety Risks

When you buy new construction equipment, you upgrade performance, but also actively reduce on-site hazards.

Construction work is inherently plagued by safety risks.

Additionally, old equipment increases the dangers due to its unpredictable nature.

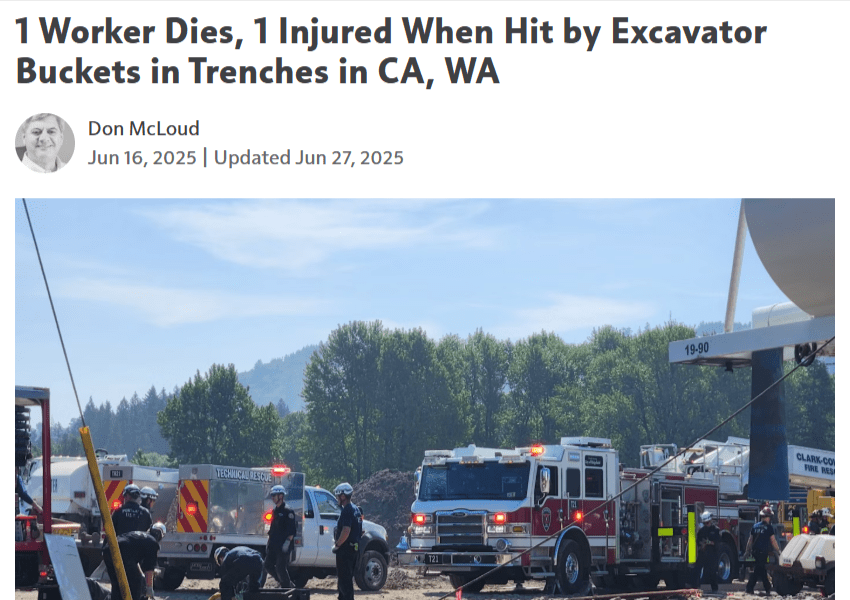

Take excavator buckets, for example.

Equipment World reported on two recent incidents of buckets detaching and striking workers in California and Washington.

Source: Equipment World

Limited visibility and maneuvering space increase the risk of accidents, emphasizing the need to comply with strict safety standards like OSHA’s Specific Excavation requirements.

The 29 CFR 1926.651(e) explicitly prohibits workers from standing under lifted loads, mandating safe zones around operating machinery.

The coupler systems are another contributing factor.

Failure to properly secure the attachment, coupled with reliance on outdated models with fewer safety mechanisms in place, is a fatality simply waiting to happen.

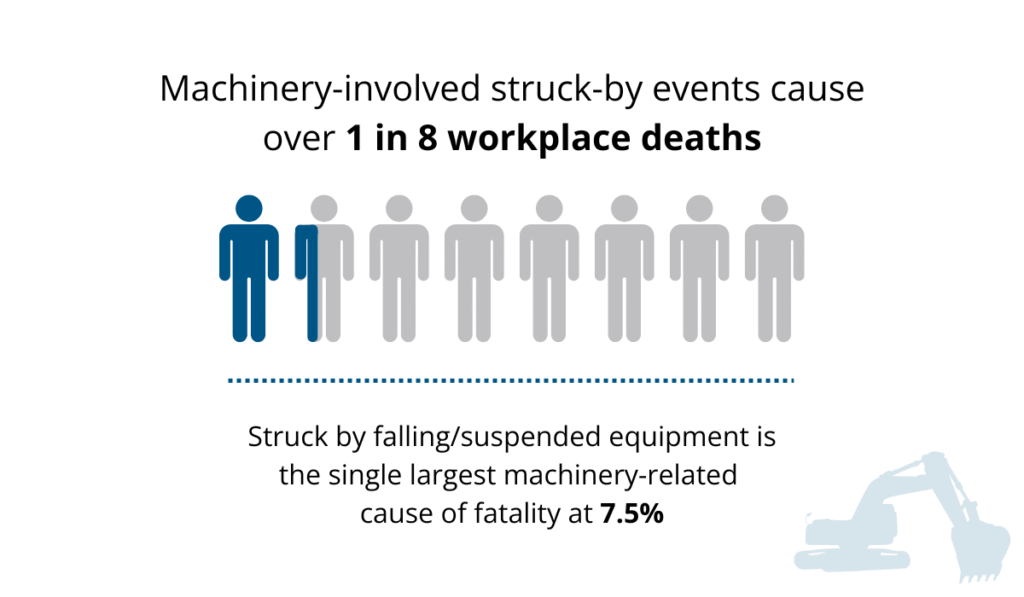

Data confirms just how widespread these incidents are.

According to the U.S. Bureau of Labor Statistics (BLS), machinery-involved struck-by events cause over 1 in 8 workplace deaths, making it a major cause of concern in sectors like construction and manufacturing.

Moreover, incidents involving being struck by falling or suspended objects accounted for 394 fatalities, or 7.5% of all workplace deaths in 2023.

Illustration: GoCodes Asset Tracking / Data: BLS

These alarming figures have prompted deeper investigations.

A case study of one such accident, conducted by California’s Department of Public Health, revealed that inadequate training, lack of inspections, and poorly maintained quick couplers all contributed to the death of a worker.

Other common factors in fatal incidents of this type include:

- Mechanical wear or missing parts in coupler systems

- Delayed or skipped maintenance

- Outdated quick coupler designs

In other words, the compliance baseline is just a part of the equation.

The authors of the report recommend installing retrofit safety kits on older machinery, or better yet, upgrading to equipment with built-in protections.

Illustration: GoCodes / Quote: CDPH

Modern machines and equipment offer precisely that.

Steelwrist’s automated couplers, showcased in the video below, feature a patented Front Pin Lock that keeps attachments firmly in place, preventing fatal drops.

Source: Steelwrist on YouTube

The mechanical lock works regardless of the excavator brand, adding a consistent layer of safety while also enhancing efficiency.

Most new excavator models already come equipped with safe-coupler systems that meet or exceed industry standards, eliminating the need for add-ons.

Some even feature human detection systems, automatically halting movement if a worker enters a danger zone.

The bottom line is that equipment upgrades ensure safety is built into the machine itself, contributing to a safer, more controlled environment for all your crews.

Enables Access to the Latest Technology

Acquiring new equipment means unlocking access to the latest technology, helping you transform your operations directly in the field.

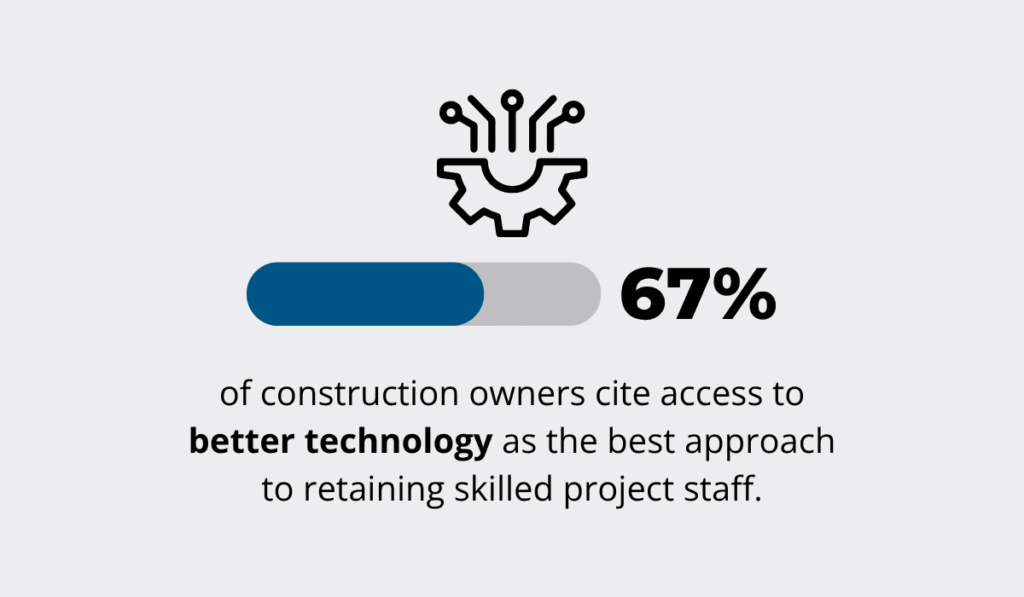

Construction digitalization helps businesses boost efficiency and improve cost estimates, but it also plays a key role in retaining skilled workers and ensuring optimal performance.

According to Procore, 67% of construction owners see access to better technology as their top retention strategy.

Illustration: GoCodes Asset Tracking / Data: Procore

However, access to advanced equipment and modern machinery is even more important when it comes to new workers.

Reports show that the industry is missing an estimated 500,000 workers in 2025, which puts contractors under growing pressure to keep projects on time and teams fully staffed.

While younger talent slowly trickles into the workforce, many seasoned operators are retiring, taking decades of hands-on experience with them.

This results in a widening skill gap, especially in complex tasks like grading, where precision and consistency are everything.

Sam Meeker, Product Application Specialist at Caterpillar, puts it plainly while also noting the invaluable role of technology:

“There is a struggle to get operators—you are getting guys that want to work and gals that want to work, but they don’t understand grade […] So, we need this 3D grade control technology to take that brand new operator and make them able to spread that material by the end of the week.”

With 3D grade control systems, operators can navigate challenging terrain and perform this work with the necessary precision, even without years of experience.

These systems provide full control over the blade’s movement, allowing for smoother, more accurate passes.

The dash display, like the one used on CAT graders, acts like a touchscreen, showing the design plan in real time.

While sensors track positioning and elevation, the blade automatically adjusts to maintain the correct grade.

And to make operating as intuitive as possible, grade control buttons are built into the joysticks.

As we touched upon previously, technology also supports safety.

Take DEVELON’s Smart AVM and Virtual Wall tech.

These systems detect humans or obstacles within six meters and automatically halt machine movement before accidents occur.

Source: DEVELON Europe on YouTube

That kind of intervention can help prevent fatal accidents like the bucket failures we mentioned earlier.

But while many new machines come equipped with advanced safety and grading technology, not every construction company is ready to overhaul its entire fleet.

Fortunately, retrofitting is another practical solution, giving older machines new life through added sensors, smart components, or enhanced attachments.

Mark Colvin, senior product manager for grade management at John Deere, explains how even minor adjustments, such as adding advanced sensors and GFSS heads, can make a difference.

Illustration: GoCodes Asset Tracking / Quote: For Construction Pros

Retrofitting can involve a range of important upgrades, from smart asset tracking and diagnostics to telematics and safety enhancements.

Ultimately, modern construction equipment is no longer just about raw power.

It’s about smart, data-driven performance.

That’s why investing in the latest equipment is a strategic move toward greater efficiency, safety, and long-term competitiveness.

Preserves Equipment Value

New equipment doesn’t just improve performance on-site. It also retains value longer.

This makes it easier to resell, trade in, or use your current assets as equity toward your next purchase.

For construction businesses, this flexibility is key to maintaining a healthy equipment cycle without suffering major financial losses each time you upgrade.

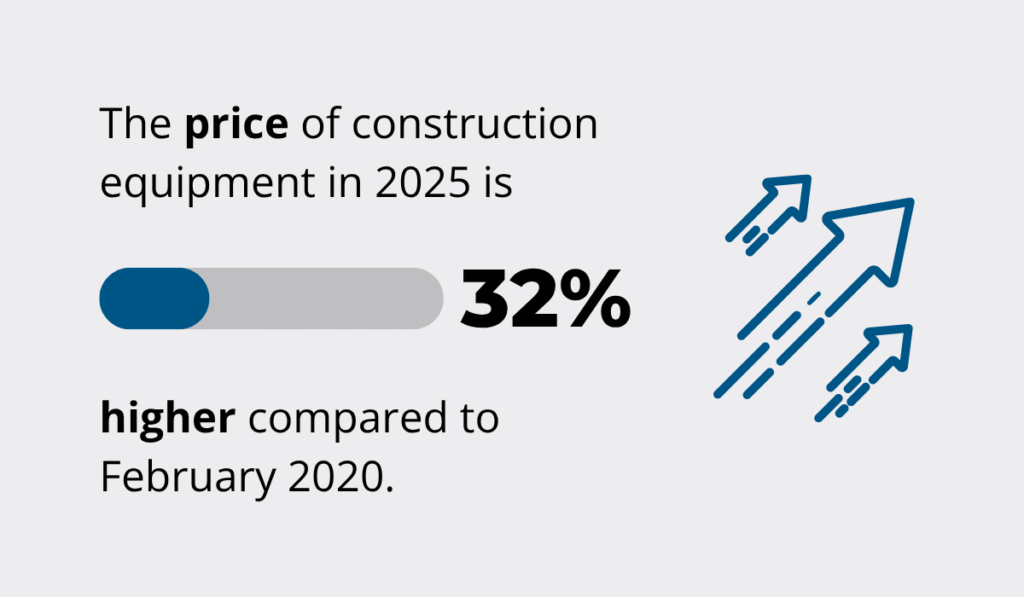

This is even more important given the steady price increases.

Namely, data suggests that the price of construction equipment has jumped 32% compared to just 5 years ago.

Illustration: GoCodes Asset Tracking / Data: Construction Equipment

Of course, heavy machinery depreciates over time, just like any asset.

However, newer models depreciate at a slower rate during their early years, meaning you preserve more of your investment.

According to Quipli’s calculations, a used heavy-duty machine can be sold for anywhere between 40 and 70% of its original price.

Most new equipment follows a “double-declining balance” depreciation model, indicating the biggest value drop happens in the first two years.

Here’s how this would look on the example of one excavator.

| Year | Estimated Value | Depreciation (%) | Notes |

|---|---|---|---|

| 0 | $200,000 | – | Initial purchase |

| 1 | $160,000 | 20% | Drop in value |

| 3 | $130,000 | 35% total | Levels off |

| 5 | $110,000 | 45% total | Resale range |

Naturally, a newer, well-maintained machine is more appealing to buyers or dealers than one that’s outdated or heavily worn.

In some cases, high resale value can even give you leverage when negotiating trade-ins or financing.

There are a couple of factors that impact the final figure:

- Usage hours

- General equipment condition

- Obsolescence

- Equipment brand

- Market conditions

According to one study, operating hours and the overall condition of the equipment are the most influential factors that shape equipment resale value.

As such, routine maintenance plays a critical role in getting the most from resale or trade-in, and you need to make sure you’re keeping records of service, usage, and any part replacements.

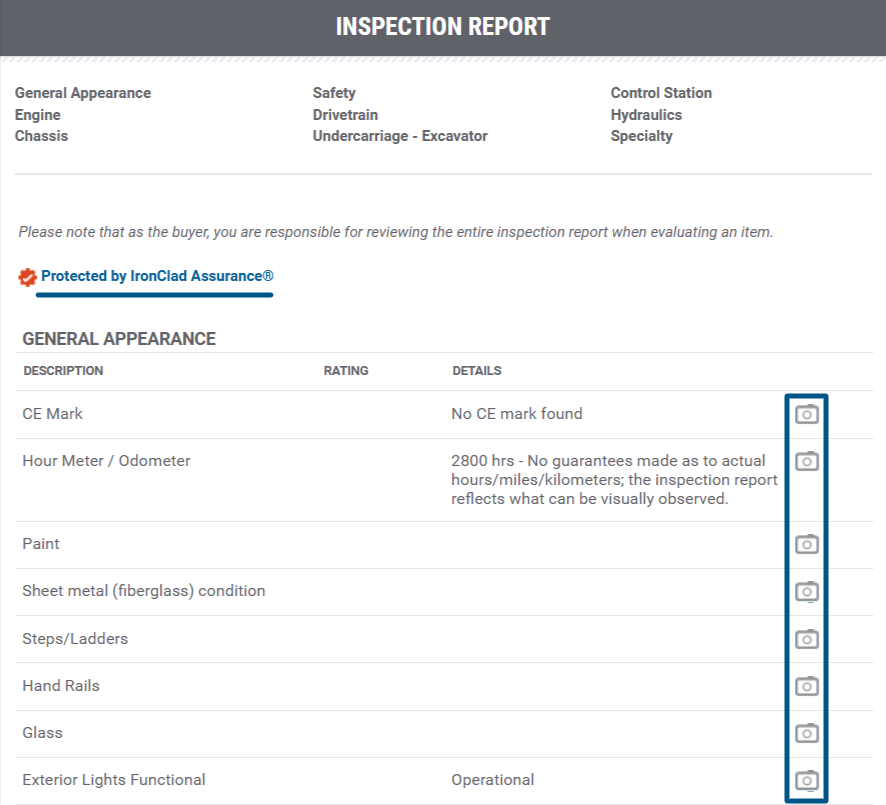

New and used equipment sites like Iron Planet inspire customer trust by providing detailed documentation and condition reports on as many listed assets as possible.

Source: Iron Planet

Their IronClad Assurance means that the company conducts its detailed checks, which can then be accessed online.

However, it’s best to keep detailed records of every intervention, from regular service checks to emergency patching.

A digital asset management solution that automates documentation and service log tracking can make this much easier.

Still, while maintenance and documentation matter, understanding shifting market demand and resale values is critical when closing a deal.

Heath Watton, former VP of Southeastern Equipment, puts it clearly:

Illustration: GoCodes / Quote: Equipment World

In other words, no equipment purchase should happen without first thinking about what you’ll be able to get for it in five years.

Yes, new equipment comes with a high upfront cost, but smart budgeting keeps your finances flexible and your construction business resilient.

Conclusion

Whether it’s reducing downtime, improving safety, or leveraging smarter technology, one thing is clear:

Newer equipment helps you work smarter, safer, and longer.

Repairs and retrofits will surely help you bridge the gaps, but they rarely offer the same long-term value as new equipment.

Upgrading is a significant investment, and it carries risks.

But waiting too long can be just as costly, if not more.

Now’s the time to take a clear-eyed look at where your business stands, and fortunately, you already know one of the most effective ways to move it forward.