Because they often move from place to place, construction assets are especially subject to theft or misplacement.

Effective construction asset management is vital for increasing profits, deterring employee and outside theft, locating missing items, and making your construction site overall more efficient.

Maximizing effective construction asset techniques is helpful to decision makers, front line employees, small business owners, and those in management positions.

In this post, we will teach you about asset lifecycle, the importance of regular asset reviews, regular and preventative maintenance, how to find the best software, and much more.

So let’s get started.

In this article...

Know What You Have and Understand the Lifespan of Your Assets

Understanding the life span of your assets is important, as it facilitates planning the right time to replace them. Doing so will help your company spread out costs, prepare for major expenditures, and avoid expensive panic-buying.

Effective construction asset management means becoming thoroughly familiar with each asset’s status as it journeys through its life cycle.

This knowledge is applicable to both fixed as well as moveable assets.

A fixed asset is one which does not move, such as a water heater; movable assets travel, if only a few feet down a hallway.

Projecting the asset’s useful life demands an honest assessment of its condition and how well it has been cared for. An honest life span assessment also includes taking into account its function within your organization, as well as whether or not its form of technology will quickly become outdated.

For example, a well-maintained but occasionally used hand tool will likely last much longer than a heavily traveled tablet.

Depreciation will always occur, but this can be limited by wise management of the asset’s life span. The amount of time a construction-oriented asset is useful varies widely.

Factors can include:

- The age of the asset

- The era in which it was manufactured

- If acquired used, the condition in which it was kept by the previous owner

- The asset’s immediate environment (indoor, outdoor, the range of extreme temperature, etc.)

- Faithfulness to a preventative maintenance schedule

- How often the asset is used

- Operation of the asset according to manufacturer guidelines

Categorize Your Assets According to Profitability

It’s important to take the time to know the ratio between the costs of the assets and the profit it generates in your organization. By investing the time to examine this, decision makers can sell or replace the asset as soon as it fails to meet profit or performance goals.

Companies tend to operate more efficiently when using up-to-date and properly-functioning equipment.

Still, if the technology is not operating correctly or if employees don’t understand how to use it, the purchase will struggle to pay for itself.

However, if maximum profitability is an area of concentration, the time and attention paid to tracking the data will reap dividends quickly.

Here are some profitability ratios to keep in mind as you examine your construction assets:

- Return on sales (net profit margin): (Net profit before taxes/Net sales) multiplied by 100

- Return on owner equity (return on investment): (Net profit before taxes/Net worth) multiplied by 100

- Return on assets: (Net profit/total assets) multiplied by 100

Using these formulas can help to evaluate your company’s operational efficiency, capital return, and profits after paying taxes.

When assets are tracked in real time, categorizing and managing them makes analyzing their operational data much easier, as the information is more reliable and can be acted upon quickly.

Use our free ROI online calculator to see how would your investment in asset tracking pay off.

Conduct Regular Asset Reviews

Properly managing assets should stand out as a priority.

The regular review of construction assets is a significant aspect of this. This helps decision makers create an accurate assessment of their depreciation. It also forces the re-evaluation of maintenance schedules and budgeting.

Keeping on top of demolition costs, ghost assets, and intangible assets such as intellectual property is also advisable.

More importantly, conducting regular asset reviews contributes to a wise tax planning plan.

When a company fully understands how to take advantage of the depreciation of multiple assets, a myriad of deductions becomes possible.

This increases cash flow and might even lead to retroactive deductions.

Regularly reviewing assets facilitates the decisions concerning the right time to move to the disposal phase of an asset’s life cycle.

Data-driven choices also have the happy effect of lengthening a life cycle or deciding to commit resources to repairing an asset that fits well within the company’s mission and daily flow.

Conducting regular reviews for your construction assets can also:

- Increase compliance for state, municipal, county, and federal regulations

- Maintain an efficient flow of inventory

- Streamline schedules based on data rather than arbitrary timelines

- Contribute to a predictable and sustainable repair and maintenance schedule

Recommended reading: Preventive Maintenance Checklist

Communicate With Your Team

The fastest way to build trust amongst employees, or between management and implementation workers is to communicate well.

This is a natural outgrowth of healthy relationships, which can begin as soon as a company decides to move forward with a transparent and open form of discussing expectations and problem-solving strategies.

Team communication goes far beyond a flurry of emails and flyers tacked to an employee message board. It’s also much more than meandering meetings and collaborative decision making.

To best communicate with your team about the management of your construction assets, consider putting the following strategies into play:

- Establish a proven, regularly-updated training program on specialized equipment. The input of current operators and newly hired employees will be essential for the program’s success.

- Ask for and discuss employee feedback.

- Discuss irregularities in tracking or operational data with equipment managers and operators.

- If possible, encourage stakeholders to visit construction sites and study equipment for first-hand information on operations and procedures.

- Prove a willingness to adjust guidelines, rules, and techniques for greater efficiency and employee safety.

- Discuss employee concerns with stakeholders, as well as stakeholder concerns with employees.

- Share definitive data so that decision making does not appear arbitrary.

- Encourage questions and suggestions to improve asset management.

Conduct Regular Asset Maintenance

Regular and preventative maintenance goes hand in hand with regular asset reviews. When regular maintenance is established as a priority, compliance is more straightforward, profits are more trackable, and employee accountability rises.

Taking care of the company’s equipment shows that decision makers care not only about the viability of the assets but the employees’ safety and efficiency as well.

When construction assets are carefully maintained, warranty claims are often simplified, and outside technicians have a better idea of how to repair or upgrade equipment.

Moreover, proper preventative maintenance helps detect and manage problems before they escalate into a major breakdown, which threaten to cripple construction progress and employee productivity for days or even weeks.

Acting at the mercy of whether or not an asset is operational is not a viable way to serve your customers, stakeholders, or employees.

Increasing reliability and decreasing uncertainty makes for a happier workforce while also reducing the pressure on budget managers and timeline producers.

This also includes a defined company procedure for disposing of small unusable or expired assets. Organizing equipment from the bottom to the top can create not only a strong safety culture but a company-wide commitment to efficiency.

Good maintenance plans, which all those concerned rigorously update and adhere to, are simply good economics and sustainable employee care.

Make the Most of Equipment Downtime

Properly executed preventative maintenance staves off or even eliminates major downtime.

To avoid unexpected downtime, consider conducting studies on the profitability of investing in a backup or alternate solution, such as providing generators in the event of an emergency loss of power.

Establish good relationships with rental agencies to effortlessly arrange for and obtain rental equipment. Researching and preparing for even unexpected downtime yields opportunities to solidify contacts across the industry and become an invested member of the community.

However, in spite of your best efforts, downtime can occur due to a manufacturer error, weather events, or unexpected stress on a particular component.

Companies with incorporated flexibility in these events can pivot quickly to avoid wasting employee time and resources.

Panicking or stranding employees in the field indicate a lack of planning and a failure to adapt to changing conditions.

Other useful tasks to take on during unscheduled downtime can include:

- Preparatory paperwork

- Conducting inventory

- Clearing out backlog tasks

- Safety or refresher training

- Listening and feedback sessions

- Priming other equipment for future tasks

Communication is vital during downtime. Tamp down rumors and frustrations by clearly explaining what you expect from your workforces during a breakdown.

Help all employees feel involved and informed by sharing timelines and regular updates.

Give Your Team the Know-How for On-Site Repairs

Using your industry’s most cutting-edge equipment reduces downtime, prevents injuries, and maintains efficiency.

However, even the latest new shiny object can act as a hindrance when employees are not adequately trained, or the equipment isn’t a good fit for your daily operations and goals.

Empowering employees to conduct on-site repairs isn’t always possible, especially if your team uses specialized equipment that requires licensed operators or technicians. Labor agreements, warranty stipulations, overtime issues, and constantly changing worksites also come into play.

When on-site employees can safely repair equipment without calling in an outside crew, operations can not only begin again more quickly, but decision makers and the workforce have a more intimate knowledge of the equipment.

Understanding the specific characteristics of each tool is invaluable as it increases operator efficiency and precision.

Connecting operator education to accountability also often leads to better operations. If an employee feels he or she is working with “my machine,” he or she will likely treat it with more care and pride.

Employees who can trust their equipment and are thoroughly familiar with its noises, odors, and timing may well regard these assets as members of the team. Respecting this perception and relationship helps an entire company operate more harmoniously.

Be Sustainable

Sustainable practices that concentrate on cost and waste reduction are valuable to each member of the company. These contribute to long-term competitiveness and help with local or EPA (Environmental Protection Agency) compliance.

The benefits of a sustainable asset management plan include:

- The ability to market to environmentally conscious customers and investors

- Wise resource management across the organization

- Better health for employees

- Minimizing waste

- Tamping down noise pollution

- An understanding of how to re-use materials

- Increasing donation of materials to social organizations

- Meeting new market demands

- Allowing experimentation among architects, contractors, and material producers

Sustainability can include a zero-waste initiative or entail reaching out to community organizations to form partnerships. In some areas, sustainable practices are mandated, and staying ahead of regulations can avoid scrambling when they arrive.

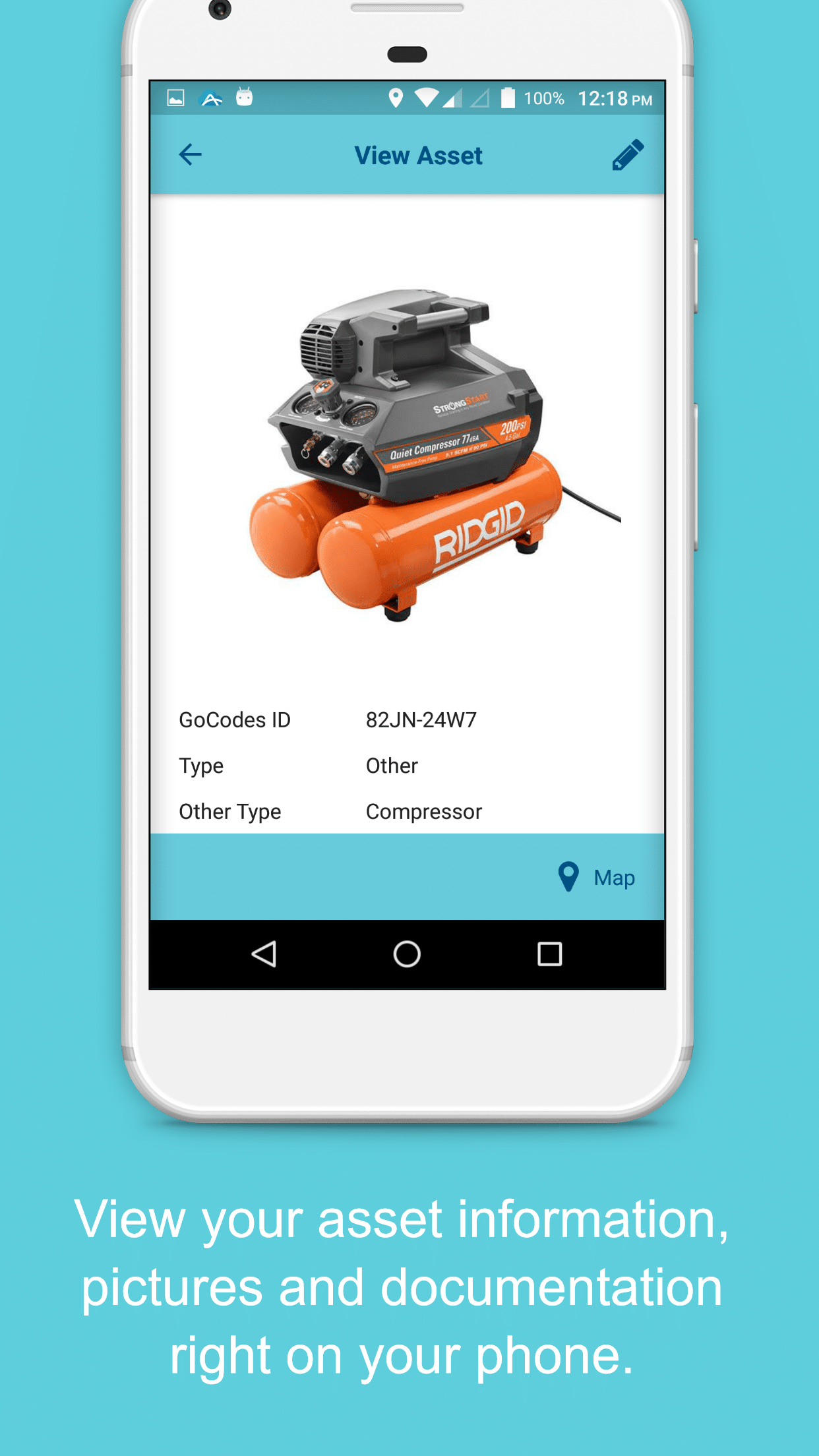

Use the Right Software

Relying on the right software for your organization is the number one prerequisite for successful construction asset management.

When effectively managed, material tracking provides valuable real-time data that can be used to predict downtime, maximize efficiency, and increase employee participation in giving input.

Building materials, as well as assets are essential for starting and completing a construction project.

No matter which software a company chooses, it must commit to proper employee training and constant monitoring since it first starts with its implementation.

When it comes to software, best practices entail comparison shopping, beta testing, budget considerations, and the use of unique tracking identifiers.

The right fit means the difference between an increase in productivity and an expensive failure. Consult with employees as well as stakeholders to find the best tracking software for you.

When Construction Asset Management Is Effective

Your company deserves effective asset management. A well-implemented asset management system is holistic. It includes decision makers, budgetary recommendations, data analysis, and workforce buy-in.

Strong communication and commitment to follow through are vital aspects. When all these elements are a part of the management system, a company becomes more effective for its customers, employees, managers, and owners.

GoCodes Can Help

We use QR code tags with a unique visual code that you can scan with your smartphone. When scanned, GoCodes tags provide GPS information about the location of your equipment, resulting in effortless construction asset management. Sign up for a free trial here.