Safety on a construction site is an important concern for contractors and project managers. Fall prevention especially is an aspect of safety that cannot go ignored.

Even the simplest jobs can involve working from heights, and it’s easy to ignore basic safety protocols when workers feel comfortable on a site or are rushing to meet a deadline.

However, even the dangerous nature of working in construction from platforms, roofs, and tall equipment can become safer through simple fall prevention procedures.

Fall prevention tactics can include education about fall prevention requirements, daily site inspections, focusing on site cleanliness, and regular fall protection equipment inspection.

Let’s look into them.

In this article...

Get Informed About Fall Prevention Requirements

It is difficult to help a team become aware of the dangers of falls on the jobsite if the foreman or project manager doesn’t know much about them, either.

Staying current on the best forms of fall prevention should be an ongoing company goal.

Also, impressing upon workers that falls are usually the most dangerous aspect of construction work can help to remind your team about the importance of keeping themselves and their co-workers as safe as possible.

OSHA uses the slogan PLAN-PROVIDE-TRAIN to emphasize the significance of leadership at a company level when it comes to fall prevention:

All three of these elements must remain present and updated for a leader in the construction industry to fully meet their responsibility of safeguarding their employees.

Construction companies should also inform themselves about fall prevention requirements.

OSHA’s (Occupational Safety and Health Administration) Subpart M formulates the requirements for fall protection on construction sites; these codes have the force of federal law.

Fall prevention requirements differ depending on the site and type of work. Here are some examples:

- Safety nets, guardrails, or personal fall arrest systems are required for work over a leading edge of six feet or more

- The same rules apply to bricklaying at heights of over six feet; in addition, this work may only take place in a controlled access zone

- Low-slope and roofing work requires these items in addition to warning line and safety monitoring systems

- Steep roof work calls for all this plus use of toeboards

Subpart M not only enumerates federal standards concerning fall prevention requirements, it also clarifies and defines otherwise murky points as the construction industry continues to evolve.

For instance, this document discusses how to work with ladder hoisting wheels, requirements for sites located over water, and what to do about skylights, new telecommunication towers, and portable stepladders.

Implement Fall Protection Systems

Construction companies are responsible for the safety of their construction workers, and should therefore invest in quality fall protection systems.

It is important to put a plan in place for forming these systems, then evaluate how to implement them on worksites that might vary from temperature-controlled warehouses to high-altitude locations exposed to extreme weather.

Fall protection systems include:

- Guardrails

- Safety nets

- Personal fall arrests

- Positioning devices

- Fall restraint systems

Implementing proper fall protection systems involves purchasing quality, undamaged equipment that meets local and national standards.

If decision-makers balk at the cost, it is important to emphasize that providing basic protection for team members isn’t just basic responsibility, it can also serve as an investment.

An accident on the job site could cost a great deal of money in repairing damage, paying fines, finding a temporary worker replacement, providing training, instituting new protocols, meeting legal fees, and covering insurance obligations.

In fact, OSHA estimates that each dollar invested in robust safety protocols and equipment can yield an average of $5 in savings.

When talking about safety equipment, full body harnesses are an excellent option:

This visual demonstrates the many parts and pieces of just one piece of a comprehensive fall prevention plan and system.

If the lanyards begin to fray or team members do not keep the shock absorbers in good repair, chances increase that this equipment might not work as needed.

And skimping on such important gear is unacceptable in implementing a fall protection system.

Perform Daily Construction Site Inspection

Regular site risk assessments are a must in lowering the risk of falls. These are most easily organized via daily site walk-throughs.

This activity asks everyone to think about safety and code requirements before a shift or day begins.

Safety walk-throughs help shift managers and contractors detect and manage potential fall hazards.

It’s best if construction workers, supervisors, and construction safety officers join the inspection. Everyone will have a different perspective to offer.

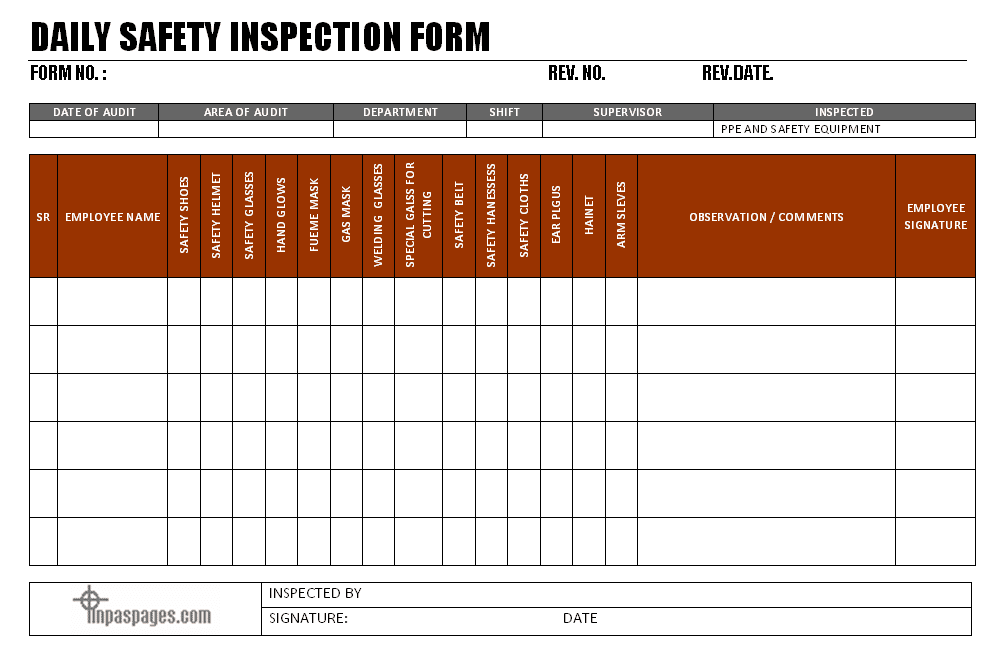

One person responsible for inspecting the construction site can use a checklist to ensure that the team has fully examined each item.

A section pertaining to fall prevention can bring attention to this important part of the pre-shift work. The checklist should also include OSHA, local, union, and company expectations.

Here’s an example:

Notice that this checklist focuses on the safety equipment needed for the shift.

Others can include checking the soundness of toeboards, testing safety nets, and inspecting harnesses for rust or tears.

The checklist also includes the name of the employee responsible for the inspection, as well as room for observations and comments.

This allows team members to ask questions or note that some equipment is nearing the end of its useful life, or encourages notations of special conditions on the site, such as the presence of ice on metal surfaces.

Checklists such as these not only create a day-to-day evidence chain that might prove useful during audits or incident reviews, but they also ask those undertaking the inspection to maintain responsibility for it.

Keep the Construction Site Clean

Construction is almost never a “clean” job; it usually involves digging holes, stirring up concrete dust, or cutting through lumber or drywall.

However, encouraging team members to keep a construction site as debris-free and organized as possible can help to prevent a chaotic or potentially dangerous work environment.

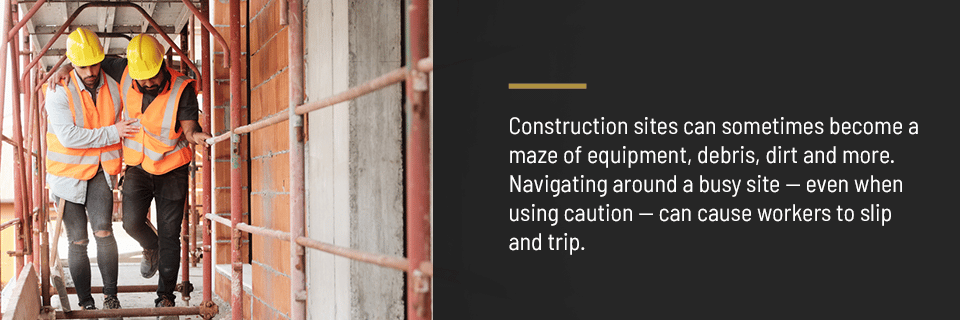

Eliminating “hidden” trip hazards can go a long way in avoiding a fall on a construction site.

This image provides a reminder that dirt and debris are not the only slip-and-trip dangers that construction workers come across.

These can also include unattended electrical cords, plastic sheeting, and bungees:

Project managers can highlight the importance of cleaning up debris, tossing pop cans and wrappers from meals into garbage cans, disposing of raw material packaging, and taking care of tools and equipment by securing them when they are not needed.

It is also important to clear out slip hazards when they occur—clearing up oil spills or chipping away ice can contribute to a safer workplace.

Make Fall Prevention Courses a Requirement

Fall prevention and fall protection courses are a federal requirement for construction workers; therefore, companies are bound to provide them.

OSHA demands these as a means of educating construction workers in recognizing, as well as minimizing fall hazards.

Fall prevention courses should also include thorough training in how to use, secure, and inspect personal safety equipment and such site enhancements as nets and guardrails.

A comprehensive fall prevention course should include the following:

- Reminders of why fall prevention is important

- What to look for in site safety inspections

- Discussion on fixed ladder safety precautions

- How to use site emergency response systems and plans

- Education on techniques such as three-point contact when using tall equipment, platforms, or ladders

- How to inspect fall protection equipment and report deficiencies

- Using a buddy system to spot one another

- Basic first aid

Courses should also include information about common citations.

For example, this infographic from OSHA reveals that the most-cited violation in 2019 was indeed failure to meet general requirements on fall prevention.

In addition, scaffolding citations came in at #3:

This indicates an industry-wide failure to take fall prevention seriously.

Impressing this upon workers can act as a reminder that turning this dangerous trend around is a goal to which they can all contribute.

Inspect Fall Protection Equipment Regularly

Just like important vehicles, tools, or heavy equipment, fall protection items should undergo regular inspection.

This includes personal items such as harnesses and metal fail-safe points, as well as large site-wide items like guardrails, nets, and scaffolding structures.

Company-wide inspection is important, but so is empowering employees to check their own equipment for themselves prior to each shift.

Deterioration, damage, fraying, rust, and over-wear should all signal that it’s time to replace an item. These inspections call for an examination of every part of the item.

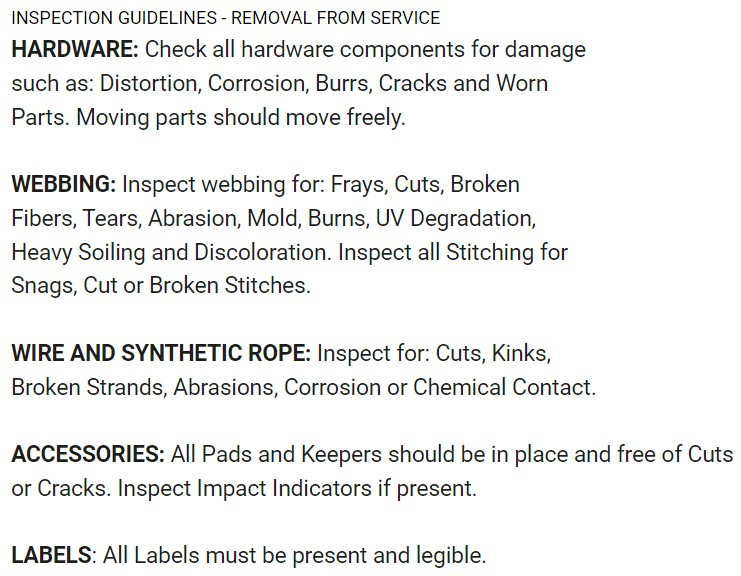

This chart from a safety equipment provider offers a snapshot of what workers should look for when checking hardware, webbing, ropes, and even warning labels:

The chart includes a recommendation to remove an item from service if it falls short of even the most cursory inspection.

Used fall protection equipment should not be redistributed or resold, much less purchased by others. In addition, if the equipment has been used to arrest a fall, the company should not put it into service again unless properly inspected.

Factory inspection or refurbishment is required of some fall protection equipment.

Conclusion

Construction companies are responsible for providing their employees with every possible weapon against dangerous falls.

These include investing in quality personal equipment as well as site-wide equipment.

Employees should also receive regular and useful education on updated safety codes, first aid basics, and how to use or inspect safety equipment.

A site-wide safety inspection of fall prevention equipment, as well as seeking out potential trip hazards, can contribute to avoiding falls.