The construction business is dependent on quality tools that enable your team members to do their best work. Keeping your tool collection operable, safe, and always available is paramount, and starts with proper care and adequate storage conditions.

Nevertheless, improper storage practices are not a rare sight at worksites of all kinds, so it’s clear that managers and company owners need to keep a closer eye on this problem.

To protect your investment in power tools, keep reading to learn about six common tool storage mistakes and how to avoid them.

In this article...

Not Cleaning the Tools Before Storage

One of the most common mistakes when handling power tools is not cleaning them after every use. This shortens the lifespan of your tools and, in the worst-case scenario, can lead to serious injury.

Luckily, there are simple things you can do to protect yourself and your finances from taking a hit.

As mentioned earlier, worn out, damaged, or malfunctioning power tools can cause injuries or, at the very least, slow down your project.

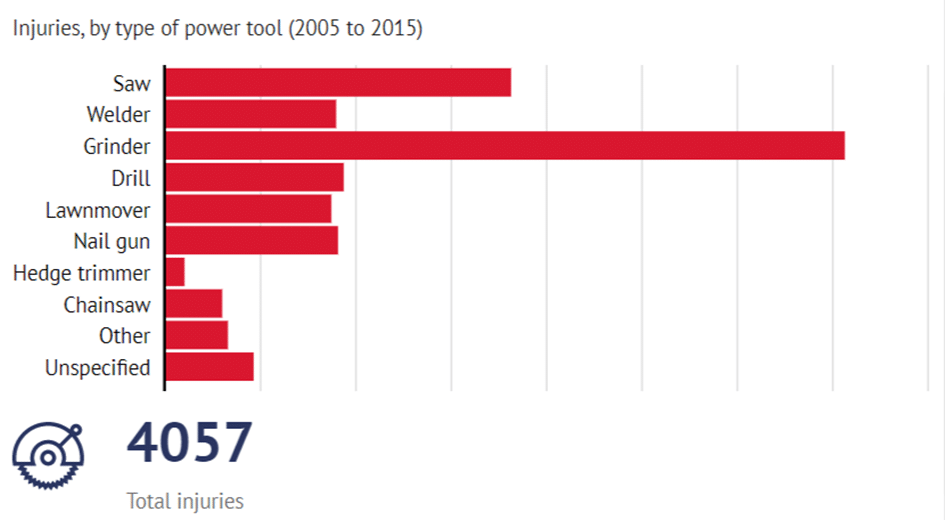

For example, a study on power tool injuries treated in just two hospital emergency departments produced these results:

As you can see, angle grinders are the leading cause of injuries, followed by saws and three almost equally dangerous power tools—drills, nail guns, and welders.

A lot of these accidents can be avoided with good upkeep and cleaning, so let’s take a look at some easy steps you can take to make sure you’re always storing tools in optimal condition.

The first step you need to take is to always read the instruction manual, because it contains tool-specific cleaning and storage tips.

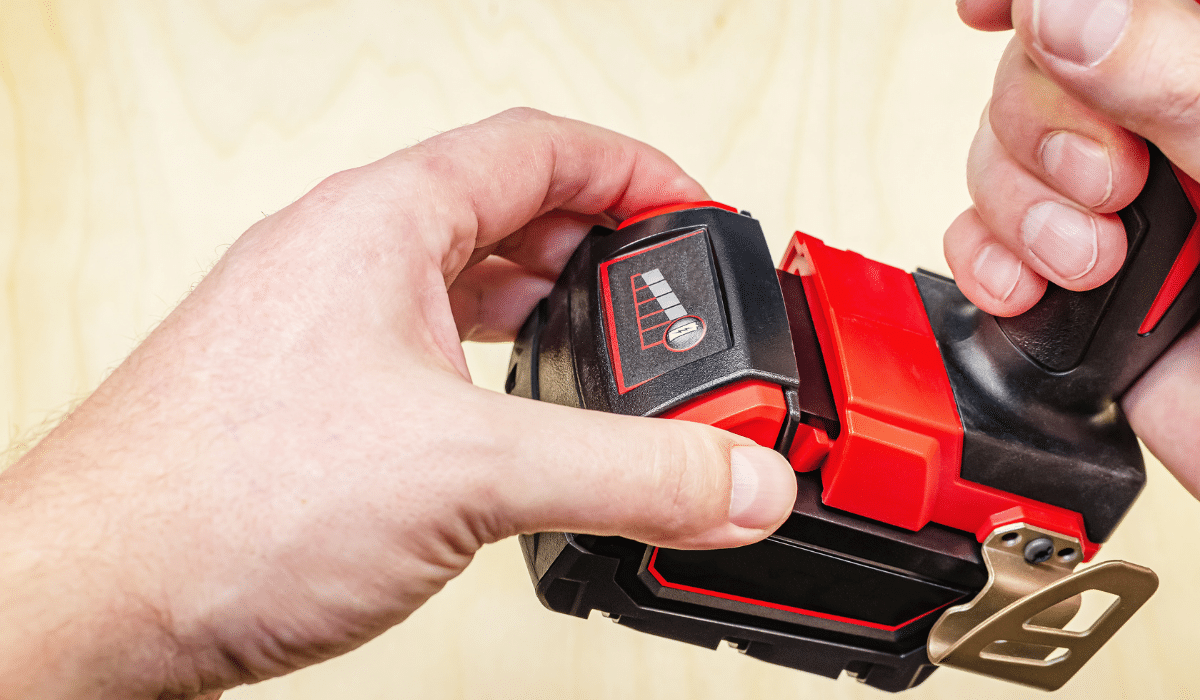

Before cleaning the tools that run on electricity, always disconnect them from the power source. If the tool is cordless, unclip and remove the battery.

Next, remove all accessories. They could cause damage to other tools while in storage, or get damaged themselves.

Finally, when these preparations are out of the way, clean the tool using a rag to remove any build-up of dirt and grease.

Where larger power tools are concerned, compressed air is often the most effective cleaning method. For example, here’s how compressed air can be used to clean a chainsaw.

Just remember to wear safety glasses.

When cleaning the tool, make sure to also inspect it for any damage. It’s an easy way of keeping an eye out for any potential problems that could arise while the tool is in use.

Storing Your Power Tools Wet

The next common mistake is storing power tools wet and/or failing to keep them dry in storage. Exposing tools to moisture causes rust, mold, and mildew and damages batteries and circuits.

There are some good practices to follow to keep your tools dry.

Should your tools come into contact with an excessive amount of water, the first thing to do is to wipe them down with a dry cloth.

Since water also tends to penetrate places you can’t reach this way, you should also place the tool in a dry place and avoid using it for a while until it has the chance to dry off.

These tips also apply if a soft rag lightly dampened with soapy water was used to clean the tool’s plastic parts. Just make sure it’s completely dry before you use it again.

Another good idea is to use cotton swabs to dry all those hard-to-reach places.

Now that they’re clean and dry, we need to keep them that way.

If you plan to store the tool for longer, some further actions are required.

Since rust is enemy number one when it comes to power tools, it’s wise to use some type of corrosion inhibitor on the metal parts. Solutions range from regular machine oil to specialized rust-inhibiting formulas.

WD-40 is always a popular choice for its famous blend of lubricants and anti-corrosion agents.

However, be sure to check the instruction manual, as your tool may call for a specific type of lubricant.

Let’s move on to where to store your power tools to prevent condensation and the occurrence of moisture.

On a smaller scale, the original cases tools came in are often ideal for storage. But this depends on how your storage space is organized, as you’ll see below.

Going bigger, your best bet is a dry and cool space with minimal temperature fluctuations.

For extra protection, you can put some silica gel bags in your toolbox, cabinet, or storage container.

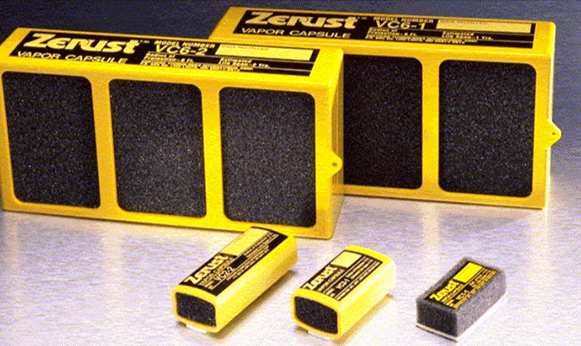

Or you may go for more advanced options like the one shown below.

These rust prevention vapor capsules contain a patented formula and release molecules that create an anti-rust shield around the surfaces of anything that’s stored inside an enclosed space like your toolbox or, since they can cover up to 6 feet (180 cm), an entire locker.

As you can see, keeping your power tools dry involves some effort, and there are some advanced options to consider.

It is important to dry your tools quickly after they come in contact with water, use anti-corrosion agents and lubricants, and secure dry storage space with a stable temperature.

Disregarding Best Practices for Battery Storage

Handling and storing battery packs properly will keep them at their best performance.

However, when it comes to storing batteries, some of the actions you take with the best intentions could actually be shortening their life.

There’s a lot of misinformation floating about, so it’s easy to make mistakes.

So, what are the most common mistakes when storing the batteries used in power tools?

The first one is storing lithium-ion (Li-ion) batteries fully charged, which can considerably shorten their lifespan. Moreover, such batteries are more likely to explode if exposed to high temperatures.

However, that doesn’t mean you should store your batteries in a drained state, as storing a drained battery will also result in damage. This mistake can be avoided by charging the battery before long-term storage.

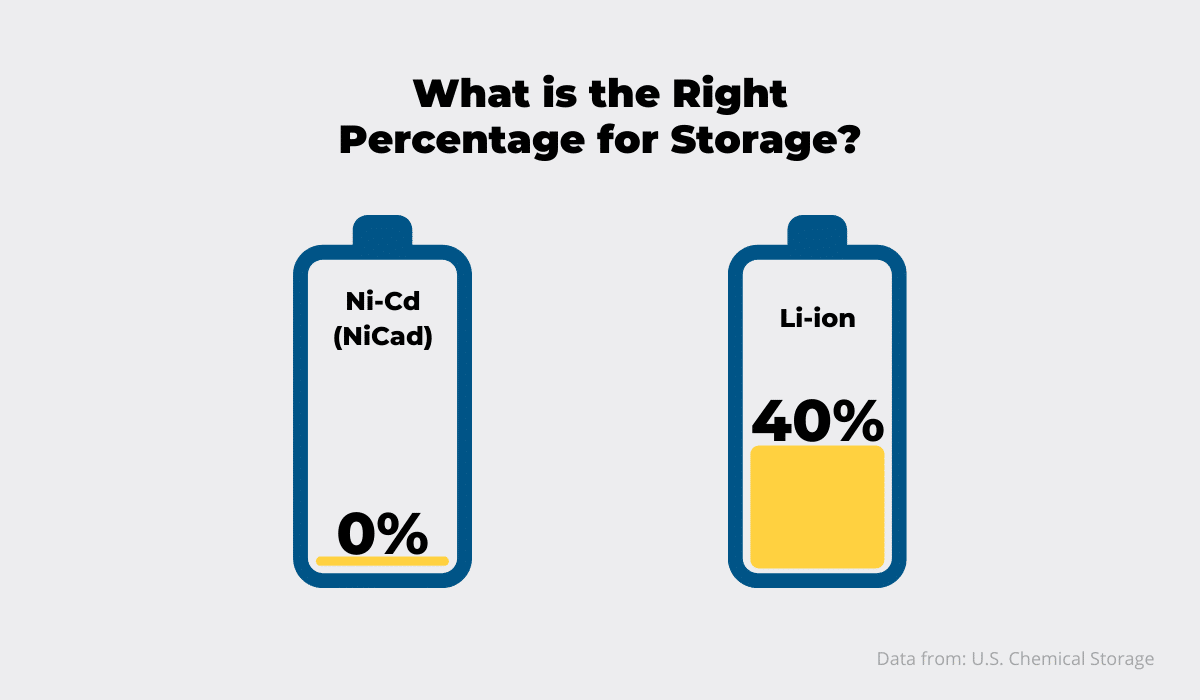

So, how well-charged should the battery be when you put it in storage?

According to different sources, somewhere between 30% and 50%, while the most cited value for an optimal lifespan is roughly 40%.

Note that the misinformation that batteries should be completely drained before you store them likely stems from the recommendations for the older nickel-cadmium (Ni-Cd or NiCad) batteries,

Hence, your best storage solution will differ depending on whether your battery pack is Li-ion or Ni-Cd.

Let’s move on to storage conditions.

Batteries don’t fare well when it’s too hot or too cold. However, heat causes more extensive battery degradation.

In fact, batteries will start to deteriorate at about 80°F (27°C) and, if the temperature continues to rise, the damage to your batteries will increase accordingly.

When the temperature reaches 100°F (38°C), that’s when deterioration becomes particularly rapid.

As for rust-causing condensation, the above-mentioned rules for preventing moisture on your stored power tools apply—a cool and dry place with minimum temperature variations is best.

One more thing. Although storage is important, heat also hurts the batteries when power tools are used. It just can’t be avoided.

In other words, if the battery feels hot to the touch, replace it with a spare or let it rest.

So, for both battery usage and storage, the same rule applies. Let them cool off and keep them that way.

To sum up, there are many traps and some misconceptions to avoid, but doing so will keep your batteries in prime condition.

Keeping Power Tools on the Ground

The next mistake on our list is keeping power tools on the ground. This exposes the tools, as well as you and your employees to all sorts of risks.

Let’s start with what can happen to the power tools left or stored on the ground.

Concrete floors are usually cold and moist. The cold itself wouldn’t be so much of a problem, but moisture wreaks havoc on their electrical wiring and metal parts.

That’s one reason why your power tools should be kept off the ground, preferably in their original cases or other storage solutions.

In addition to humidity, tools kept on the ground are at risk of flood hazards. If they get covered in water, they might be ruined.

This is the second reason to keep them on higher shelves or even just slightly elevated in the case of tools that are just too big to be on shelves, like the ones below.

In April 2021, due to NWS floods, a lot of equipment was damaged because it was kept on the floor of the workshop. This could have been at least partially avoided if they had been kept in an elevated place.

Luckily, a lot of these tools were repaired by volunteers from Laurieton Men’s Shed. They achieved an astonishing 90% repair success rate.

Additionally, if tools are kept on the ground, they could be run over by mistake, or something heavy could be dropped on them.

Now let’s look at what dangers you or your employees are exposed to when power tools are left on the floor.

First, there’s a risk of somebody tripping over them or their cords.

If you take into account that power tools usually come with sharp edges and blades, you’ll see that this is no small matter.

As for cords, if they’re lying tangled on the floor, they fray. This can lead to electric shock or even fire when they’re plugged in again.

It’s better to coil them up or hang them, depending on your preferred storage method.

That’s why power tools should be kept off the ground. Admittedly, it takes some planning and investment to build elevated spaces, but the risk mitigated is well worth the effort.

Failing to Organize the Storage Space

If your storage space is disorganized, that usually means power tools aren’t stored in the right way. Good organization ensures your tools are stored safely and protected.

Now the question is how. There’s a myriad of ways to go about this. So many ways, in fact, that there’s a whole industry dedicated to storage spaces.

To illustrate this, the global tool storage product market in 2021 was worth $3.61 billion and is expected to grow about 4% per year in this decade.

That said, there are some essentials we can cover to help avoid the biggest mistakes.

A well-organized power tool storage like the one above will do at least two things.

First, it will enable you to find what you need faster. Second, it will provide optimal storage conditions for your tools, thus extending their lifespan.

Among the countless combinations, here are a few DIY solutions.

For example, this video shows how you can organize your small hand-held power tools.

As for those grinders that cause the most injuries, here’s a practical way to safely store them.

Efficient organization will also help prevent mistakes, such as using non-compatible chargers, resorting to the wrong tool for a task because you can’t find the right one, or leaving batteries exposed.

Next, labeling shelves, cabinets, and transparent plastic containers is a good idea. It should help you find anything you’re looking for much faster, no matter how small the item is.

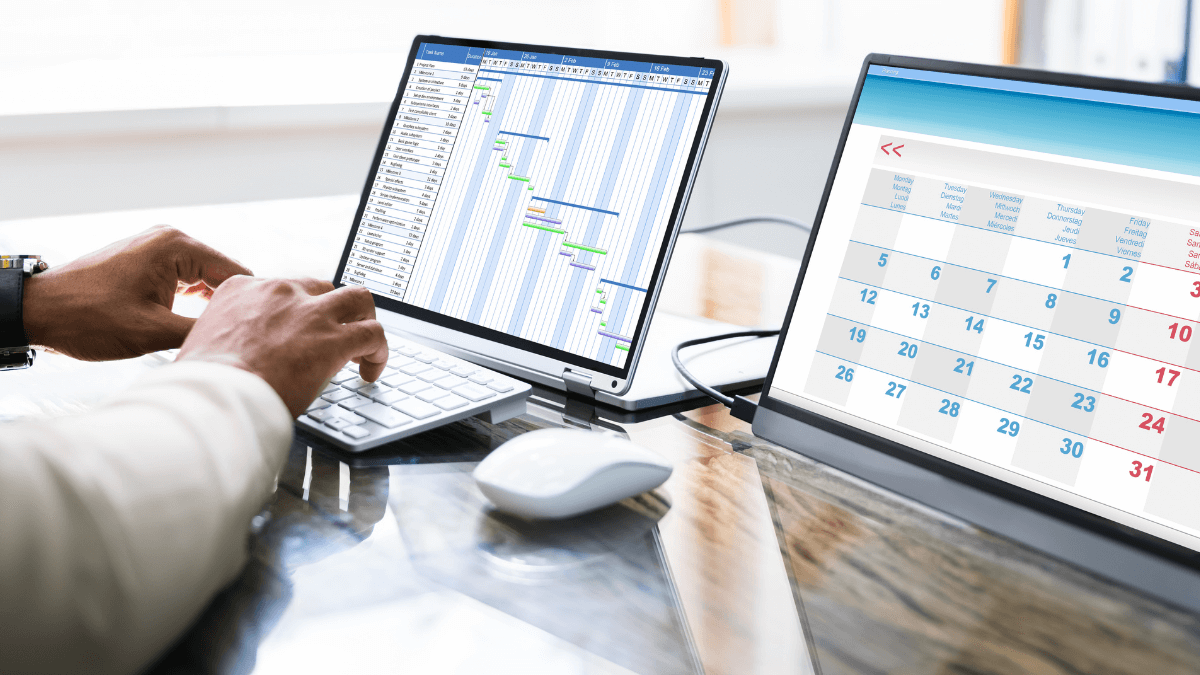

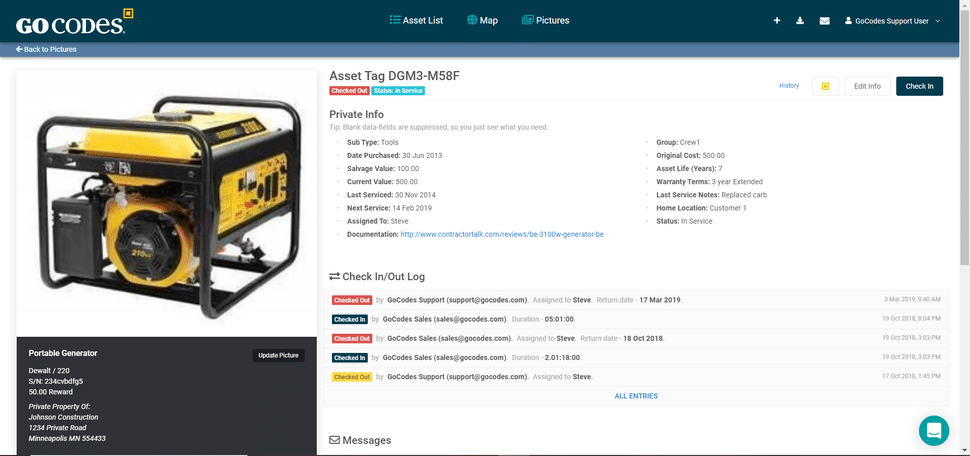

Labels can be useful, but If we’re talking about mid-sized or larger construction firms that have a lot of tools and materials to track, a more high-tech solution is to use QR codes which can be scanned to record the item’s usage, location, and handy information such as maintenance schedules.

Our asset-tracking software, GoCodes, offers all of this and much more.

If you want to dive deeper into ideas for storing your power tools, you can do so here, while best storage practices can be found here.

Storage organization comes with both high-tech and low-tech solutions. Use a combination of the two to keep your storage space neat and all of your tools accounted for.

Holding on to Damaged Tools

Power tools can be expensive, so it’s natural to want to keep them in good condition as long as possible. But this can lead to some mistakes you just can’t afford.

For example, if you’re holding on to damaged tools or worn-down accessories, thinking they might come in handy one day, you’re actually just cluttering your storage space.

You may also forget that the tool you’ve kept is damaged and decide to use it, thus risking injury.

So, if a power tool is damaged, either get it repaired or get rid of it. In such cases, it’s wise to consider a few factors.

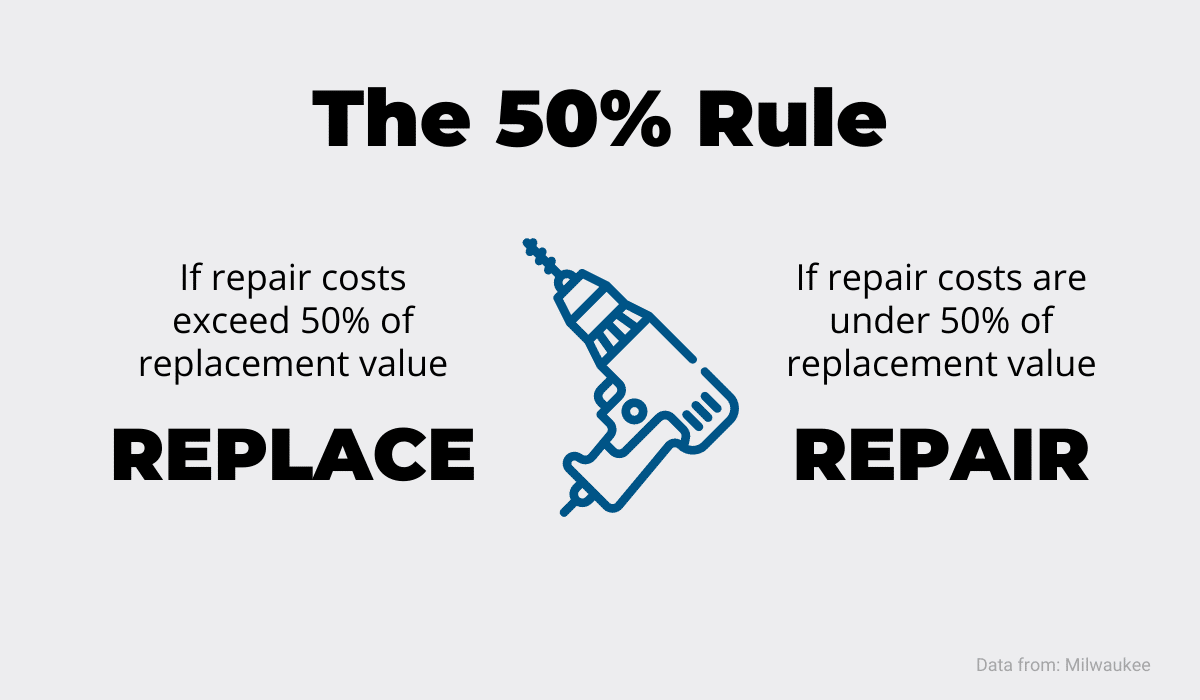

The first one is repair vs. replacement cost.

And the rule is simple: If repairing a power tool would cost more than 50% of the price of a new one, it’s time to part with it.

Other factors to consider when dealing with worn-out tools are their performance and safety features.

For example, a drill that no longer does its job in an intended way should be replaced.

As for its safety features, just looking at the tool will reveal a lot—cracked plastic housing or exposed internal electronics can lead to electric shock. Thus, if you notice any, it’s time to repair or replace the item.

Owner’s manuals are a great source of tips on avoiding injuries when using power tools.

They usually also provide instructions on what signs are that your tool has become ineffective, malfunctioning, or damaged.

For example, here are a few words of caution on how to spot faulty electrical wiring from the instruction manual for a DeWalt drill.

As you can see, the manual points the user to common signs that the tool’s wiring is damaged, such as exposed wires, damaged insulation, and defective fittings. It also provides the next step if such damage is found (i.e., replacing the cord).

Similar instructions can be found for other types of damage, so it’s always a good idea to keep an eye out for them and replace the damaged tool on time.

In a nutshell, holding on to damaged tools clutters up your space and exposes you to injuries. Their timely repair or replacement will do just the opposite.

Conclusion

As we reach the end of these most frequent power tool storage mistakes, it’s evident they can be turned into best practices that will keep your tools running smoothly for a long time.

Ultimately, these practices save you money and protect you at the same time.