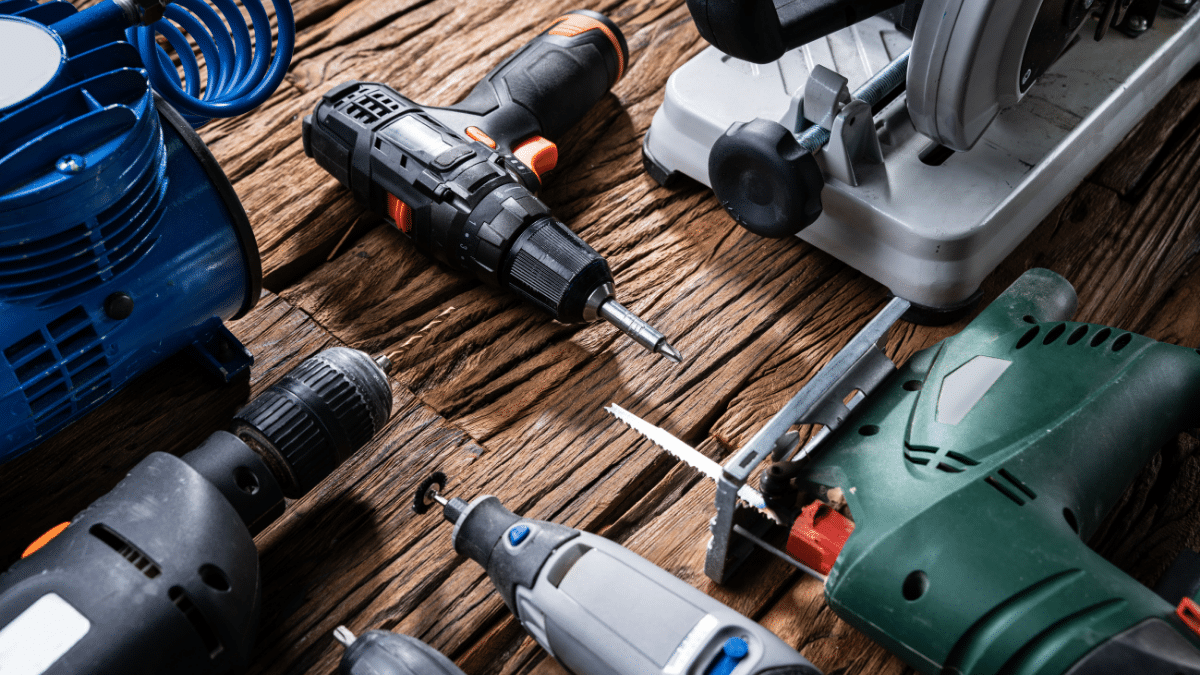

Whether big or small, corded or cordless, power tools need to be stored correctly to avoid injuries and keep tool maintenance and turnover costs low.

Knowing what the best practices for storing power tools are can be a real life and cost saver.

So, without further ado, here they are.

In this article...

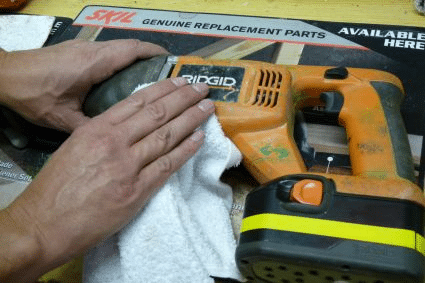

Conduct Pre-storage Maintenance

It makes a lot of sense to conduct maintenance on all tools before storing them, and power tools are no exception.

However, the amount of effort put in cleaning and maintaining tools before putting them in storage will depend on how long you intend to keep them there.

In other words, if you’re storing them on a construction site overnight in gang boxes, storage trailers, or tool sheds, you should worry more about them being stolen than about pre-storage maintenance procedures.

That being said, even in that case, there are some quick steps you can take to make sure the tools remain in mint condition.

On the other hand, if those power tools are supposed to sit unused for longer, it’s prudent to dedicate more attention to these preventative maintenance measures.

The process usually starts with removing accessories that could cause or suffer damage in storage. This includes batteries, which we’ll cover in the next section.

Before removing the accessories, it’s wise to make sure that switches, levers, or throttles are on “off” or “idle”, to avoid any mishaps or injuries.

The next step is cleaning them. That can be done by wiping them with a dry cloth or using an air compressor to clear off any dust.

As your team members clean it, they’re also checking the tool for damage and reporting any malfunctions, either to your supervisor, an equipment and tools manager, or directly to yourself.

This is usually enough for storing equipment on-site day-to-day.

Long-term storage includes some additional measures.

When tools are not going to be used for a while, it makes sense to lubricate their moving parts with machine oil.

As for power tools other than electric, preparations for long-term storage include putting antifreeze into water-using equipment like pressure washers, checking engine oil, and draining fuels.

In conclusion, we’ve seen that any storage of power tools requires some effort.

However, even a couple of minutes spent on preparations for storage can go a long way in improving safety and reducing costs. That’s particularly true for measures taken before putting equipment in long-term storage.

Consider Unique Requirements for Individual Tools

When storing power tools, one-size-fits-all solutions usually aren’t advisable.

Considering unique storage requirements for different power tools can go a long way in keeping them functional and protecting them during transport and storage.

As we all know, power tools come with instructions. Although they’re usually quickly forgotten and often ignored, manufacturers do provide requirements concerning the preferred storage temperature, moisture, and exposure to natural elements.

Manufacturers also provide cases for your tools: sturdy, usually plastic ones.

Why? Because cases the tools usually come in are designed with those requirements in mind, so it’s a good idea to use them for storage too.

When tools are missing their case, you can use plastic storage boxes or a large container for tools with long handles.

Let’s look closer at the most used power tools on construction sites—cordless drills.

This is the type of drill 84% of contractors use the most frequently, according to a survey.

As they are quickly replacing corded drills and other power tools, they deserve a bit more space (in your storage too).

Cordless tools come with batteries, and batteries require different storing practices than power tools. For example, drills are designed and tested to withstand falls. And they do.

However, batteries attached to them are much more delicate, and one fall at the wrong angle can end the battery’s life.

The useful life of batteries is most affected by heat, cold, vibration, moisture, and over-discharging.

Therefore, batteries should be stored inside, at room temperature, and kept away from sunlight, heat, water, and moisture.

The most important thing to remember is to store batteries at half charge. Why? Because their chemistry is most stable in a half-charged state. Incidentally, so is their performance.

Considering that batteries can be expensive, especially Lithium-ion (Li-ion) ones, you want to extend their life as much as possible. Charging them up to half and then leaving them until the next day is perfectly acceptable and won’t limit the battery’s life.

When storing batteries for transport or otherwise, battery terminals should always be well insulated and protected from coming in contact with materials that could cause a short circuit.

Naturally, it’s always a good idea to read the manufacturer’s instructions.

Thus, this example shows how different tools can have different requirements as to their storage. If possible, keep them in their original case and under conditions recommended by the manufacturer.

One final word of advice. Remind your coworkers: “When the battery feels hot, give it a rest.”

Create a Proper Storage Space

When it comes to storage space, the construction industry has created a whole other sub-industry around tool storage and organization. In this section, we’ll focus on storage space.

If you need one, there are probably as many options of where and how to store them, as there are the types of tools.

For instance, a small contractor might be keeping their tools in their basement or garage. A mid-sized construction firm is maybe renting one or more self-storage units.

And a big construction player probably has tools and equipment warehouses across the country. Or the world, for that matter.

Thus, all of them will have a different idea of an ideal power tool storage space.

But, it goes without saying that any proper storage space should be dry, protected, and under lock and key.

As for long-term storage, your primary objective should be to select a storage space that minimizes the negative effects that environmental conditions could have on tools.

In doing so, the use of devices like humidifiers, temperature regulators, and air-conditioning is highly recommended, especially when some specialty tools and batteries are concerned.

Again, keeping manuals or jotting down storage instructions for different tools means you’re thinking ahead.

As for the on-site storage of tools, their security takes precedence.

The annual losses due to stolen equipment range between $300 million and $1 billion, so safety precautions really should be taken seriously, even for tools stored in gang boxes, lockers, storage trailers or shipping containers.

If you want to learn more about preventing theft on construction sites, click here.

So, it makes sense to protect your power tools from bad weather and, even worse, thieves.

Also, keep in mind that, according to the Occupational Safety and Health Administration (OSHA), all powder-actuated tools like nail guns and fasteners must be kept in a lockable container and used only by authorized personnel.

Finally, having one designated on-site storage area where workers can check tools in and out improves the safety of the site, as it reduces tripping and falling hazards.

Keeping the site organized also streamlines the construction site workflow because workers don’t have to run around looking for tools.

All in all, proper storage space will provide for both optimal storage conditions and practical organization of tools.

Organize the Power Tool Storage

As we said, a whole industry was built just around tool organization.

Appropriate tool storage organization will not only make sure that power tools are stored safely and securely but also simplify workflows by providing easy and practical access to them, thus boosting overall productivity.

Let’s start with something that may be obvious but still needs to be said.

We’re talking about haphazardly throwing tools on the ground and leaving them lying around.

The first one could damage the tool, while the second can endanger both tools and workers.

Leaving power tools on the ground might be the single biggest mistake when it comes to power tool storage.

Why? Because the tools could, for instance, be crushed when something is accidentally dropped on them, or the storage space can be flooded.

The second reason is safety. Tools on the ground are tripping magnets.

And, considering that in 2020 one in three fatalities in the construction industry resulted from slips, trips and falls, you should do everything in your power to avoid them.

So, how to best organize your power tools, both on- and off-site?

That, of course, depends on the number and the kind of power tools you have.

Starting small, a special storage cabinet that protects your power tools from damage or use by unauthorized personnel (e.g., children) might be a great idea.

Some types of dedicated storage cabinets even have charging stations for those batteries we talked about.

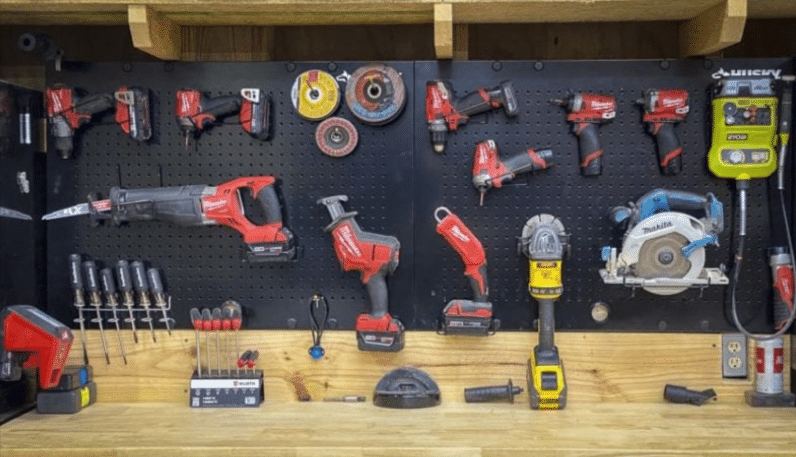

If a cabinet does not suit your needs, placing power tools on shelves or pegboards with hooks might just do the trick.

Such solutions allow you to “go vertical”, thus saving precious floor space. This also means that tools are within sight and reach.

If you’re using storage racks, storing power tools in see-through plastic containers may provide additional protection while keeping everything in sight.

We’ll close with “Keep the original packaging and use it”.

Why? Because it was designed to protect the tool from impact and damage in transport and otherwise, so it can be your best friend for long-term storage.

In conclusion, whatever you choose as fitting for your needs, keep in mind that organized storage leads to more efficient operations, which ultimately results in higher productivity.

As it also boosts safety, we can say that it saves both money and lives.

Make Use of Labels

When the power tool storage is clearly labeled, it’s much easier to efficiently organize your or your workers’ tasks on a construction site.

Depending on your needs, labeling solutions can range from a simple label maker used to mark where everything goes in your garage to asset and inventory tracking software solutions that track your tools wherever they go across multiple sites, states, and even continents.

As you know, power tools are small and can be easily displaced (or stolen) when they are moved from site to site, changing hands frequently.

Keeping track of power tools can be demanding, to say the least. But that job is made much easier with some smart planning.

Let’s look at an organization with an arsenal of tools spread across almost 100 facilities within an area of 2,000 square miles (5,000 km2).

We’re talking about the maintenance department of the Anchorage (Alaska) School District.

With a diverse array of tools and 125 staff members, the department uses a manual tracking system to manage power tools, i.e., a massive board with check-out and check-in dates.

However, they’re constantly running into problems.

According to Chris Borst, a maintenance supervisor for the district, one example is when a worker does not return the tool they checked out. When this is noticed, they have to notify that employee and so on.

“It’s a daunting task to keep track of everything. We’ve discussed using a computerized system, but we haven’t done that yet,” says Borst.

Now imagine if they did.

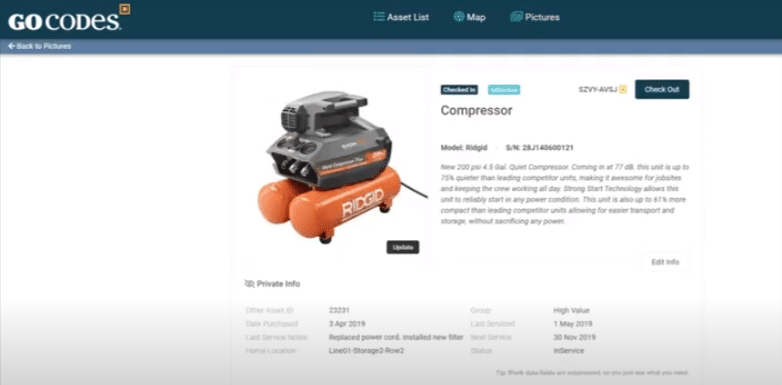

By labeling their power tools with barcodes or their more advanced cousins—QR codes—employees could scan the tool when checking it out, and the person designated for tool management could scan them back in upon their return.

This solution also makes checking tools out fast and easy, allows for tracking their location, and can be used and accessed from any computer, smartphone or tablet.

Such labels can also be used to mark storage space, so all tools are returned to where they belong, and another employee can then find them easily.

Tracking solutions like these are quite commonplace in today’s business.

For example, our own product, GoCodes Asset Tracking is an affordable tracking solution that features patented QR code labels and an integrated app which makes scanning possible with mobile devices.

So, making use of labels, whether they’re hand-written or come with patented QR codes, can significantly increase accountability, reduce theft and help plan for more effective maintenance.

Conclusion

Now that we’ve reviewed these best practices, it’s clear that there’s a lot to consider when storing your power tools.

It’s also clear that the scope and form of these practices will largely be informed by your needs, available storage space, and the number of tools you or your company have.

We hope this article will help lead you to the best possible storage solution for your tools.