So, you’re looking for some good reasons to invest in quality software to manage construction materials?

Whether you’re handling your company’s material inventory on stock or the materials used on multiple construction sites, software brings a ton of benefits.

Here are five of them.

In this article...

Improves the Material Procurement Process

Quality material management software can vastly improve the way your company procures materials for construction projects.

It can streamline the entire procurement process from estimating what and how much you need, to helping you decide what supplier to select.

Even though recent technological advancements offer plenty of opportunities to make procurement quicker and cheaper, construction companies still seem reluctant to utilize them.

Research by Bain & Company shows that less than 10% of construction businesses use high-tech procurement solutions. In addition, it shows that over 60% of companies use spreadsheets or nothing at all.

However, it’s now clear that software can optimize the entire construction material lifecycle or, depending on its scope, just one or more of its stages.

Such software can compare supplier bids based on the price and availability of their materials.

Basically, with the right solution, you’ll have all potential suppliers listed in one place, making it much easier to evaluate their bids, i.e., their eligibility in terms of matching your material requirements.

Secondly, the software you choose can handle and store documentation, which leads to more transparency and traceability across the materials lifecycle.

Naturally, before any procurement can take place, the first step is to determine what materials you’ll need, and in what quantities.

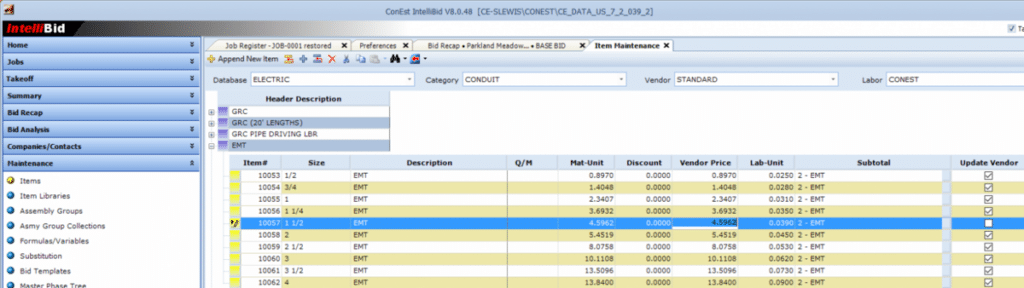

Although they come with different features and functionalities, most material management software solutions come equipped with the estimate function, giving you a starting point for procurement.

Another very useful feature offered by some software is a database regularly updated with prices of materials available from local suppliers. This makes estimating the costs of materials much easier, thus saving you a lot of time.

Finally, quality software will enable you to issue precise and well-documented purchase orders automatically.

So, if you found a fitting software solution that integrates the above features, just sit back and watch your procurement process become simpler, more effective and cost-efficient.

Enhances Inventory Management

As you’re probably aware, tracking the use and consumption of inventory (materials, in this case), as well as leftover waste, is cumbersome when done manually.

In contrast, when all this data is fed to a software solution, its built-in analytics provide an easy way to, among other things, check inventory levels and track your materials, ultimately reducing over-ordering and waste.

This will also lower the chances of your company running out of stock, thus risking delays and possibly even contract penalties.

But the benefits don’t stop there. As material management software can feature end-to-end tracking along the supply chain, the ultimate result of their use boils down to higher productivity and fortified profitability.

Both arise from more efficient handling of inventory that saves time (productivity) and money (profitability) across all stages of materials management.

Let’s give a real-life example.

Meet Ray St. Clair Roofing, a company from Ohio specializing in roofing repairs and replacement. As their business grew, their material stock inventory followed.

They soon found themselves with too many materials on stock, resulting in higher storage costs.

Aiming to correct this, they looked for software that could be seamlessly linked to their existing construction management system. In the end, they opted for a simple inventory tracking solution.

“[It allowed us to do] our material counts, enter purchases, and create purchase orders to better control the amount of inventory we kept on-hand,” says Tom Grabo, the controller of this family-owned business.

With this, the company managed to cut its inventory keeping costs and raise its productivity through improved time management.

GoCodes Asset Tracking is a great example of a simple and effective inventory management solution. Our patented QR code tags can be used for tracking all your material inventory and more.

So, it’s clear that software can enhance your company’s inventory management across the board.

Naturally, construction material management is usually a part of the wider solution that simplifies the management of all projects.

You can find out more about construction material tracking here.

Simplifies Project Management

Material management software can help simplify the otherwise very complex task of project management up to a point where projects being finished on time and within budget is no longer an issue.

It will allow for more accurate estimates, enhanced inventory management across multiple locations, and more economical procurement. It will also provide access to financial overviews and analytics, thus leading to efficient resource allocation.

Let’s start with why more and more construction companies are turning to software to simplify their processes and streamline their operations.

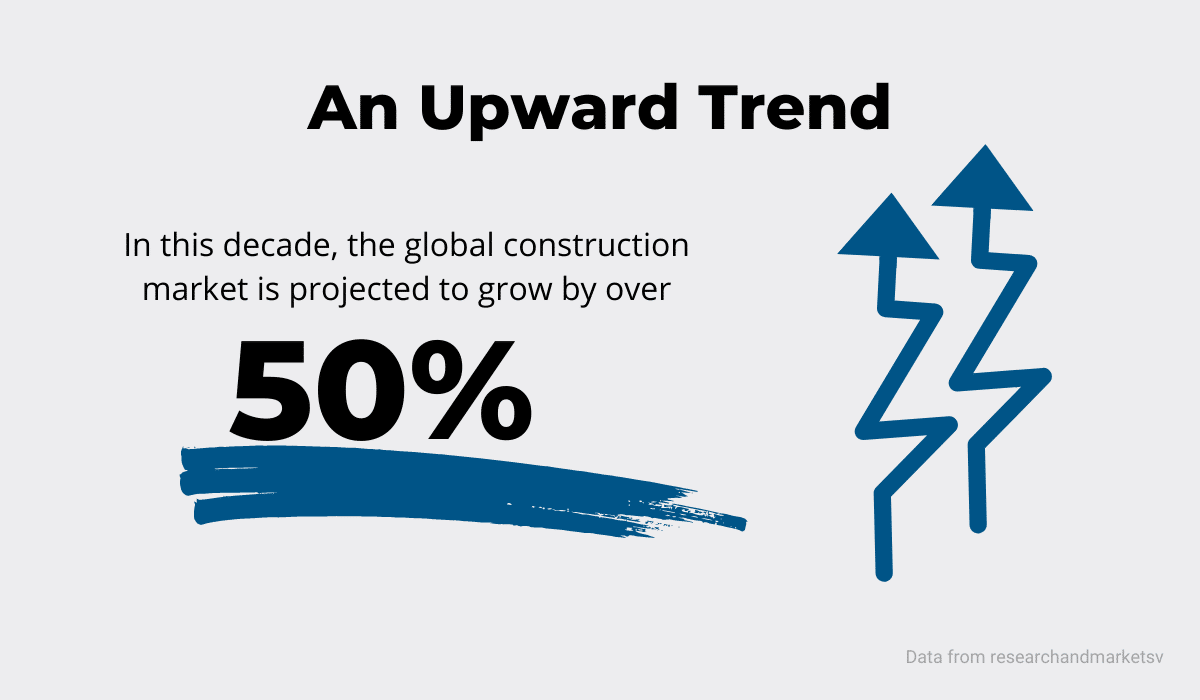

First, the global construction market is expected to expand at an average rate of 7.3% from 2022 to 2030, meaning it will grow over 50% in this decade.

Second, new technology trends are rapidly changing the construction industry, and material management is no exception.

Third, a survey showed that 79% of construction managers found that software significantly reduced project completion time.

Having said all that, we could consider you convinced and finish this section here.

But let’s give you a few more perks brought on by implementing material management software in your business.

Let’s focus on the competitive advantages it provides.

First up, many issues your construction firm encountered when dealing with materials will be alleviated, and even more of them will be entirely eliminated.

Here are some of the issues that can crop up along the material supply chain:

- miscalculated estimates

- over- or underestimated procurement

- incorrectly delivered quantities

- misdirected deliveries

- incorrect billing

- improper use

- poor waste management.

When you eliminate those, construction crews can stay on schedule and within budget more easily, thus improving your company’s reputation and growing the number of customers.

With your business booming as a result, you can now efficiently manage a larger number of projects by using software.

One more thing. As you now have access to a virtual paper trail on all material inventory in a centralized repository, you can more easily identify who is responsible for specific stages of material management.

This leads to higher accountability of your team and reduces, for example, duplicate handling of materials.

Now, keeping in mind these added benefits, are you convinced?

Promotes Efficient Communication

Material management software will promote efficient communication within your firm and with your clients, thus improving productivity internally and quality externally.

It might also pave the way for some easy cost reductions.

Since software is essentially a centralized information system, it improves the quality of the data and facilitates information exchange, enabling your company to make better-informed decisions and save money.

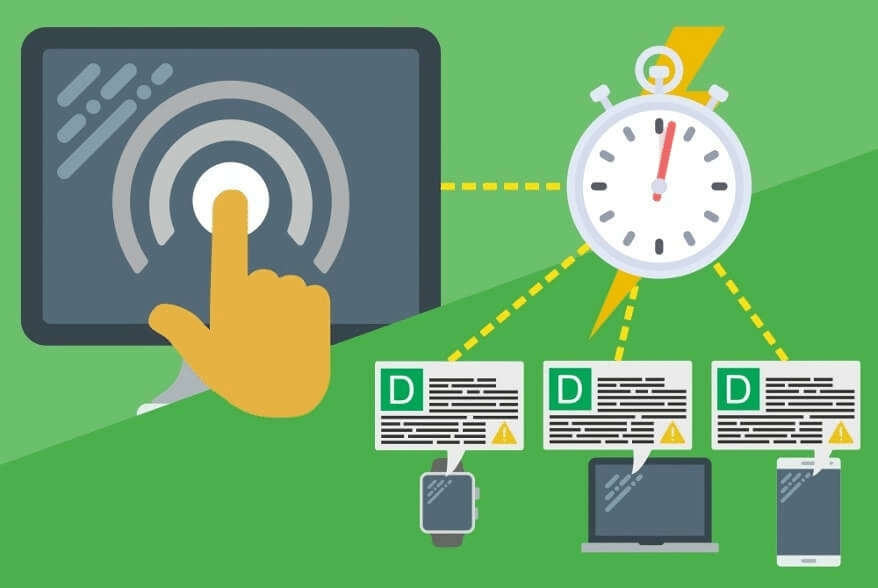

Also, with all stakeholders getting timely information on material orders, their allocation and inventory levels, any required approvals go much faster.

Moreover, as most software is cloud-based nowadays, meaning it’s available online from any location, this enables different project stakeholders to communicate in real time.

As many programs come equipped without automatic notifications and alerts, this further streamlines communications between different construction project stakeholders.

Remember the problems that faded away in the previous section? Well, several of them were caused by miscommunication or lack of communication.

Since material management software enables your firm to standardize workflows and track all documents related to construction materials, this results in more effective communication between all involved parties—the client, the crew, and the on-site supervision manager.

For you, this means avoiding many misunderstandings and resulting delays during the project.

It also means that the effects of good communication with clients will continue long after the job is finished.

As for your clients, their benefits start even before they retain your services.

In the initial stages of the project, when they’re just potential clients, you’ll be able to provide more precise cost estimates, and they’ll probably be lower than before.

Finally, once streamlining the materials management provides for the better quality of the provided service and enables your construction crew to finish the project on time, your clients will be glad to spread the word.

To wrap up, material management software will significantly improve communications in general. It will also facilitate a more coordinated approach to both projects and clients.

This, in turn…

Helps Reduce Risks

Material management software can allow you to conduct audits and streamline quality assurance processes related to construction materials across your organization, which can minimize many risks associated with their lifecycle.

The ability to analyze and research material workflows across multiple construction sites gives you the power to better evaluate your material needs and hedge your business against various risks inherent to construction projects around the world.

When you consider that, according to the Construction Industry Institute, a single construction project faces around 107 risks in total, the necessity of conducting comprehensive risk assessments becomes evident.

Just to be clear, nobody can address all those risks as there are many we can’t control.

Instead, we’ll look at just one (actually two). And we’ll do that from the perspective of managing materials and what software can do about it.

We’re talking about once potential, and now real, risks related to supply chain breakdowns or, in other words, the availability of construction materials.

As many in the construction industry have experienced, a shortage of just one material can end up causing major delays in all construction projects if that material is vitally important.

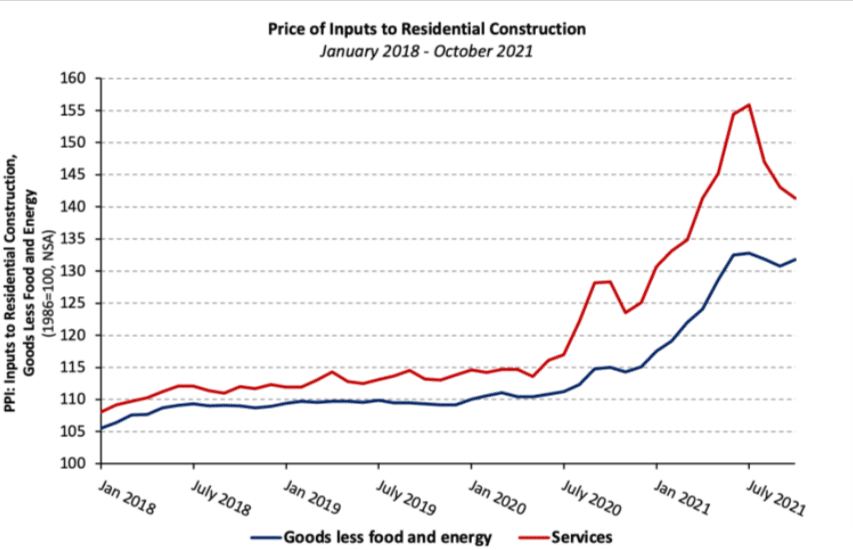

Moreover, since problems often come in pairs, supply chain issues are usually closely followed by price increases.

Should we even mention that the prices of building materials in the U.S. went up almost 20% in 2021 compared to 2020?

Material management software allows you to organize, update, and analyze material flows, thus giving you all pertinent information to make well-informed decisions in real-time.

It also provides far better insight into your future needs, resulting in better planning of all key functions critical for materials management.

Ultimately, it gives you the tools to devise a resilient and optimized material management strategy that helps reduce associated construction risks, thus making your organization more agile and less fragile, which is becoming more important than ever in the times we live in.

Supports Data-Driven Decision Making

This is probably the most important benefit of any kind of modern software, and it definitely applies to material management software.

Let’s start with the basics and talk about manual data entry vs. automatic data capture.

It’s human to make mistakes—and typos when entering data by hand!

Also, when people don’t have the right information or expertise, they often make bad calls.

However, when the data is captured by software, errors and missing numbers go away.

Additionally, data has no bias in decision-making, regardless of whether you’re purchasing materials for a small construction job or a multi-million project.

That said, do you know what are the top reasons construction companies consider when deciding to utilize technology in general and software in particular?

Ease of use and the price, according to the Dodge Report.

Our own software solution for quality asset tracking, GoCodes Asset Tracking, ticks both of those boxes, since it’s simple and easy to learn, while offering great value for money.

With it, you can also create customizable reports aided by various sorting options. This supports data-based decision making.

Data-driven construction means that a company is aware of how having a single data source of truth is essential for improved decision-making.

That’s why it strives to capture, manage, share, and leverage the key data. It also looks for ways to present it in an easy-to-use, simple and understandable way.

In terms of materials management, software makes Master Data Management (MDM) possible, even on a smaller scale.

Naturally, it all starts with having the right solution. Preferably one that captures data accurately, can be updated in the cloud, and provides advanced analytics, thus allowing you to make data-driven decisions.

Conclusion

We’ve reached the end, so let’s just point out why, now more than ever, it’s essential to use software for construction material management.

Having covered six areas where such software offers major improvements, we’re sure the right solution can provide you with the tools to skyrocket your business into the future.

As a final word, here’s a quote by Elon Musk:

“Great companies are built on great products.“

In light of his track record, we’re sure he wouldn’t mind if we added:

“…and software.”