Key Takeaways:

- QR codes and smartphones help digitize, organize, and automate your asset management workflows.

- A QR code-based tracking system can help save between 5 and 15 workdays per worker per year by reducing the time spent searching for assets.

- One company cut annual equipment loss from $30,000 to $1,500 by implementing QR codes and a smartphone-based tracking app.

For many construction businesses, keeping track of fixed assets like tools, equipment, and machinery across job sites can feel like chasing shadows.

Tools go missing, time gets wasted, and efficiency takes a hit.

But it doesn’t have to be that way.

With QR codes and smartphones, construction teams can bring order to asset chaos without big budgets or complex systems.

Here’s a quick guide to how it works, what you need, and how it’s applied in practice.

In this article...

Why Fixed Asset Management Matters in Construction

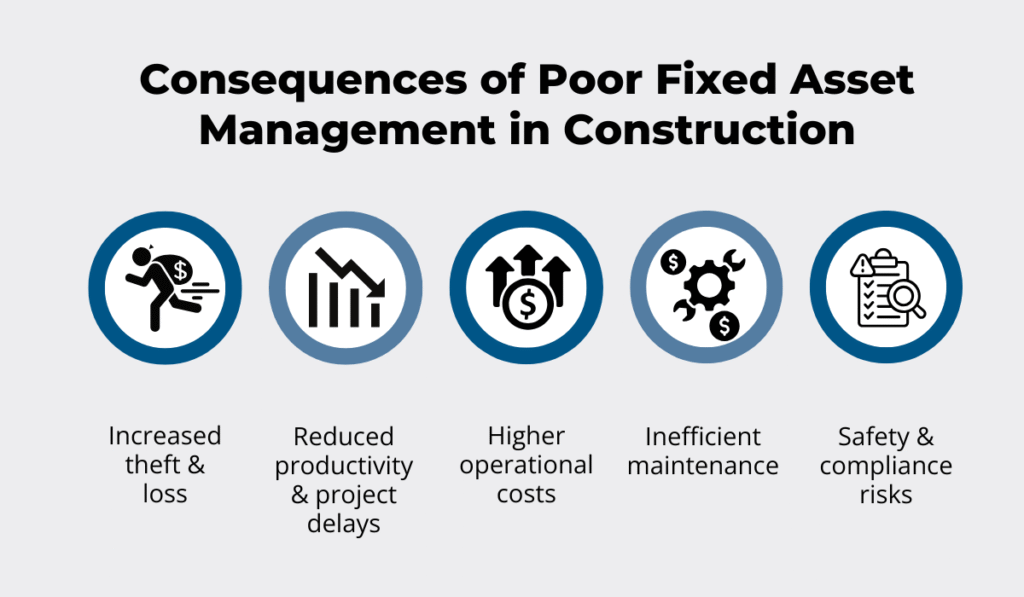

Before we dive into the practical side of things, it’s worth briefly reminding ourselves why fixed asset management matters, especially in construction.

With high-value tools, equipment, and machinery constantly moving between job sites, it’s easy for items to go missing, be stolen, or fall behind on maintenance.

Without a clear, organized system, construction companies are more exposed to a range of risks.

And many of those risks directly affect timelines, safety, and the bottom line.

Here are some of the most common problems associated with poor asset management:

Source: GoCodes Asset Tracking

Of course, that’s not all.

Disorganized asset tracking also leads to poor allocation, misjudged asset values, inaccurate financial reporting, and insurance claim issues, each posing serious challenges for contractors.

Take theft as just one example: in 2024, nearly 80% of UK tradespeople reported being victims of theft, with tools stolen on average every 21 minutes.

It’s a clear reminder that construction assets—regardless of size or type—are highly attractive to thieves.

With that being said, let’s look at how QR codes and smartphones can help.

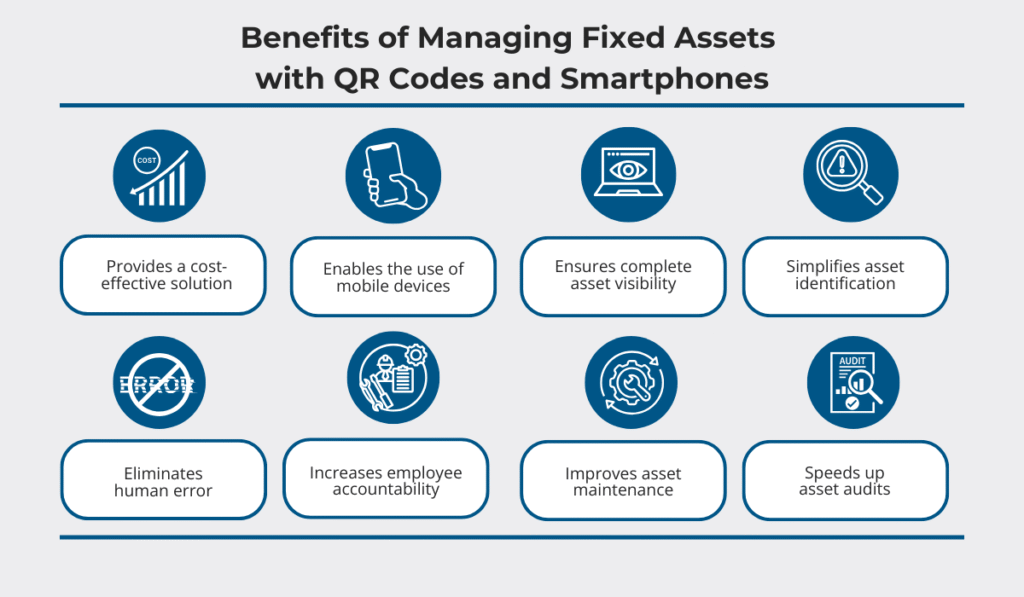

Here are eight key benefits a QR code-based, smartphone-enabled asset management system offers:

Source: GoCodes Asset Tracking

Cost-effectiveness, ease of use, and minimal training are just a few of the reasons QR codes paired with smartphones stand out.

While other asset tracking methods—like RFID, Bluetooth, or GPS trackers—can offer extra benefits, they also come with higher costs.

In fact, QR codes are so affordable that they’re frequently used as an additional means of asset identification, often on the very tracking devices we just mentioned.

In short, no other system delivers the same return on investment as using QR codes as asset tags, combined with smartphones and a cloud app for scanning and tracking.

Let’s take a closer look at how it all works.

How QR Code Tracking with Smartphones Works

All you need to digitize, organize, and track construction assets are QR codes and smartphones.

Let’s begin with the unique identifiers you’ll use to label assets of all types and sizes: Quick Response (QR) codes.

You’ve surely seen them—and probably used them—plenty of times.

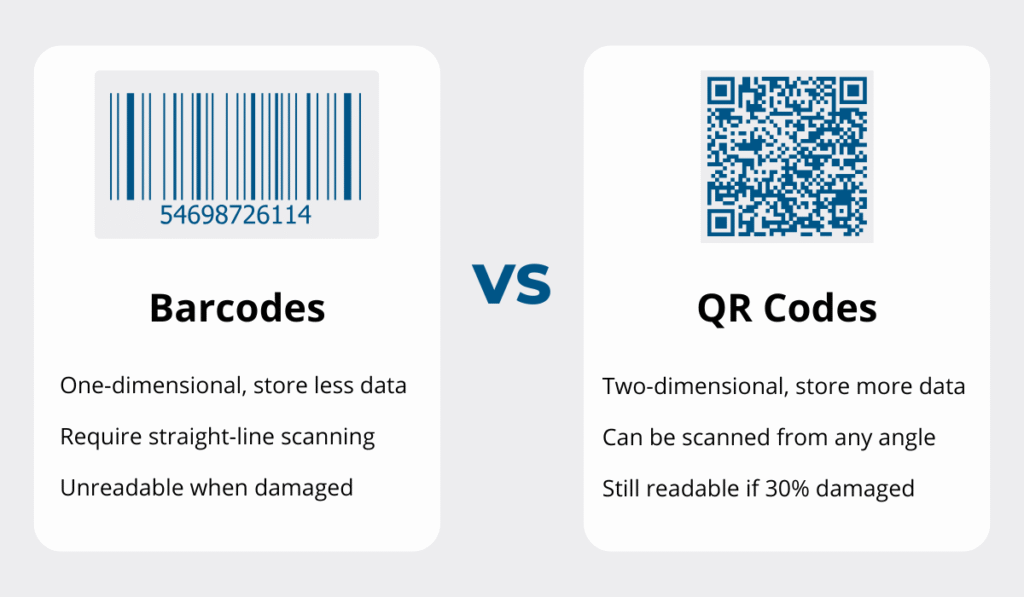

Essentially, QR codes are a more advanced version of barcodes, but with several key advantages that make them ideal for construction asset tracking.

Here’s how they compare:

Source: GoCodes Asset Tracking

Additionally, unlike QR codes, barcode-based tracking systems often require dedicated handheld scanners, which adds to upfront costs.

The above QR code advantages are coupled with several useful traits shared with barcodes, such as:

- Easily generated and customized

- Printable on wear-resistant labels

- Typically assigned unique asset IDs

Once printed, these QR code labels are attached to assets, becoming scannable gateways to essential asset data.

Now, let’s turn to the other core part of the system: smartphones.

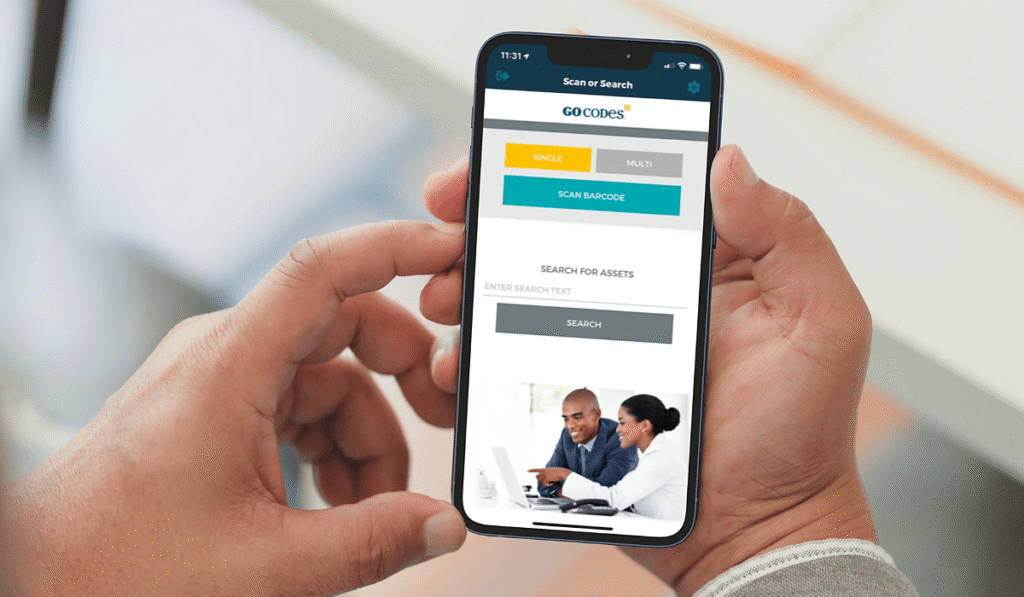

Source: GoCodes Asset Tracking

There’s certainly a lot to like about smartphones when they’re used as the main tool for asset tracking.

First, almost everyone has a smartphone and already knows how to use it, including how to scan QR codes and access the data linked to them.

Second, smartphones come with built-in cameras that function as scanners.

This eliminates the need for separate hardware often required for barcodes.

Finally, they can easily run cloud-based asset tracking apps, making them ideal for use in the field.

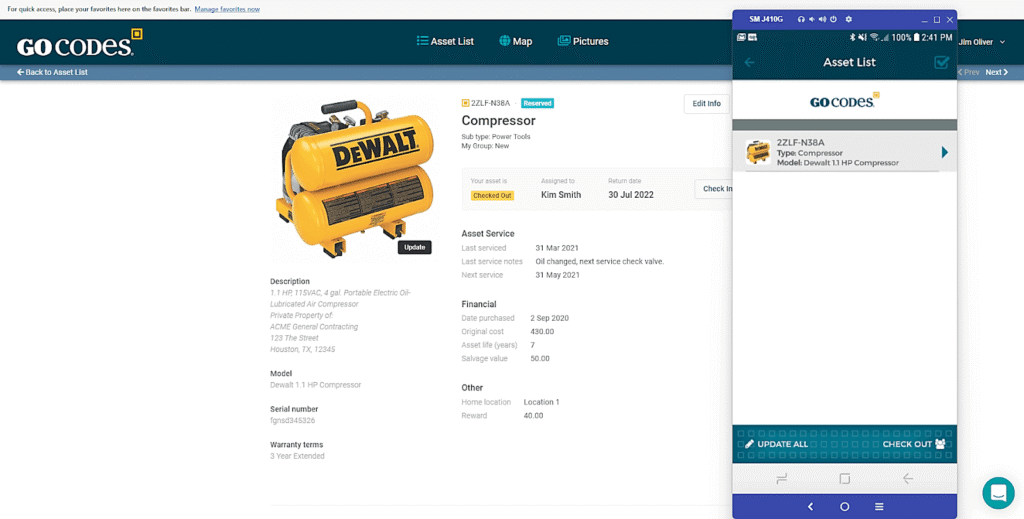

Once the system is set up, users simply scan a QR code label or tag with their phones to instantly access that asset’s summary view.

Source: GoCodes Asset Tracking

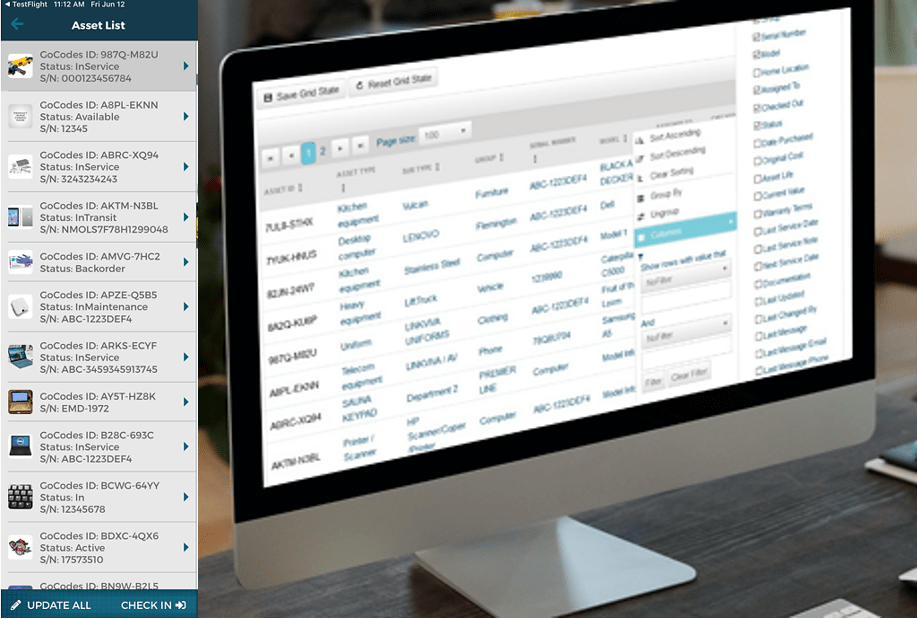

Of course, office-based staff can access the tracking software from desktops or laptops, while field users rely on the mobile app to manage assets on the go.

Once QR codes are digitally linked to the tracking app’s cloud database, your system is live and ready.

From there, both managers and workers, based on their user permissions, can perform key tasks like:

- Viewing and updating asset data

- Checking assets in and out

- Tracking asset condition and location

- Scheduling upcoming maintenance

- Managing inventory levels

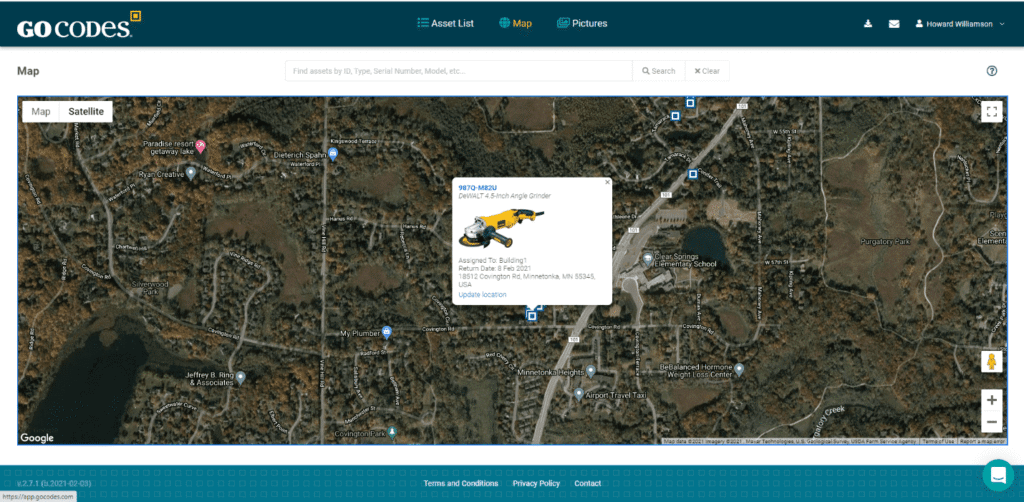

As for asset location tracking, most apps allow users to enter location updates manually.

But GoCodes Asset Tracking, our all-in-one asset tracking solution, goes a step further.

When a user scans an asset’s QR code, the GoCodes Asset Tracking app automatically captures GPS coordinates using the scanning smartphone’s (or tablet’s) built-in GPS.

This location is saved in the cloud and instantly visible on a map, showing where the asset was last scanned.

Source: GoCodes Asset Tracking

Since workers regularly scan assets for various tasks, this scan-based GPS tracking can provide near real-time visibility into asset locations.

That makes GPS-enabled QR codes an ideal solution for tracking everything: from small tools and consumables to heavy equipment.

Of course, your QR code-based system can and should be enhanced with other methods, such as real-time GPS trackers or Bluetooth beacons, especially for high-value, mobile assets.

Even so, QR codes paired with the right smartphone app create a low-cost, easy-to-use system for streamlining fixed asset management.

Let’s walk through how to set it all up.

What You Need to Set Up Your QR Code System

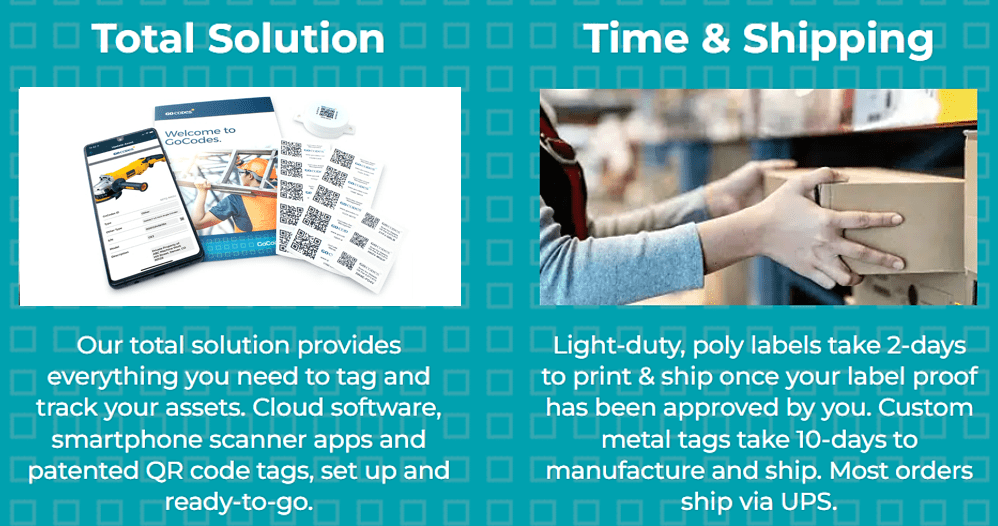

As discussed, setting up a QR code-based tracking system requires two main components: asset labels and a smartphone tracking app.

In theory, you could generate and print your own QR code tags and then pair them with tracking software of your choice.

However, apart from potential software integration issues, such DIY tags may not withstand the harsh conditions of construction sites or outdoor storage.

That’s why it’s best to start by selecting a provider that offers both a robust tracking app and customizable QR code labels, made from wear-resistant or tamper-proof materials.

Source: GoCodes Asset Tracking

Choosing a single provider—ideally one that also offers complementary tracking devices like GPS and Bluetooth trackers—comes with several key advantages:

- Ensures seamless integration and compatibility across all tracking components

- Allows you to choose the right label or tag material, size, and format

- Simplifies the setup process with centralized customer support

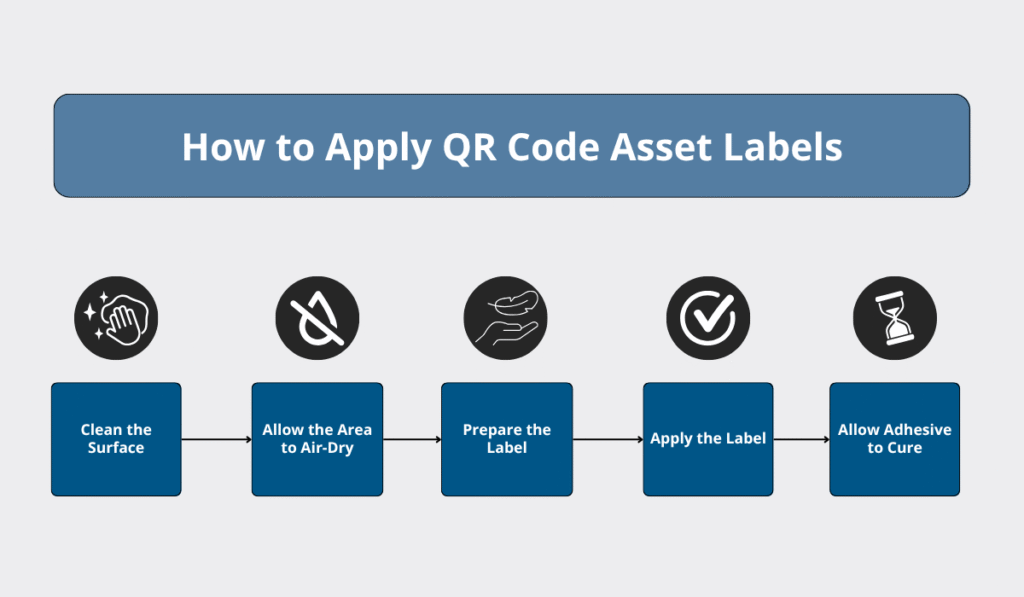

Now, let’s assume your QR code asset tags have just arrived.

The next step is to attach them correctly, ideally in a location that’s easy to scan but protected from direct wear or damage.

Here’s the general process for applying adhesive-based QR code labels:

Source: GoCodes Asset Tracking

As you attach QR codes to assets, it’s best to scan them immediately and create a dedicated info page using your smartphone app.

Depending on your process, asset details can be entered manually or imported later.

This step can take time, especially because you want to ensure all data is accurate and up to date.

In other words, you may need to:

- Locate or remove missing assets from your old inventory list

- Verify details like purchase date, current value, and depreciation

- Attach key documents such as receipts or manuals

Essentially, you’re auditing your entire inventory, but the result is worth it.

You’ll end up with a fully digitized, centralized asset list that’s accessible from any device and updated in real time for all users.

Source: GoCodes Asset Tracking

Assuming all users have downloaded the tracking app to their smartphones, your system is ready to go live.

Workers and managers can now use the app to check the status, availability, and location of any tagged asset.

When a QR tag is scanned, it takes the user to that asset’s page, displaying the initial details and its first-scanned location.

From there, the database grows through a combination of automated updates, such as user and GPS location, and manual but digitized and field-friendly updates.

This scan-based, cloud-powered system unlocks the full set of features we’ve discussed, from location tracking and check-in/out functions to task management, analytics, reporting, and more.

Given the many applications enabled by a smartphone-based QR code tracking system, let’s look at a few real-world use cases next.

Real-World Use Cases on Construction Sites

The QR code-based smartphone app system we’ve described—and the features it enables—have many practical applications for asset management on construction sites.

To start, both managers and workers can access the app by logging in or simply scanning a QR code on any asset.

Source: GoCodes Asset Tracking

If they’re searching for a specific asset, they can filter the list by type or name.

The results will show how many matching assets are listed, along with their maintenance status, last-scanned location, and availability.

As you can imagine, this helps managers plan and allocate resources more efficiently, while saving workers time spent locating tools and equipment.

In fact, studies suggest that workers spend between 10 and 30 minutes a day looking for what they need, equivalent to 5 to 15 lost workdays per year, per person.

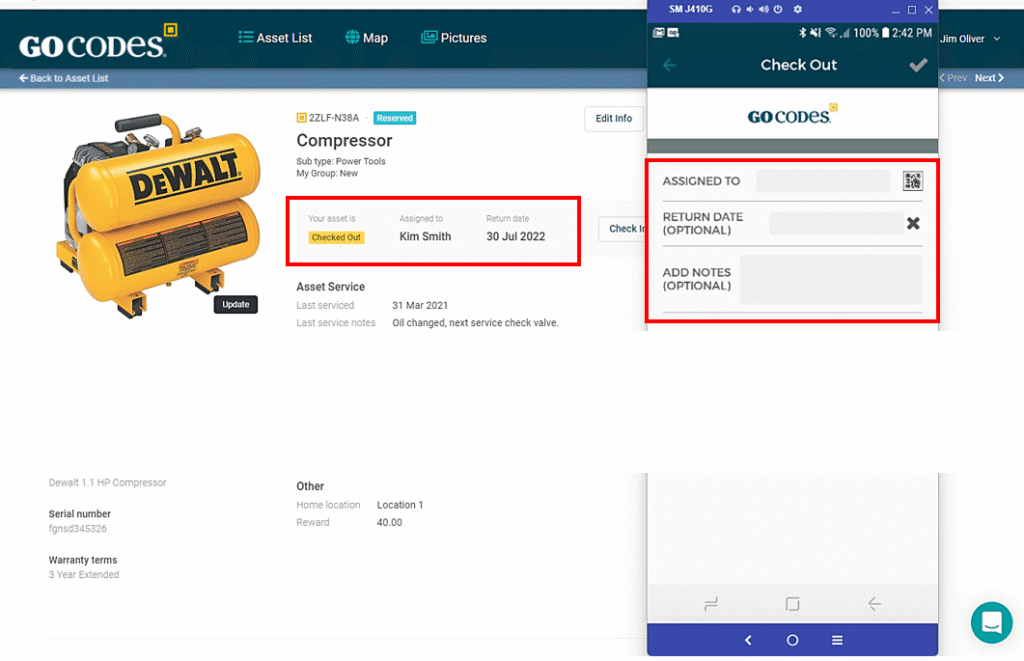

Another key use case is the automated asset check-in/check-out function.

Source: GoCodes Asset Tracking

Workers are instructed to scan a tool or piece of equipment when taking it, either on their own or under supervision, and scan it again when returning it.

As illustrated above, the tracking app automatically records these actions.

Managers can also add notes and, for longer check-outs, set expected return dates.

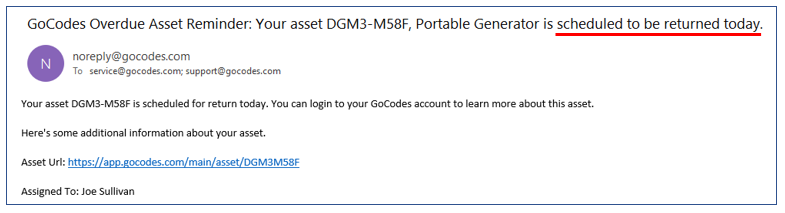

To help ensure assets are returned on time, they can enable time-triggered reminders, which are shown in the app and sent via email.

Source: GoCodes Asset Tracking

Requiring workers to check tools and equipment in and out—and knowing these actions are recorded in a central system—has several benefits, namely:

- Reduces internal theft

- Boosts worker accountability

- Promotes better handling of tools

It also makes it easier to track down forgotten or misplaced assets using their last scanned location.

For example, J&M Keystone, a company specializing in flood and damage restoration, used to lose about $30,000 a year, mostly from equipment left behind at job sites.

To solve the problem, they tagged their equipment with GPS-enabled QR codes and equipped their workers with a smartphone-based tracking app.

Lee Sherman, a manager at J&M Keystone at the time, described the impact:

Source: GoCodes Asset Tracking

Of course, asset tags can also help in cases where equipment is not just misplaced but stolen.

Tags can be made tamper-resistant, i.e., difficult to remove, which makes resale harder and deters theft in the first place.

If left intact, they can also serve as proof of ownership when stolen assets are recovered.

Overall, the wide range of real-world applications shows just how versatile, simple, and cost-effective a QR code-based, smartphone-enabled tracking system is.

Conclusion

Hopefully, we managed to show why QR codes and smartphones are a practical, affordable way to gain near real-time visibility over your fixed assets.

With features like easy access, check-in/check-out tracking, automated location updates, maintenance scheduling, and more, it’s a solution that fits seamlessly into everyday construction workflows.

From heavy machinery to small consumables, this smart system can simplify and improve how you track and manage assets across your job sites.

So, find a provider that fits your tracking needs, and start setting up your QR code system today.