Key Takeaways:

- Metal QR codes are highly resistant to wear, heat, and chemicals.

- With a tracking app, each QR code scan updates the asset’s GPS location.

- This system reduces downtime, enhances inventory control, and improves aircraft maintenance processes.

Efficient aviation asset management is critical to keeping operations smooth, safe, and cost-effective.

Yet, traditional asset-tracking methods often fall short in the face of harsh conditions and high operational demands.

Enter metal QR codes and tracking apps.

They are a game-changing combination that brings durability, precision, and real-time insights to aerospace asset management.

In this article, we’ll explore why aviation equipment and tools need specialized tracking solutions and how metal QR codes and apps perfectly meet those needs.

In this article...

Why Aviation Assets Require Specialized Tracking Solutions

If you’re an equipment manager in the aviation industry, you know that tracking the tools and equipment required for aircraft maintenance is no small task.

From high-value machinery to essential hand tools, every asset plays a critical role in maintaining aircraft safety, compliance, and operational efficiency.

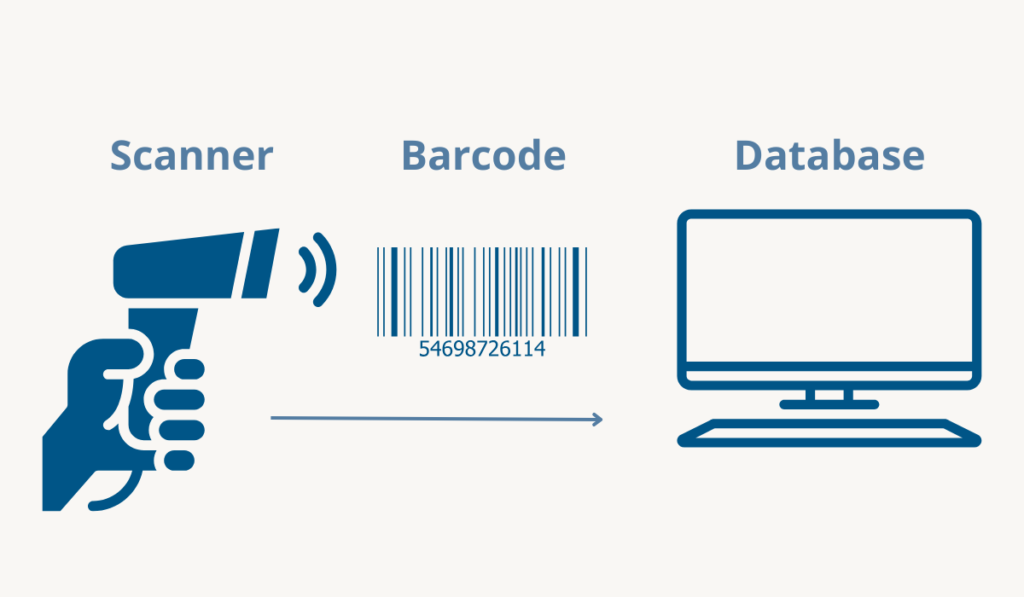

Traditionally, the usage and condition of these assets were tracked manually using paper logs or spreadsheets.

Later, databases paired with barcode tags and handheld scanners became the standard.

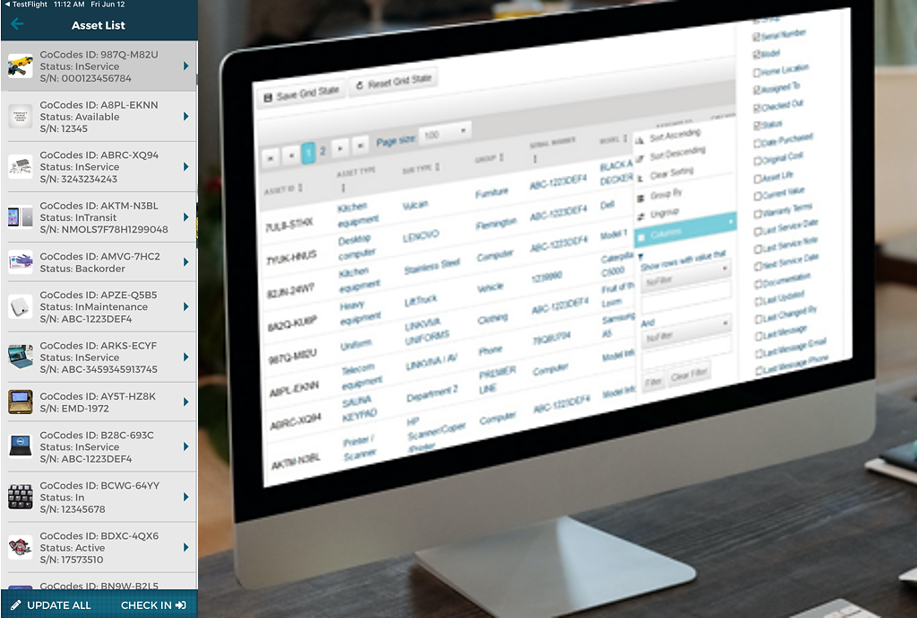

Source: GoCodes Asset Tracking

Although these systems are an improvement over manual methods, they face several challenges when applied to aviation assets.

First, there’s the issue of harsh environments.

Aircraft maintenance tools and equipment are often exposed to extreme conditions, including heat, pressure, and frequent wear and tear.

Traditional labels, paper tags, or standard barcodes can be easily damaged or quickly degrade under these conditions, making them difficult or impossible to read.

The example below illustrates this.

Source: Reddit

But this issue leads to another significant challenge: regulatory compliance.

Aviation is a highly regulated industry with strict requirements for audits, maintenance logs, and traceability.

Therefore, missing or inaccurate asset and maintenance data can result in fines, operational delays, or even compromised safety standards.

Additionally, the high stakes of downtime and errors in aviation amplify these issues.

A misplaced tool or improperly tracked equipment can disrupt operations, causing delays, cancellations, or even grounded flights.

All these outcomes carry significant financial and operational consequences.

Given these challenges, it’s clear that equipment managers in aviation need a specialized tracking solution.

So, let’s explore why metal QR codes and tracking apps are the optimal choice for effective and cost-efficient aviation asset management.

Metal QR Codes and Tracking Apps: A Perfect Pair

With various tracking options available, such as RFID and Bluetooth tags, it’s essential to find a solution that balances durability, precision, and cost-efficiency.

In this section, we’ll dive into the unique advantages of metal QR codes and tracking apps, as well as explore why they’re a perfect pair for aviation asset management.

Metal QR Codes

When used as aerospace equipment tags, metal QR codes offer several advantages over other tracking methods, especially traditional barcodes.

Compared to barcodes, QR codes can:

- store more information,

- be scanned from any angle, and

- remain readable even when partially damaged.

These benefits are further amplified when QR codes are printed on durable metal tags rather than on paper or polyester labels.

Here’s an example of one such metal tag:

Source: GoCodes Asset Tracking

These tags can then be affixed to an asset’s surface using a permanent, industry-grade adhesive.

Alternatively, they can come with pre-drilled holes for mechanical fastening, or a combination of both adhesive and holes can be used for added security.

All this makes metal QR code tags highly resistant to wear and fading, ensuring durability even in extreme conditions.

Moreover, these tags can be printed in various sizes, from very small to large, without compromising scanning quality.

This means QR code tags can be attached to even the smallest hand tools, let alone larger equipment.

Ultimately, this ensures that all your critical aviation assets are tracked effectively.

While metal QR codes offer unmatched durability and flexibility, their true potential is realized when combined with modern tracking apps.

Tracking Apps

QR codes or other types of asset-tracking tags would be useless without software to read and store the data received from these trackers.

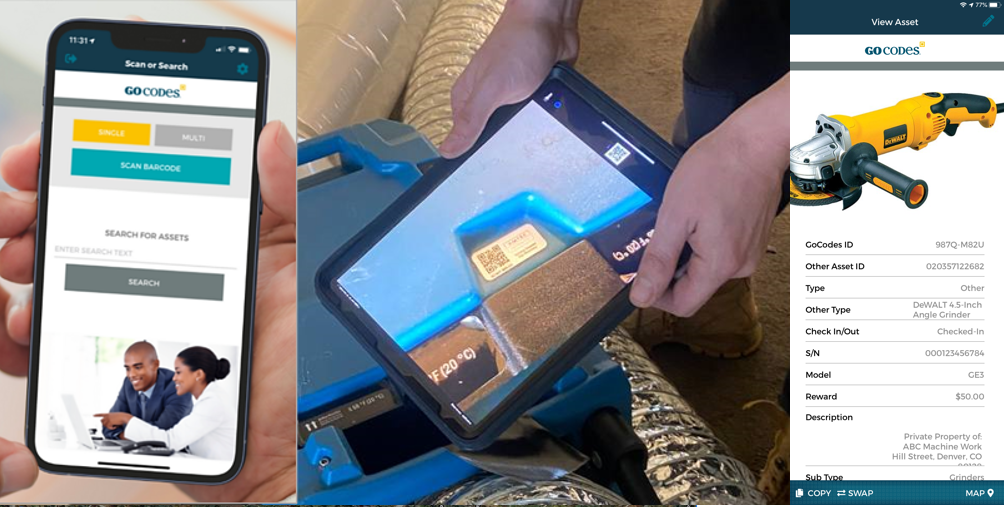

Today, most asset tracking software apps are cloud-based and accessible from any device with an internet connection.

This means they can be installed on devices your company and employees already own, including smartphones, tablets, laptops, and desktops.

Source: GoCodes Asset Tracking

One of the key advantages of modern tracking apps is that they eliminate the need to purchase on-premises software, separate scanners, or specialized label printers.

Instead, the only “hardware” you need are, in this case, durable and affordable metal QR code tags for your aviation tools and equipment.

The remaining components—a cloud-based tracking app and an in-app scanner—can simply be downloaded and installed on your existing devices.

The in-app scanner operates on mobile devices like smartphones and tablets, allowing users to scan QR codes for instant access to detailed asset information.

You can see this simple and quick process illustrated here.

Source: GoCodes Asset Tracking

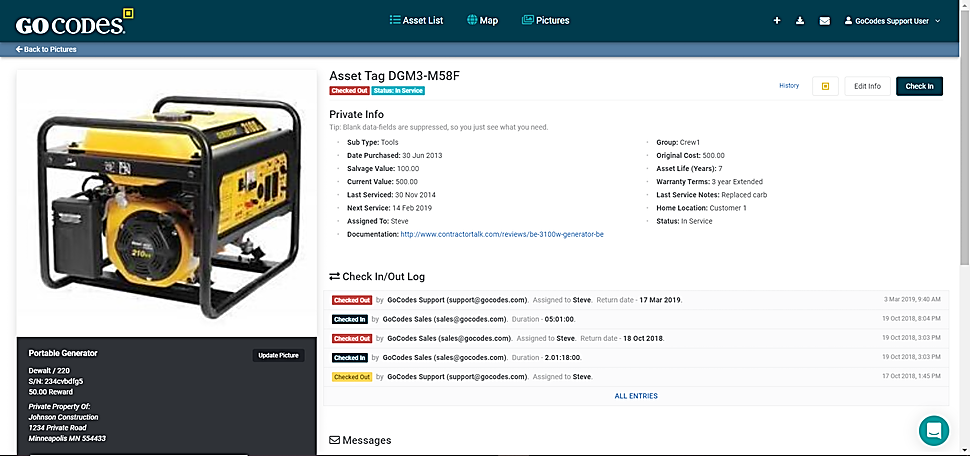

For laptops and desktops—which typically lack scanning capabilities—the app provides full access to all other features, including the central database of assets.

This allows both aviation equipment managers and maintenance staff to easily access, review, and update asset records.

Source: GoCodes Asset Tracking

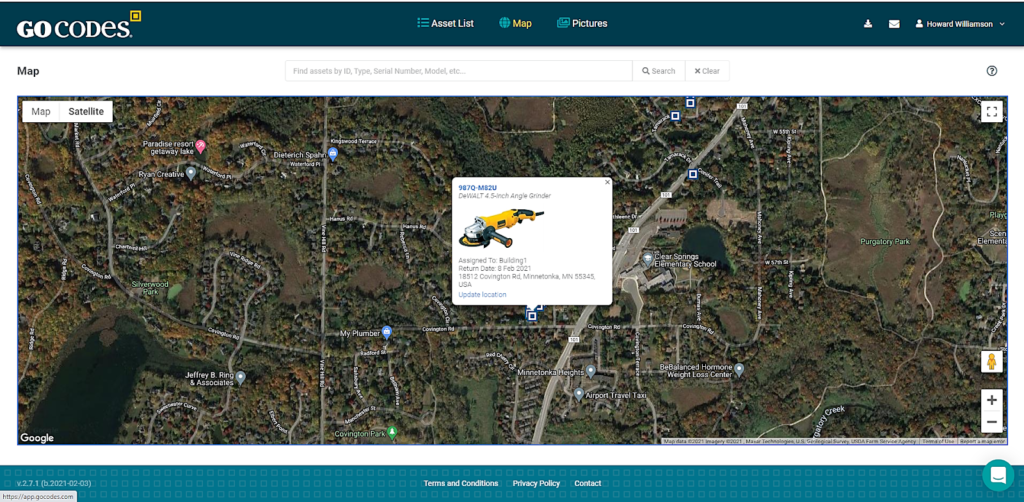

Some tracking apps also provide near real-time visibility into the GPS location of aviation equipment and tools.

Although QR codes do not function as real-time GPS trackers, this can be achieved using the GPS feature of the scanning device, such as a smartphone or tablet.

Each time a QR code on an asset is scanned, the system automatically records and updates that asset’s GPS location, displaying it on a map.

Source: GoCodes Asset Tracking

So, when users access the app to locate a specific tool or piece of equipment, they can see the location where it was last scanned.

Since this automatic location-capturing process also logs who scanned the asset, this promotes employee accountability and encourages responsible use of aviation equipment and tools.

Many modern tracking apps also offer seamless integration with aircraft maintenance schedules and compliance requirements.

They enable timely updates to maintenance logs, simplify record-keeping for audits, and help ensure adherence to regulatory standards.

Combined with metal QR codes, they create an easy-to-use, cost-effective tracking system that tackles the unique challenges of aviation asset management.

Let’s now explore the key benefits this powerful pairing brings to the table.

Benefits of Combining Metal QR Codes with a Tracking App

For equipment managers and service technicians in aviation, the combination of metal QR codes and a tracking app provides multiple benefits.

Some, such as mobile accessibility and real-time asset visibility, have already been mentioned.

Another advantage is improved accuracy and reliability in tracking aviation tools and equipment.

As covered earlier, metal QR codes offer a durable, scannable solution resistant to wear, heat, and chemicals.

When paired with the tracking app, these tags enable real-time, on-site updates to asset data, significantly reducing errors common in manual tracking methods.

Source: GoCodes Asset Tracking

This ensures that events like breakdowns, inspections, and regular maintenance of aerospace equipment and tools are timely recorded, and that info is instantly available to other users.

As a result, technicians can quickly and reliably locate the tools and equipment needed for efficient aircraft maintenance, minimizing delays and downtime.

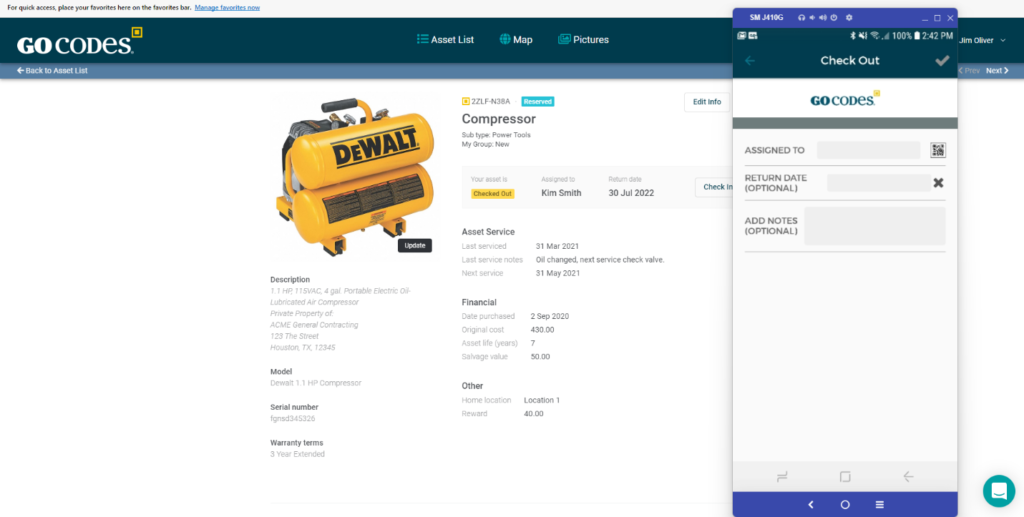

Another advantage is that technicians, either independently or under supervision, can use the app to check tools and equipment out and back in.

Source: GoCodes Asset Tracking

For equipment managers, this feature provides real-time visibility into who is using specific tools and equipment and when they are expected to be returned.

This level of transparency not only boosts worker accountability, though.

It also strengthens compliance and traceability of aircraft servicing activities.

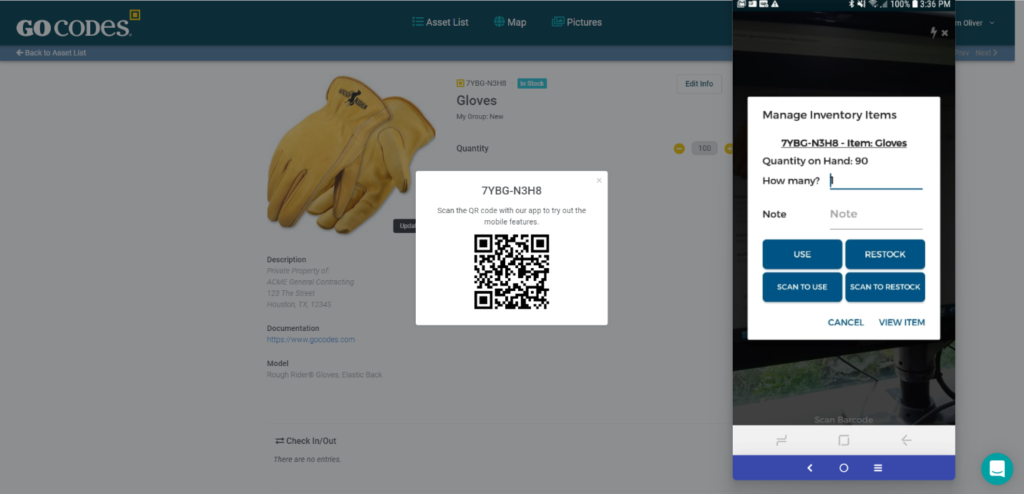

The next upside is that QR codes—whether made of metal or other suitable materials—can also be attached to containers holding spare parts.

This allows the tracking app to serve as an inventory management tool, enabling users to monitor the quantity of items in each container.

Source: GoCodes Asset Tracking

When inventory tracking is enabled, the app can be configured to send automatic low-inventory alerts whenever stock levels fall below a predefined threshold.

This ensures aircraft technicians have everything they need—from protective equipment to spare parts—to perform their work without delays.

Ultimately, all these benefits translate into cost savings, primarily achieved through minimized downtime and the efficient utilization of aviation assets.

If everything you’ve read so far has sparked your interest in implementing metal QR codes and a tracking app for your aviation assets, the next section will show you how to get started.

Getting Started With QR Codes for Aviation Asset Tracking

To demonstrate how to set up a system with metal QR codes and a tracking app, we’ll use our solution, GoCodes Asset Tracking, as an example.

The process begins with subscribing to one of our service plans that includes custom asset tags.

After subscribing, you’ll receive an onboarding email titled “Urgent Action Required.”

This email contains simple instructions and a link to an online form where you can select your QR code label design, type, size, and quantity of asset tags required.

Once you’ve completed the form, you’ll receive a request to confirm the final design of your labels.

For custom metal labels, production takes up to 10 business days after approval.

Source: GoCodes Asset Tracking

Once the QR code tags arrive, attach them to the respective assets using the chosen method—adhesive, bolting holes, or both.

Be sure to position the tags in visible and easily accessible locations for scanning.

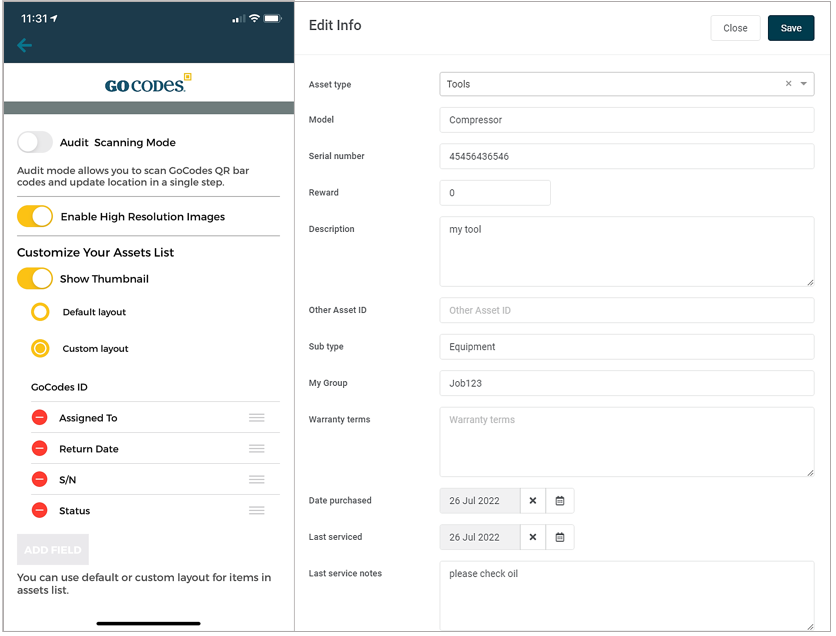

With the GoCodes Asset Tracking app downloaded to your devices, the next step is to populate your cloud database with initial data for your aviation assets.

Source: GoCodes Asset Tracking

First, link the metal QR codes affixed to specific equipment and tools to their individual info pages in the database.

Next, input the data for each asset, either by importing it from your existing asset management spreadsheets or another system, or by entering it manually.

Ensure that all asset information is up to date, including details such as:

- asset type,

- purchase value and date,

- depreciation rate, and

- maintenance history.

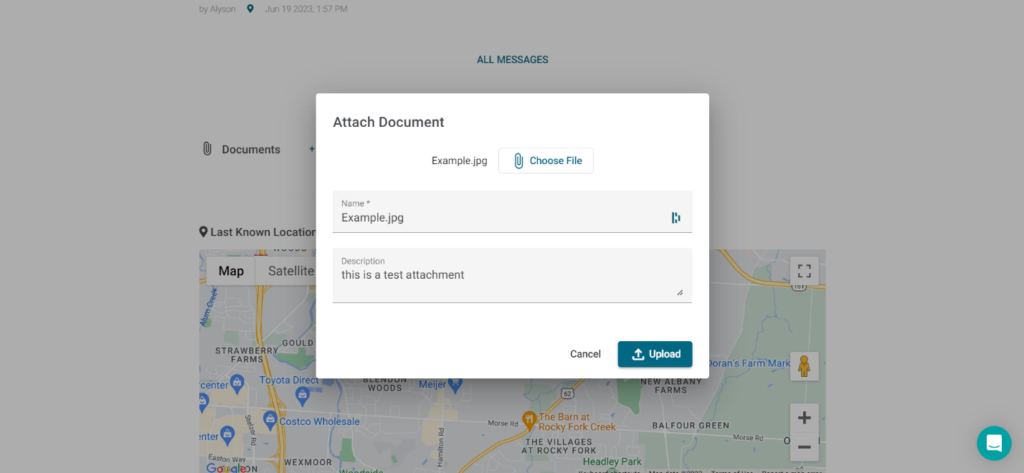

You can also attach relevant documents, such as user manuals, inspection reports, videos, or images, to each asset’s record in the database.

Source: GoCodes Asset Tracking

Once the app’s database is populated with the initial data, the system is ready to go.

Users can access the app to search for QR code-tagged aerospace equipment, tools, and other inventory items in the central asset list.

Since the first scan of each QR code recorded the assets’ current locations, search results will display this information alongside the initially entered data.

This setup unlocks the full range of features, including scan-based GPS tracking, check-in/out functionality, task management, reporting, and more.

With this system in place, aviation teams are empowered to efficiently manage their assets from day one.

Conclusion

We hope this article has successfully highlighted the transformative power of pairing metal QR codes with a reliable tracking app when it comes to the management of aviation assets.

This combination offers equipment managers and technicians in aviation a durable, efficient, and cost-effective solution for managing assets.

By adopting this technology, your organization can enhance accountability, improve maintenance, and ensure your aviation equipment and tools are always ready for use.

So embrace this innovation and keep your aviation assets performing at their best.