When you organize heavy equipment towing, you have to account for loading, unloading, and safety measures that go into transporting heavy machinery from site to site. This is not something you should take lightly or neglect because you’re in a hurry.

Handling any heavy-duty equipment poses numerous dangers, so complying with safety regulations during transport is imperative.

The media often features stories about heavy equipment falling off trailers and causing damage to property, infrastructure, or even harming people.

In 2019, an excavator rolled off a trailer in Hudson Valley, NY. The arm of the machine caught up in utility wires and caused a power outage in the area.

Even more recently, after a hauling truck hit a guardrail on a highway, an excavator fell onto the off-ramp, killing a person sitting in their car behind it.

If you don’t want to become one of these stories, read on to familiarize yourself with important safety recommendations for towing heavy equipment.

That way, you’re making sure you’re always following the best practices and complying with safety regulations.

Let’s start!

In this article...

Consult the Equipment Manuals

Your first step in the heavy equipment towing process is to check the equipment manual. This will influence every other decision you make to ensure safety in transporting heavy equipment.

The equipment manual holds valuable information, for instance, listing the item’s weight and dimensions.

That’s the kind of information you’ll need if you want to know which type of trailer to get and which truck has the suitable towing capacity to haul your equipment.

If your equipment is heavier or taller than state regulations prescribe, you might need a special permit to transport them.

For example, in Indiana, you’ll need a permit if your equipment is taller than 13 feet 6 inches or exceeds 80 000 pounds. Otherwise, you might be liable to penalties that can reach up to $10 000.

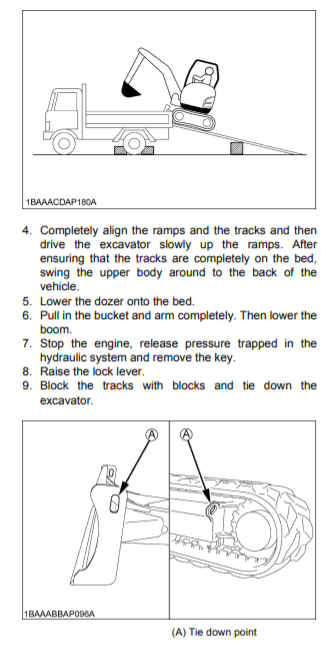

For instance, Kubota provides a detailed manual that covers everything from operation to maintenance for their model U48-4 excavator.

They even give towing advice and step-by-step instructions on how to load their excavator onto a transporting vehicle.

One of the steps includes placing the bucket and dozer on the truck bed and releasing the pressure from the hydraulic system.

When it comes to taking care of their equipment and transporting it safely, manufacturers know best. After all, they designed the machine.

So, it’s advisable to consult their manuals to ensure you’re securing the equipment properly and protecting more sensitive areas.

Remember that every machine has technical specifications that influence the entire hauling process. The most important thing is to have the right information before your equipment moves anywhere.

Even if you no longer have the manual, you can contact the manufacturer and ask for a replacement. Many equipment manufacturers also make their manuals available online.

Work With Well-Trained Operators

Driving a truck that hauls heavy equipment can be extremely dangerous simply because of the truck’s size.

For example, speeding is one of the most common causes of truck-related accidents. This is because trucks have a slower response time, so once they gain momentum, it is difficult to stop them, especially for inexperienced drivers.

There are a lot of things to consider with transporting heavy equipment, so it’s best to leave heavy-duty towing to professionals.

Even once you decide to hire professionals for this, you might find yourself trying to cut corners by hiring the cheapest available hauling company. This is another big mistake.

Your construction equipment is extremely valuable, and opting for a low-quality hauling company means risking costly potential damage.

Even though insurance might cover some of your expenses, you will still suffer from unnecessary project delays and productivity loss.

To ensure you hire the right people to tow your heavy equipment, consider the following:

- Expertise in the field

- Good referrals

- Reliable track record

- Proper licensing, certifications, and insurance

It’s essential to do your research and hire a quality hauling partner for your transportation needs. Basically, don’t be afraid to pay extra for reliable service.

Use the Proper Towing Equipment

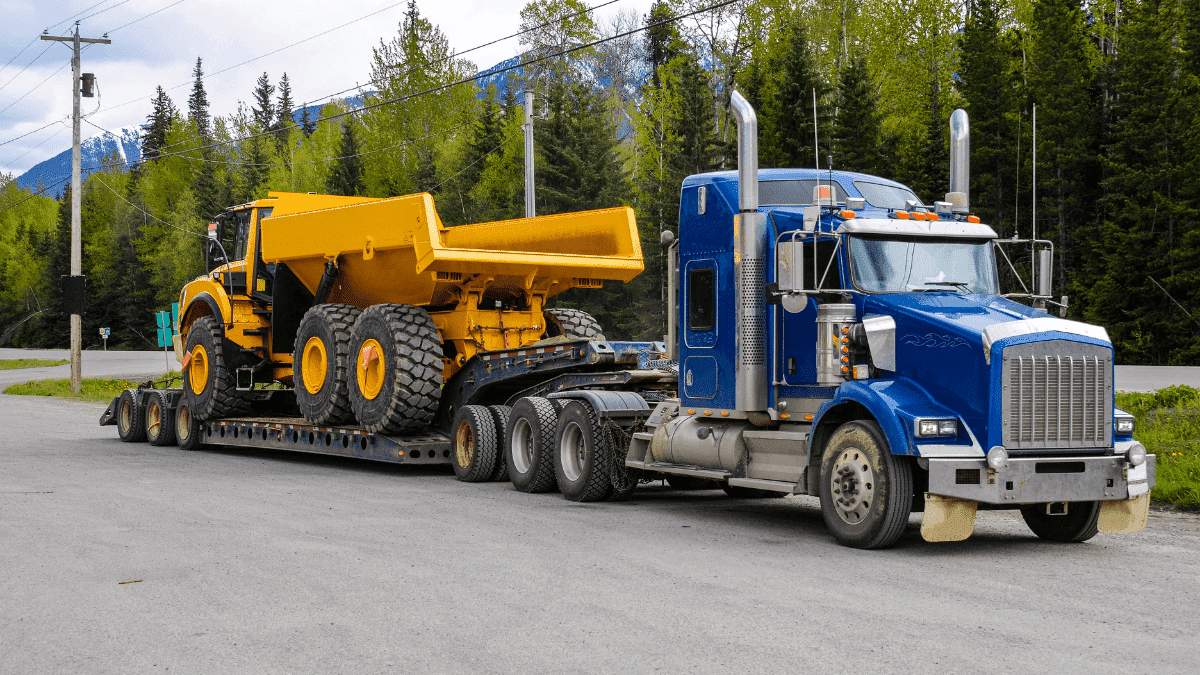

Industry experts agree on the importance of finding the right trailer for heavy equipment towing.

Nathan Uphus, sales manager at Felling Trailers, says that you need to have an appropriately sized trailer and towing truck to carry the load. A trailer that is too small is unsafe, while a too-large one is a waste of money.

So, a good trailer and a truck with enough power are your key equipment for towing heavy machinery. But which trailer to choose?

| Removable Gooseneck or Lowboy | Large towing capacity Good for overwidth machines Limited to hauling one piece of equipment at a time Designed to keep the load as low as possible to maximize vertical clearance Most common type |

| Step Deck or Drop Deck | Can carry loads of up to 10 feet 6 inches without additional permits |

| Double Drop | For load needing a height clearance of 12 feet The middle part is lower than the front and end parts of the trailer |

| Flatbed Trucking | Most common type for typical loads Makes loading and unloading easier Ideal load is up to 24 tons |

| Stretch Trailer | Includes all other types of trailers but can extend the deck for loads over 53 feet in length |

As you can see, there’s a lot of variety in the types of trailers, so it’s essential to know the dimensions of your equipment to choose the best option.

Jim Ladner, national sales manager at Landoll Company, advises buying one trailer that could carry 80% of your equipment and hiring professionals for more specialized loads.

Additionally, you should look for trailers that can carry more pieces of equipment in a single move so you can cut costs for transport.

Now that we’ve covered trailers, let’s see what to look for in a towing truck.

Know the Maximum Towing Capacity of Your Truck

Heavy-duty towing requires powerful trucks to lift and move massive loads. We’re talking about weights that start at 25 tons and end at 165 tons, which your typical pickup truck couldn’t handle.

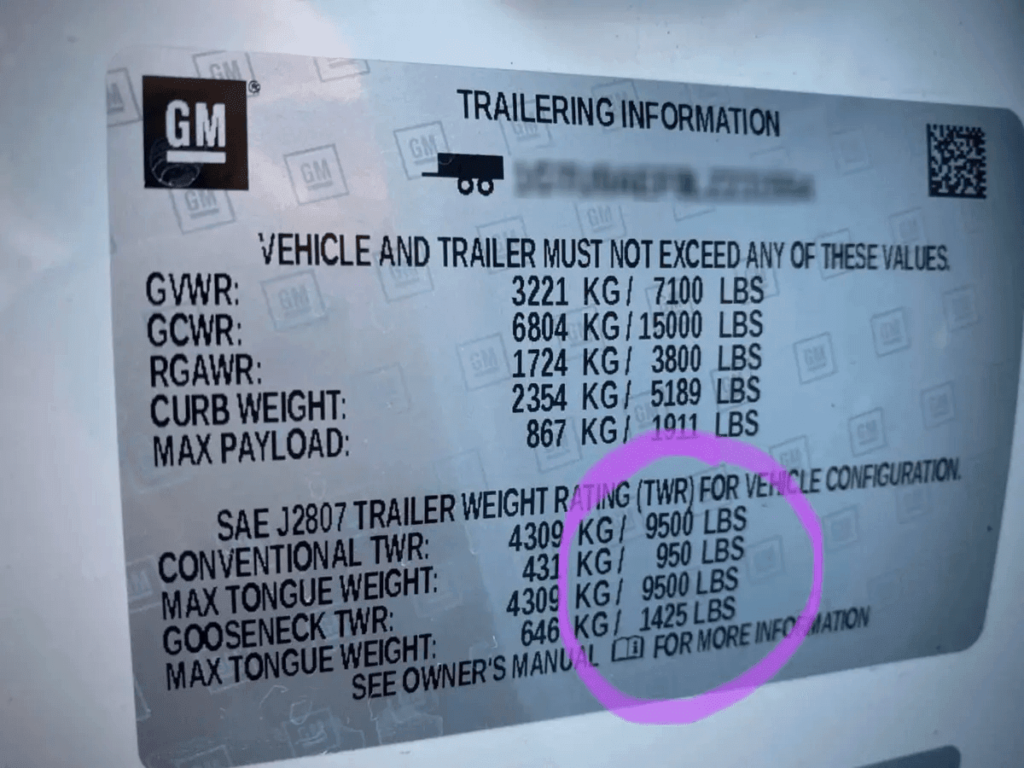

It’s important to know your truck’s exact towing capacity exactly, not just estimate it.

But what exactly is towing capacity?

Simply put, it’s the maximum amount of weight a vehicle can safely pull. After you establish this number, make sure the weight of the load is lower than the maximum amount the truck can safely haul.

Additionally, keep in mind that you also need to consider weight distribution and additional load (attachments, the driver and other people in the vehicle, etc.).

All the important numbers to calculate towing capacity will be in the manufacturer’s manual or on the VIN sticker on the truck’s door.

If you skip this step, you risk overloading your truck and putting your driver and other people in danger.

Overloaded trucks are at risk of brake failure. If the load exceeds the truck’s towing capacity, breaks cannot stop the truck safely.

So, how do you calculate your truck’s towing capacity?

First, you need to find out the curb weight of your towing vehicle. This is how much your vehicle weighs with a full tank but without passengers or any items inside.

Next, you need to subtract curb weight from your truck’s Gross Combined Weight Rating (GCWR).

GCWR is the maximum weight of the entire load (truck, trailer, heavy equipment, people, etc.) your truck can move without risking damage.

The final number is the vehicle’s towing capacity.

In the end, to ensure maximum safety, you have to know the towing capacity of your truck, so you’re not overloading your vehicle and endangering everyone on the road.

Perform Safety Checks on the Towing Vehicle

Ensuring safety on the road doesn’t stop at knowing the towing capacity of your truck. You also need to perform a full inspection of the vehicle and the trailer to ensure they are in proper working condition.

Here is a checklist of things you need to look at before you send your truck and trailer on the road:

| Tires | Check the tire pressure on the truck and the trailer. |

| Lights | Check the front lights, brake lights, turn signals, and hazard lights. |

| Brakes | Examine all brake functions and components. |

| Oil and fluids | Find out when the truck last underwent an oil and filter change. Also, look at the engine coolant level in the reservoir and see if there’s enough transmission fluid. |

In addition to these basic check-ups, there are other things you need to do to ensure safety. First, have a spare tire in the truck at all times, as well as the proper equipment to change it if necessary.

Next, towing mirrors are handy if your trailer and cargo are wider than your truck.

Good visibility is essential for your drivers, and it’s especially important to cover all blind spots, particularly when backing up.

Finally, it’s important to keep your towing equipment in top shape by conducting maintenance after you use it. Inspect the equipment for any sign of damage or stress, especially on the tires.

If you notice any irregularities, it might be wise to replace them or conduct the necessary maintenance.

Regularly checking and inspecting your towing equipment is the best way to ensure safe transportation.

Secure the Heavy Equipment You Are Towing

Are you familiar with images like this one?

Unfortunately, heavy equipment sliding off the trailer and causing accidents is nothing new. Simply typing excavator towing accidents can lead you to Youtube compilations like this one:

In several examples in the video, you can see equipment falling off trailers during transport and blocking the roads. This usually happens because the load is not secured according to the Department of Transportation’s (DOT) regulations.

It’s your responsibility to secure heavy cargo properly, so it does not fall from the vehicle or shift to affect the hauling vehicle’s stability.

Failure to do so can result in citations and fines (for both the driver and the company), and you might even be forced to put the hauling vehicle out of service.

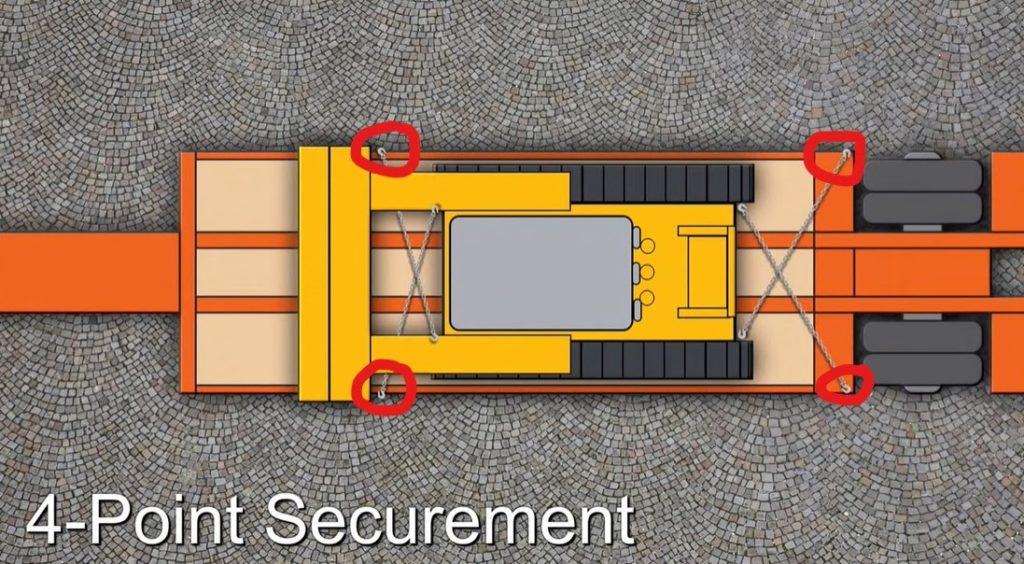

DOT’s rules prescribe that cargo has to be secured using four tie-downs. Any additional tie-downs apply to equipment with extra parts, such as arms or attachments.

To learn about other requirements, watch this video.

Basically, all chains have to be fastened linearly, with downward force, but avoiding sensitive parts of the equipment. There should be no twists, bends, or slack.

If your chain is longer than necessary, wrap it around the rest of the link. You want to prevent the equipment from moving on the trailer during transport so check if the tie-downs are tight enough.

The strength of your tie-downs and chains should equal at least 50% of the weight of the cargo to ensure they can keep it in place during transportation.

It is also important to regularly check the chains during transit. Whenever the driver pulls over, he or she should inspect if the straps and chains shifted, and re-tighten them if necessary.

Even industry experts stress that securing heavy equipment should be your top concern:

If you want to avoid incidents that could result in losing the load while your driver is moving on a busy highway, then it’s in your best interest to strap your cargo onto a trailer with utmost care.

Protect Sensitive Equipment Areas

There are certain parts of the equipment you’re transporting that are particularly prone to different kinds of damage. For instance, driving in bad weather can harm electrical wiring or gears.

Therefore, in order to make sure that the machine you’re transporting reaches its destination in operating condition, you need to protect these sensitive areas with particular care.

Check the manufacturer’s manual if there are instructions on protecting and covering sensitive parts of the equipment.

Additionally, you can dismantle the equipment and transport the removable pieces separately to ensure maximum safety.

Here’s what else you should do to protect your heavy equipment before leaving for the highway:

- Close and secure the doors

- Check knobs and bolts for tightness

- Remove the battery so it doesn’t drain

- Avoid chafing on hydraulic hoses

- Inspect straps and chains for visible damage

Finally, it’s advisable to take pictures to document the state of your equipment and inspect for damage when it arrives at the unloading area.

Protecting your equipment from damage during transport involves implementing the appropriate safety measures and conducting the appropriate checks throughout the transportation process.

Inspect the Route in Advance

Now that you secured your equipment on the trailer and your truck is ready for transport, the final step is to research the route.

Why is this necessary?

Trucks carrying heavy equipment are always in danger of encountering infrastructure they are unsuitable for, such as overpasses or low-hanging bridges.

Planning the route ahead of time helps you keep away from obstacles such as these, as well as too-narrow roads, or even rush hours, so that you can avoid any unfortunate incidents.

In Israel, one such incident happened when a truck hit an overpass on the highway between Tel Aviv and Jerusalem. The bulldozer and the truck caused a traffic jam which lasted for several hours.

But there are also examples close to home. One particular low bridge in Delaware, Ohio, is a big problem for truck drivers.

Not only is the overpass just 12 feet 7 inches tall, but the road it is on is State Route 37. It is heavy with traffic, making it near impossible to turn around quickly.

The city has put up signs and yellow flashing lights, but truck drivers still find their way to the overpass and end up stuck.

What’s worse, each time a truck runs into the infamous bridge, the city has to pay from $2000 to $5000 for clean-up, police calls, etc.

What about the truck drivers?

They have to pay a $1000 fine for damaging the bridge and $750 for getting the police to help them turn around. This doesn’t count in the lost time and costs of the damaged trailer and equipment.

In the end, planning the best driving route will pay off to ensure your equipment arrives at the destination on time and in the best possible condition. You can check for any obstacles that might cause delays.

Conclusion

Safe and efficient transportation of heavy equipment requires a lot of skill, precision, and knowledge.

Estimating and hoping for the best is a surefire way to cause accidents, which can lead to hefty fines and trouble for your construction company.

Therefore, you need to take every precaution to properly secure your heavy equipment, perform safety checks and inspect the driving route.

In the end, when you put effort into safely towing your equipment, you’re also positively affecting your company’s efficiency and regulatory compliance.