While it is best to try to minimize the storage time of your heavy equipment and maximize its useful time, that’s not always possible.

However, storing your heavy equipment can either help preserve their condition or irrevocably reduce their lifespan.

If you regularly put the equipment away without cleaning or inspecting it first, you shouldn’t be surprised when it breaks down mid-operation. Luckily, a few healthy equipment storage practices can keep that from happening.

In this article, we’re sharing tips on how to store your heavy machinery.

In this article...

Make Sure the Equipment Is in Top Condition Before Storing It

When workers use heavy equipment, it’s vitally important that they make sure it’s in top order before putting it into storage at the end of the day.

The machinery consists of delicate parts that can be worn out, especially after being put to work in rough conditions. Without a thorough inspection, workers can easily miss signs of imminent critical failure.

Even when the malfunctions that occur aren’t quite fatal, neglect can still lead to long-term equipment underperformance.

Therefore, safe lockdown procedures have a major impact on the state of your equipment, as your equipment will deteriorate over time without them.

Here’s what you need to do to make sure your equipment is in top condition.

Clean Your Equipment

It’s virtually impossible to use heavy equipment without getting it dirty, yet mud, grease, or other types of impurities can seriously affect your gear’s performance.

That’s why effective cleaning procedures are essential.

To clean your equipment thoroughly, dismantle it first, so you can reach each piece with ease.

When it comes to the cleaning itself, the water pressure washer is the most efficient tool because it helps you remove fluids, grease, and mud quickly.

Make sure your equipment is clean when you store it away.

Lubricate the Parts

When you neglect to lubricate your equipment, the parts are subject to unwanted friction during operations. The friction can damage the key parts and cause the machine to break.

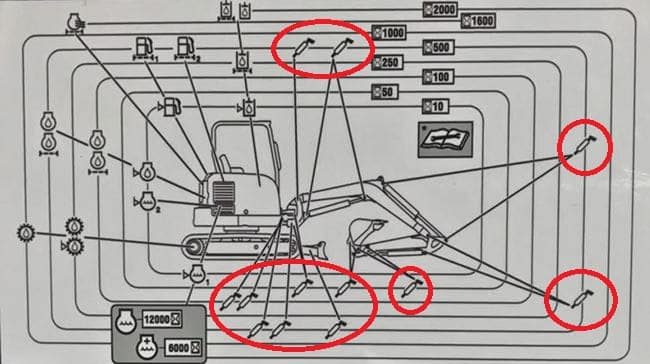

Therefore, lubricate the grease points in your equipment; they are highlighted in the user manual.

For example, here are the grease points of a Cat Mini Excavator.

Your operation and maintenance manual will also describe the greasing schedule. It will explain how to grease your parts, how long you should be greasing, and when to do it.

Finally, don’t forget to wear safety gloves to protect your hands as you do it.

Fill the Tires

Despite the common misconception, not all heavy machines require the same tire pressure; filling the tires by instinct with no regard to the guidelines might harm your equipment.

So, consult with the manual’s guidelines for the specific tire pressure of each piece.

Some experts suggest slightly over-inflating the tires so they don’t flatten while in storage, but make sure to double-check the recommendations for your specific product.

Top off Fuel

Fill your machines with fuel at the end of each workday. A full tank will help you eliminate water condensation as your machines cool down.

As a result, you’ll spend less on maintenance—and your workers won’t have to waste time refueling in the morning.

But this advice comes with a caveat.

It might be wiser to drain the fuel if you don’t plan to use the equipment for an extended period. That’s because gasoline can expire after 3 months because it has combustible components that evaporate over time.

Then, it turns to varnish that can clout up your equipment’s gas tanks and carburetor ports, making it difficult to ignite.

If that happened, you’d have to fix your machine and face additional maintenance costs.

Store Equipment Indoors

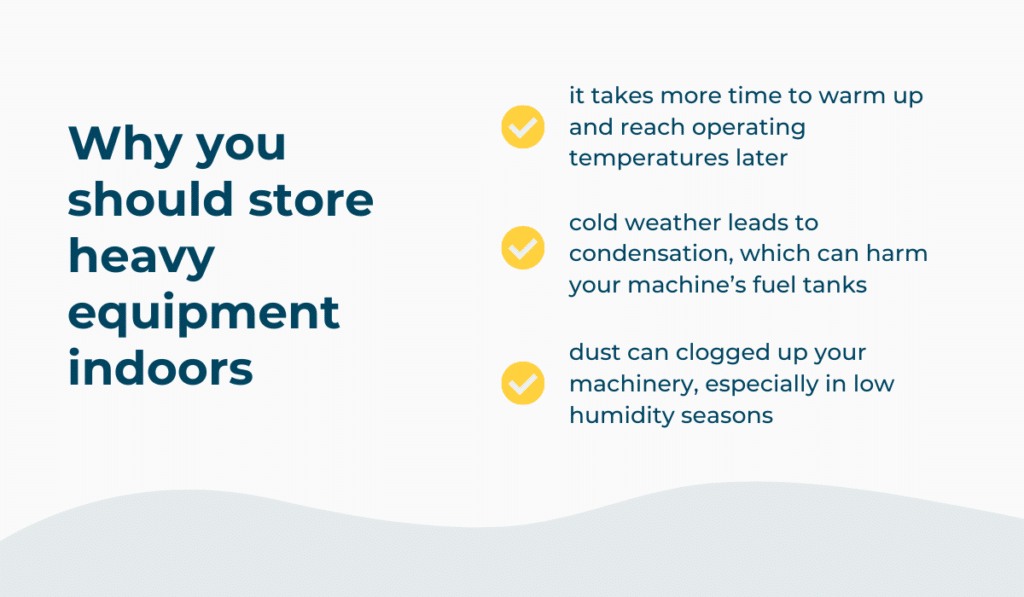

When you store your equipment outdoors, you’re taking a series of unnecessary risks.

For starters, your heavy equipment is likely to become exposed to the elements that impact its long-term performance. We’re not just talking about extreme weather, like heavy rainfall or snow.

When you leave equipment in the cold, it will take more time to warm up and reach operating temperatures later. This means that you won’t be able to use your equipment in full capacity right when you need it, so if workers rush things in the morning, they may damage it.

Additionally, cold weather leads to condensation, which can harm your machine’s fuel tanks, as mentioned earlier.

On the other hand, if you leave your machinery in dusty outdoor areas or construction yards, they’re likely to be clogged up with dust, especially in the summer when the humidity is low.

In short, it’s safe to assume that your maintenance costs will increase if you leave your equipment out in the open.

Additionally, when you’re storing your heavy equipment indoors, it’s wise to keep the environment minimally heated when it’s cold outside.

You want to prevent your machine’s engines from cooling down too much, which can easily happen in cold storage spaces with no heating.

To sum up, before setting out on a construction project, research indoor storing options. In case the site is far from your equipment hangar, work out storage options in advance to avoid keeping your equipment outdoors overnight.

Continue With Regular Maintenance While the Equipment Is in Storage

Regular maintenance of your equipment shouldn’t stop when they’re not used actively on projects.

It would be best if you looked at storage time as an opportunity to continue with regular maintenance in less hectic conditions than usual. Since the equipment is not currently in use, you can open it up and give it a thorough check-up.

That way, you’re more likely to identify failing parts and change them before they break and cause further damage.

You also have substantially more time to maintain your machines than on-site.

When maintaining your machines on site, the maintenance conditions are rarely as good as in storage. Maintenance professionals have limited equipment and often can only provide reactive care.

If you want to improve your maintenance procedures while the equipment is in storage, you should first look at the manufacturer manuals.

There you’ll find the guidelines for each piece of machinery, complete with specific requirements and potential problems you should be on the lookout for.

A good maintenance practice is to create a regular maintenance checklist. The checklist will give your workers a step-by-step walkthrough of what the check-up routine should include.

That will ensure your equipment remains in top condition, even if it’s going to be months until it’s used again.

Implement Security Measures

When it comes to heavy equipment, there are other concerns besides maintenance.

As you know, heavy machinery is quite valuable, which puts it at risk of theft. If your storage has faulty security measures, malicious individuals can break in and steal your equipment overnight.

Besides resulting in considerable costs of replacing the missing machines, theft would disrupt your operations. Moreover, you’d have a limited chance of recovering your original equipment.

With this in mind, it’s easy to see that investing in excellent storage security is not optional.

Getting a security upgrade is considered costly by many decision-makers, but that view isn’t necessarily accurate, not least because the benefits far outweigh the costs.

Nowadays, there are many cost-effective security solutions that will keep your equipment safe once it’s locked down.

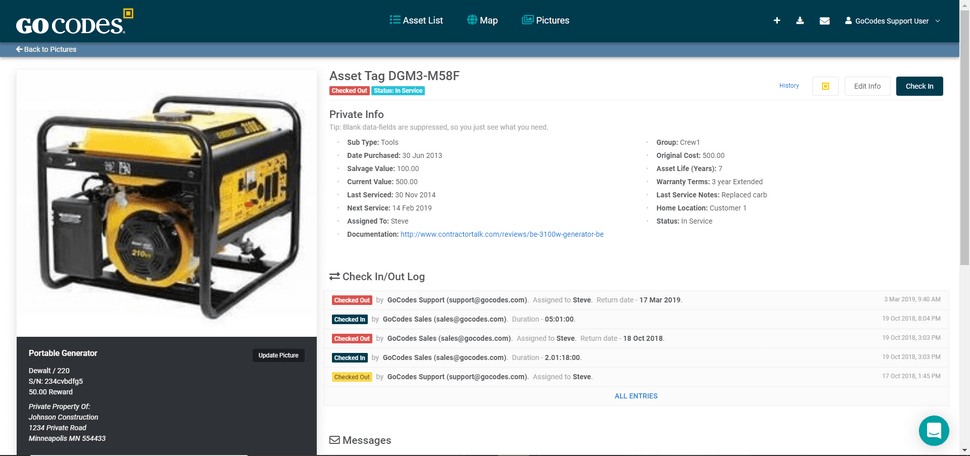

The first one that comes to mind again is equipment tagging. This is one of the best equipment tracking practices. When you label your equipment with tracking labels, you can instantly access the GPS coordinates of your gear once scanned.

Location is not the only thing stored in these labels. They also contain other information on the piece of equipment and can serve as proof of ownership.

Below is an example of various pieces of information available once you scan a label attached to your equipment. In this case, it was a portable generator.

You can see in the lower-left corner whose property is this generator. That way, even if your equipment gets stolen, you will be able to provide the last known location to the authorities, prove that you own it, and they’ll be more likely to recover your assets.

Another vital security measure you should implement is installing security cameras. Cameras enable indoor and outdoor surveillance around your equipment warehouse.

If there’s any unauthorized activity around the entry points, you’ll be able to spot it and send security. Moreso, if individuals steal your equipment, the camera footage will be of great help to the authorities.

Lastly, make sure your storage facility has high-quality security doors and fences.

Specialized security doors are hard to break in and thus make it difficult for thieves to enter your facility and escape with your property. Similarly, security fencing enables you to set a perimeter around your hangar to keep unwanted presence outside your facility.

If you have a large fleet of construction machinery, hire personnel to patrol the site, monitor security cameras, and actively contribute to the safety of your heavy equipment.

Conclusion

How you store your heavy equipment is one of the deciding factors for its longevity.

Many contractors falsely assume their equipment is in the clear just by being stored after performing well. However, that’s often a costly mistake.

Now you understand the importance of quality heavy equipment storage and the practices that support it, it’s your turn to reassess the equipment storage routine in your organization. Follow up on these tips, and your heavy equipment storage procedure will improve.