Why does heavy equipment failure always seem to occur at the worst of times?

When you least expect it, a big project is suddenly put on standstill because a particular machine doesn’t operate properly.

The toughest part is that it will inevitably cost you money. And not just a little, but most likely, lots of it.

A study by Caterpillar found that this unplanned downtime can cost project managers around 400 to 800 non-productive hours per year, per machine.

In addition to the machines being idle, these lost hours mean a reduction in productivity and sometimes even injury claims if the equipment was faulty and hurt operators.

The most common type of heavy equipment failures occurs with forklifts, bulldozers, scrapers, excavators, tractors, and more. Any equipment in your inventory can break down and have adverse effects on your site.

Heavy equipment failure is not only stressful for managers, but also for operators and everyone else who’s a part of the team.

To put a plan in place to prevent it, you first need to understand what the primary causes of these failures are.

In this article...

Common Causes of Heavy Equipment Failures

1. Having Untrained Operators

In an ideal world, every operator in your team will receive adequate training on the equipment they use, before they use it.

This training would include basic troubleshooting, operation, and the best safety procedures to adhere to when using the equipment.

But what happens when you have unexpected absences, and you’re short-staffed?

What happens when you have to get an operator from another team to handle a machine for which they haven’t received adequate training?

Or when you have to outsource additional staff for a busy week?

Untrained operators are a common cause of heavy equipment failure. As companies grow, it becomes increasingly challenging to ensure that every operator who works with the equipment has received sufficient training for it.

2. Disregarding Warning Signals

What happens when something isn’t quite right with many of the machines we use?

In most cases, a warning light will light up on the screen. Whether it’s a signal for high engine temperature or low hydraulic pressure, these warning lights signal to the operator that something is wrong with the machine.

But the problem is that operators will often overlook or ignore these warning lights. Sometimes they intend to report this to their supervisors. However, they have a busy day, and it slips their minds.

Not addressing the warning signals and continuing to operate the machine will inevitably result in more damage to that equipment.

3. Overlooking Preventative Maintenance

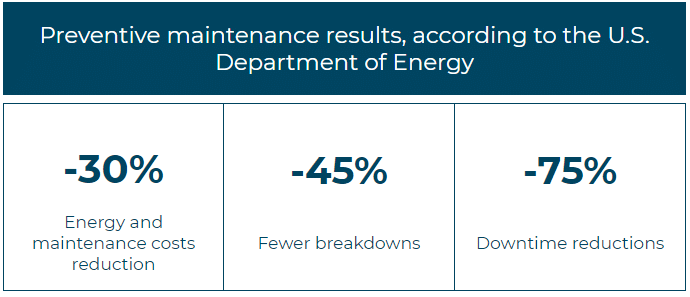

As the name suggests, preventative maintenance is the regular maintenance of equipment, to reduce its chances of failing. It involves servicing, checks, and the repairing or replacing of parts of equipment to help prolong its lifespan.

Most managers or supervisors understand how important preventative maintenance is.

However, sometimes your team is overwhelmed or short-staffed, with a lot of work to do. Unfortunately, this is when preventative maintenance falls to the sideways.

The team will assume that the equipment is working fine and that there is no harm from skipping a couple of maintenance days.

But here’s the thing – regular equipment checkups can help your maintenance technicians identify small issues early and attend to these issues on time.

Overlooking preventative maintenance will often result in facing costly heavy equipment failure in the future.

4. Overworking the Machinery

No good can come from overrunning any machine.

However, sometimes, you will find your team overworking and pushing some devices to their limits.

This often leads to the equipment either failing prematurely or at least straining the joints and not being able to perform at their optimum level anymore.

5. Forgetting the Operator’s Manual

Every machinery comes with an owner’s manual, especially when it’s a heavy piece of equipment, and you’re dealing with a lot of separate parts.

But often, once they’ve been trained on the equipment and feel confident using it, operators will forget about these manuals.

While it’s great that the operators feel comfortable enough with the equipment to not rely on the manuals, the problem is that these manuals cover everything, from calibration to troubleshooting.

If they don’t read the manuals, it can be challenging to identify some of the issues that may arise from the equipment.

Taking too long to sort out these issues can also result in unnecessary repair costs in the future.

6. Weather-Related and Storage Issues

This one on our list shouldn’t come as a surprise.

Heavy rain or scorching heat conditions can adversely affect your heavy equipment. For instance, if it was raining the previous night, operating your tractors in muddy conditions will not only result in having your tractors get stuck in the mud.

Pieces of dirt can also get stuck between the wheels and other sensitive areas, which may affect how effectively the machine operates.

Storage issues are also a common culprit of heavy equipment failure. Storing the large equipment outside can leave them exposed to pests such as rats, which tend to gnaw on wires.

7. Flaws and Defects from the Manufacturer

Companies that manufacture heavy equipment put a lot of time and effort into their machinery. Every component, including the nuts, bolts, and shafts, work in unison.

Still, sometimes it happens that some elements of the machinery aren’t working correctly from the manufacturer. Maybe the tighteners aren’t tracking straight with the chain or belt, or perhaps some nuts or bolts can’t align perfectly.

Whatever the case may be, these little defaults in the equipment can cause you unexpected heavy equipment failure.

8. Being Selective About What You Replace

Usually, when dealing with large equipment, instead of the whole machine breaking down at once, different components will fail at different times.

In this situation, many people will rush to replace or fix that part of the machine that’s no longer functioning.

But the important question is- what caused that part of the device to fail?

Neglecting to check what caused the initial failure often results in the problem recurring and resulting in much more damage down the road.

After reading the above, you might have noticed that these eight common causes of heavy equipment failure fall into three main sections.

Types of Machinery Failure

Thermally-Induced Failures

As the name suggests, these types of failures occur in relation to the temperature. More specifically, they occur when there are significant temperature fluctuations.

For instance, when starting a cold machine in freezing weather, its temperature will quickly rise. This difference in temperature can contribute to the breakdown of the machine.

Thermally-induced heavy equipment failures can also occur if the machinery gets too hot. If a machine is operating in extreme heat conditions, it can overheat and break down.

Mechanically-Induced Failures

The second category of equipment failures is mechanically-induced failures. These failures most often occur when the operators fail to take care of the mechanical parts of the machine.

Some of the most common causes of mechanical failure are shock, excessive or unusual vibrations, collision, or overrunning the machines.

The great part about mechanically-induced heavy equipment failures is that they are easy to avoid. Having a solid preventative maintenance plan is often the key to reducing these mechanical breakdowns significantly.

Erratic Failures

Erratic failures may just be the worst kind of equipment breakdowns because your machinery can work perfectly one minute and then suddenly stop. There are no warning signs, no gradual slowdown. Nothing to let you know that something is wrong.

These failures can happen because of multiple reasons, such as an overload in your electrical system.

The challenge about these failures is that, unlike mechanically or thermally-induced failures, there isn’t much you or your team can do to prevent them from occurring as they often happen randomly.

Luckily, these types of failures aren’t an everyday occurrence.

Heavy equipment failures can also fall into the following categories:

1. Sudden failure

This is similar to an erratic failure. The machinery will randomly stop without any warning signs.

2. Intermittent failure

This is when a machine will stop working and then, after a while, start working again.

These occurrences can be frustrating to operators and supervisors. One minute you’ll be convinced that the machine needs a technician, and the next minute it will be running again, with no issues, making it hard for technicians to detect the problem.

3. Gradual failures

Studies have found that there are six failure patterns that most equipment will go through.

In a nutshell, these failure patterns are:

- A – Bathtub Curve – accounts for about 4% of equipment failures

- B – Wear Out – accounts for about 2% of equipment failures

- C – Fatigue – accounts for about 5% of equipment failures

- D – Initial Break-In Period – accounts for about 7% of equipment failures

- E – Random – accounts for about 14% of equipment failures

- F – Infant Mortality – accounts for about 68% of equipment failures

These heavy equipment failure patterns tell us that most machines fail because of induced failures, meaning that we can significantly reduce these failures by putting an effective plan in place.

This is where technology can help. Software programs that help with asset management not only improve remote monitoring of assets but also allow for service or maintenance requests directly from the job site.

Turning to technology to help with these failures makes sense.

But what type of plan will be most effective?

How to Prevent Heavy Equipment Failure

Instead of waiting for equipment to break and then have to repair it, there are steps you can take to act before a machine brings your job to a halt.

Leverage Preventative Maintenance

As we’ve briefly discussed, preventative maintenance is about having a regular maintenance plan in place for your machinery, to prevent failures from occurring in the first place. This helps to prevent not only machine breakdowns but also prolongs their lifespan.

A preventative maintenance plan will often include:

- Oil changes

- Inspecting and replacing the parts that need to be changed

- Operator education

- Cleaning of equipment parts

- Repairs

- Lubrication

- Scheduling complete overhauls

- Taking notes after each maintenance

- Regular check-up intervals

It’s important to note that a preventative maintenance plan is also unique for every machine.

A piece of equipment that gets used every day, for hours on end, would naturally need a more regular maintenance plan than a machine that’s in use only for a couple of hours per week.

Understanding each type of equipment in your inventory and how often it is used is one of the key elements to having a successful preventative maintenance plan.

Even though the point of preventative maintenance is to help improve your equipment’s lifespan and reduce idle time, sometimes it’s overdone.

And unfortunately, this results in doing more harm than good.

How NOT to Do Preventative Maintenance

1. Capture Inaccurate Data

When you have a preventative maintenance plan in place, then checkups, tune-ups, and servicing are regularly performed on the equipment.

But keeping track of all of this information can be a challenge, especially when you’re not using software that enables you to enter all this data.

The result?

It becomes hard for your technicians to pre-empt when to order new parts or when specific machines are due for a simple oil change.

2. Lack of Instructions for the Technicians

Preventative maintenance includes a lot of elements.

The technicians in charge of maintenance should receive clear instructions so that they know what is expected of them.

They need to understand what steps to take if they find that a particular piece of machinery is unsatisfactory, what signs to look for, and what they need to measure to ensure that after the inspection, the operators will be able to use the equipment with no problems.

3. Improper Scheduling

As we’ve already discussed, each machine needs to have its own preventative maintenance plan because every equipment is used at a different frequency and has a different lifespan.

If you take too long to service one machine or service other machines too often, it can lead to overspending, unnecessary usage of inventory, and even wasting technicians’ time.

The key to a successful preventative maintenance plan is to find the right balance.

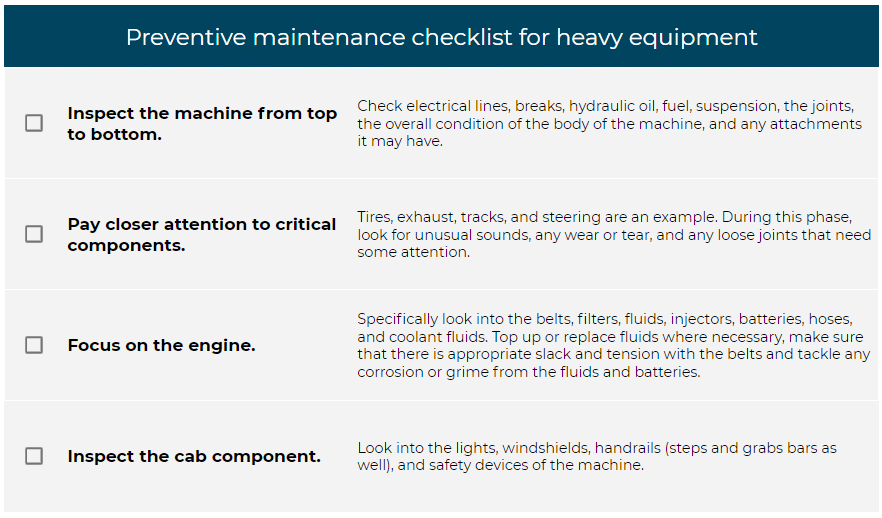

To help you get started, here’s a useful checklist that you can adapt to your own specific needs and requirements to reduce heavy equipment failure.

The engine part of the preventative maintenance plan may take the longest to get through.

However, considering how vital engines are, this time will be worth it as it will help to ensure that the equipment continues to run and function properly.

Benefits Of Repair And Maintenance Automation

Repair and maintenance automation is useful in multiple ways, including providing us with a more accurate process and reducing human error.

Automation has become possible thanks to various software solutions.

One such example is using quick-response codes or QR inventory tags that significantly speed up data collection and enable real-time analysis.

For maintenance, it means that you can easily track every piece of equipment or replacement parts, even across various construction sites or warehouses.

Automation has also made it possible to implement diagnostic software and hardware to spot problematic areas. Specialized software, coupled with sensors, can identify changes in vibration, temperature, noise, or exhaust, which can be indicative of certain equipment issues.

And speaking of exhaust, there are software solutions for fluid analysis tools that analyze fuel, oil, and coolants to provide a myriad of information about the state of the engine.

For example, the presence of soot in oil can indicate unburned fuel, and soot can shorten the life of the engine.

Also, automation can assist with:

1. Less Paperwork

An automated repair and maintenance plan helps to schedule inspections and services for preventative maintenance.

As discussed, being more proactive than reactive to the equipment maintenance will help to extend the lifespan of the machinery.

Turning to software for your maintenance plan will help to reduce or eliminate your need for paperwork. This is because management and supervisors can easily capture important information automatically.

Since team members can easily access data on cloud-based software without having to dig through filing cabinets, it improves productivity and ensures that everyone on the team is on the same page.

2. Reduce Idle Time (For Machines and Operators)

Every company that experiences downtime loses a lot, both in revenue and brand. An automated preventative maintenance system, where repairs and services are planned and adhered to, will minimize downtime.

3. Save Costs

Since you’ll be regularly maintaining equipment, it means that they will last longer, and you won’t have to spend as much money as you did before in fixing or repairing significant issues from the equipment.

4. Stay Compliant

Regular maintenance and keeping a clean record ensures that you don’t inadvertently violate regulations concerning workplace safety.

It is every business owner’s responsibility to maintain work equipment in such a state that it doesn’t pose a risk to employees.

A maintenance log can serve as proof of compliance with these regulations, but it can also serve you well in case of warranty issues, inspections, selling pieces of equipment, and safety certification procedures.

Future of Preventing Heavy Equipment Failures

In this article, we’ve spoken about the challenges of heavy equipment failures and how preventative maintenance is the current answer to a lot of these challenges. But, what lies ahead?

As a project manager or supervisor, it’s always important to stay on top of industry trends. One trend we’ve noticed gain more popularity is the asset-as-a-service trend.

In a nutshell, it allows maintenance teams to monitor the condition of company assets in real-time.

The technology that makes this possible is IoT (Internet of Things) technology.

You might have heard this term before, but what does it mean?

An article from Forbes describes IoT as “basically connecting any device with an on and off switch to the Internet (and/or to each other).

This includes everything from cell phones, coffee makers, washing machines, headphones, lamps, wearable devices and almost anything else you can think of.”

For your company, this means that you can connect all your assets, both small and large, to one device. With this, project managers can then predict issues or challenges that may arise from the machines before they occur and act accordingly.

It seems that the future of preventing heavy equipment failures will be more proactive than reactive.

There are already some technologies that will help to reduce and eliminate equipment failures.

Aside from the IoT for asset management, there is also condition monitoring.

This is the process of collecting information from a machine while it’s running to help detect any changes in its operation. With this technology, you measure various components of the machine, such as vibration, temperature, and lubrication.

Conclusion

Heavy equipment failure can be very costly to production teams.

As we’ve discussed, there are many reasons why your equipment might fail. Besides understanding the causes, it’s important to know and understand what you can do to help prevent these failures.

Having a sound preventative maintenance plan, where you routinely check and service your equipment, is key to helping you reduce breakdown costs and idle time. Cloud-based solutions make this preventive maintenance easy to achieve.

Automation is the present and future of reducing heavy equipment failure.

Don’t get left behind. Automate today.