Cleaning heavy equipment might seem like a time-consuming chore. But keeping your machines clean has more benefits than you might think.

When you take great care of your heavy equipment, you’re ensuring better efficiency because you reduce unscheduled downtime by discovering potential issues before they escalate.

This, in turn, improves the safety of your workers.

Moreover, regular cleaning, compounded with other forms of preventive maintenance, enables you to tackle wear and tear as it occurs, ensuring that your machines remain in top-notch condition, thus prolonging their service life.

Now, efficient heavy equipment cleaning requires specialized products and techniques.

So, in this piece, we’re outlining the most important things to consider if you want your heavy equipment to be in pristine condition and serve you for a longer time.

In this article...

Set Up a Wash Bay

First, ensure you have a dedicated space for cleaning your heavy equipment.

Wash bays are useful locations where companies can remove dirt, grease, and other debris from their equipment, but providing a designated space for cleaning the machines is not their only purpose.

They also ensure you comply with strict environmental regulations.

First of all, the contaminants you wash off from your equipment are often severely harmful to the environment. Therefore, many laws prohibit those unregulated substances from entering the soil and groundwater reservoirs.

So, using wash bays means you’re adequately equipped to dispose of contaminated wastewater, making your company more environmentally conscious.

But how do wash bays work?

Heavy equipment enters the wash pad area, and the dirt is rinsed off using a pressure washer. Then the polluted water flows into the catch basins below the wash pad and goes into the water treatment recycling system.

The water is then recycled and filtered. What is left can be stored for future use, while pollutants are moved into a disposal system.

One good thing is that wash bays can be permanent or mobile, depending on your needs. They come in many available sizes to accommodate even the largest heavy equipment.

You can transport them from site to site, thus containing waste and complying with every environmental regulation.

Remember that ensuring environmental compliance is as mandatory as properly cleaning your equipment.

Dismantle Your Equipment

Next, before you start deep cleaning your heavy equipment, dismantle all removable parts.

First of all, it’s far easier to clean all the different attachments and parts of heavy equipment one by one.

By doing so, you’re also saving so much time because, otherwise, a dirty splash from one part can transfer to another, which would render all your previous efforts moot.

Additionally, you’ll be able to reach some problematic areas a lot easier when you disassemble all removable parts.

Accumulated dirt can be easily washed off with a power washer, and then the attachment can be put into storage if it’s no longer needed.

Therefore, make your cleaning job easier by dismantling removable parts on your heavy equipment.

Start With The Dirtiest Part

When cleaning your equipment, it’s important to consider which parts to clean first to be the most efficient.

But to make your cleaning order easier, here’s some advice from professionals.

John Bourbeau is the CEO of Champs Pressure Washing & Steaming Ltd., and he has a decade of experience in cleaning operations.

His advice for cleaning heavy equipment is to always start with the undercarriage. This will be the dirtiest part of the machine.

So, if you started with, for instance, the cabin or any other part, the eventual splashing from the undercarriage would likely force you to clean it again later. So, make sure you minimize unnecessary rewashing of machinery to save time.

Then, once you’re done with the undercarriage, wash the machine from top to bottom. Gravity will pull the wastewater to the wash pad floor.

After you’ve successfully removed the mud and grease, you can complete your cleaning regime with more detailed procedures.

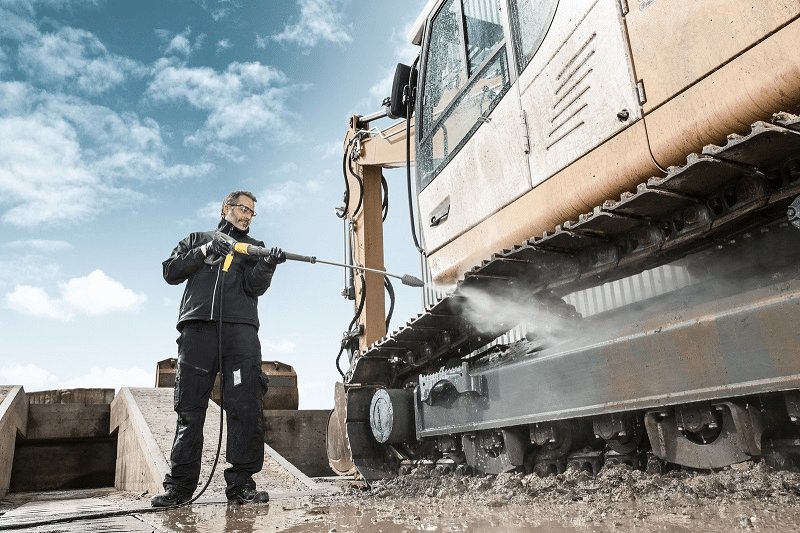

Use a Pressure Washer

One of the essential tools in your cleaning set is a pressure washer.

Pressure washers are a staple in cleaning construction equipment because they’re specialized products designed to remove dirt and grease. Powerful concentrated water streams can get into the smallest crevices that are impossible to reach by hand.

But how much power do you need to clean your machines?

The amount of pressure that can be produced by pressure washers is measured in PSI (pounds per square inch), and the minimum requirement is 4000 PSI at 4 GPM (gallons per minute). GPM is the amount of water coming from the machine.

When you’re looking for a pressure washer, take both specs into account to get the power you need to efficiently clean your machines.

When it comes to choosing the perfect pressure washer, you have two choices: a standard pressure washer and a water cannon.

Pressure washers are smaller and have a limited amount of water flow (the PSI ranges between 2,500 and 3,000, and 5-10 GPM), while water cannons have a larger water volume (sometimes 15 times more than a pressure washer).

Because of that, some companies use water cannons for rinsing and pressure washers for more detailed work.

In any case, to get the cleaning job done properly, a pressure washer is a must-have if you ever do any heavy equipment cleaning.

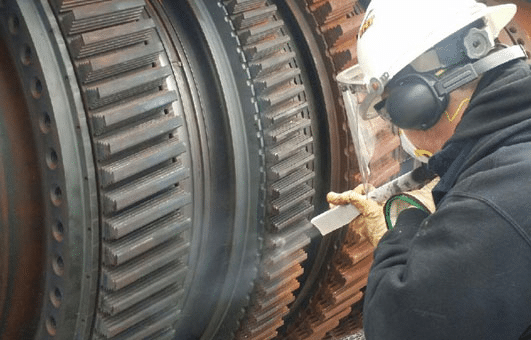

Try Ice Blasting

If you want a modern alternative to using harsh chemicals, the answer is ice blasting.

But first, what is ice blasting?

It is a non-destructive method of cleaning industrial and commercial machinery where dry ice is used as cleaning media. As the name suggests, the process consists of blasting dry ice particles with pressurized air on the intended surface.

This combination provides abrasive friction and then sublimates or causes a kind of mini-explosion, removing the contaminant.

Here are some advantages to using dry ice blasting.

First, there is less damage to the surface you’re cleaning than other cleaning methods (such as sandblasting). Other advantages include less environmental impact. For example, there is less secondary waste because ice simply evaporates.

Furthermore, dry ice is non-flammable and non-toxic, which makes it more environmentally friendly. It can even be used for cleaning in the food production industry.

So if you want a non-destructive cleaning method approved by the FDA, EPA, and USDA, try ice blasting.

Use Proper Cleaning and Degreasing Agents

Sometimes just using water is not enough to remove the more challenging contaminants. In those cases, you’ll need special cleaning and degreasing solutions.

The first thing you’ll have to consider in your cleaning process is the type of contaminants you’re dealing with.

The three most common types are:

- organic

- inorganic

- mixed

Organics usually consist of grease, fuel residue, as well as vegetation and animal waste. With inorganics, you’re dealing with minerals such as sand or gravel.

Finally, mixed compounds have organic and inorganic particles, and the most common is soil. The latter type is usually the most difficult to clean, so you’ll have to use detergents.

Most industrial detergents are extremely efficient because of the different surfactants and chelating agents mixed in the solutions.

Not to get too technical, but these chemicals work to break bonds between dirt and surface once they’re dissolved in water. The result is the easy removal of contaminants from machine parts.

Here’s how you approach cleaning with detergents.

The first step before using specific products is to check the owner’s manual to see which ones are recommended for different types of heavy equipment. Once you do that, you’ll successfully remove oil, grease, and grime from your machines.

Use detergents sparingly, but pay special attention to visible contamination on the engine and radiators. Then wait from 15-30 minutes for the cleaning solvents to work.

After that, you can use a pressure washer to rinse off the soft contaminants.

Take Special Care of the Cab

Everyone deserves to work in a clean environment, which is especially important during these times of heightened focus on health and safety standards in workplaces.

Since they are enclosed, cabs are ideal spaces for harboring viruses and bacteria. So, if anyone spends even a minute inside them when they’re dirty, they could potentially catch diseases.

The solution is to tackle cab cleaning in steps according to the surface you’re cleaning.

Your main cleaning areas will be:

- Hard surfaces

- Upholstery

- HVAC and air ducts

Starting with hard surfaces, wipe down any areas your operator frequently uses, such as a joystick or grab bars. Remember to use specialized cleaning products for automotive interiors because other cleaners might damage plastics or leather.

Next, remove and scrub floor mats if you have them. Brush and rinse them with a hose and leave them to air dry. Then you can vacuum the entire interior of the cab.

After that, you can finish by using a microfiber cloth and a dedicated cleaning solution to clean windows.

Cleaning the upholstery is next.

With a specialized product in spray cans, you can easily wet the area and scrub it down. That way, you can clean seat covers and seat belts.

But some professionals advise using a steam cleaner for a deeper cleaning process. This is because steam injected into the fabric gets to 160 degrees Fahrenheit and kills most microbes.

Finally, clean the AC to get rid of mold or mildew. Proper cab ventilation is necessary to keep viruses away.

To do this, most professionals use ozone machines. Have the windows up, turn the HVAC system, and put the ozone machine in the cab to circulate ozone for the recommended time.

After you do all the necessary steps in cleaning your cab, it will be polished and compliant with the highest health and safety standard.

Conclusion

Cleaning heavy equipment can be a tough and long process if it’s not done regularly. Yet, the bottom line is that you have to maintain your fleet in pristine condition.

This not only helps your heavy equipment produce better results, but you’re also presenting your company in a better light. Companies that take care of their equipment are perceived as more reliable and responsible.

So to keep a solid reputation and avoid costly machine breakdowns, schedule regular cleaning time. This will help you maintain your heavy equipment properly and give you peace of mind.