Handling and storing materials might seem easy, but it’s a process riddled with obstacles. You’ll have to move, transport, and control heavy and sensitive materials, so it’s important you do it safely and efficiently.

Moreover, different materials need to be kept in special conditions to maintain their quality.

In short, you should handle and store materials in a coordinated and organized process, so everyone knows their duties, safety protocols, and methods they need to employ.

So, read on to learn what you need to do to handle and store your construction materials better.

In this article...

Training Employees

Since your employees will be the main people responsible for handling construction materials, it’s vital that you give them the right training.

First of all, it’s important to be aware that there are certain risks involved with moving any type of construction materials on and off-site.

If you tell an inexperienced and untrained worker to move materials without supervision, you’re endangering other people on your construction site and risking damaging valuable resources.

Moreover, an average bag of cement weighs 94 lbs (or 43 kg), so imagine the catastrophic consequences if an entire pallet fell on one of your workers!

Aside from having to deal with compensating workers for the sustained injuries, you’ll also have to face productivity loss, construction material replacement costs, and OSHA penalties for having an unsafe working environment.

Second, construction material handling requires logistics and protocols to safely lift, carry, and transport materials of different shapes and sizes, as well as monetary value. You won’t use the same equipment as when handling large window panes or bricks.

So, to mitigate most safety risks associated with construction material handling, it’s necessary to have regular safety training. This way, you’ll explain important safety practices and instruct your employees about procedures related to moving different types of materials.

For example, you’ll teach them how to properly tie and secure loads or which equipment to use to avoid too much manual handling. Following that, workers should use lift trucks, forklifts, carts, and wheelbarrows whenever possible to avoid back injuries and sprains.

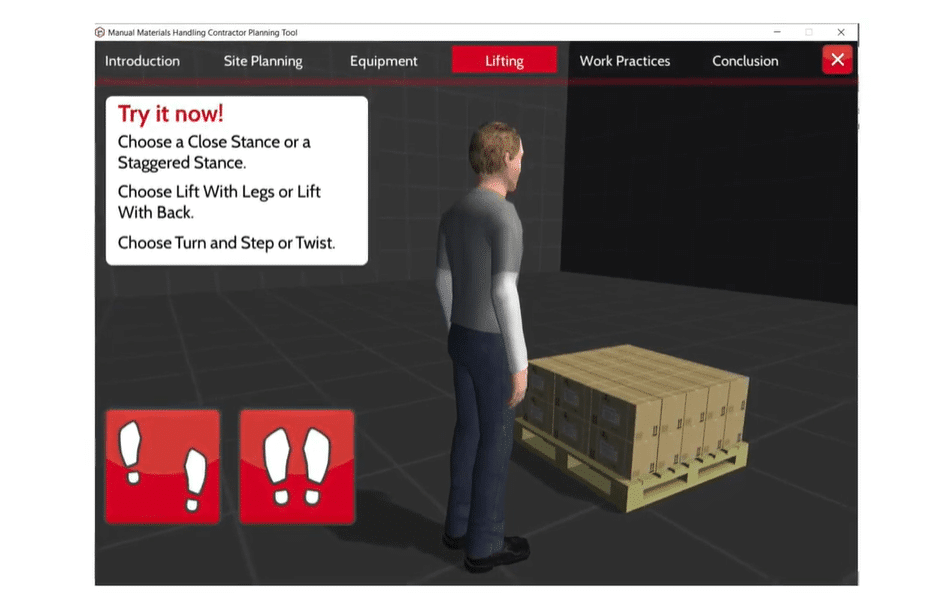

To help you in this process, The Center for Construction Research and Training (a non-profit organization dedicated to minimizing injuries, illnesses, and fatalities in the construction industry) has a special training program called Best Built Plans.

Whatever your training procedures might be, it might be wise to supplement them with this practical, interactive training program that’s always available to you and your workers.

This program aims to provide resources for contractors and their employees for safer material handling practices. One of them is an interactive training and coaching tool that shows different material handling scenarios and injury risks.

It also comes with a mobile app that can be used in a training class or on its own.

Remember that day-to-day construction operations are riddled with safety risks. Therefore, necessary procedures must be followed when workers are handling construction materials. With regular training, your employees will be empowered to move any type of material safely and efficiently.

Choosing the Right Place to Store Materials

The place where you store your construction materials also matters. Ideally, you want to avoid scenarios like this one.

But what’s wrong with this photo?

First of all, these cement bags are directly exposed to weather conditions. Think about what will happen if it starts to rain heavily. Cement will absorb the moisture and become unusable for the construction project.

So, you’re going to have to throw it away and break your budget by needing to order new materials. But you’re not just harming your wallet; you’re also harming the environment by creating unnecessary waste.

Not to mention that this will cause a delay in project progress since your workers will have to wait for new materials to arrive so they can do their tasks.

The next problem with the photo above is that materials are put directly on the ground. You must never do that. This is because moisture can also be absorbed from the ground and damage the material.

What you should do instead is to put all your construction materials on pallets to keep them above ground, and cover them with a tarp in all weather conditions.

But there is one good practice you can notice in the photo above. That is placing materials as close to the construction site as possible.

Time is precious in construction, so you don’t want your workers to walk too far to get what they need for their job. Yet, you also need to pay attention that the materials aren’t too close to the structures, so you’re not violating any OSHA regulations.

To solve this problem, you should choose an area on the construction site where it makes the most sense to place materials. It should be easily accessible to people and transporting equipment to minimize delays as much as possible.

Essentially, you should place your materials as close as possible but keep them above ground and under a tarp. This should be enough to keep your construction materials in good condition until they’re installed.

Being Strategic About Storage Space

If you have a dedicated storage facility for your construction materials, be aware of how you store them.

According to OSHA, properly stored materials should not create hazards for employees. This includes tripping, fires, explosions, or even household pests.

Therefore, construction materials should be stored and stacked firmly to prevent falling and deterioration, but also enable free passage.

So, the first thing is to store materials by type. For example, you should keep highly flammable chemicals and materials separate and take extra precautions when storing them because they pose one of the biggest risks.

Furthermore, keep chemicals in special containers, so they don’t contact incompatible materials and cause damage.

The next thing is to know the weight of your materials. It goes without saying that you shouldn’t put the heaviest materials on great heights since they can easily fall and injure workers.

Even if you’re using heavy-duty racks that can take up to 7000 lbs, always put the lightest materials on top and never go above the storing limits.

But let’s see some examples of how you should store specific materials, like cement, PVC pipes, and paints.

When it comes to cement, you’d want to stack the bags on wooden pallets that are at least 7 inches above the floor and 17 inches away from the storage wall.

Also, stack up to 15 bags close to each other, so you avoid air circulation and lumping of cement.

Your stack should also be 9 feet wide and arranged alternatively lengthwise and crosswise, so the bags don’t fall over.

It’s also a good idea to implement a system in which the first bags of cement that arrive should be the first ones to be used. This is to avoid keeping the cement in storage for too long and losing quality.

Now, storing PVC pipes has different requirements primarily due to the shape and type of material. Generally, you’d want to place pipes on flat surfaces and away from sharp objects.

Avoid creating large piles of PVC pipes because otherwise they can get distorted and be difficult to assemble in joints. Instead, keep them in piles up to four feet high.

Also, do not put one pipe inside another. Place them in shady areas far away from any heat source.

Finally, storing paints is an entirely different ordeal. This is because paints, varnishes, or lacquers are considered flammable materials, thus requiring special care. Keep them in sealed containers in a ventilated location.

There should also be at least four inches of thick loose sand on the floor of the room where the pain is stored. Additionally, to avoid contact with sparks, or flame, the paint storage should not have any electrical wiring.

As you can see, storing materials isn’t easy, and you should carefully consider the type of materials you use and the proper storage solutions.

Properly Handling Waste Disposal

The problem of waste in construction has long been known. Just consider the fact that in 2020 alone, the industry produced over 2 million tons of waste.

This is more than just an environmental concern. Governments all over the world want to combat the construction waste problem with more strict regulations.

Therefore, you’re required by law to dispose of your construction waste properly; otherwise, you could be facing hefty fines, for example, up to $500,000 in Australia or $1,000 000 in Hong Kong for repeated behavior.

Let’s face it, no matter how carefully you use your construction materials, it’s inevitable you’ll accumulate construction waste. But how you collect and dispose of that material is vital.

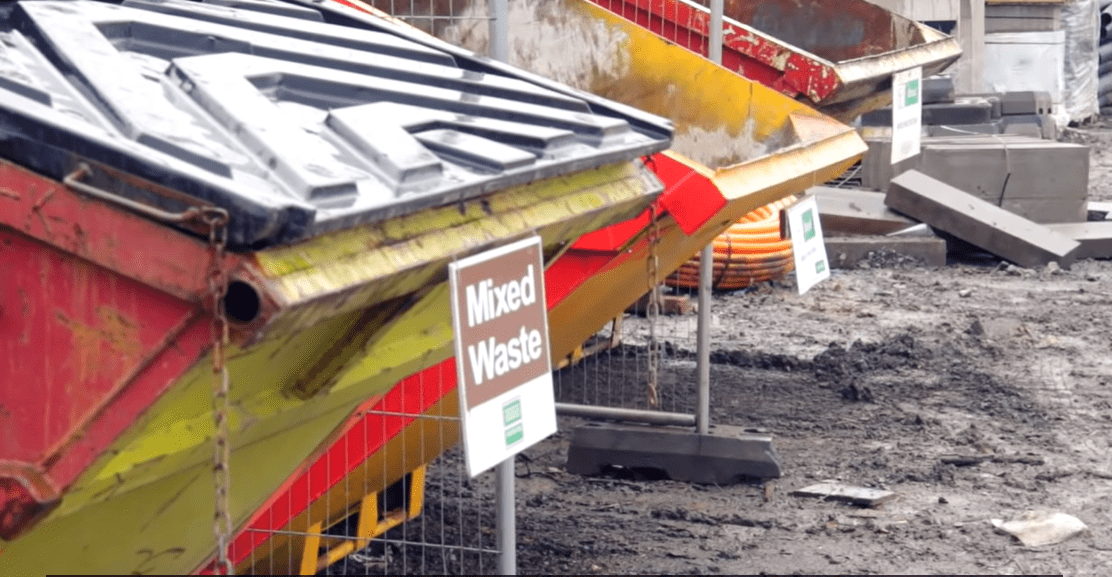

Here is how Graham Construction, a company from the UK, handles construction waste on all their recent projects.

For every project they take, they create specific waste segregation areas. This means they’ll have several dumpsters with clear labels to separate recyclable and non-recyclable materials. Usually, they separate timber, metal, inert waste, and plastics. Everything else goes into the mixed waste dumpster.

Also, they keep hazardous material in a secure and sealed area labeled with warning signs. After they accumulate enough, they hire a specialist to dispose of it.

What you can learn from this is that dealing with waste is easier with a dedicated waste disposal area. It’s useful to have several dumpsters with company-approved labels so your workers can easily separate materials on site.

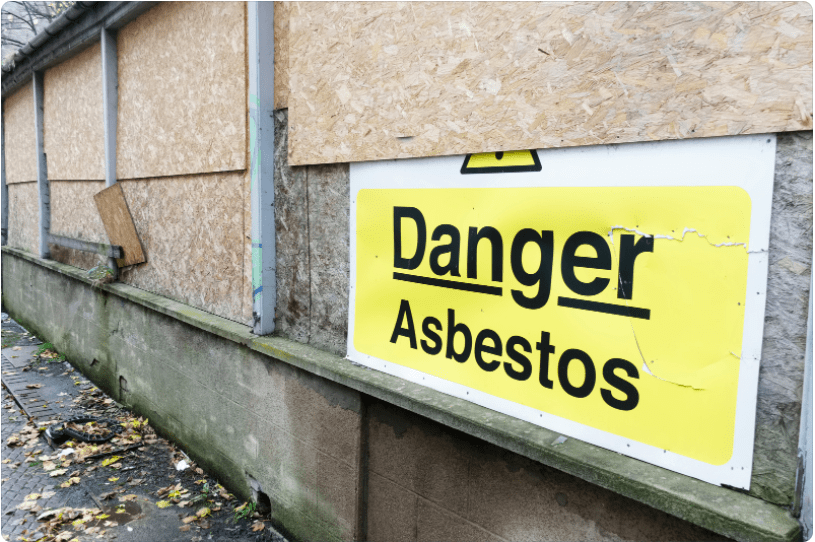

That way, you don’t put together non-hazardous and hazardous materials. After all, you don’t want to leave asbestos, leftover paints, or products containing mercury with other materials assigned for landfills.

They should be processed and disposed of by specialists to ensure safe removal from construction sites.

This process might take additional time and cost you more resources, but it’s worth your time to comply with government regulations and protect the environment.

Securing the Construction Site

You might be wondering what the use is of securing the construction site when ill-intentioned people will always find a way to steal valuable construction materials.

This might be true, but you’d be surprised by how many thefts occur when construction companies have poor security measures in place.

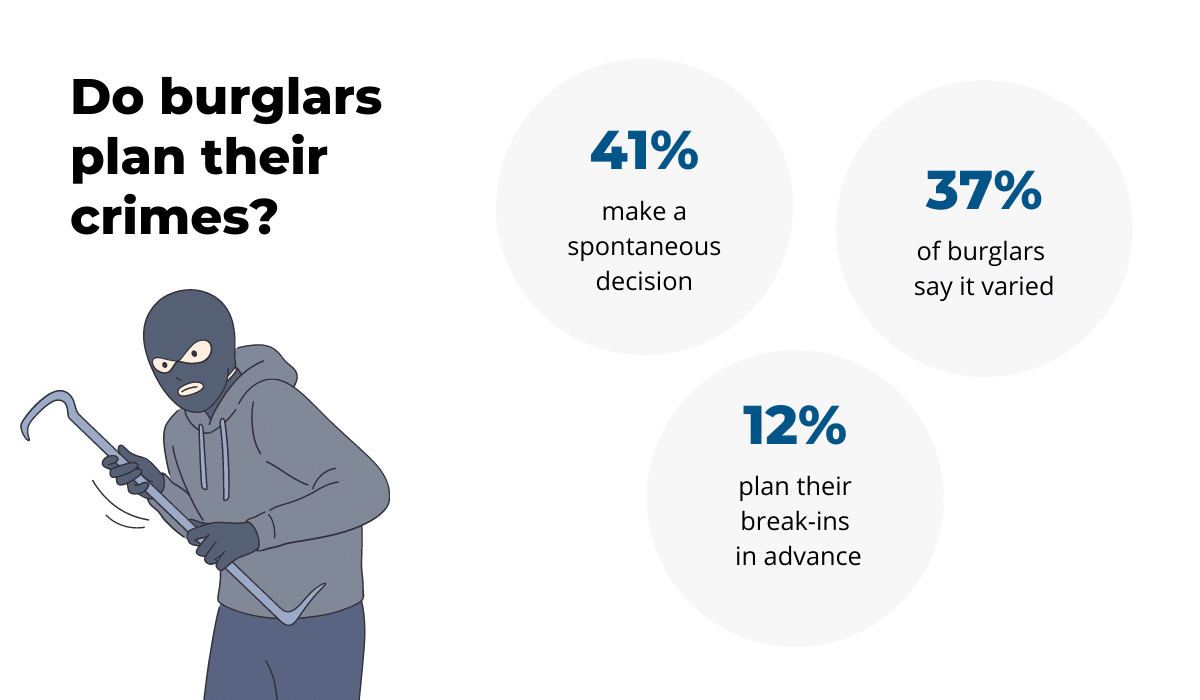

If you look at a study conducted by Joseph Kuhns from the Department of Criminal Justice and Criminology at the University of North Carolina in Charlotte, you will see that most crimes can be prevented with simple solutions.

The research found that burglars will consider the proximity of other people to the site and signs of increased security such as alarms, dogs, or outdoor surveillance cameras before making an attempt at a break-in.

41% of burglars admitted that most of their break-ins result from a spontaneous decision, and 60% of them said they’d find another target if they noticed any security measures.

What do these findings mean for your business?

First of all, even a slight investment in security can pay off. This can include fencing off your construction site, locking up doors, and closing the windows. While these might not be the most secure methods, they act as a deterrent and keep opportunistic thieves away.

Next, install a good security system with motion sensors and video surveillance. This is a practical way of monitoring an entire construction area and will become helpful to track thieves if the worst happens.

But most importantly, let passers-by know you’re watching by using signs. Nobody wants to be caught breaking the law, and they’re more likely to walk away if they’re warned that being caught is a real possibility beforehand.

Finally, consider hiring a security guard. This might be costly, but having a dedicated person to ensure non-authorized people enter the construction site will give you peace of mind.

But why is this even necessary?

As you’re well aware, construction materials are expensive. Recent reports about the price of copper estimate $4.50 per pound, so you’d want to use it for your construction project and not let thieves steal it for their benefit.

Another reason construction site security is important is that your insurance premiums will go up. If you file claims to recover the costs of the stolen materials, insurance companies will increase your rate from 20% to 40%, which can stay in effect for years.

Long story short, the repercussions of burglary can follow you for years, and you’ll wonder why you didn’t install a security camera on time.

Conclusion

When it comes to construction material handling and storing, you should focus on four crucial tasks: moving, protecting, storing, and controlling.

So, if you follow the best practices we’ve outlined in this article, you’ll be on the right track to improve your material handling and storing operations.