The desire to innovate is in our nature as humans.

We want better solutions to existing problems, so it’s no wonder a wave of innovative construction materials is sweeping the industry.

Whether finding more eco-friendly alternatives to existing materials or finding new durable and more functional ones, the main goal is to improve existing construction practices.

So, let’s look at innovative construction materials that will transform the construction industry and become part of future buildings.

In this article...

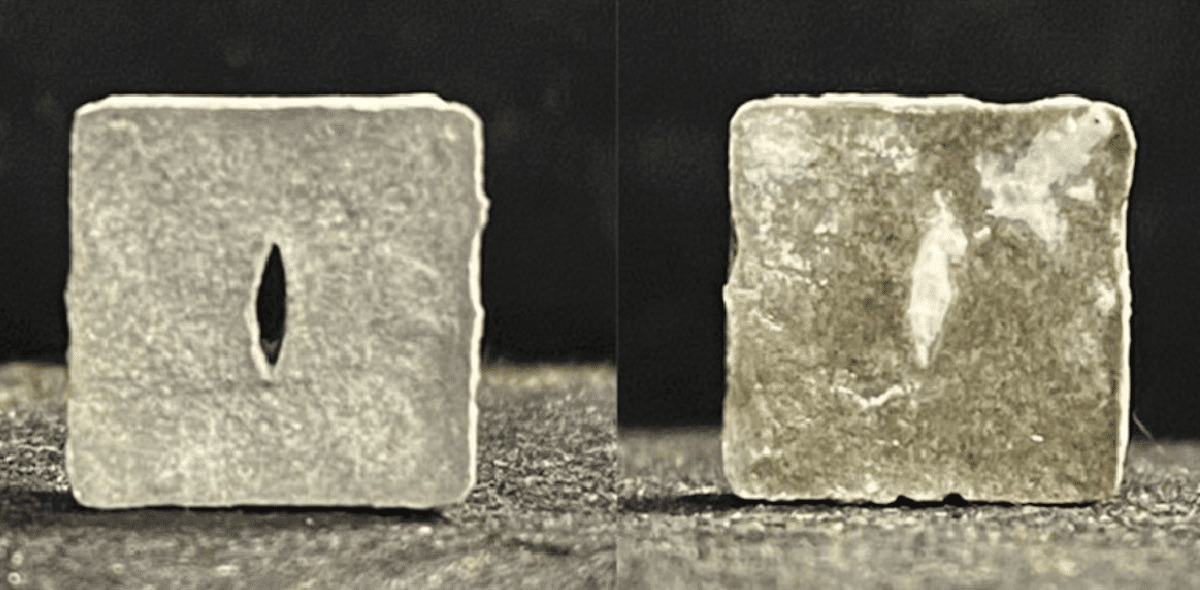

Self-Healing Concrete

If you thought you’d have to deal with concrete cracks for the rest of your working life, there’s good news!

Researchers around the world are coming up with different types of self-healing concrete. This is a type of concrete that can repair itself by using bacteria. Bacillus bacteria is put into the concrete before pouring, and once a crack appears, it produces calcite to fill in the gap.

The best thing about this material is that it can last up to 200 years, which is a great long-term solution for this common problem.

Hardwood Cross-Laminated Timber

In a quest to find more sustainable materials, engineers have created cross-laminated timber. It has a layered design, with small pieces of softwood that are laminated together.

These layers are glued together under high pressure in opposing directions, resulting in a strong structure.

A great benefit of cross-laminated timber is better water resistance than traditional wood. It also boasts a reduced carbon footprint.

It’s already being used in the US in the construction of roofs, floors, beams, and columns, but it could potentially replace reinforced concrete or structural steel for building skyscrapers due to its strength.

Bioplastic

To put it simply, bioplastic is made from renewable biomass resources such as algae, cellulose, or other materials which can degrade faster once they’re disposed of.

In construction, bioplastic can be used for cladding, structural elements, water pipes, bridges, or piers.

Plastic is a common building material, and we’re not going to get rid of it in the near future. But the good news is that there’s a green alternative that construction companies can consider using in order to reduce their carbon footprint.

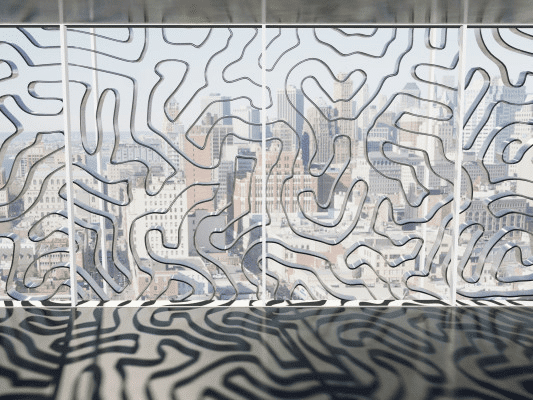

Homeostatic Facade

Thanks to homeostatic façades, people will no longer have to endure living and working in overheated or too brightly lit rooms. There are different models and materials used, but the principle is the same for all.

The Homeostatic Façade System has mechanisms and materials that will respond to the weather and temperature outside to create optimal indoor conditions.

When the sun hits the façade, the surface material will expand to block it, thus creating more shade inside, and when the temperature drops, it will shrink to allow the sunlight to pass through more easily.

As a result, the building will heat up faster.

In a nutshell, homeostatic façades are a smart solution to regulate heat and save energy.

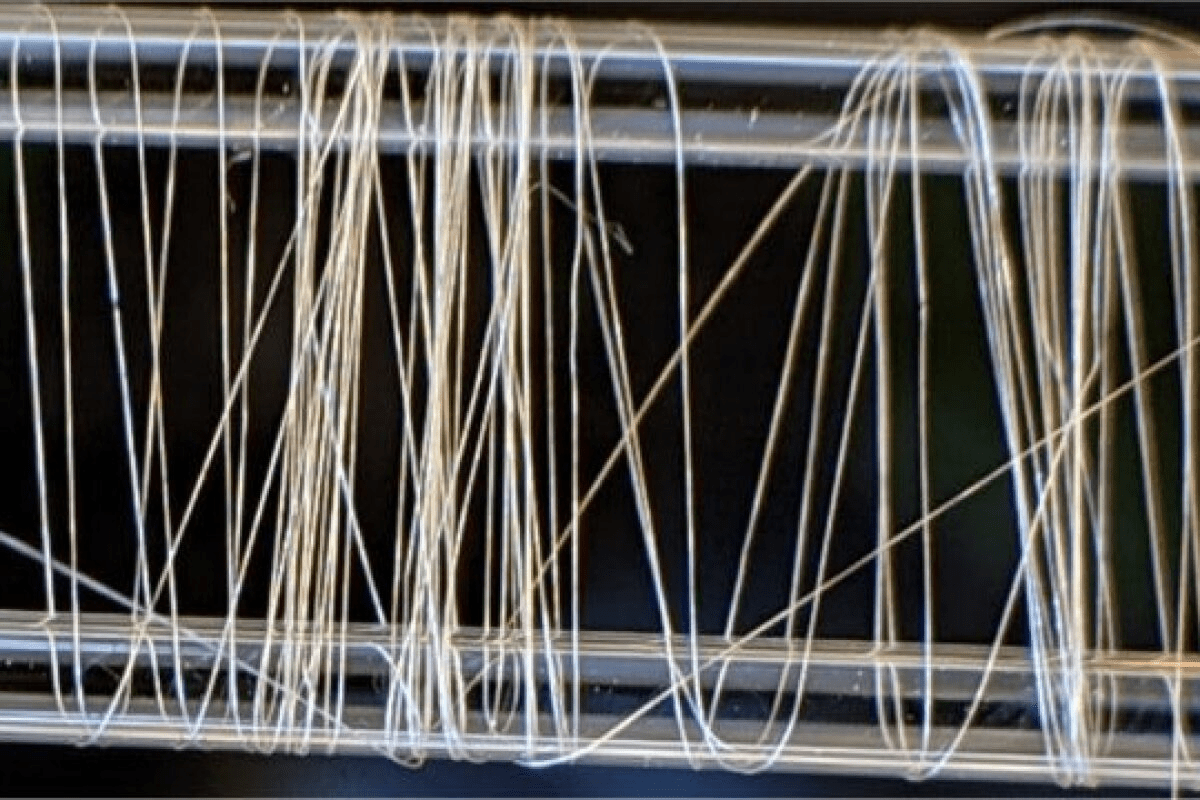

Artificial Spider Silk

According to recent scientific research, natural spider silk is five times stronger than steel. If we were to scale it to human size, it would be powerful enough to pull an airplane.

But what if we could harness that power for use in construction?

Scientists have been developing artificial spider silk for years.

Still, a Japanese company called Spiber Inc. claims they have produced a material that is 340x stronger than steel, which may one day become a green alternative for many petroleum-based products.

3D-Printed Graphene

Graphene is considered one of the strongest artificial materials in the world. Sadly, its two-dimensional structure of sheets or flakes is basically useless for construction purposes.

Now, a team of MIT engineers wants to change that. Since 2017, they have been experimenting with three-dimensional graphene, which in theory could be 5% the weight of steel but 10x stronger.

The team says that the new graphene structures are so complex the only way to produce them is with 3D printing. Further research and development are certainly needed, but the current results look promising for the future of construction.

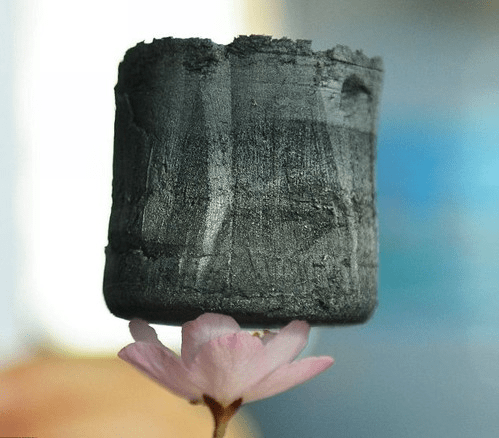

Aerographite

Aerographite is an artificial material made by researchers at the Hamburg University of Technology in 2012.

What makes this material great for construction purposes are the following characteristics:

- Bendable

- Strong

- Stable at room temperature

- Withstands a lot of vibration

- Conducts electricity

But the most impressive thing about this material is that it’s made from hollow carbon tubes, which makes it 75x lighter than Styrofoam.

Because of this, it can be compressed into a space that’s 95% of its usual size, and the stress only makes it stronger.

Currently, it’s being used in aviation, satellites, purification systems, and electric cars, but it’s bound to find its further purpose in construction due to its excellent physical properties.

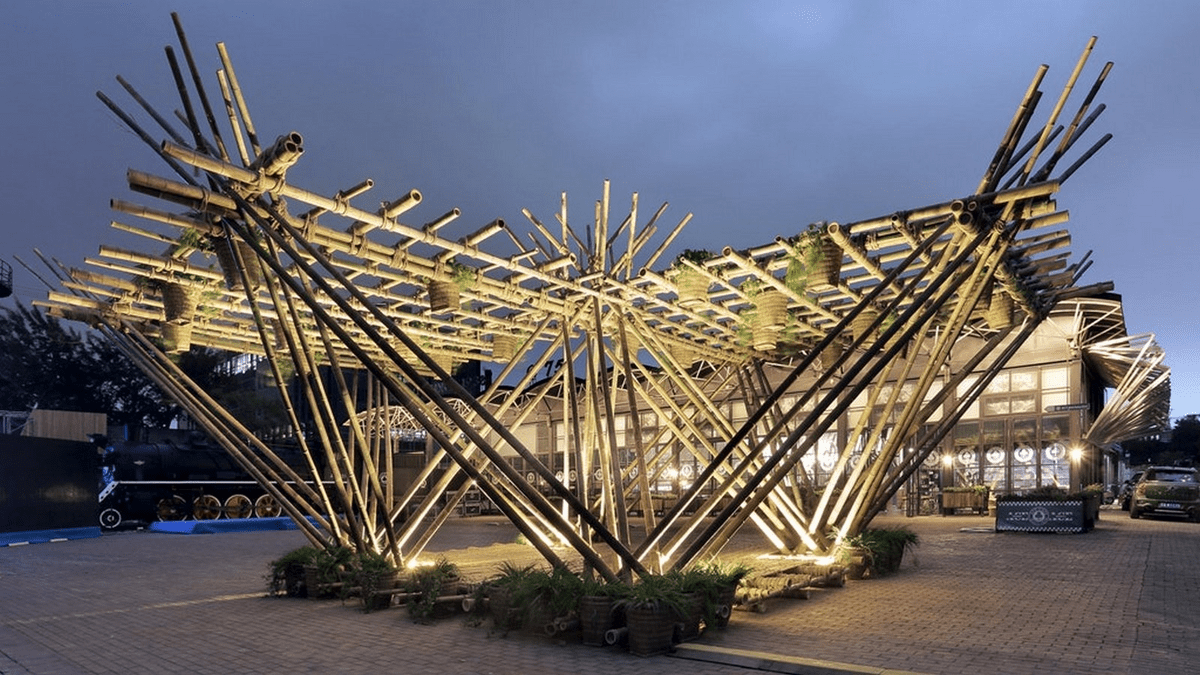

Modular Bamboo

Bamboo has been a staple construction material across East Asia, but it’s gaining popularity in other parts of the world.

One company even plans to build a bamboo settlement for 20 000 people by 2023.

In a nutshell, it’s a lightweight, low-cost, flexible, and strong material that can create versatile and earthquake-proof structures in diverse environments. A whole stem of bamboo can be used for either structural or decorative purposes.

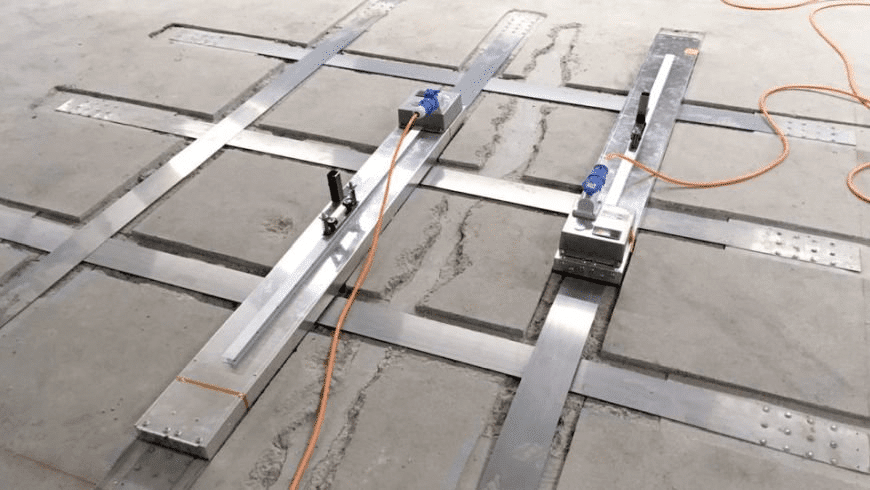

Memory Steel

Empa, a Swiss company dedicated to materials research and development, has created a new material called memory steel.

It consists of a shape memory alloy based on iron which is heated only once and becomes permanently prestressed.

This is much more efficient than prestressing hydraulically, where you’ll need large, multi-strand jacks to transfer enough force, thus spending a lot of time, equipment, and space to improve the performance and strength of the final structure.

Memory steel can be used to reinforce new and existing buildings, bridges, roads, and highways. But since these projects often have limitations in space, using memory steel can be a great solution to finish necessary tasks in confined spaces.

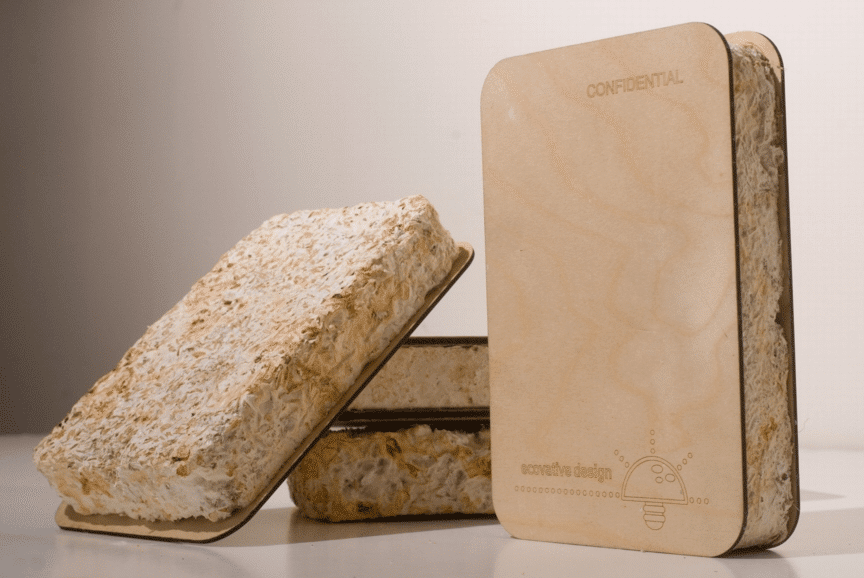

Mycelium Insulation

Creating biomaterial from fungi is growing in popularity. But why is that?

The fungal biomaterial is created from mycelium, a vegetative structure of mushrooms.

Similarly to bamboo, the dried product is biodegradable, but what makes it great for the construction industry is its high durability and resistance to mold, water, and fire.

According to David Cheshire, a sustainability expert, mycelium has better insulation properties than most standard insulation used nowadays and even removes carbon from the atmosphere.

It has virtually no negative impact on the environment, so it’s a matter of time before it becomes widely used in construction.

Precast Concrete

Precast concrete is not a new material. It has already been used in structures like the Sydney Opera house, but its sustainability and cost-effectiveness make it an increasingly popular choice among contractors.

It takes less energy and materials to produce precast concrete than pouring and curing concrete on site, which is a great advantage.

Typically, precast concrete will be cured in an off-site facility and shipped to the construction site. Then these precast concrete slabs can be placed and affixed together.

For projects that require a lot of identical components, this can be a cost-effective way to finish buildings faster. You won’t have to worry about the weather or wait a long time for the concrete to reach its full strength before you start a new task.

Zero-Carbon Cement

When you consider the fact that the cement industry produces a quarter of all CO2 emissions in the construction industry, it’s no wonder researchers are trying to find greener solutions.

Companies like DB Group have created ultra-low carbon concrete with a carbon savings of 80% compared to traditional concrete mixes.

Their product, Cemfree, doesn’t contain cement but still retains its strength, and it has already been used for commercial and public projects in the UK.

For companies wanting to reduce their embodied carbon, this is a great solution.

Air-Purifying Facade

What if your building could clear the air around it? This is not mere science fiction because the technology to do so is already here.

Builtd, an architecture firm from New York City has created a residential tower with an air-purifying façade. They used Neolith sintered stone slabs treated with Pureti, a photocatalytic finish that can remove pollution and improve air quality.

Some tests have shown that the material reduced harmful nitrogen oxide levels by 70-80%.

The result is a purifying and self-cleaning façade that will surely become a construction staple for more eco-conscious developers.

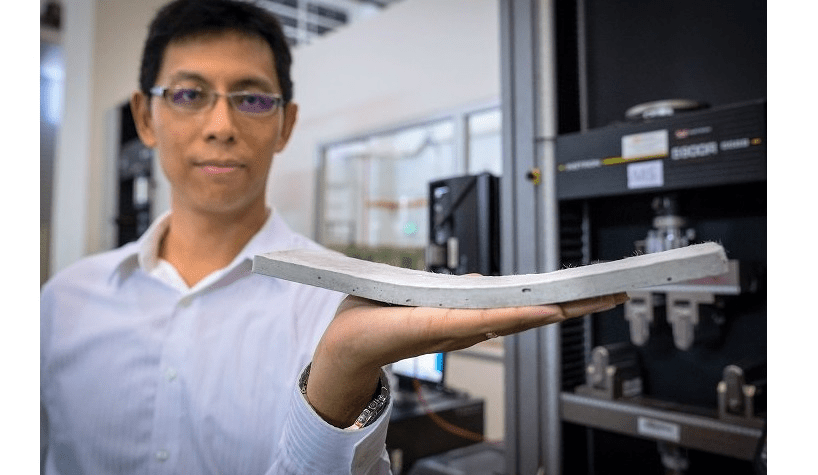

Bendable Concrete

As you’re well aware, traditional concrete is a solid material you can’t bend without producing cracks.

Since these cracks are costly to repair and generate carbon emissions in their own right, producing concrete infused with polymer fibers which make the material more flexible is presented as a solution.

Not only does this material crack less, it also provides more shock absorption. The only downside is that it can cost four times more than standard concrete.

However, the investment might be worthwhile because you’ll spend way less money repairing cracks down the line.

Conductive Paint

Conductive paint is essentially paint that conducts electricity. But where would you use that in construction?

The system works like this. First, you place electrodes around the outer layer of the building. Then you put conductive paint, which consists of conductive pigment (particles of silver, copper, graphite, or nickel) dissolved in liquid.

After that, an electrical current passes through the electrodes, and an algorithm determines changes in electric potential.

Conductive paint can be used to create sensors that help optimize energy efficiency. Bare Conductive, a company behind Electric Paint (a conductive paint product), says their clients even monitor water leaks with such censors.

And that’s just the beginning. There are many unexplored possibilities for effective and widespread industrial use of conductive paint.

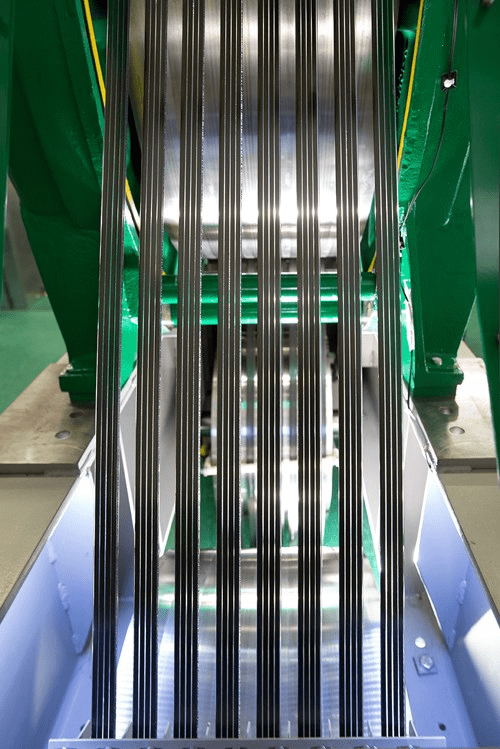

Carbon Fiber Rope

According to Simon Kim, an architect and principal at Ibañez Kim, carbon fiber is highly performative, which means that it’s very light but can take enormous loads.

This is promising for the construction industry and the development of skyscrapers, but namely, for elevator technology.

When the carbon fibers are woven into ropes, they can replace steel rope and support elevators twice over the current weight limit.

Kone, a Finnish company, is already producing UltraRope, a carbon fiber rope that can pull elevators up to a kilometer in height. An additional benefit is that it requires less maintenance and will last twice as long as a steel rope.

Invisible Solar Cells

Have you ever wondered how much solar power could be harnessed if every window in a skyscraper was turned into a solar panel?

Well, you don’t have to wonder anymore, since researchers and manufacturers are doing exactly that! The invisible solar cells are taking in ultraviolet and infrared light to make energy. They could be installed into windows or doors, thus seamlessly blending into buildings.

Therefore, we don’t have to restrict solar panels to roofs, and we can extract more energy by putting invisible solar cells in buildings with large glass surfaces such as skyscrapers.

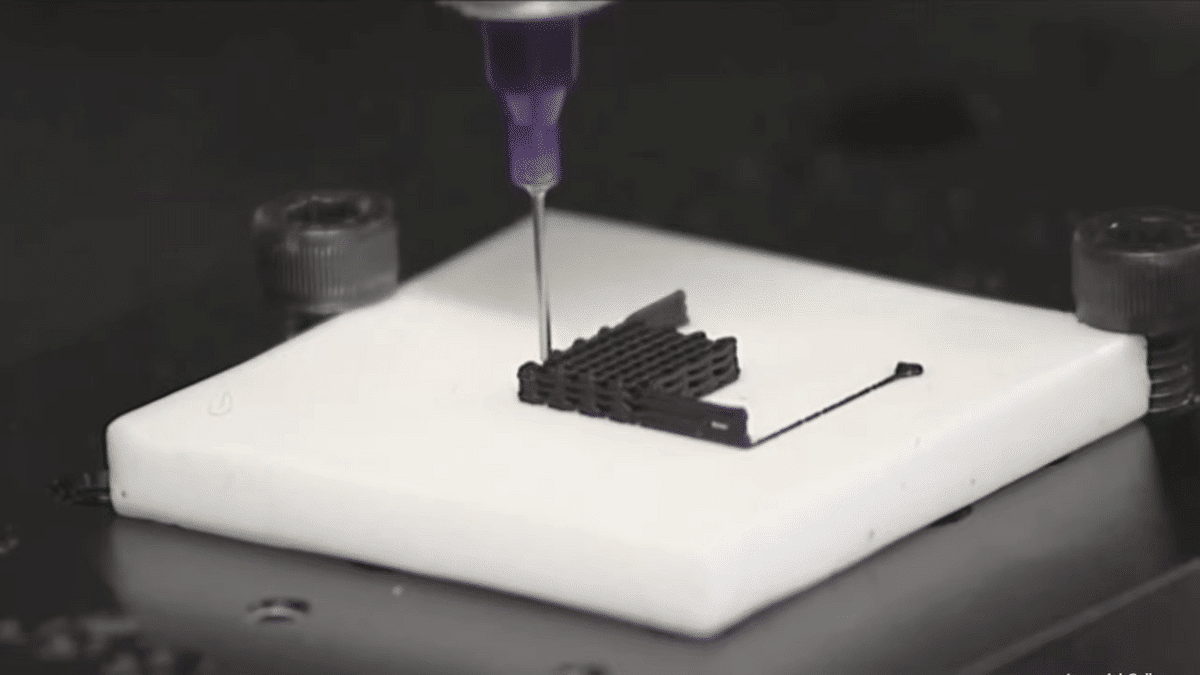

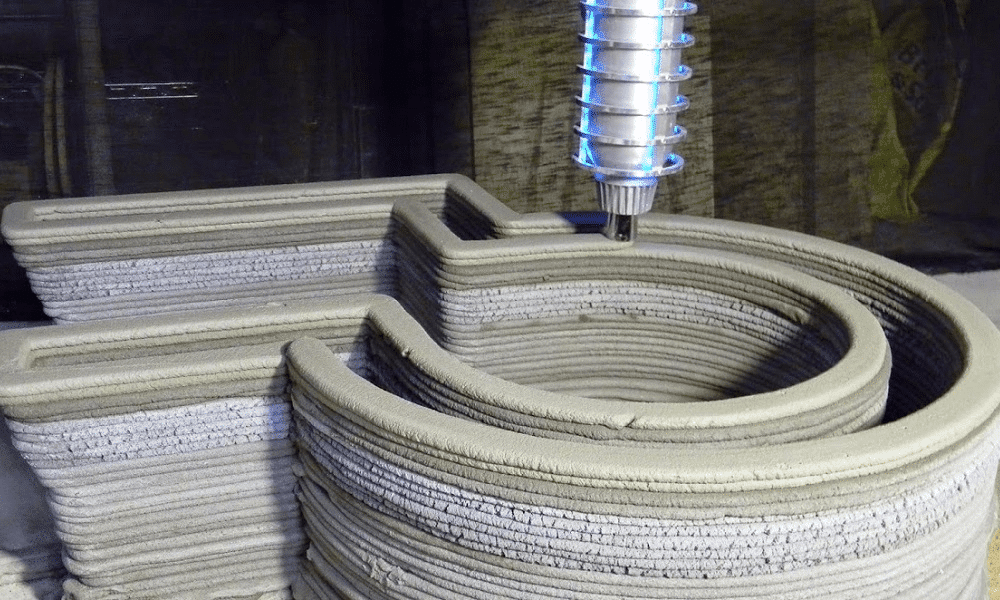

3D Printed Concrete

3D printing has enabled contractors to design and construct buildings faster, save money and produce less waste. 3D concrete printing is no different.

Basically, you can design any shape and create it using a special mix of concrete that flows through the nozzle of the printing machine. The concrete is poured in layers, one over the other, until the final structure appears.

Simply put, this eliminates the need for using molds, and 3D printed concrete can cure in three days. So, it’s a faster, cheaper, and more sustainable new method of creating concrete structures.

The only downside is that the technology is still developing as different mixtures and techniques are being tested. Also, these 3D printers need to be larger than the project being built, so they might not be suited for large-scale projects.

Nevertheless, this technology looks promising. It seems set to bring more efficiency to construction sites worldwide.

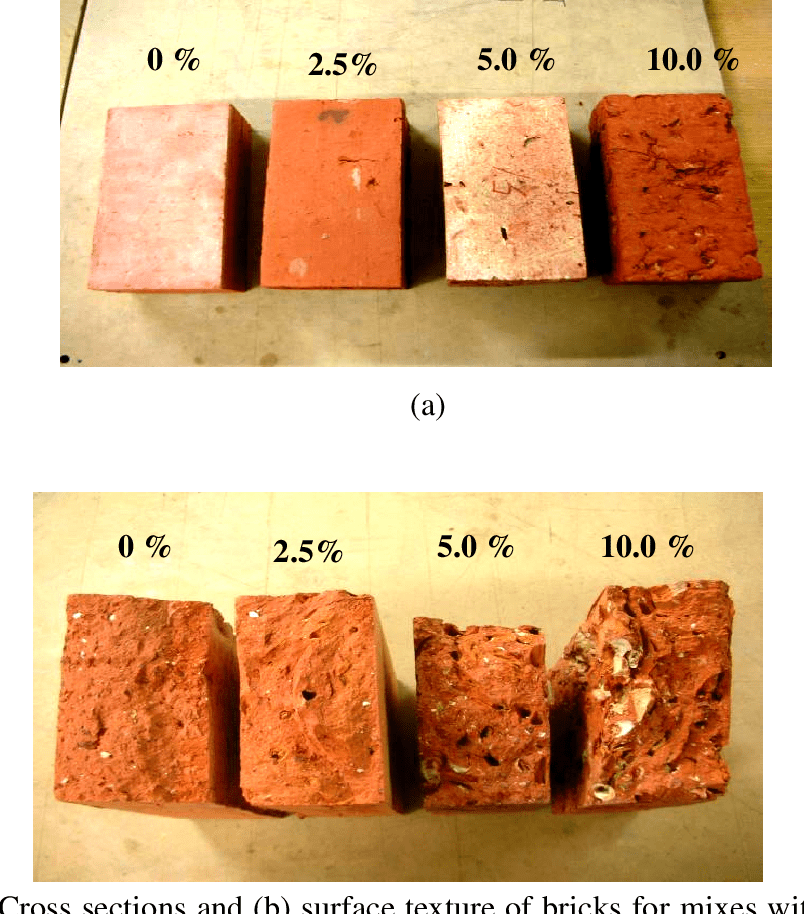

Cigarette Butt Bricks

Smoking is universally considered a bad habit. When it comes to the environment, the issue is that cigarette butts create a lot of harmful waste.

They’re made from cellulose acetate, which takes decades to decompose. They also contain toxic chemicals that can cause genetic damage to birds.

So how to combat this problem?

Royal Melbourne Institute of Technology (RMIT) has come up with a solution. They’re creating a sustainable building material—cigarette butt bricks. This material is produced by adding cigarette butts to the mixture needed for brick production.

This results in lighter bricks with better insulation properties, so you’re solving energy and environmental problems simultaneously.

Conclusion

Even though some of the materials we’ve described are still in development, they’re well on their way to becoming a staple of the construction industry.

Construction companies that want to be competitive need to stay up-to-date with the latest innovations in construction materials. Creating stronger, more sustainable buildings will give your clients more value, improve your bottom line and protect the environment.