Let’s start with some good news, shall we?

According to a recent report by Commercial Construction Index, almost 37% of contractors expect revenue to increase in the coming year, and 24% of them expect their profit margins to rise as well.

These numbers are great because more money usually brings more investment into the company.

This investment usually comes in the form of buying more equipment to support upcoming projects. The above mentioned report confirms this and states that 40% of contractors say they’ll spend more on tools and equipment in the next six months.

While reinvesting in your business is always commendable, there are unexpected challenges that come with owning a lot of equipment.

Now, if you’re one of those who want to increase their inventory because of new projects, let’s take a look at some problems you might be facing if you own a lot of equipment.

In this article...

Estimating Equipment Maintenance Costs

Whether you have new or used equipment, keeping them functional is vital. You can’t accomplish your project goals without properly maintained equipment.

So, many construction companies try to avoid unexpected delays and low productivity by routinely upkeeping their equipment. This resulted in the repair service market hitting a $43.6 billion market size in 2021.

But estimating maintenance costs becomes difficult when you have a lot of equipment.

Calculating costs is different for a fleet of 100 pieces of heavy machinery than a fleet of 20 excavators simply because you’ll have to pay more for spare parts, software upgrades, mechanic’s time, and so on.

Another thing to consider is that these costs will have to be budgeted for the entire lifetime of your fleet, so it’s essential you have a good financial plan for keeping up with maintenance costs.

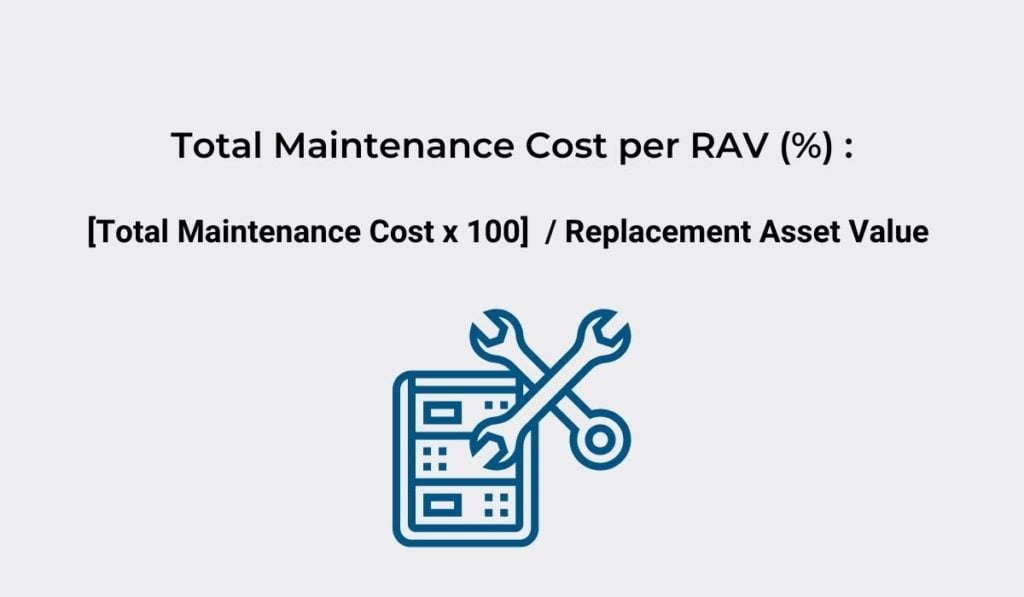

One piece of advice is to budget between 2-5% of the asset’s total replacement value (RAV).

With RAV, you can easily calculate if the cost for repairs and replacement parts is justified compared to buying an entirely new piece of equipment.

If the maintenance costs exceed your expected RAV, it might not be worth maintaining the machinery.

Of course, the RAV numbers are not set in stone, and the %RAV is different for higher costing equipment, but this is a good starting point to estimate your maintenance costs.

Also, keep in mind that %RAV can increase or decrease as your equipment gets old.

In the end, keeping your equipment in good operational condition is necessary, but maintenance costs might become too high if you own a lot of machines.

Equipment Obsolescence

Think about the leaps in technological advancement we’ve made in the past ten years. So many devices and a lot of equipment went out of use and were replaced with new models.

So, if you buy cutting-edge heavy machinery today, you can expect it will become obsolete in two to five years.

This poses a concern for those with a lot of equipment because a good portion of your fleet might not be up to par with the industry standards in a few years.

This doesn’t only mean your ten-year-old excavator won’t have the same load capacity as the newest model, but it also might lack some essential features and software that will be required by law.

For example, the current governmental concern is to decrease pollution in the construction industry, so manufacturers are designing fully electrified vehicles and machinery.

This means that stricter regulations will increase your total cost of ownership for old non-complying equipment and even forbid you from using or renting it.

Here’s another interesting trend to consider.

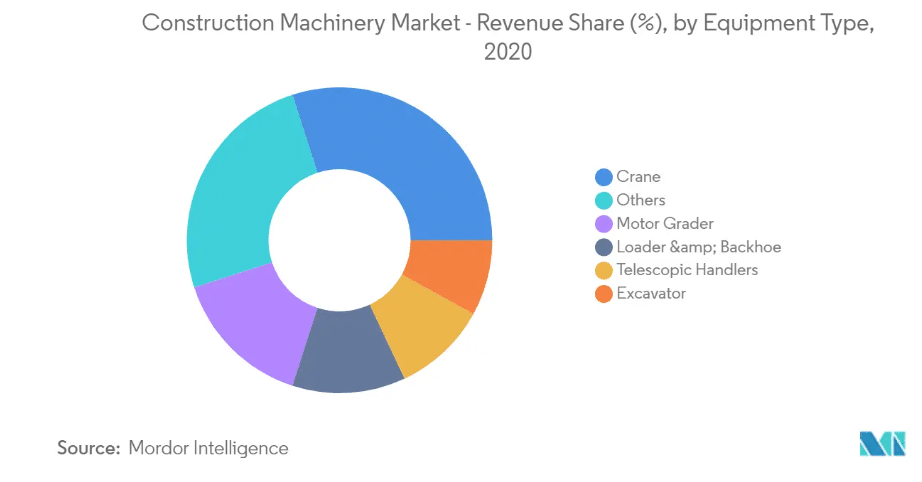

In 2019, the high demand for skid steers and excavators had reached $110 billion in global sales.

But just a year later, another research reported a new demand for cranes in the largest construction markets–North America, Europe, and Asia which significantly surpassed the need for excavators.

So what happened to the skid steers and excavators that were bought a year ago?

Well, they were probably shifted towards projects that required them, like the residential market.

But it’s interesting to see how the industry shifts rapidly towards new construction demands, which consequently results in new trends in equipment requirements.

What can we learn from this?

When you own a lot of machinery, you could spend more on storing and maintaining your equipment than actually using it.

Customers are more concerned with project outcomes, so if your old equipment can’t fulfill the expectations, you can’t use it to complete the project’s demands.

Manufacturers are also keeping up with technological advances and the newest regulations, making old heavy machinery obsolete with each new model.

In the end, whether you own a lot of old or new equipment, one thing you can expect is that your fleet will become obsolete sooner or later.

Getting Used to New Equipment

As manufacturers develop more sophisticated equipment, there is an increased demand for training employees to use them efficiently.

Simply put, new equipment often means new controls, so it’s important that your operators know how they work.

But even if the equipment is not full of advanced software and new controls, it’s largely recommended that you train operators to handle the machinery properly.

When you own a lot of equipment, you have to be aware that no two machines are the same.

Hands-on training will ensure operators know how to use each piece of equipment in the best way possible. That way, you minimize the risk of damaging the equipment with improper use.

Second, operators will be more confident to use the machine to its full potential and spot when there’s a performance problem during their daily checks. This will help you prolong the lifespan of your equipment and reduce costs.

Third, with proper training, you’re ensuring all your new hires are up to speed with safety and operational procedures when it comes to operating heavy equipment.

You’re advancing their skills, but you’re also creating a safe working environment.

Finally, there’s one thing you have to remember. Onsite and hands-on training works best to ensure your operators are familiar with your heavy equipment.

When they use and train on actual machines they’ll work with, they’ll be more competent and fulfill their tasks as expected.

Training workers to operate a large fleet might seem time-consuming, but if you want to avoid costly damages and comply with safety standards, then you’ll have to invest time in doing it properly.

Facing Equipment Depreciation

Whether you use them or not, your assets will be worth less than when you first bought them. So, equipment depreciation is a metric that shows how much a piece of equipment is losing in value each year.

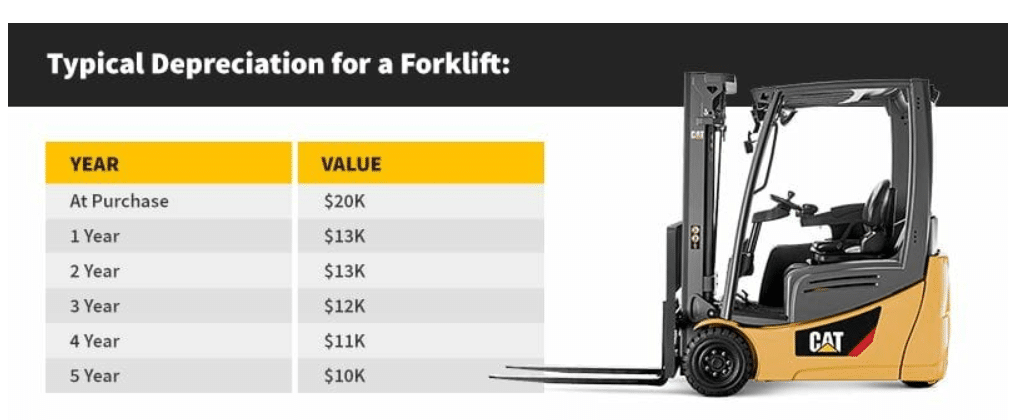

Here’s an example of a forklift’s depreciation.

As you can see, depreciation is the highest during the first year after the delivery. On average, heavy equipment loses 20-40% of its value within the first year after purchase. After that, depreciation slightly becomes linear.

But why is this important?

First, equipment depreciation can help you write off item costs as assets lose value. This means you’ll have to pay less in taxes for business assets as years go by.

Furthermore, you can make better decisions for maintenance or re-investing in newer equipment.

Knowing equipment depreciation can help you during the reselling process. With the correct depreciation calculation, you’ll get back the most money out of your old equipment.

So to calculate depreciation, you’ll need to look into four main values:

- Cost

- Salvage

- Book

- Useful life

If you want to learn more about asset depreciation, read our dedicated in-depth article.

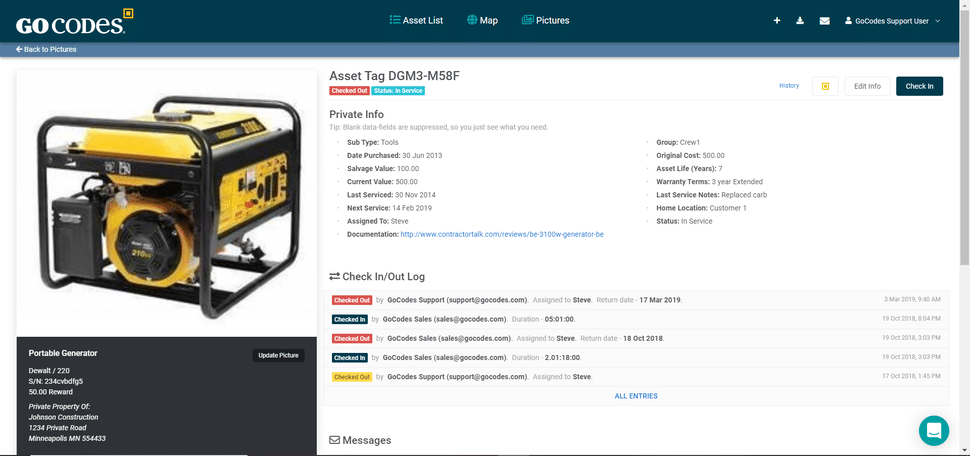

Managing Equipment Availability

With a lot of equipment comes the increased responsibility of managing it properly. This means knowing when and where your equipment is at all times.

With this data, you can allocate your assets to job sites and handle equipment requests. Additionally, if you also rent your equipment, you’ll know which assets are available so you can avoid double-booking.

How to handle equipment management most efficiently?

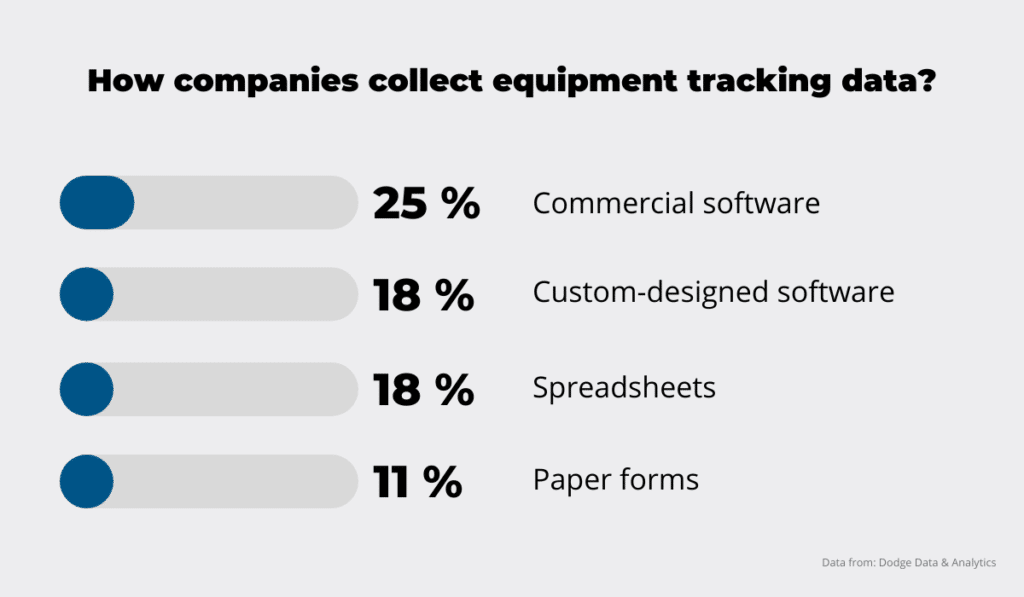

Your go-to method might be using spreadsheets. This is still a popular method among many contractors due to the low cost, ease of use, and minimal implementation needed.

But when you have a lot of equipment, you’ll have to manage a lot of data, and mistakes can happen more often.

Over time, this can lead to data entry fatigue. This means that people could enter wrong data, skip a step, or copy the information over existing data.

Data analysis with spreadsheets can be unreliable, and you can’t make good business decisions based on wrong information.

That’s why more contractors are switching to asset management software. Some opt for in-house solutions, but a vast majority invest in commercial software.

Having a centralized system is invaluable to handle equipment requirements for many projects at the same time.

But besides full visibility of your assets, you get real-time updates to their location, which allows for quick action in unexpected events (such as weather conditions, breakdowns, etc.).

In the end, if your workers don’t know if an asset is available, they won’t use it, so it might as well not even exist for the company.

With an asset management system, you’ll ensure your fleet is organized and accessible to the right people.

Monitoring Equipment Utilization

As you track your equipment’s availability, you can also track its utilization. In other words, if you properly allocate your resources, you also ensure you’re using them to their fullest potential.

With a lot of equipment, you can easily overlook certain machinery and underutilize them.

Sometimes projects might not require a portion of your fleet, so you can rent them instead of letting them collect dust in storage.

Basically, equipment in use is more valuable to your company than equipment sitting in storage. So, for this aspect of asset management, it’s also advisable to invest in digital solutions.

Tracking an asset’s performance can give you real-time data about fuel use, and engine hours.

Additionally, you can also set a regular maintenance schedule according to the data you collect. Greater operational efficiency makes construction companies more profitable.

Or in other words, the equipment you use more frequently should be checked more regularly, so you’re optimizing your maintenance costs and increasing the lifespan of all your equipment.

In the end, the core purpose of your equipment (no matter the size) is to complete the work effectively.

The only way you can maximize utilization is through a comprehensive data analysis which you can get from a good asset management system.

Issues With OEMs for Ongoing Equipment Support

Every machine breaks at some point. The scope of the damage will determine whether you’ll fix it in-house or contact the original equipment manufacturer (OEM).

If you choose the latter, there are several things you need to be aware of.

During the purchase process, you rely a lot on warranties and OEM’s support if a machine breaks at some point after delivery. But that support often becomes costly or too complicated. In some cases, the support doesn’t even cover all types of damage.

The first reason for this is that it doesn’t make business sense from the OEM’s perspective. If a piece of new equipment costs five to ten times more than repairing it, then it makes sense they’d want to push for customers to buy new.

But if you have a lot of equipment, you can’t afford to buy the newest models constantly, and thus you heavily rely on OEM’s support and warranties.

On the other hand, if your equipment is too old, the OEM might not even have the spare components available anymore.

This comes back to old equipment becoming obsolete faster than ever. OEMs create new and more sophisticated heavy equipment each year, so naturally, they’ll want to promote those.

Their main goal is to sell more equipment, so their profit will plummet if they continue to provide support for 15-year-old machines.

In the end, there is no easy solution for this problem because it impacts customers in every industry. Manufacturers will continue to make fixing their products complicated to drive more sales, but it’s up to the customer to call them out on their bad practices.

Conclusion

As you face new opportunities in construction, having a lot of equipment at your disposal might seem like a good business idea.

But, consider the pitfalls that could stunt your business growth or even damage it when you own a lot of equipment. Look at maintenance costs associated with a large fleet, but also how the market impacts equipment obsolescence.

Managing a large fleet can be challenging, but not if you invest in the right tools to make that process easier.

There’s nothing worse than having a lot of unused equipment. You don’t want to be spending money on machinery that will end up sitting in your storage for years.

In the end, having a large fleet should only be justified if you can manage it efficiently, and it makes sense for your business.