When you think about it, tires are the only thing that’s keeping your truck on the road from point A to point B. So, it makes sense to invest more time to properly inspect and care for them to ensure safety and top performance.

Otherwise, you could seriously damage your truck and cause traffic accidents by ignoring issues like mismatched tires or inadequate inflation pressure.

Let’s look into the most common commercial truck tire problems and ways you can fix them.

In this article...

Wrong Tire Selection

When it comes to truck tires, people seem to be spoilt for choice nowadays. At least, that’s what Aaron Murphy, vice president at Double Coin, believes:

“Tires, like vehicles, have become very application-specific in recent years. Different patterns, sizes, designs and components of a tire offer the vehicle the best productivity and efficiency in a specific application.”

Therefore, choosing the wrong tires is no excuse for poor results.

Don Baldwin, former product marketing manager at Michelin, also adds that incorrect application is the easiest way to reduce a tire’s effectiveness—for example, using tires for off-road conditions when they’re designed for the highway.

Premature wear and tear will become more pronounced if you push your tires on roads and conditions it’s not designed to handle.

So, how to choose the right truck tires?

First, get to know the specs of your truck tires. Have you seen the numbers on the sides of your tires?

Those numbers and letters are indicators for the following:

Tire Type | ‘’P’’ stands for passenger vehicles in the US. ‘’LT’’ stands for light trucks or SUVs. |

Tire Width | Set of numbers measured in millimeters from sidewall to sidewall of the tire. |

Aspect Ratio | Slash followed by numbers indicates the tire’s height from cross-section to width. |

Construction | ‘’R’’ means that layers run radially across the tire. |

Wheel Diameter | These numbers tell you about the right-fit size of the tire for the truck’s wheel. They are measured in inches. |

Load Index | The higher the number, the more weight your tire can handle. If there are two numbers, the first one applies to a single tire, and the second is for cases when two tires are mounted next to each other. |

Speed Rating | This letter represents the maximum speed tires can deal with. They increase from ‘’A’’ to ‘’Z’’. For example, ‘’K’’ means tires can handle 68 mph. |

After you familiarize yourself with the tire code, you can expand your tires’ performance by picking a tire to match the conditions you’ll work in. For example:

- Summer Tires

- Winter/Snow Tires

- All-Season Tires

- On/Off-Road Tires

- Trailer Tires

In the end, take advantage of the available tire choices to find the ones that suit your needs.

Mismatched Tires

Here’s a self-evident fact: truck tires wear down over time. Optimally, all your tires will wear evenly, but driving conditions, load distribution, or improper tire inflation can cause uneven wear and tear.

When that happens, most people will resort to replacing only the badly damaged tires and keep the rest to avoid the extra costs of replacing the entire set.

While that might be a good emergency solution, mismatched tires are a recipe for disaster in the long run.

First of all, mismatched tires can put additional stress on the truck’s suspension and transmission and change the handling of your vehicle, making driving in certain weather conditions dangerous.

But when are tires considered mismatched?

Apart from being in different stages of wear and tear, if you buy tires from different manufacturers or have tires of different sizes, they’re all mismatched. That is the case even if you buy identical tires, but with different air pressure.

Guy Walenga, director of engineering for commercial products and technologies at Bridgestone Bandag Tire Solutions, says that just a 5/16 inch diameter mismatch means the larger tire will drag the smaller one and cause a quick scrub on the smaller tire’s tread.

To be on the safe side, it’s always best to replace all tires simultaneously, with an identical tread pattern, size, and construction.

But since that isn’t always the most viable and cost-effective option, at the very least, adhere to a few basic principles.

When you’re replacing tires, ensure that you match them on the same axle. They need to be the same size and wear to handle road conditions and evenly distribute the weight.

Check the following features in your tires:

- Tread depth

- Tire diameter

- Tire pressure

- Manufacturer

- Level of wear

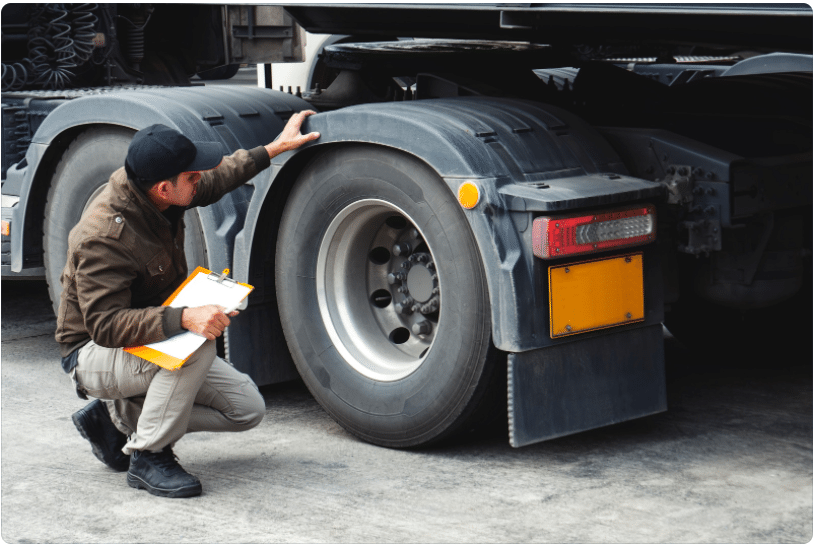

Finally, before going on the road, check all your tires as a preventative measure. This will help you uncover any potential problems and ensure safety on the road.

Sooner or later, your tires will become mismatched, but regular inspection and replacement should ensure they don’t become the cause of a road accident.

Blowouts Caused by Under-Inflation

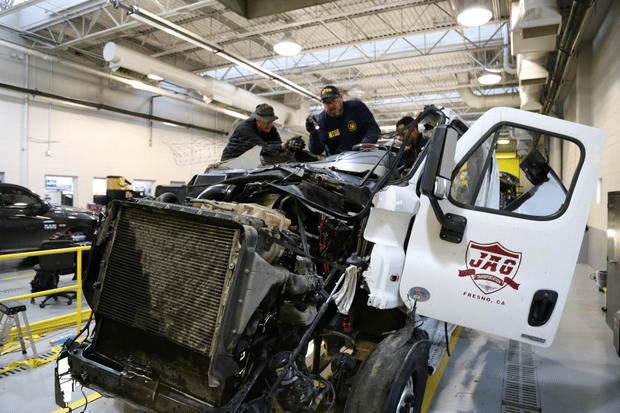

What happens when a tire unexpectedly blows out? In most cases, crashes occur.

If you’re lucky, you might avoid severe injuries or damage to the truck, but more frequently than not, tragic scenarios like this one are more likely.

The picture above is the result of when a front left tire blew out on a truck in New Mexico, causing the driver to veer in the opposite lane and crash into a Greyhound bus.

Five people were killed in that accident, and the driver miraculously survived.

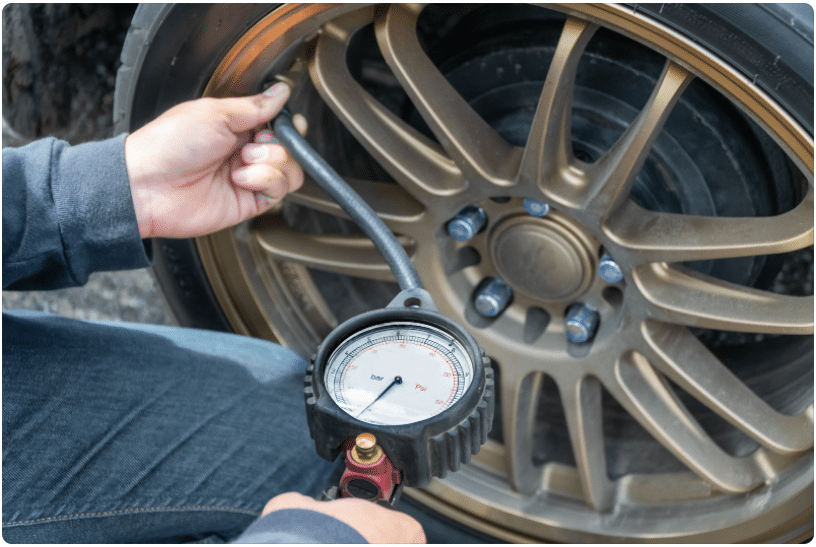

Most people believe that blowouts occur when vehicles hit an object on the road, but according to Curtis Decker, product development manager at Continental Tire, improperly inflated tires are the more likely cause of blowouts.

In fact, he estimates that 80% of tire failures are due to the tires being under-inflated.

The good news is that you can actually do something about that! With regular inspections and maintenance, you can prevent underinflation.

First, get accurate tire pressure reading from a calibrated tire gauge.

You’ll get reliable numbers that will determine your maintenance procedure, so you don’t rely on ‘’tire thumping’’ to check the pressure by ear.

This should be done at least once a week, or more frequently, depending on the kind of tire you’re using.

Another thing to consider is investing in a monitoring system to check your tire pressure and alert the driver of any unusual changes. F

or example, if the system registers sudden air pressure loss, the driver can immediately pull over, prevent further damage to the tires, and avoid accidents.

Without a PSI monitoring system, truck drivers will have to rely on unusual noise, vibration, or changes in truck performance, which might be a riskier prevention method (especially if the truck driver is young and inexperienced).

Remember that underinflated tires are an easily preventable problem if you approach them in the right way.

Lack of Maintenance

You knew this would be on our list, didn’t you?

Regular tire maintenance might prove difficult, especially if your trucks are always on the road, so the mechanic doesn’t see them as often as he should.

But, tire maintenance is unavoidable if you want to keep your trucks in optimal working condition and prevent major problems that can jeopardize the driver’s safety.

Furthermore, if you’re located in certain states, like Texas, tire maintenance is a requirement to pass the state’s annual inspection. Your tires could be rejected if there are large cracks, cuts, or damage larger than an inch in length and depth.

Other reasons for tire rejection could include structural damage, dual tires that are in contact with each other, or re-cutting of the original groove depth.

So, what can you do to keep up with regular maintenance?

The obvious solution is to conduct regular weekly and monthly checkups. But if you don’t have time or the manpower to do it yourself, consider outsourcing maintenance to a local service provider.

You can also invest in good software to alert you of scheduled maintenance, so you don’t miss an appointment.

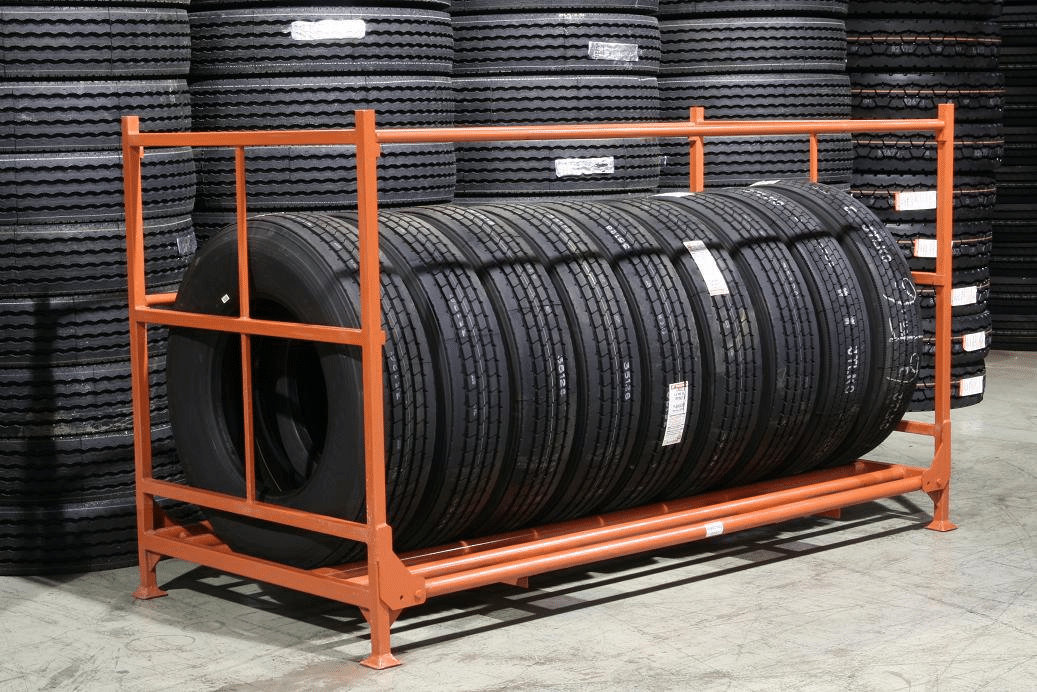

Another thing to keep in mind is tire storage when switching them for different applications. For example, how will you keep your winter tires in perfect condition during the summer?

Tires are sensitive to big temperature changes and weather conditions. So the best solution is to keep them in a dry and temperature-controlled facility that will slow down their deterioration. Here are some other things you can do:

- Remove tires from the vehicles that remain idle for a long time

- Clean and dry your tires thoroughly

- When not in use, keep each tire in an airtight plastic bag

- Lay the tires in the same direction when storing, either vertically or horizontally

Remember that tire maintenance doesn’t have to be difficult if you rely on standard procedures that ensure you comply with regulations and keep them in good shape.

Mechanical Tire Issues

Mechanical issues such as misalignment or worn-out parts can hugely affect tire wear.

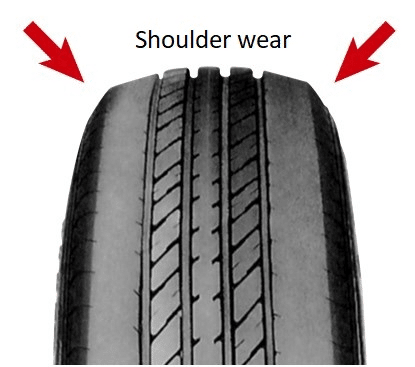

Misalignment can come in different forms, like drive axle misalignment, bent axles, or chassis misalignment. Yet, by closely inspecting the type of wear on your tire, you can identify the truck’s mechanical issues.

For example, toe-in or toe-out misalignment can cause diagonal, shoulder step, or radial feather wear on the tire.

After that is done, you can investigate probable causes further.

Then, you should also check kingpins, U-bolts, ball joints, and wheel bearings. If they’ve become worn out or loose, this will prevent the truck from driving in the straight line and accelerate the wear and tear of tires.

Another sign there’s some mechanical issue you should inspect immediately is worn shock absorbers. The tires will bounce more than they should, creating irregular patterns and a scalloped appearance.

Finally, for additional assistance in detecting tire problems, read The Maintenance Council’s (TMC) Radial Tire Conditions Analysis Guide. This will provide you with relevant procedures and methods to diagnose and repair common tire problems.

All in all, solve these problems before they get out of hand and ensure a longer lifespan for your tires.

Torque Caused Wear

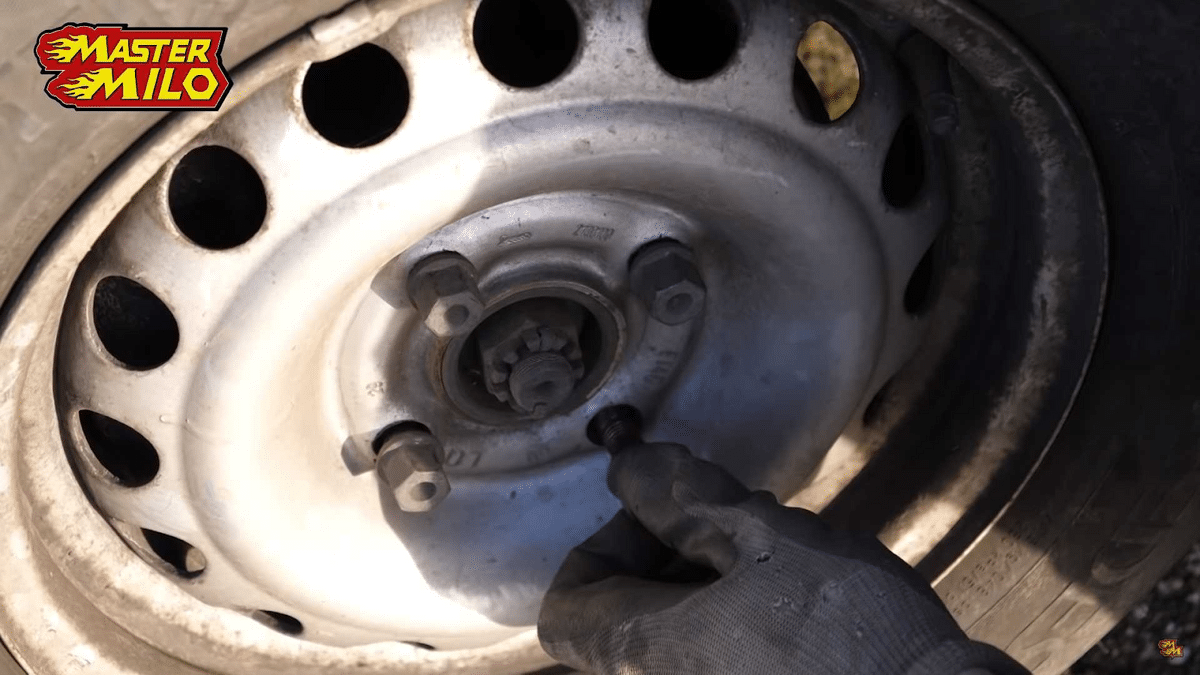

Every time you rotate your tires, mount new ones, or perform routine maintenance, pay special attention to tightening the bolts to the right torque.

These bolts don’t always stay secure, and different factors can affect them—namely, changes in metal properties, vibration, temperature, and road stressors.

Failure to regularly check their tightness can make the wheel become unstable and fall off the vehicle.

That’s why many mechanics often over-torque bolts and nuts to solve this issue, which is a mistake. Too much torque can overstretch the studs and cause them to fail.

On the other hand, insufficient torque on one nut can distribute the weight stress on others and weaken the entire hardware.

General advice is to use a calibrated torque wrench to ensure you’re torquing the bolts according to recommended specifications. But you should also revise the torque specs as the tire and wheels wear out.

Additional advice comes from Kevin Rohlwing, senior vice president of training at the Tire Industry Association.

He says that you should make sure to always tighten the bolts in the correct pattern.

This means torquing wheel nuts in a star pattern starting at the 12 o’clock position and using a dry torque for stud-piloted systems, while an oiled torque is better suited for hub-piloted systems.

Finally, inspect the tires after installation and after 25, 50, and 100 miles the truck has traveled.

It all boils down to that regulating torque will increase the quality and safety of truck tires but also prevent costly repairs to wheel alignments and brakes.

Conclusion

When it comes to common truck tire problems, most of them stem from infrequent maintenance and negligence.

Spending some extra time and effort on regular inspections can help you identify minor problems on time, before they escalate.

Ignoring these problems would only lead to increased safety issues and high replacement costs, so monitoring and managing your tires properly is the company’s best investment of time and money.