Choosing the right supplier for your construction business can mean the difference between finishing your project on time for a happy customer, and suffering a complete work stoppage as furious clients threaten to stop payment.

Especially in times of supply shortages and supply chain struggles, it’s crucial to ensure you have a relationship with fair, reliable suppliers you can count on.

Read on for some useful tips on choosing the right suppliers for your construction business.

In this article...

Shop Around for Your Specific Needs

Many contractors buy more or less the same materials for different projects, so it’s best to look for a supplier who can provide all or at least most of them.

To find out which supplier has the best deals and most consistent prices, send quote requests to different suppliers.

Give them a try, and after a few projects, you’ll see who has the best prices and is the most reliable when it comes to each aspect of the purchasing process.

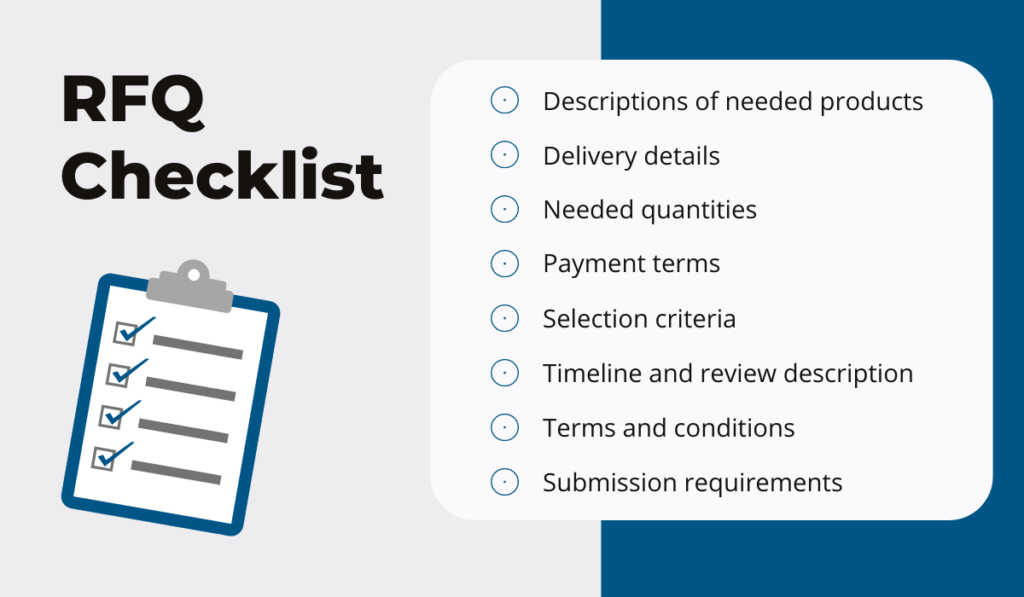

When creating an RFQ (Request for Qualifications), keep the following specifics in mind:

Reputable suppliers should have this information on hand, or at least reasonable estimates of it.

Sometimes the price and quality of supplies fluctuate due to season, supply chain issues, or market forces, but business owners who have strong knowledge and experience can anticipate these issues.

Some construction companies prefer to manage their own supplies—for example, purchasing timberland and sustainably managing the resources there to provide for a steady, quality-controlled supply of wood.

The ability to remain self-sufficient and avoid potential supply chain complications could pay for itself many times over when a market crisis such as the COVID-19 pandemic hits.

Although contractors must invest in a sawmill and manage the logistics of managing timber, it’s possible to do so with good planning or pairing with like-minded business partners.

Ask Your Network for Recommendations

Networking is easier than ever in the digital era, and it’s well worth your time to undertake targeted research.

Asking other professionals or partners in your field for recommendations is one of the best ways to choose a supplier, especially after you’ve narrowed your list down to a few names or businesses.

Word of mouth is a great way to gain honest and nuanced information about a supplier’s customer service.

To cast a wider web, you can join a construction association and check with colleagues in your area. In addition, groups such as ContractorTalk are good places to quickly find answers to targeted questions.

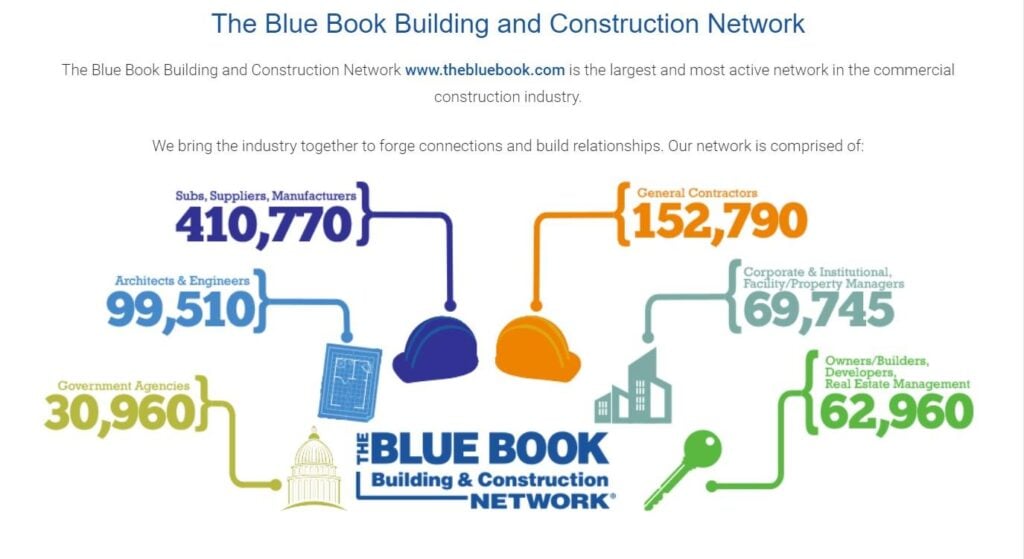

As the above graphic indicates, building and construction networks can extend far outside your own area of expertise.

If you know a lot about engineering, for example, but don’t have much experience in choosing suppliers or working with real estate management, reliable answers are just a few clicks away.

Especially if you see red flags in the potential suppliers you are researching, for example, if the business is offering prices that seem too good to be true, or you can’t uncover much about the supplier online, checking on this information could save you a great deal of time and trouble.

Fellow contractor professionals seldom shy away from steering colleagues away from unethical companies, so use their wisdom to find the best supplier available for your needs.

Learn About Your Supplier’s Background

Once you find a suitable candidate for a supplier, it’s time to feel them out and get a better sense of their background.

To do that, just ask the business a few specific questions on important factors such as:

- how long the company has been in business

- how much experience the team has

- whether or not they can work with potentially specialized aspects of your project

- which parts of your project they are particularly prepared to work with

- if references are available

- do they have the capacity and infrastructure to meet your needs

- the scope of past projects (can the company supply the right amounts of material at the right time?)

In addition to this information, invest time and resources into a credit check. Will this business become a weak point or liability for your project, and create problems that can set off a chain-reaction disaster?

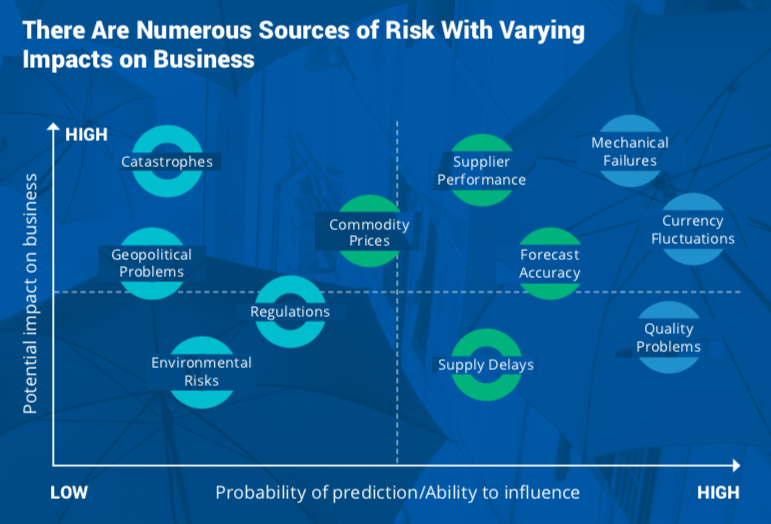

The graphic below notes risks to watch out for when assessing your potential suppliers:

Of these probability predictions, note that supplier performance is high in both the potential impact on a business as well as the probability of prediction or ability to influence.

One of the ways to predict good supplier behavior is by taking a thorough look into potential past wrongdoings, patterns of failure, or constant default.

Taking the time to examine these matters, then, can help to avoid other potential problems with quality.

To sum up, working with a new supplier carries with it a certain risk. To mitigate that risk, be diligent in finding out everything you can about your potential supplier and checking if they are an upstanding company.

Look For Good After-Sale Service Terms

If you’re looking for a supplier for equipment and parts, the after-sale service is one of the most important considerations. Reputable suppliers stand behind their products and never “ghost” when the delivery is completed.

What are after-sale service terms? These can include the items listed in this visual aid:

After-sale support provides solutions, advice, and guidance. They might also have the ability to provide operator training, maintenance instructions, or even onsite visits.

Sometimes, after-sale support includes software troubleshooting, liability agreements, and remedies for damages.

Look for details about these items in the contract with your seller and bear in mind that quality suppliers and contractors stand behind their work and go above and beyond to help ensure their clients’ projects are successful.

Check the Quality of the Supplies

Your job as a construction professional doesn’t end after you’ve chosen a supplier and signed a contract. In some ways, checking the quality of your supplies is just another step in building a relationship with your supplier.

It’s important to ensure that your materials are compliant with all appropriate regulations, quality standards, and legal requirements.

For example, you should never accept repurposed or recycled metals for key structural components such as metal rebar or steel columns.

Doing so could affect the integrity of the entire structure, and you might be liable in the event of instability.

Ask about warranties and guarantees, insurance, licenses, or quality certificates. In addition, each item should receive inspection on a number of points.

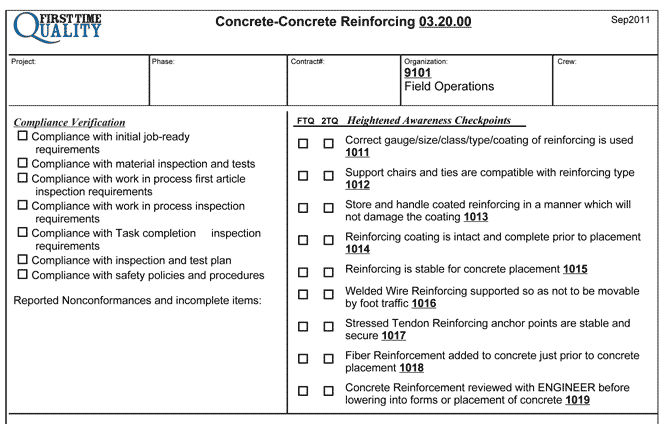

Here’s an example of a quality checklist for concrete reinforcing.

Not only do checklists such as this help your team remember each item, but they can also be helpful in the event of litigation or compliance checks.

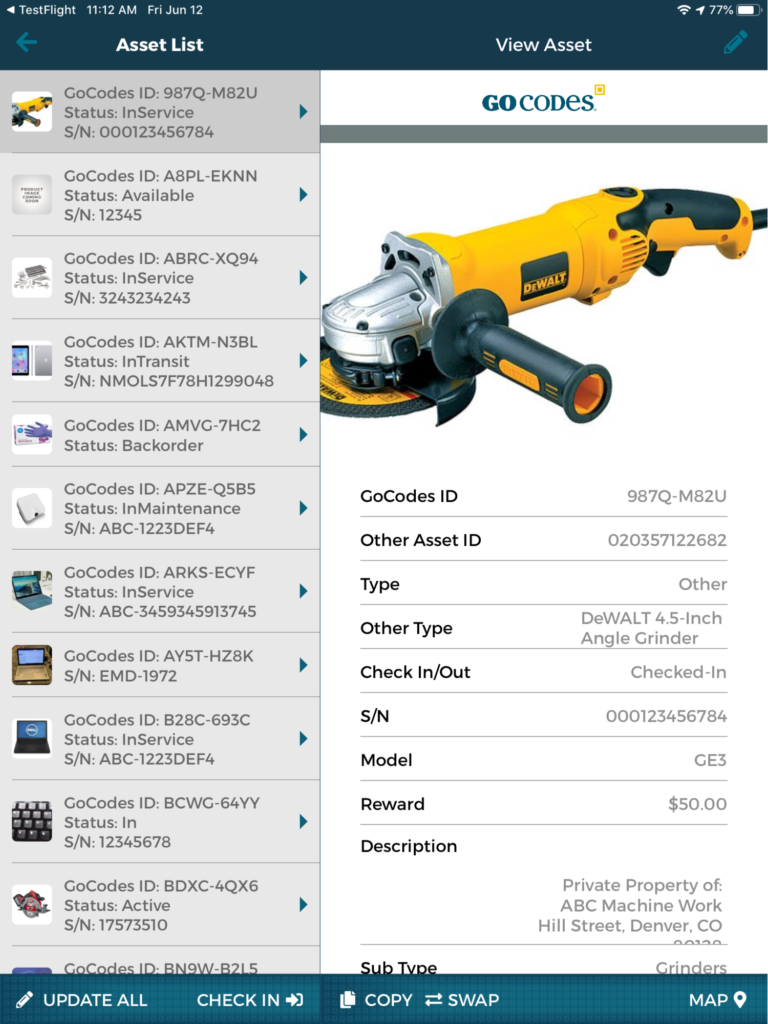

Maintaining records of such complex information is easier with a strong, multifaceted asset tracking system, such as our own product, GoCodes Asset Tracking.

Asset tracking not only provides a GPS location update as your materials proceed through the supply chain; it can also help to alert you when supplies are low, ensure employee verification, maximize efficient resource distribution, and provide a chain of employee custody for each item or shipment.

Once your materials become integrated with an asset tracking system, you can also generate reports or access centrally-sourced information with just a few clicks.

Best of all, the data is easily stored in the cloud for better security and reliability.

In conclusion, verifying the product quality of a new supplier can be a huge responsibility, especially if there’s a lot of material to check.

Investing in asset tracking helps to ensure all the hard work that went into choosing your suppliers is prime for preservation, updating, and accurate analysis.

Aim for a Long-Term Business Relationship

It might seem tempting to constantly be on the lookout for new suppliers, especially if one offers an irresistible price or if you’re temporarily unhappy with your current one.

However, jumping from one supplier to another ultimately wastes time and money. It can also compromise the stability and quality of your projects.

If you won’t commit to a supplier, why should the supplier commit to you?

Canceling orders at the last second, making accusations about inferior quality without first examining the situation, and failing to place orders in a reasonable time frame can greatly damage your business relationship with your suppliers.

Instead, investing in a long-term relationship with a supplier is beneficial to both sides.

Establishing yourself as a prompt payer, reliable client, and trustworthy professional will buy you a great deal of goodwill in times of financial fluctuations, supply chain emergencies, and worksite complications.

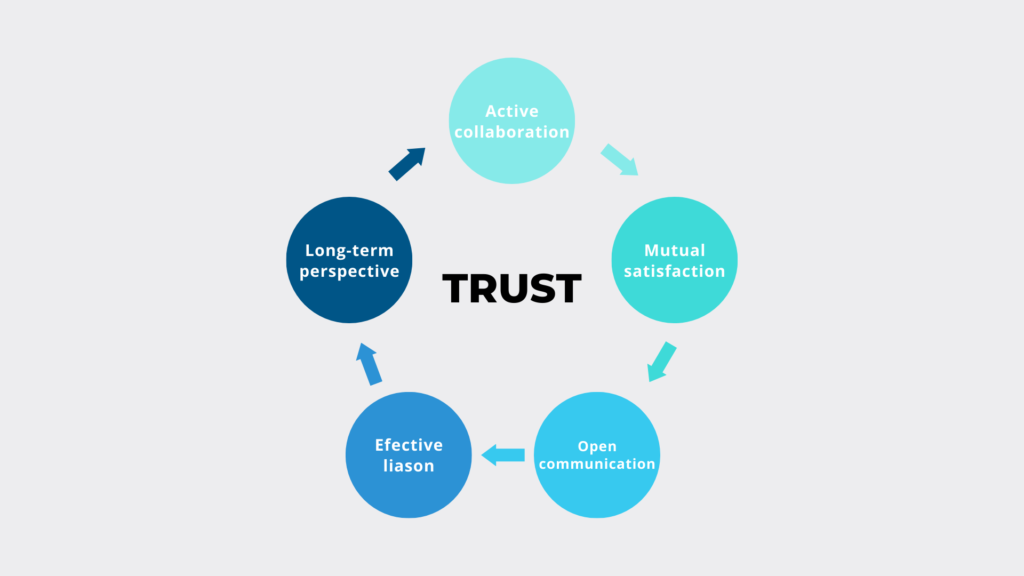

The graphic above shows the various aspects of a trust-tested relationship. As you can see, honest communication, satisfaction on both sides, and a commitment to fairness are essential from your side as well as your supplier’s.

Sticking with the same satisfactory supplier instead of “trying out” slightly less expensive competitors can result in many benefits:

- Increased efficiency and reliability in the supply chain

- Better communication as you work with the same employees

- Reduced costs on bulk items

- Ability to outsource such activities as customer service interfacing

- Honest feedback and opportunities for improvement

When you establish a long-term relationship with your suppliers, you establish yourself as a more dependable professional throughout the industry. Your reputation then gets communicated to your client.

For example, if you know you can reliably source quality bricks on short notice because you have a longstanding relationship with a certain supplier, not only do you have an advantage over your competition, you have proven yourself as a valuable team member to your client.

Clearly, stability, reliability, and trust are qualities that can help you deliver outstanding results.

But in order to get these traits from a supplier, you’ll need to exhibit them yourself. As they say, you only get what you give.

Conclusion

Choosing the right supplier for your construction business is vital to keeping your team equipped with the raw materials it needs, from the tiniest nails to entire pre-fab buildings.

When you take time to shop around for specific needs, ask your network for recommendations, and learn about your supplier’s background, you stand a better chance of making a knowledgeable choice.

Moreover, good after-sale service terms can help you with training, maintenance, and obtaining parts or service.

Finally, regularly checking the quality of supplies and fostering a long-term business relationship can pay great dividends over time.