Choosing the right profession for yourself can be overwhelming. You want a job that pays well and offers long-term security, while also providing you with opportunities for growth.

Pursuing a career as a heavy equipment operator checks all three of those boxes.

If you want to become a heavy machinery operator, this article will help you understand not just how to achieve that, but how to be good at what you do.

So, let’s get right into it!

In this article...

Get Relevant Education

Education is key to nailing just about anything, including the job of a heavy equipment operator.

From an outside perspective, it may seem like machine operators simply move materials around the construction site or install them. However, there’s much more to this job than that.

Just think about it: heavy equipment operators are in charge of operating the equipment while keeping themselves and those around safe. This requires a certain level of education and training.

That’s why a heavy equipment operator has to have a high-school diploma, at the very least.

If you excelled at maths or technology at school, you are likely to have an easier time getting a job in the field. After all, these subjects are closely related to the skills necessary for the position.

However, since secondary education represents the bare minimum of necessary qualifications, many people invest in further education instead of trying to find a machine operator job right out of high school.

Some opt for a union or state apprenticeship because of the benefits they offer. These options allow you to get on-the-job training and work directly with the kind of equipment you’ll be dealing with in your own workplace.

Moreover, after your apprenticeship ends, you may be offered a job with the company that trained you, which means that you get a work opportunity on top of all the training and experience you’ve gained.

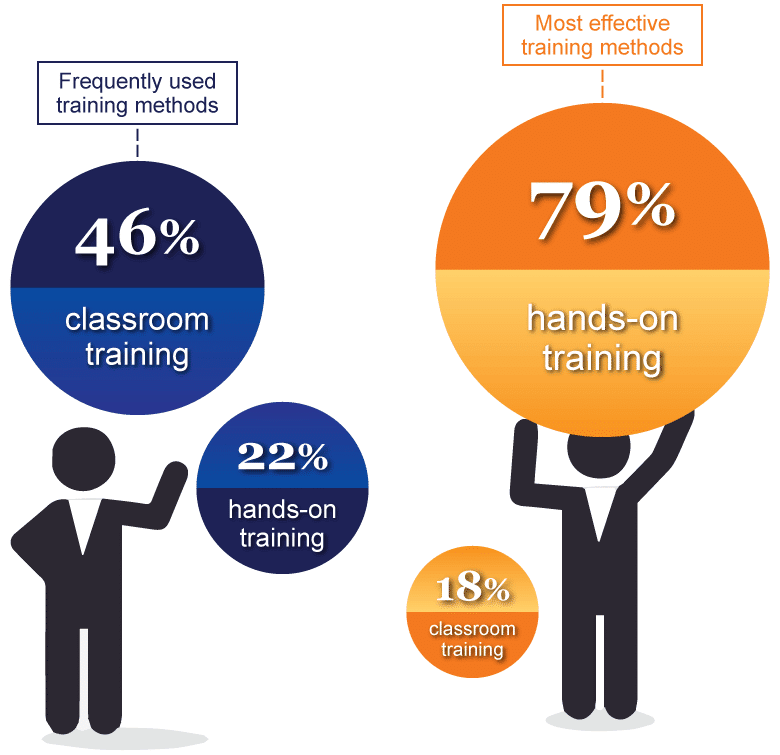

In simpler terms, an overwhelming majority believes that learning is easier if you get to do the task yourself instead of watching someone else do it or just hearing about it.

Sadly, only 22% of trainees got to experience this method, as most mentors opt for old-fashioned classroom training, which is four times less effective.

Finally, instead of an apprenticeship, some people pursuing a career operating heavy equipment choose to continue their education at a college or a technical school.

This option typically lasts longer than an apprenticeship and doesn’t offer as much hands-on experience, but it promises a higher wage after getting a degree.

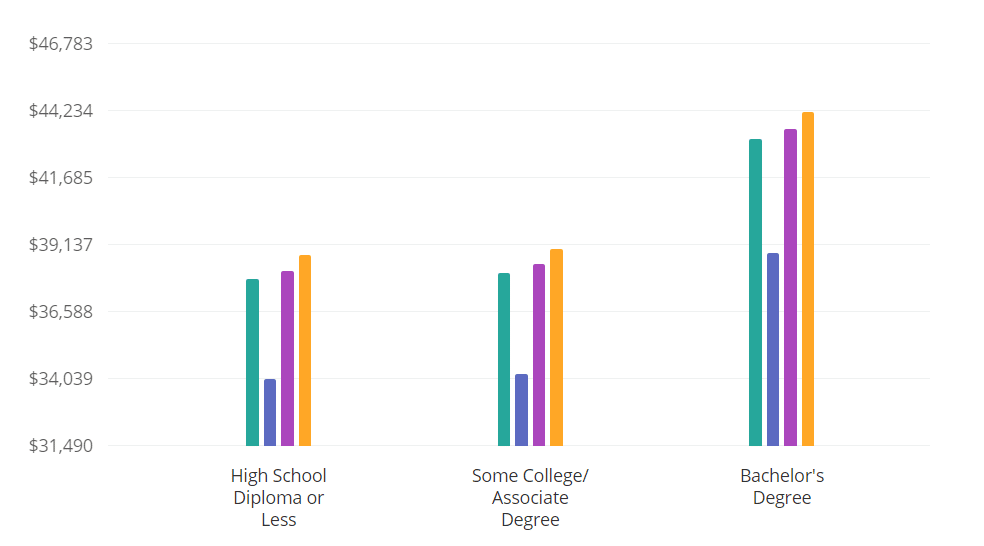

When looking into the average salaries in the field, Zippia’s research has found that they increase with the level of education. So, if you choose to get a college degree instead of going for an apprenticeship, that’s a significant advantage.

Nevertheless, if you want to be competitive in the construction business as a heavy equipment operator, you should focus on earning licenses and certifications on top of your degree.

Some, like the commercial driver’s license (CDL), are a must-have if you want to be considered for the job. After all, you will be operating large machinery and often moving it from place to place, so driving skills are essential.

Others, like certifications to operate specific machinery, are required by some states, so you should look into the regulations in force in your area before applying for jobs. Certificates usually have to be renewed every five years to stay current, but they go a long way.

To choose the right education path for yourself, you should first understand what the market is looking for. Otherwise, you might not be as competitive as others applying for the same spot.

Understand the Market and Its Needs

Before becoming a heavy equipment operator, you should know what to expect from your future job.

Do extensive research to figure out:

- whether to get a degree

- what kind of training you need

- where there’s a need for equipment operators

- how well you can get paid across the country

This information will help you determine whether it pays off to be a machine operator.

For example, if your state has more than enough experts in this field, it might be necessary to move to a different one to get hired, which is a step you might not be ready to take.

Besides, the more you know the industry, the easier it will be to decide whether it’s the right choice for you. Once you’re sure this is something you want to do, you should start thinking about where to work.

Industry and Location

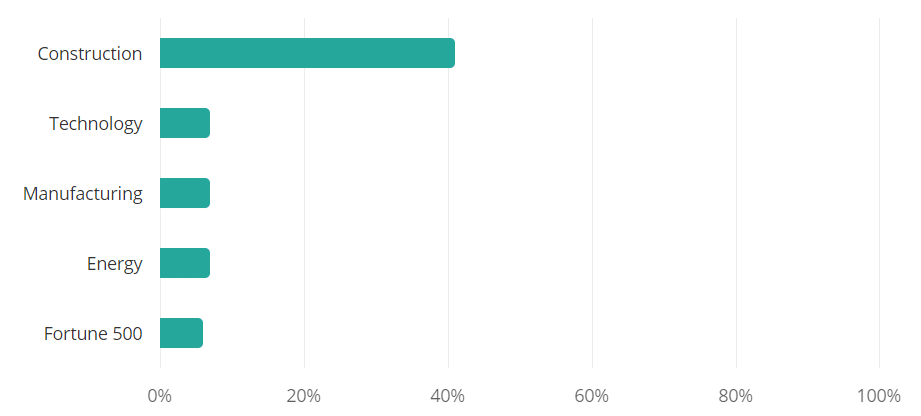

First, let’s see which industries hire heavy equipment operators to understand where you are most likely to get hired. According to Zippia, an overwhelming majority of operators get a job in the construction industry.

Other sectors that are interested in machine operators are technology, manufacturing, energy, and even Fortune 500 companies, but in a much smaller percentage.

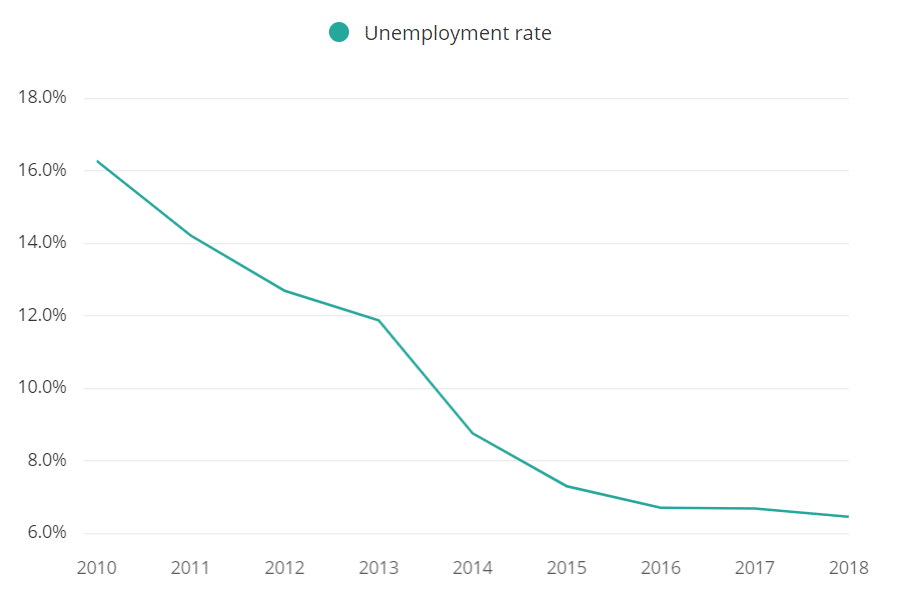

Generally speaking, you shouldn’t have a hard time landing a job as a heavy machinery operator. The unemployment rate in this profession has been going down since 2010 when it was at a high 16%.

Nowadays, only five percent of heavy machinery operators are unemployed. So, if you’re scared of unemployment, remember that there is a high chance of you landing a job in this industry.

Another thing that can help you figure out where to look for a job is your location.

Currently, according to the research we previously cited, the counties that have the most open heavy equipment operator positions are:

- Hamilton County (OH)

- St. Louis County (MO)

- Cook County (IL)

- Los Angeles County (CA)

- Allegheny County (PA)

If you’re looking for a job right now, this is where you should look since the chances of you getting hired are better there.

Source: Zippia.com

However, you can also take into account where most of your competition is. The latest data shows that most heavy equipment operators live in Houston (TX) and Phoenix (AZ).

If there are many heavy equipment operators in a country, there is some work to do.

Education and Salary

Education is the next aspect you can consider when thinking about getting a heavy equipment operator job. The chances of finding employment are higher the more educated you are, of course, but many companies also value experience.

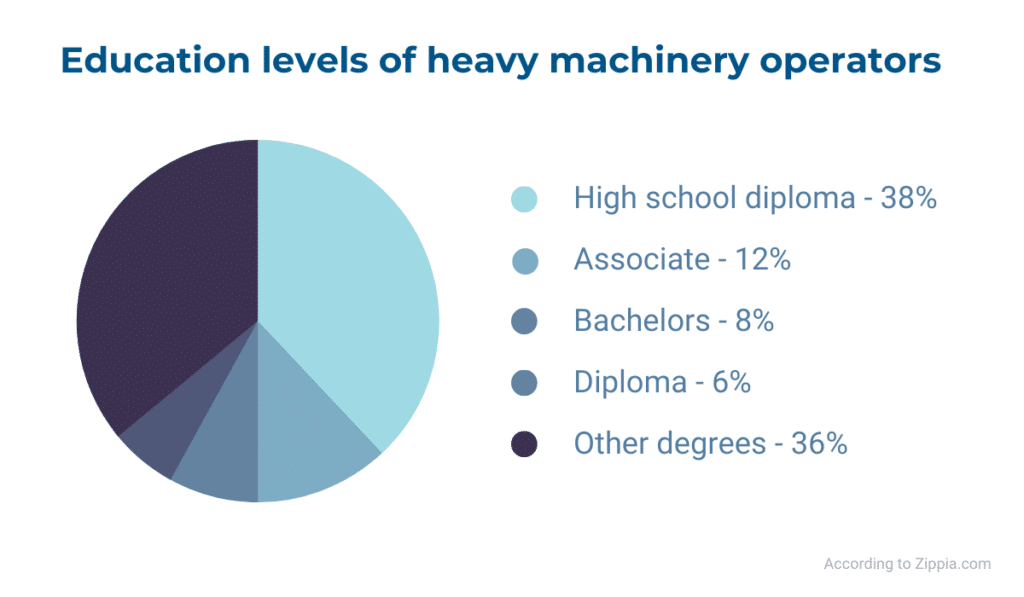

Currently, the majority of heavy machinery operators have a high school diploma.

Twelve percent of them have an associate’s degree, while less than ten percent have a bachelor’s degree or a diploma. However, 36% of them have other types of degrees.

Since the profession doesn’t exhibit a preference when it comes to higher education, you can get by with or without a degree, according to the current landscape.

But, as already mentioned in the education section, your degree will affect your salary. As mentioned earlier, Zippia reveals that the difference between the salary of someone with a high-school diploma and a degree can be up to $6,000.

So, the higher your degree of education, the more you will earn.

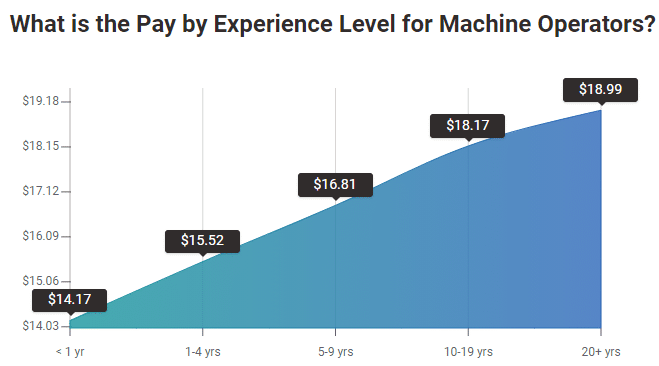

Nevertheless, experience also affects your salary. According to the current statistics, the longer you work as an equipment operator, the more you will make.

Those with little to no experience earn almost five dollars less per hour than those with twenty or more years of experience. That’s $40 for an eight-hour workday, $200 for a five-day workweek, and $800 for a work month. Annually, the salary difference can go up to $9,600.

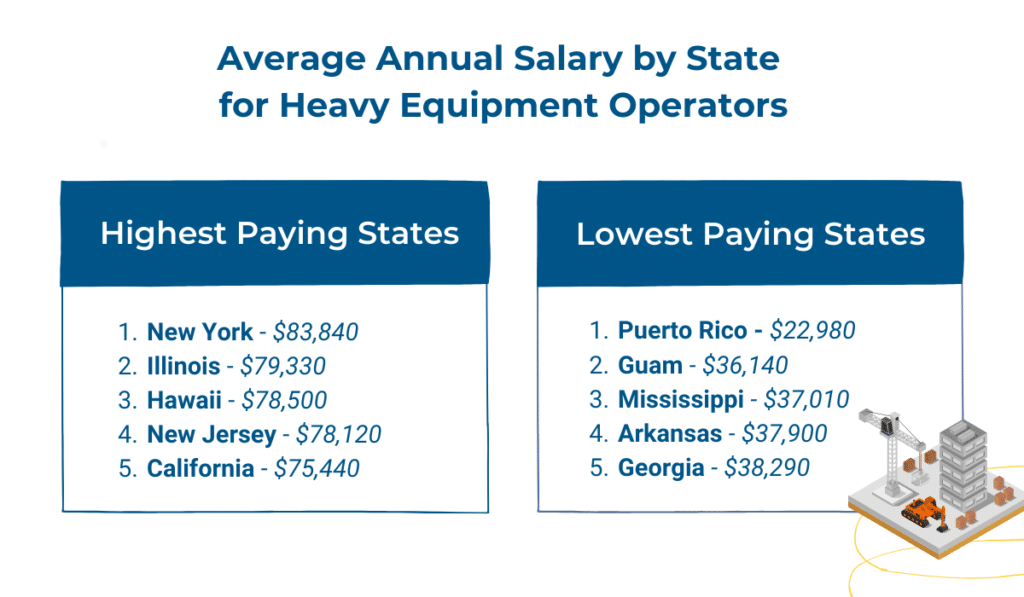

Finally, your salary can also vary depending on the state you are in, as for any other industry.

While the yearly national salary average for heavy equipment operators is $54,210, they can make over $83,000 in the highest paying state, New York. On the other hand, the lowest-paying part of the country, Puerto Rico, averages at just under $23,000.

Therefore, the difference between the two is a staggering $60,000! When choosing whether to relocate and work in another state, you should consider this data as it can significantly affect your income.

Finally, keep in mind that, if you’re a woman, you’ll earn around $2,000 less on average than your male peers. Sadly, the heavy equipment industry still doesn’t pay women as much as men, which may sway your decision about selecting it as your profession.

Because of this disparaging difference, it’s no wonder that only three percent of heavy equipment operators are female.

Work on Your Communication Skills

You can’t be a good equipment operator if you don’t hone and use your communication skills.

When people think of the qualities of a great machine operator, the first things that come to mind are skills like good depth perception, hand-eye coordination, and attention to detail. Not many would think of communication skills as necessary for this position because operators usually work alone.

However, people in this line of work should be great communicators precisely because they have to rely on themselves most of the time.

Here’s why: a construction project consists of many different stages, and each employee is vital for keeping it on track. If one task is delayed, the subsequent activities will be too. But, delays won’t happen if the issue is reported on time.

Operators spend a lot of time at the worksite waiting for the field crew to perform a task to start operating heavy machinery for the next activity and vice versa. If the two teams communicate, they can speed up the whole process and not waste as much time idling.

At the same time, operators are faced with the setback of being isolated at work: while other employees can work in groups, operators run machinery on their own. Even if there is someone around, the chances of hearing what that person is saying over the sounds that heavy machinery produces are very slim.

The main point is that if workers fail to communicate expectations from the very beginning, they can quickly run into setbacks and experience downtime.

These consequences cost a lot: the construction industry spends an extra $17 billion a year due to poor communication, which is very expensive for something so preventable.

Despite the disadvantages operators face, you have to know how and when to get your message across to other workers.

Think of it like this: if you spot something that can affect the project completion in any way, let others know.

You should get in touch with your teammates if you:

- notice an unusual noise that can mean there is something wrong with the equipment

- finish a task soon so they can prepare

- want to inform them of the opposite, so they know they have spare time for other tasks

- have to report an urgent equipment problem to the maintenance team

More and more companies are investing time and effort into making communication a priority in the field, so you might be asked to use mobile apps to communicate with your colleagues.

Some businesses use asset tracking software to establish and promote contact between the equipment operators and the maintenance team, which will impact you directly.

Because of this, you should get familiar with some of the most used tools at the worksite and understand how they function.

Being open to such technology will go a long way if your future employer opts for such tools.

Take Safety Seriously

An excellent heavy equipment operator is someone who doesn’t take safety for granted.

After proper education and adequate training, you will surely know the best practices for operating equipment. By doing that, you eliminate many safety hazards.

However, keep in mind that, while you may be familiar with the machinery and all its hidden threats, the other field workers might not be. Since you’re the one operating the equipment, you should adequately handle it to protect those around you.

Sadly, many forget this point, which often results in injuries and workplace accidents.

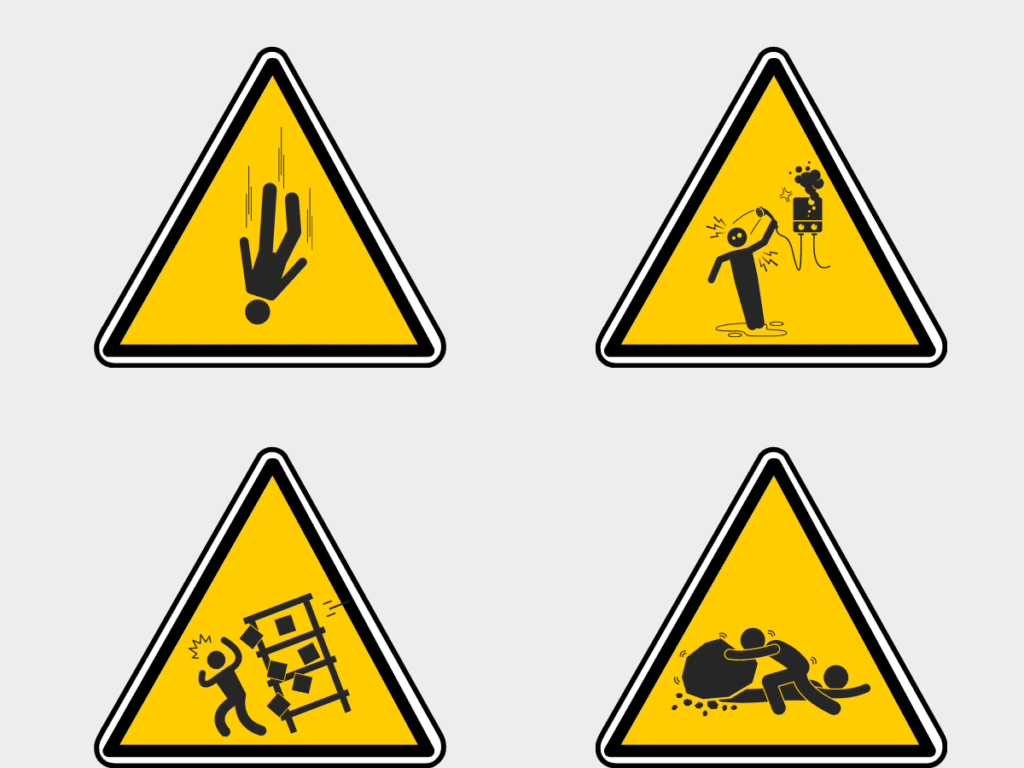

The Occupational Safety and Health Administration (OSHA) calls the four most common fatal construction injuries the “fatal four.”

These injuries are:

- falls

- struck-by injuries

- electrocution

- caught-in/between incidents

Note that the struck-by hazard is directly related to equipment at the worksite. On top of being one of the fatal four injuries in this industry, struck-by is also the number one cause of non-fatal injuries, making it all the more dangerous.

Luckily, as an equipment operator, you can work on the prevention of struck-by injuries at your worksite.

This is how: firstly, you should always get familiar with your surroundings before using heavy machinery.

Look around the work perimeter and try to spot any potential hazards. Take into account your swing radius to avoid striking an employee with a part of the machinery.

When there are workers in your equipment’s immediate surroundings, ask them to move away for their safety. If they have to stay there, pay close attention to them and warn them about potential hazards.

Then, you should also be careful when you enter and exit the machinery. While this might seem self-evident, many operators get injured because they fail to follow the three points of contact rule for heights.

So, when climbing in and out of the equipment, always hold onto it with three limbs, which helps you stay safe.

Before using the equipment, you should carry out a basic inspection to ensure that it is safe to use. Otherwise, you might put yourself and others at risk. This type of check shouldn’t take long, but it benefits you greatly.

Lastly, use the equipment for its original purpose only to avoid accidents and malfunctions.

Additionally, despite your training and education, you might forget how to properly operate a piece of machinery, especially if you haven’t used it in a while.

In that case, the correct course of action is to get refreshment training or go through the manufacturer’s instructions. Misusing the machinery can cause it to malfunction or experience more wear and tear than expected, which creates new safety hazards.

Make these tips a habit to keep yourself and other employees safe.

Conclusion

Armed with all these facts, you’re on the right track to deciding whether becoming a heavy equipment operator is the right choice for you.

If you decide to do so, you should invest in education as it goes a long way, even in industries such as construction.

Still, keep in mind that formal education isn’t everything. You should hone skills that help you perform your job better, which will make you a valued team member.

So, get enough training and practice, and you’ll become a great heavy equipment operator.

Good luck!