Installing an asset tagging system invites greater efficiency, control, and profits.

Whether items function as fixed or mobile, asset tagging optimizes employee efforts and the flow of information within a business.

Not only are assets organized easily and quickly, but such important data as fixed-asset depreciation becomes quickly available and intuitively shared.

This post will discuss what asset tags are and how they are best deployed.

In this article...

What Asset Tags Are and Where They’re Used

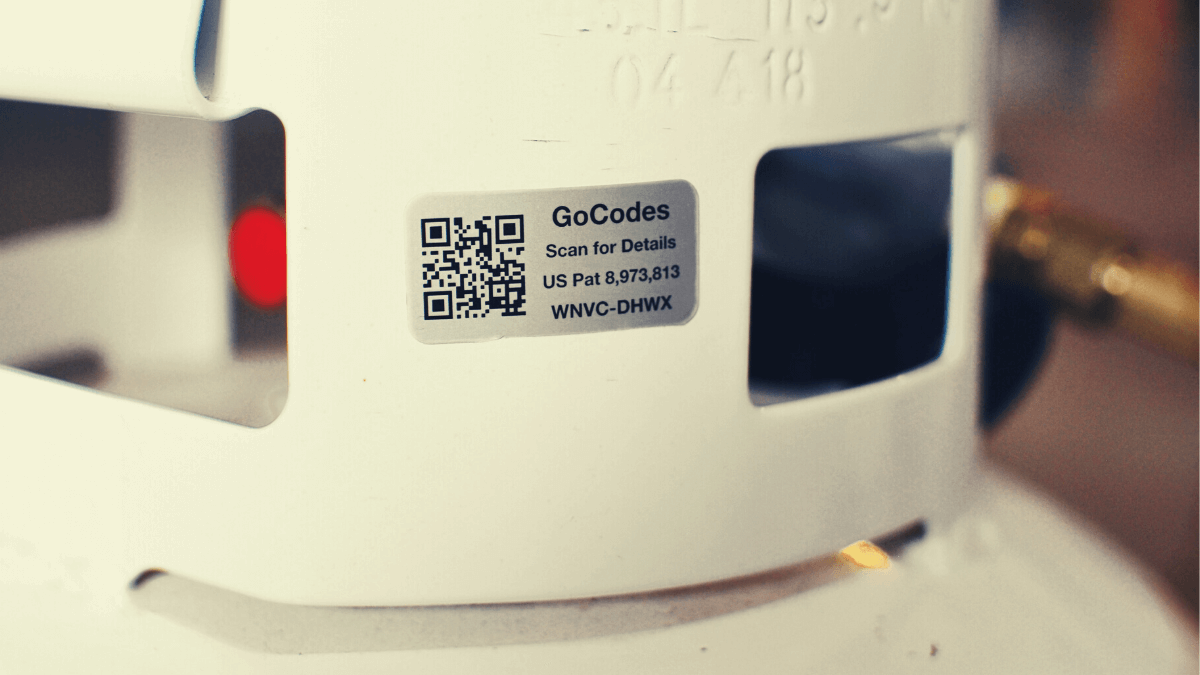

Asset tags serve as printed, scannable markers affixed to any item your company wishes to track.

Manufacturers make them from a wide variety of materials—metal, plastic, mylar, or even vinyl.

Each asset tag carries a unique alphanumeric code to distinguish it from identical items.

While they are applicable in almost every industry, businesses use asset tags most heavily in the following industries:

- Construction

- Education

- Sports

- Healthcare

- Hospitality

- Indoor office work

- Industry and manufacturing

- Retail

Scanning the tags at regular intervals, as the object moves through the supply chain or when it receives maintenance, creates a time-stamped capture of the asset’s condition at that moment.

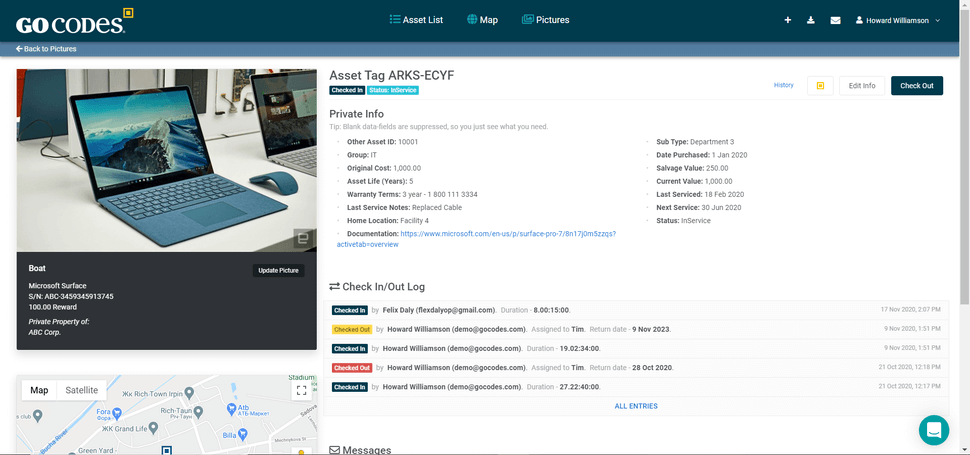

Additionally, scanning calls forth a great deal of important information about the item, such as its name, stock location, and operator’s manual.

Over time, scanning creates a comprehensive record of where the asset has been and how well it serves its purpose.

In the case of fixed assets, a scan can provide vital environmental or performance-related data.

Which Assets Need Tagging?

It sounds like a frustrating riddle, but there is a maxim that helps to clarify the issue.

The assets that need tagging are the ones that require tracking.

So, which assets require tracking?

The answer is different for each industry and individual business.

Here are some categories to think about:

Assets the company cannot perform without: Manufacturing equipment; information technology items such as computers, laptops, tablets, and smartphones; construction vehicles and tools.

Valuable assets: Non-tangible assets such as song lyrics or building plans; irreplaceable historical or art items.

Assets with a potential liability risk: Staff vehicles, maintenance equipment, items used for transport such as forklifts.

Peripheral IT items: External hard drives used for storage, monitors, software.

Appliances: Many companies host employee lounges, which usually contain microwaves, refrigerators, dishwashers, and stoves.

HVAC: Equipment for heating and air conditioning is also more useful when tracked.

Furniture: Some organizations own valuable furniture items for use in lobbies and client lounges; others store items in this category and move them frequently. Folding chairs, education equipment, and carts are easier to account for when tracked.

Enhancing these items with asset tags means they are safer, better understood, and more profitable.

Tracking helps provide an accurate count of items, as well as confirm where they are located.

The Purpose of an Asset Tagging System

When companies invest in an asset tagging system, it rarely takes long before this new arrangement yields great dividends.

The mission behind acquiring and activating an asset tagging system is easily tailored to the needs and goals of your business.

Here are just a few purposes of an asset tagging system:

Tracking Equipment Effectively

Tagging assets can help organizations track many different kinds of equipment. It can be just as important to know who has used it, how, and where.

Asset tags make this possible.

Knowing where an item is in a warehouse, large worksite, or company branch system helps employees save valuable time.

Some workplace analysts estimate that the average employee spends an hour and a half a day just looking for items.

Asset tags allow employees to concentrate on the task at hand.

The reliable tracking of equipment, then, whether in an office or in the field, preserves time and money while lowering employee frustration and creating a more positive work environment.

Asset tags also provide a custody chain.

A custody chain is extremely valuable in the event of loss, theft, injury, or an audit.

The transparency provided by equipment tracking also increases trust, accountability, and productive relations between managers, workforce members, and stakeholders.

Inventory Control and Maintenance

Inventory control encompasses much more than the prevention of loss or theft.

Using a QR code or barcode in an asset tag means that your system provider assigns every item with a unique identifier.

That means if one of your assets goes missing, law enforcement can verify your ownership as soon as officers retrieve the item.

In addition, the asset tag will prove prior possession in the event of a dispute with a competitor who uses similar or identical items.

Maintenance is much more easily managed with an asset tagging system.

Employees scanning items that require maintenance on a regular basis form a long and valuable record chain.

This information is vital when decision makers are eager to gather information about depreciation, the environmental factors affecting the asset, ROI (return on investment), and overall efficiency.

An asset tagging system also simplifies reporting equipment breakdown.

This expedites regular maintenance actions and facilitates sending reminders for preventive maintenance.

Operating manuals and manufacturer parameters are easily accessible with a simple scan, as is a list of past maintenance appointments.

Contact information for the vendor or a third-party maintenance provider are also easy to include.

Preventing Theft and Loss

In addition to the loss prevention effects mentioned above, asset tags help protect items that might not ever leave a locked room or carry a great deal of monetary value, but which contain sensitive, proprietary, or classified information.

Specially designed tags assist with security measures.

They are available in the following forms:

- Tamper-evident tags: Sealed with a distinct adhesive that leaves a checkerboard design if someone attempts to remove it

- Two-part asset labels: Printed with identical information on two attached tags, they indicate if the item underwent use, opening, or other forms of tampering.

- Metal labels: Usually welded or screwed onto an item, typically one that experiences an outdoor environment. Virtually unremovable, metal labels are also useful to assets exposed to constant vibration, corrosive materials, or extreme temperatures.

Not only do these types of asset tags provide additional layers of protection, they assure clients and employees that their security is your organization’s priority.

The reinforcement of this concept helps to strengthen trust and confidence in your services and products.

Five Steps to a Streamlined Asset Tagging System

An asset tagging system is only as good as its initial organization and continued upkeep.

Keep the following in mind while establishing an asset tagging system.

1. Select the Right Tag for Your Work Environment

Just as each organization’s goals and needs for an asset tagging system are different, so are the tags themselves.

Asset tags are available in many different combinations of styles so that a company can track its fixed assets, movable assets, and outdoor items alike.

Here are a few types of asset tags:

- QR code: Unique lock of black and white patterned squares that link to an asset profile; employees scan them with a smartphone or tablet

- Bluetooth: This low-energy technology is best used for small amounts of data

- GPS: Tags return a signal to the asset tracking system to signal location

- Barcode: Non-unique but inexpensive series of black and white lines used most often in retail

- RFID (Radio Frequency Identification): Radio waves provide non-line-of-sight tracking

The best tag for your company depends on the style of your operation and what you hope to achieve with your system.

2. List Your Fixed and Moveable Assets

Before deciding what to label, take inventory. Which of your organizations would you like to track, and why?

Remember that this list might include fixed as well as movable assets.

Obtaining an accurate count and condition report of the state of your assets is critical.

You must know exactly what you have before you attempt to optimize it.

Not only is this important for insurance information and data precision, possessing a big-picture idea of the state of your assets can better guide your actions in the steps that follow.

3. Apply Asset Tags Securely

The proper form of asset tag application depends on the type of tags and assets in question.

A priceless work of art, for example, should not receive the same kind of tag and adherence methods as a textbook or an excavator.

On most items, it’s best to place the asset tag in a location which is easy to find—but one that will not endure a great deal of handling.

The asset tag should not experience direct sunlight.

However, it should be situated on a surface that is easy to scan.

The most popular tags for indoor items adhere permanently to assets with an adhesive.

The surface of the asset should first undergo testing to ensure that the label will adhere well without leaving damage behind.

By cleaning the area, smoothing away air trapped beneath the label, and avoiding the use of the asset for 24 hours, employees can ensure that the labels have set fully.

Allowing the adhesive to cure at room temperature and in low humidity is best.

Additionally, it is recommended to store extra tags at 72 degrees F/22 degrees C in 50% relative humidity.

4. Record All Important Information in Your Asset Database

Choosing the type of tagging structure and the technology that the system will use is half of the equation of installing a successful asset tagging system.

The other half is setting the foundation of the information database that each scan will build.

This includes deciding what kind of information your labels will hold, and to what degree of detail.

Depending on the type of asset, information encoded in your tag will typically include:

- Name of asset, a brief description, and its manufacturer serial number

- Purchase date, value, life cycle estimates, and phase of depreciation

- Insurance, warranty, and legal contact information, including all policy certificates and details

- Maintenance history

- Contact information of third party service teams

- Shift manager, emergency, and security contact information

- Operator’s manual

- Manufacturer guidelines

- Employee custody record

- Schedule of where the item has been and where it will move next

As you can see, loading this information will provide an instant overview of the asset’s most important details.

Locating this data in the same place renders searching for information much easier.

In addition, since the data issues from a central location, all members of the workforce will work from identical information.

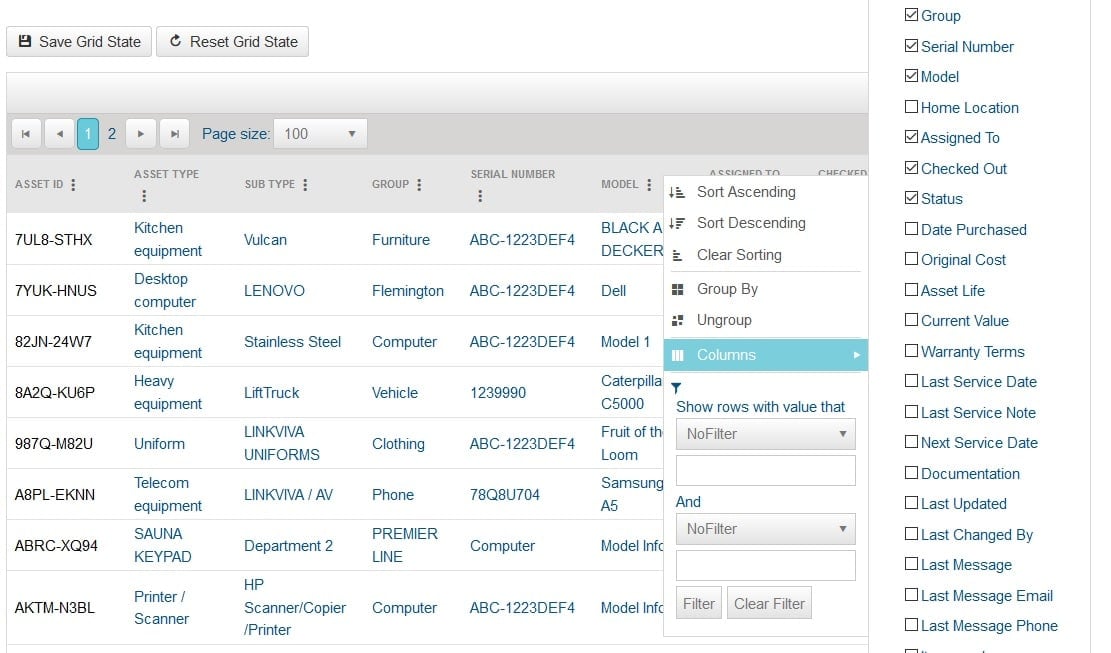

5. Select a Tagging System With Easy-to-Use Software

There are many key features to look for in a software system to pair with your asset tags.

These are a few:

- Scalability: Can this system meet your organization where it is now, then grow or contract along with it?

- Free trial: Reputable companies offer free trials of their asset tagging systems so that their clients can ensure the technology and methods are suitable.

- Cloud storage: The use of the cloud is essential in safeguarding your company’s data and enabling employees and decision makers to access pertinent information.

- Intuitive: The asset tagging system should not place a burden on the workforce. It should, instead, increase its efficiency, transparency, and safety culture. Well-designed systems are easy to learn and integrate into daily tasks.

- Meets the needs of the company: Rather than struggling to fit an overly structured one-size-fits-all system, the suite should offer customization to help you achieve your goals.

GoCodes Asset Tracking offers these features, and much more.

Cloud storage, an extensive menu of support services, and patented QR code tags provide seamless integration with your company’s infrastructure.

Data fields, tags, and codes are all customizable for a comprehensive tracking method.

GoCodes Asset Tracking also offers a free trial to ensure that it’s a great fit for your employees and assets.

Conclusion

The benefits of asset tagging systems are many, but only if the system itself is congruent with the business it intends to serve.

Taking a few of these actions will ensure that your assets and employees will work well together.