There are many benefits to asset management, including increased organization, the ability to make well-informed decisions, and better employee accountability.

One important, yet often overlooked, aspect of asset management is how much it can increase productivity.

Boosts in productivity are measurable, quick to manifest, and stem from maximized efficiency and the elimination of redundancies.

Those who are interested in expanding productivity using smart asset management will profit from the suggestions in this post. So will companies that house a great deal of inventory, organizations involved in fieldwork, and COOs of companies that retain physical assets.

In this article...

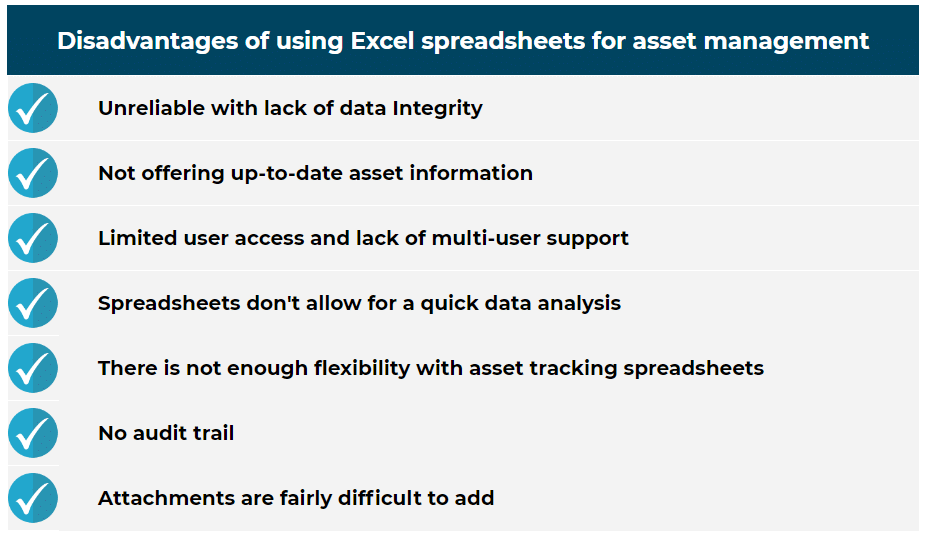

1) First, Stop Using Spreadsheets

Some people who are currently in management, stakeholder, or decision-making positions may have been trained to use spreadsheets for keeping track of employee hours, equipment check-out/check-in, and maintenance actions.

However, using this form of technology for managing assets is outdated and ripe for causing confusion between departments, employees, and branches.

Weaknesses of spreadsheets used for asset tracking are already apparent to those who use them.

When multiple copies of the same program are open at once, simultaneous use is impossible, resulting in unintentional data overwrites.

No automatic updates are provided as to who has last used the asset or who currently has it in possession, as most spreadsheet programs are not designed for asset tracking.

If data is not backed up to the cloud, it becomes necessary to keep multiple copies in separate locations, but on-the-go updating is impossible.

Users are limited by tiny input boxes and unable to attach asset images, manufacturer’s suggestions, schematics, and maintenance notes.

Additionally, since information requires manual upload, which often results in errors—security is a constant concern.

Since real-time tracking is unavailable, it is impossible to know who altered what data and when, as the data in the spreadsheet is not physically linked to the asset.

Finally, spreadsheets are not customizable to a company’s needs.

Using a spreadsheet might have been an improvement over pencil and paper, but asset productivity is far more optimized using QR codes and asset tracking software.

2) Equipment Oversight Reduces Asset Downtime

Well-designed asset management software allows for a great many improvements in equipment oversight. These help to reduce downtime, which protects the bottom line and creates more room in an organization’s schedule.

Equipment oversight is a must, especially in companies focused on production, where breakdowns can result in defective products.

It helps to preserve employee safety, as well as meet regulatory standards and exceed customer satisfaction.

Sensible equipment oversight prevents the occurrence of many potentially costly issues. Equipment downtime can cause:

- Making restitution to clients and partners for missed deadlines and lost work

- Potential safety code violations

- Time lost to attempting to diagnose and detect the cause of the breakdown, which might involve the expensive help of third-party contractors

- Damage to reputation

- Employee dissatisfaction and client impatience

- Lost revenue from other projects “donating” equipment or standing still

Asset management software also increases productivity by allowing asset visibility. This expands understanding of an asset across its entire life cycle, from planning, design, and acquisition to operation, maintenance, and disposal.

The right software can help decision makers anticipate the onset of these events and plan accordingly. This helps avoid downtime due to catastrophic breakdown or natural and expected transition periods from old assets to new.

3) Asset Management Allows for Control and Accuracy

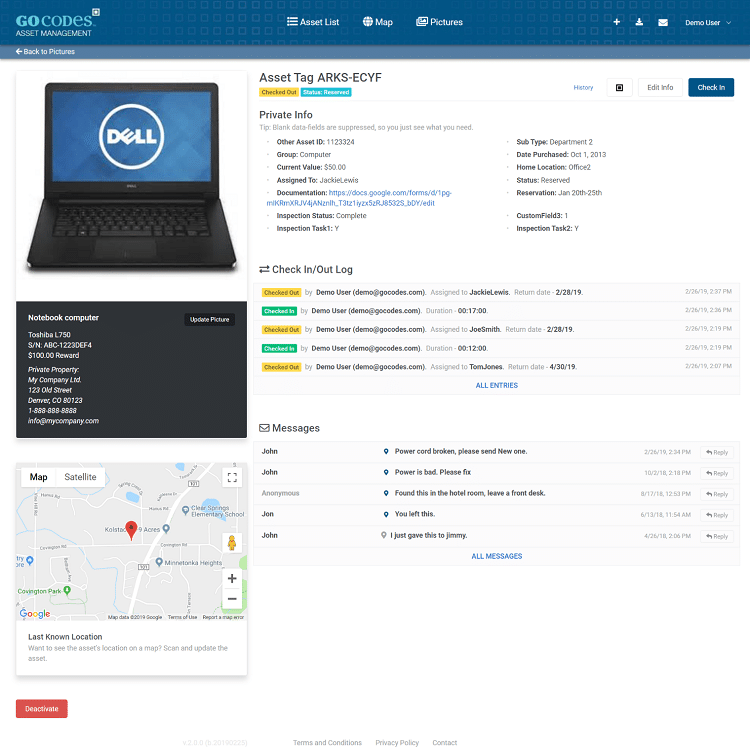

The real-time asset tracking enabled by cloud-based software is invaluable for asset productivity and exercising control over every aspect of business operations.

Such asset management solutions vastly increase accuracy and provide real-time data.

They virtually eliminate human error associated with manual data processing; many aspects update automatically or with a simple smartphone scan.

There are numerous other advantages to asset productivity and management.

For instance, harnessing recent data allows stakeholders to identify trends, potential problem areas, efficiency sticking points, and contributing factors to client satisfaction.

Items are quickly found as they make their way through the supply chain, but even more importantly for production capabilities, operators and managers can watch for potential signs that maintenance actions might be necessary.

Decision makers are also able to produce detailed data reports to project increased demand, potential slowdowns, budget adjustments, or “war gaming” for emergencies.

With this, they can forecast company operations, but industry trends and movements within their company’s economic space.

For example, if your organization is a lagging economic indicator, asset productivity is easily adjusted based on hard data rather than guessing.

Accurate data captured over time and continually updated contributes to smart decision-making, trend identification, and marketing insights.

Layer by layer, minute by minute, asset tracking builds a precise and multidimensional picture of your company’s health and future.

4) Ghost and Zombie Assets Are Eliminated

Any organization, no matter how large or small, is negatively affected by ghost and zombie assets. When slow, traditional methods are kept and inventory is hand-counted or kept track of in a spreadsheet, these two efficiency killers tend to appear.

They are frustrating wastes of money and time.

Ghost assets are any items that appear in an organization’s system, but they are not actually usable.

These items are either missing, lost due to theft or misplacement, or disposed of. The company’s records were never updated to reflect this new reality, and so the item continues to float through the system.

According to AssetWorks, as many as 35% of a company’s on-record assets are present “on the books”, but not in actuality.

Because an organization is treating the ghost asset as real, it can end up with increased taxes, higher insurance costs, skewed budgets, frustrated employees, disappointed clients, and puzzled third-party contractors.

All of this translates to a loss of money and time.

Zombie assets are somewhat the opposite of ghost assets, but they are just as maddening and dangerous to asset productivity.

These assets do exist, but they are nowhere in a company’s accounting software or maintenance records. AssetWorks reports that 12% of a company’s assets might exist as zombie assets.

A comprehensive asset tracking system with QR codes, an efficient software package, and regularly tended scanning can easily remedy both problems by deleting ghost assets and adding zombie ones.

5) You Can Dispose of or Retire Unproductive Assets Immediately

The presence of outdated, unrepaired, or even dangerous equipment in an otherwise well-organized company is detrimental in many ways.

Not only is this an inefficient waste of space, but it also affects employee morale, contributes to a sense of stagnation, and makes for an overwhelming experience for new employees or visitors.

Asset management for productivity, however, can alert decision makers and managers to this. They can then oversee activities remotely or from another branch.

Most companies don’t set out to build an ungainly collection of unproductive assets.

These items tend to gather in storage rooms or workspaces “just in case,” and employees often forget where they came from, why they are there, or even what they are.

Manager and employee turnover adds to a general sense of avoiding “what was always there,” and the items tend to collect dust and take up valuable space.

Unproductive assets include:

- Broken machinery parts

- Items too large to fit in dumpsters or which require environmentally sensitive disposal

- Extra office furniture

- Outdated or unneeded fixtures

- Parts or tools for items no longer owned by the company

- Holiday decorations no longer used

Not only is this visual clutter an attack on a sleek business model, it creates a negative impression for visitors, third party contractors, and inspectors.

When every item deemed necessary for tracking is given a tag and a unique identifier, an organization’s culture begins to change for the better.

Employees become more efficient and decision makers feel empowered to make the wise investment of time and money to clear out unnecessary items.

6) Employees Can Collaborate Much More Easily

Organizations of all sizes and types are learning the importance of having the ability to communicate remotely and in a standardized fashion, especially since the conditions forced by the COVID-19 pandemic.

Asset management software facilitates this in many ways:

- Equipment check-in and check out is optimized for speed and accuracy.

- Handoffs between employees, management teams, and shifts become hassle-free and far more precise.

- Taking equipment checkout from paperwork to digital scanning means that the information is backed up to the cloud and instantly available to multiple team members who need to see the information.

- Employees and even clients are able to ask for assistance, repairs, or replacements via the software, rather than routing through a customer service line; time is saved on both ends.

- Communication about items and procedures is standardized and streamlined.

- Employee efficiency is increased as idle time decreases.

Increased collaboration means that small businesses can interface more easily with larger corporations, and major corporations can quickly stand up vast communication systems.

Tracking information is easily disseminated through a variety of channels, securely and instantaneously.

7) Workforce Becomes More Accountable

Asset tracking greatly increases employee accountability. This means a quick reduction in theft, accidental misplacements, and location of sidelined equipment.

Each of these benefits translates to increased productivity.

When a company successfully deters theft, it saves money when assets and inventory aren’t in need of replacement.

A strong asset tracking system relies on scanning and GPS tracking.

Here are some additional benefits of this investment.

Employees tend to treat items with more care when tags are attached to assets, while operators handing off items from shift to shift can verify the condition of the asset.

If an item is stolen, GPS tracking assists law enforcement and internal security forces in finding it.

Sometimes items vanish due to honest misplacement or even natural disasters. GPS tracking can help locate these items quickly, reducing insurance costs and saving time and money otherwise dedicated to hunting for them.

If an item has not been stolen, it may have become damaged. Asset tracking will identify which guest, contractor, or employee was the last to handle it.

Even if the last “holder” was not responsible for the damage, the organization can still collect valuable information, such as when the item was last in good repair or which unusual behaviors or noises might have functioned as warning signs.

All of these can help a company stave off downtime due to theft or breakdowns.

8) Achieve Higher Personal and Process Safety

Smart asset management, along with well-executed preventive maintenance, results in better safety.

When assets are managed well, they show that an organization cares not only about the assets in its hands, but also its employees.

These are the outcomes:

- It is easier to prove compliance with safety codes.

- Training is streamlined.

- Operator’s manuals and manufacturer’s suggestions are always at hand to any operator, third-party repair team, or manager.

- It is easier to schedule preventive maintenance.

- The constant monitoring that fixed asset tracking provides can alert operators to potential damage or dangerous situations.

- Rapid communication between employees is possible.

Risk control, particularly for companies that undertake a great deal of fieldwork with specialized machinery, is far easier with asset tracking.

9) Business Risks Are Lower

While taking the plunge into a new business or expansion never has a guaranteed success, risks are mitigated with asset productivity and tracking.

Regularly updated data provides a real-time picture of the company’s health, which means that rends are more easily forecast, so decision making becomes easier.

Several high costs associated with beginning or pushing forward in any industry are lowered. These include theft margins, safety and regulation compliance fines, or equipment repairs.

At the same time, panic buying of new items due to catastrophic loss or mistimed life cycle is prevented. The risk of data loss is also lower, while storage costs drop once data moves from paper to digital.

Additionally, it becomes possible to provide faster, more comprehensive, and standardized training of new employees.

Working with an asset management tracking system can lower these risks and costs while raising efficiency and profits.

Conclusion

Asset management is much more than knowing which items a company owns—it also encompasses asset productivity and employee accountability. A well-designed asset tracking system and corresponding software are invaluable in maximizing the productivity of each asset, as well as every employee.