Key Takeaways:

- Asset identification is the core strategy that sets the tone for successful asset management.

- Barcode and QR code labels offer a cost-effective way to identify assets and streamline inventory processes.

- Advanced RFID and GPS tracking systems enable real-time tracking, but their effectiveness varies by environment.

- Successful implementation of these systems requires robust software, durable materials, and staff buy-in.

Ever lost track of a high-value asset because a label wore off or someone typed the wrong ID into a spreadsheet?

Mistakes like these happen more often than you’d expect—and they can be costly.

However, by assigning unique identifiers and building a structured system, companies can reduce errors, streamline tracking, and extend asset lifespan.

In this guide, we’ll break down what asset identification involves and examine pitfalls you’ll want to avoid.

In this article...

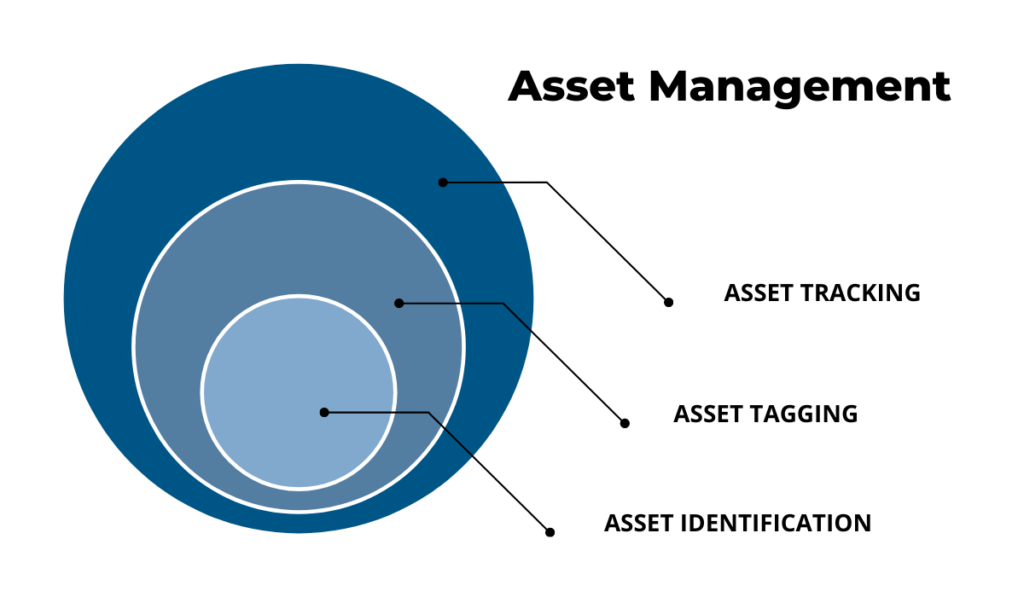

Understanding Asset Identification

Asset identification is the process of assigning a unique identifier to each asset to distinguish it from others, facilitate accurate tracking, and establish ownership and accountability.

In other words, it’s the foundation of efficient tracking and reliable asset lifecycle management within any company or system.

Source: GoCodes Asset Tracking

But wait—is asset identification the same as asset tagging?

While there are significant overlaps, tagging refers to the physical act of attaching a label to an asset: the how.

Meanwhile, asset identification is the broader strategy and system behind telling your physical and digital assets apart: the what and why.

The system varies slightly across industries, but in construction, it typically applies to a wide range of asset types, including:

- Heavy-duty machinery and vehicles

- Tools and small equipment

- IT assets and accessories

- Furniture and fixtures

- Inventory and stock

- Safety equipment

- Infrastructure

No matter the asset in question, the goal of asset identification is to save time, reduce errors, and streamline management.

It also plays a crucial role in maximizing the value of your assets over time.

As ERP and enterprise software expert James Spivey notes:

Illustration: GoCodes Asset Tracking / Quote: Construction Dive

By assigning clear ownership and improving visibility, asset identification helps ensure that full value doesn’t go to waste.

For example, a misidentified excavator is not just an efficiency or compliance issue—poorly tracked maintenance records could lead to mechanical failures and shorten its useful life.

There are several common ways to track and distinguish assets, from barcode and QR code labels to RFID tags and GPS trackers.

But in each case, the process involves:

- Assigning a unique ID to each asset

- Categorizing the asset by type, location, department, etc.

- Recording key details in a centralized register or database

An adequately identified and tracked asset yields several benefits, including:

| Operational continuity | Less downtime due to misplaced or lost equipment. |

| Compliance and liability protection | Properly documented assets make audits smoother and ensure adherence to safety regulations. |

| Chain of custody | A clear history of ownership, location, and condition helps prevent theft, fraud, and misuse. |

Now that we’ve covered the essentials, let’s look at what your asset tracking system needs to deliver value.

Key Components of an Asset Identification System

A functional asset identification system is made up of several core elements that work together to ensure easy access to accurate asset data.

These key components include:

- Unique asset IDs

- Physical tags or labels

- Scanners/readers

- Asset databases

- Asset tracking software

As we’ve already established, unique asset IDs create the foundation by helping you distinguish each asset from the next, preventing any confusion or duplicate efforts.

These identifiers are then embedded onto physical tags or labels that need to be scanned for location updates.

Businesses typically choose between several tagging options pictured below, from barcode and QR code labels to RFID tags.

Source: GoCodes Asset Tracking

Choosing the right asset identification method for a specific asset type or use case depends on several factors.

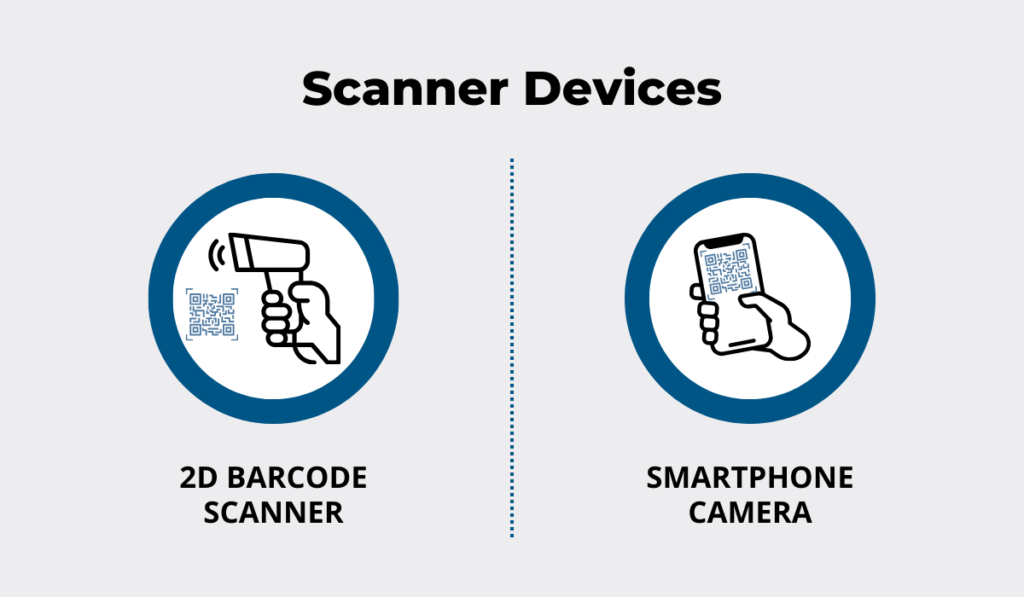

We’ll explore these shortly, but what’s important to understand is that all labels and trackers share one core function: they enable data capture when paired with scanners or readers.

These devices help link physical assets to digital records for seamless tracking.

While traditional handheld scanners still play a role, smartphone-enabled readers are becoming increasingly popular due to their widespread use and convenience.

Source: GoCodes Asset Tracking

Captured data is stored within an asset database that holds everything from latest location updates and asset condition to warranty info and maintenance logs.

Here’s a visual recap of this process.

Source: GoCodes Asset Tracking

Of course, asset data alone isn’t enough.

These components work perfectly in sync thanks to the software layer that transforms raw data into actionable insights.

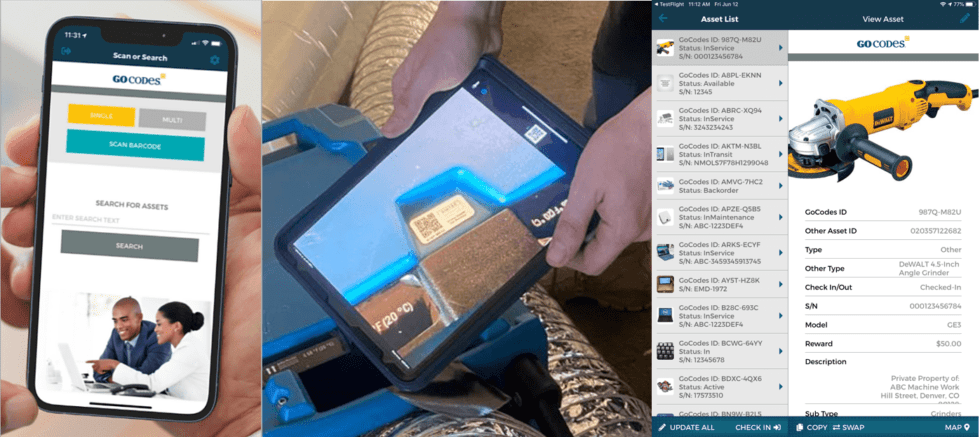

For instance, a construction company can combine QR code asset tags and a mobile app with a built-in scanner to create the baseline asset identification and tracking system.

Since the app automatically records asset users and locations when a tag is scanned, this provides crucial data needed for improved operational efficiency and enhanced worker accountability.

Ultimately, a successful integration of hardware and software transforms asset identification into true operational intelligence.

Common Asset Identification Methods

You can use several asset identification methods, each varying in cost, durability, automation level, and environment suitability.

Let’s take a closer look at them.

Serial Numbers

Asset identification often starts with serial numbers.

While asset IDs can be system-generated or manually assigned by users, a serial number is a unique identifier assigned by the manufacturer.

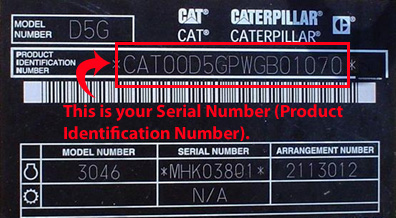

In the construction industry, this is typically the 17-character Product Identification Number (PIN), which follows industry standards and includes the machine’s serial number.

Source: Service Manual Pro

Serial numbers remain relevant today—especially if you’re not using an asset tracking system with unique asset IDs and serial numbers stored.

Why? They’re often the only identifier that allows police to flag stolen equipment.

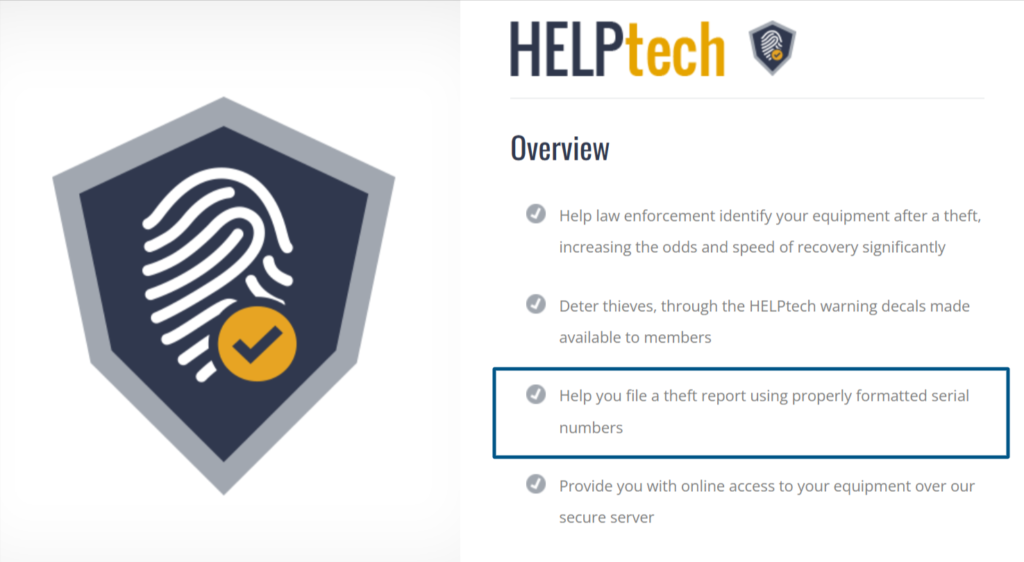

As seen in the image below, they’re also required when filing a theft report or registering missing machinery with the National Equipment Register (NER).

Source: NER

To sum up, while modern systems typically rely on internal asset IDs or tags, keeping serial numbers on file is still essential for basic asset verification, as well as theft recovery.

Barcode Labels

Barcode tracking systems offer a straightforward and cost-effective method for storing and retrieving asset information.

Traditionally used in warehouse settings, barcodes have become the foundation of inventory systems across many industries.

As explained in the following video, their simplicity and scalability make them a popular starting point for various businesses:

Source: POS Guys on YouTube

While many modern barcode-based solutions support mobile or tablet scanning, others still require separate scanners and specialized barcode printers.

This increases upfront costs slightly, but the major downside of barcodes is that they require a clear line of sight for scanning.

This also slows down the process—especially when you’re dealing with multiple assets in fast-paced or cluttered environments.

Barcodes are also vulnerable to damage from dust, moisture, or abrasion, making them unreadable, thereby contributing to delays, misidentified assets, and added maintenance.

All these challenges should be weighed carefully when considering barcode systems for long-term asset tracking, particularly in construction environments.

QR Code Labels

QR code trackers are a reliable choice for asset identification in both indoor and outdoor settings.

QR codes have been steadily replacing barcodes, due to their advantages like storing more information, enabling scanning from any angle, and allowing multiple simultaneous scans.

Another advantage is their size—they can be miniscule and still readable while also remaining functional even when damaged.

For example, GoCodes Asset Tracking’ QR code labels can be customized to fit even the smallest of assets while still providing access to asset documentation, maintenance and location logs, and more.

Source: GoCodes Asset Tracking

Combined with rugged, long-lasting QR code tag material, you can easily prevent peeling off or damage.

This helpful video summarizes several key differences between barcodes and QR codes.

Source: ASAP Systems on YouTube

Most importantly, QR code trackers can provide passive, scan-based GPS tracking, enabling:

- Easier asset search, allocation, and servicing

- Seamless asset check-in/out with enhanced worker accountability

- Support in finding misplaced or stolen assets

Keep in mind that although this technology can provide automated location updates, the asset still needs to be manually scanned with an internet-connected smartphone or tablet.

RFID Tags

RFID technology uses radio waves, offering a compelling alternative for businesses that want faster, contactless asset tracking.

With its out-of-sight scanning capabilities, you can automatically identify assets from a distance and track multiple assets completely hands-free.

This makes RFID tags ideal for handling large volumes of stock and equipment, particularly in warehouses and other large-scale indoor settings.

Companies can choose between two tracking options:

- Passive RFID tags that transmit data only when in contact with scanners

- Active RFID tags with built-in batteries, allowing them to continuously broadcast a signal

However, one major drawback of this technology is its cost, as shown in the example of one medical facility in Singapore.

Alvin Kuo, Assistant Director of Operations at KTPH, explains that with each active tag costing about $75, the hospital had to prioritize some assets for active tracking.

Illustration: GoCodes Asset Tracking / Quote: Healthcare Asia

KTPH ultimately deployed a combined approach—using passive RTLS to monitor around 8,000 assets while reserving active RTLS for 1,500 high-priority items.

Construction companies should also keep in mind that RFID solutions often struggle in rugged outdoor environments, particularly when infrastructure budgets are tight.

But that’s where GPS tracking comes into play.

GPS Tracking

GPS trackers provide real-time location updates without the need for fixed readers or on-site infrastructure.

Their global coverage makes GPS trackers ideal for monitoring mobile and high-value assets, enhancing visibility, improving route navigation, and strengthening overall security.

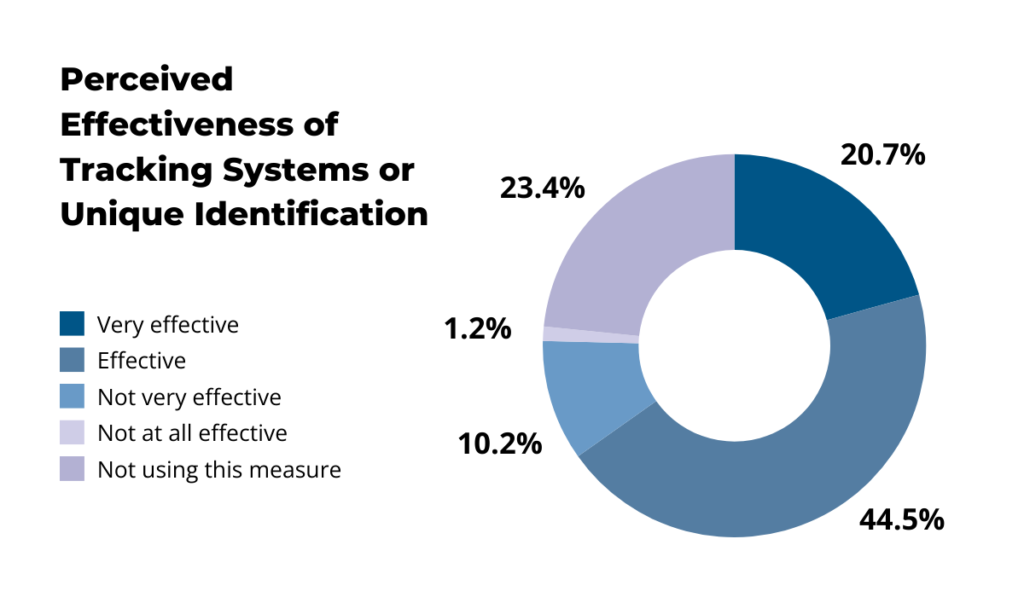

CIOB research shows that about 65% of UK-based construction professionals view asset tracking as a key security measure.

Illustration: GoCodes Asset Tracking / Data: CIOB

One major reason is that GPS tracking enables geofencing, a function that sends instant alerts as soon as an asset crosses a predefined digital boundary.

One striking example comes from Howard County, where a GPS tracker helped authorities uncover a massive theft operation and recover around $5 million worth of stolen construction equipment.

Gregory Der, the county’s Chief of Police, highlighted how deeply these incidents impact small business owners:

Illustration: GoCodes Asset Tracking / Quote: Equipment World

Although robust GPS trackers can be costly, the level of risk they help mitigate makes them well worth the investment.

They offer more than just reliable identification and real-time tracking, giving business owners peace of mind that their equipment is accounted for, protected, and ready when needed.

Challenges in Asset Identification

As with any other process, setting up or maintaining asset identification systems has its fair share of challenges.

While the idea of assigning a unique identifier to each asset may sound simple, execution often gets messy—especially when businesses rely on outdated tools.

Systems based on manual entry are particularly vulnerable to human error, and none more so than Excel spreadsheets.

James Kwak, a university professor and prominent voice on economic policy and corporate governance, points out Excel’s built-in limitations—especially when it comes to visibility and data integrity.

Illustration: GoCodes Asset Tracking / Quote: Baseline Scenario

Kwak highlighted these shortcomings in response to JP Morgan Chase’s infamous $6 billion loss, largely caused by spreadsheet errors.

And while that case involved risk modeling, the same types of issues—copy-paste mistakes, broken formulas, and inconsistent records—can seriously affect your asset management.

For instance, a mistyped serial number or duplicated ID could result in:

- Misplaced assets

- Compliance failures

- Delayed maintenance and costly downtime

The solution? Choosing robust asset management software.

However, even with a more advanced system in place, new challenges emerge—especially when it comes to consistency and physical labeling.

A common issue is tag wear and tear.

Asset identification depends on rugged, durable labels, but many businesses settle for low-quality alternatives that gradually undermine their entire system.

What you can do is choose the right tag material from the start.

Anthony Fritz, a former Camcode sales representative, emphasizes that outdoor and industrial environments call for metal tags.

Illustration: GoCodes Asset Tracking / Quote: Camcode Barcode Products on Youtube

And there’s good reason for that: Anodized aluminum tags are designed to withstand harsh conditions, including extreme temperatures.

They resist scratches, corrosion, and fading, which means you’re preventing the kind of legibility issues that could quickly render your assets untraceable.

Nevertheless, there’s still one major obstacle to overcome: employee resistance to the new system.

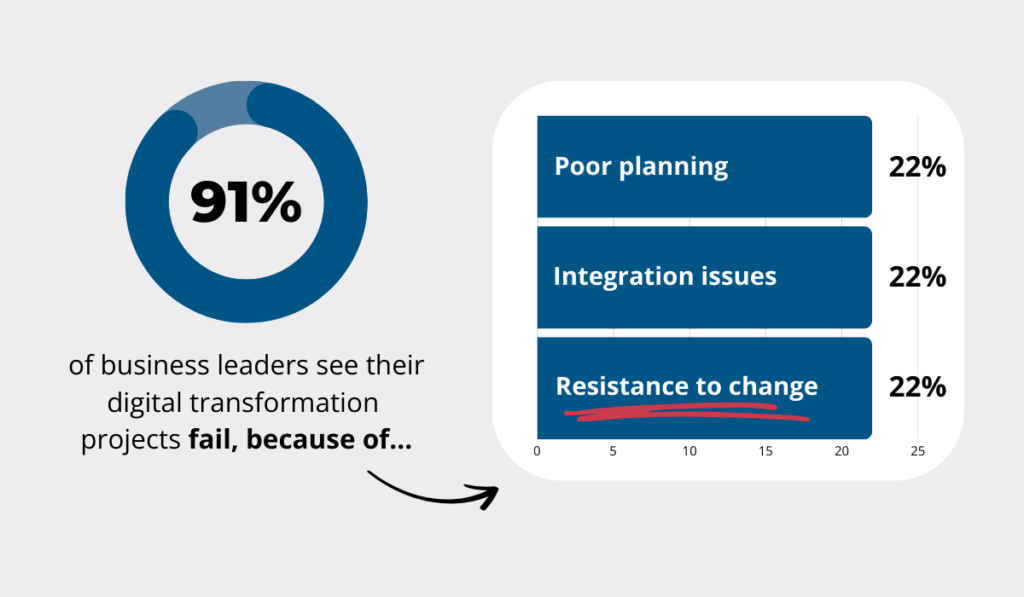

According to research from Userlane, 22% of business leaders cite resistance to change as a major hurdle to digital transformation.

Illustration: GoCodes Asset Tracking / Data: Userlane

But reluctance to change isn’t always about clinging to the familiar, as evidenced by the experience of the St. Charles Parish Public Works team.

To streamline the maintenance of over 60,000 assets, the department partnered with AssetWorks to roll out an enterprise asset management (EAM) solution.

Despite the software’s clear benefits, the transition didn’t go as smoothly as hoped.

Carly Jo Cantrelle, St. Charles Parish’s Maintenance Processor, explained that the lack of educational resources and clear guidance led to confusion and resistance among staff.

Illustration: GoCodes Asset Tracking / Quote: Asset Works

So how did the Parish turn things around?

Firstly, they designated a handful of team members to learn how to use the system first.

Then, they could guide others through adoption.

Secondly, since the organization had never used legacy software before, they also set a longer but more realistic implementation timeline.

This strategy of empowering employees to use these advanced systems eventually resulted in cleaner data, more effective reporting, and a streamlined maintenance schedule.

In the end, tackling errors, tag durability, and employee resistance takes a unified approach, but investing the time pays off when the system works reliably across your entire operations.

Conclusion

When done right, asset identification drives everything from efficient maintenance to regulatory compliance and loss prevention.

Naturally, effective implementation depends on in-depth understanding of key system components and methods, as well as commitment to properly setting up the process.

While outdated tools, weak materials, or rushed rollouts can hinder progress, investing in a comprehensive system upfront will save time, reduce errors, and bring your company a competitive advantage.

So, what are you waiting for? Now’s the time to reassess how you do things and upgrade the way you track what matters!