If you work with heavy equipment, you may think there’s nothing more to transportation than moving pieces of machinery from point A to point B. And how difficult can that be?

According to statistics, very! Around 100 deaths yearly happen in the process of transporting machinery.

On top of that, remember that almost half of the related injuries happen before and after the transport itself, which means that they were the result of insufficient preparation. In other words, companies fail to take all the necessary preventative measures, and safety suffers as a result.

Keep reading to learn how to make heavy equipment transportation as safe and seamless as possible.

In this article...

Things to Do Before Transporting Heavy Equipment

Make sure that both your team and equipment are well-prepared before you begin transporting equipment.

This means taking the following steps:

- risk assessment

- providing personal protective equipment (PPE)

- inspecting the equipment

We’ll now look into these steps in detail, so you don’t jeopardize safety by missing any of the key activities.

You should start with a risk assessment, which you need to document thoroughly. Think of it like this: if there’s no record of it, it’s as if the evaluation didn’t happen.

So, make a note of every issue you find when determining hazards related to machinery transport. The more detailed the list is, the better, as that way you get to cover more potential threats and, at the same time, prove your compliance with safety regulations.

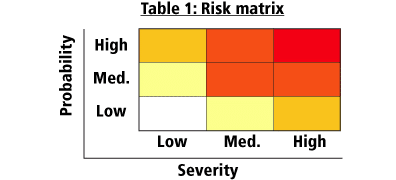

There are several levels of risks depending on how severe they are and how likely they are to happen.

Of course, a highly probable threat that may have the most far-reaching consequences is the one your team should address first.

Determine the levels of severity and probability of each hazard, so your team can address them appropriately. Being diligent about every step of the process will ensure that you don’t miss anything.

Once you’ve performed the assessment, you should decide what type of PPE your workers should wear when loading, unloading, or transporting machinery.

For example, your employees need to wear high-visibility safety vests in order to be immediately noticeable to the drivers and anyone else on the site.

You’ll be able to make an informed decision about this issue if you account for all the possible safety threats you’ve detected.

Once you’ve assessed all the risks and decided on the required PPE, you have to inspect the vehicle itself. After all, the vehicle will do most of the work, and if anything is wrong with it, you’re endangering not only the heavy machinery in need of transport but the driver and other employees around it.

Here are some of the things you need to check on the vehicle:

| The tire pressure | When heavy machinery is lifted onto the trailer, weaker tires will deflate immediately, which might cause the vehicle to tip over. |

| Brakes | There can be no safe ride without functioning brakes, so ensure they get tested before using the transportation vehicle. |

| Lights | The lights on the transporter should work as expected. |

| Weight | The vehicle should be able to handle the weight of the load. |

| Tie-down points | You need to see how many tie-down points your shipment has and determine the best way to secure them. |

When it comes to tie-down points, most states require at least four of them if the load weighs over 10,000 lbs, which is the heavy equipment category. That way, you can rest assured that your cargo is secured in place and that there won’t be any movement during transport.

However, don’t rely on hearsay. Check your state and federal regulations to ensure your compliance regarding the tie-down points. You know what they say: better to be safe than sorry!

Safe Loading of Heavy Construction Equipment

Do you know how to safely load the heavy machinery onto the vehicle?

First, you have to assign duties clearly, so your team knows who’s in charge of which part of the process.

In addition to boosting productivity, delegating tasks also ensures that each team member has a thorough understanding of their responsibilities, which minimizes safety threats.

For example, if an employee knows that they are in charge of signaling the driver, they won’t try to load the equipment at the same time. Instead, they will let the person in charge of that activity do that.

Before the loading itself, you have to clean up and inspect the vehicle, equipment, and the surrounding area. When everything is in proper order, it’s much easier to load the machinery onto the trailer, and the risk of accidents is minimized.

If the vehicle is standing on uneven terrain while you’re loading heavy equipment onto it, it can easily tip over, posing substantial safety hazards to all involved in the operation.

Therefore, it’s vital that you clean and inspect the area before deciding to load any equipment there.

Also, when loading, make sure you’re not rushing things. Remember that you’re working with heavy equipment, which means you’re balancing a lot of weight on an already heavy vehicle.

At one point during the loading, the machinery’s center of gravity will shift. One quick move could cause the equipment to move in an unexpected direction, harming someone. In this case, slow and steady wins the race.

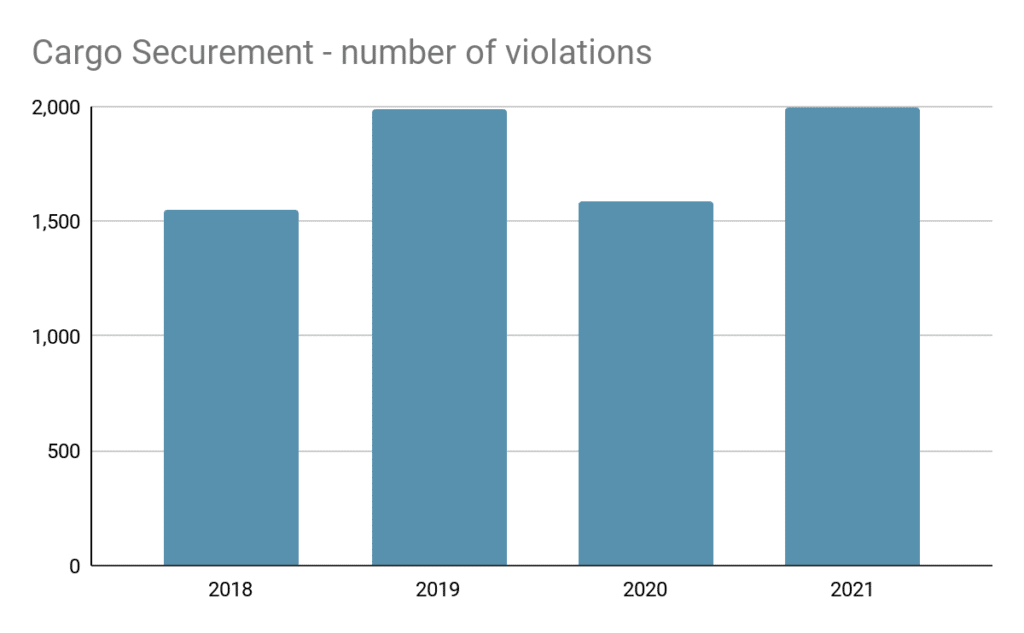

Once you’ve loaded the equipment onto the vehicle, you have to be entirely sure that it is secured. This point might seem obvious, but improper cargo securement has been one of the top five Commercial Vehicle Safety Alliance’s (CVSA) violations for years now.

CVSA stops and checks vehicles carrying heavy loads, trying to find any safety violations. For years, one of the most common mistakes companies have made has been failing to secure their cargo. Sadly, this issue is on the rise.

By August 2021, CVSA has already found more cargo securement violations than in 2018, 2019, or 2020.

Don’t be a part of this statistic. Secure your equipment correctly.

You can do this by ensuring that the chains fit tightly against the equipment and that there’s no room for it to move. Such movement may cause the vehicle to sway during transportation, which is a severe safety concern.

Then, use as many tie-down points as necessary, according to state and federal regulations. If you’re unsure of the best points for machinery tie-down, check the manufacturer’s manuals.

Using the recommended tie-downs helps you protect your equipment while promoting safety.

After that, you’ll be all set for transportation!

Staying Safe While Transporting Construction Machinery

Transporting heavy equipment safely is a more significant task than it initially seems.

To begin with, you have to think about the best route for your driver to take. Remember, they have to get from point A to point B safely, so mapping a route without many obstacles is optimal.

These obstacles come in the form of bridges, turns, difficult terrain, and overpasses, especially ones not high enough. Roads are brimming with these obstacles, which is why you have to make an effort to find the best possible route to protect the driver and the cargo.

Speaking of the driver, it’s also essential they respect state and federal laws and regulations during the drive.

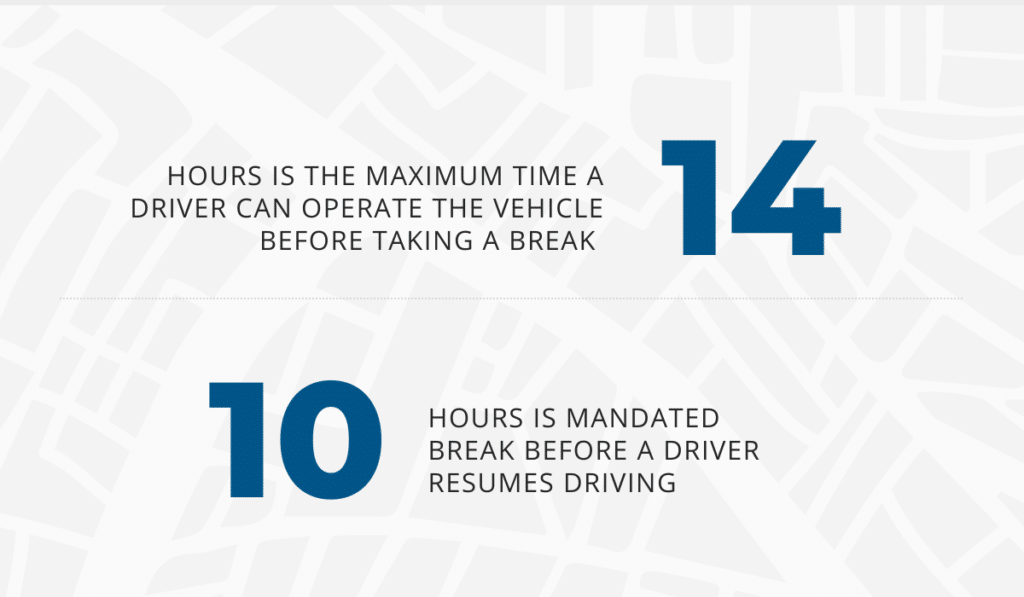

Just this year, CVSA put a whopping 1,203 drivers out of service due to hours of service. This means that over a thousand people were caught driving without having a state-regulated break, which is considered a safety violation.

When hauling, a driver can operate the vehicle for fourteen hours, after which they are obligated to take a ten-hour break before resuming driving.

The driver should also stick to the speed limit according to the vehicle weight and have all the necessary permits. Some of these permits are related to heavy equipment, which means you’ll have to obtain them from the state(s), mainly if your machinery cargo is oversized or overweight.

How can you tell if it is?

The cargo should be up to 8 feet 6 inches wide. When it comes to weight, you can go up to 80,000 pounds. If your cargo exceeds these limitations, you’ll have to size down or get a special permit.

Thankfully, careful route planning will allow you to take the relevant state regulations for heavy equipment transportation into consideration.

Anyone who transports heavy equipment needs to be aware of the rules related to cargo inspection. Occasionally, the driver should also stop the vehicle and check for any changes or damage to the cargo, chains, or tie-down points.

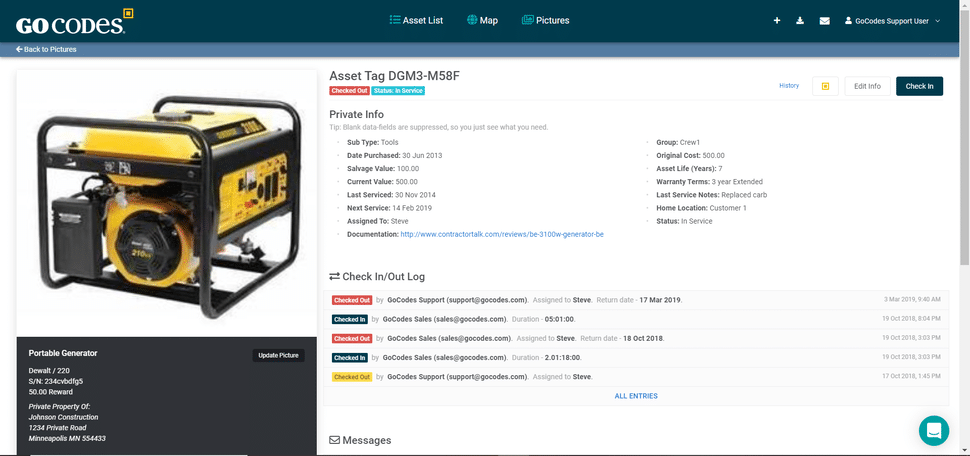

If you want to be entirely sure that your driver does this, you can use asset tracking software where they can input inspection information after a quick scan of the equipment’s QR code. The driver can do this using their mobile phone.

The data entered by the driver will instantly become available to anyone who looks for the machinery at hand in the system, thus ensuring that your drivers are following the inspection times.

The first check should happen within the first fifty miles to ensure that everything is secured correctly and that the equipment didn’t shift after the vehicle was started.

However, this shouldn’t be the only inspection. Your driver should carry out regular checks even after the equipment passes the first one. Ideally, the examinations will happen every three hours or 150 miles, whichever comes first.

Finally, the inspections that you should never skip are the ones after changing drivers. Every employee should inspect the vehicle and equipment before and after use to ensure that they’re both in optimal condition.

Safe Unloading of Heavy Equipment

The final step of heavy equipment transportation comes after a long drive, so be sure that the driver gives their full attention to this task.

Otherwise, an accident may happen.

The employees in charge of unloading should be aware of the safety hazards, such as:

- the machinery or vehicle running over their feet

- the machinery or vehicle trapping or hitting a worker

- slipping or falling while using the ramp

- tie-down chains snapping

- the machinery or vehicle tipping over

Before the vehicle enters the area designated for unloading, you should inspect and clean it, as you did before loading the equipment onto the vehicle. Again, check if the terrain is even and if the ground can hold that much weight.

Of course, don’t forget to close off the area. This includes putting up warning signs for pedestrians. You can’t risk employees or passers-by getting hurt by the vehicle and/or equipment.

On top of that, ensure that everyone working in the unloading area is wearing the necessary PPE.

Then, examine the equipment and check if everything is in place. If the chains have shifted or detached, moving the machinery might pose a risk.

The same goes for flat tires and hitches and the machinery itself. If the equipment has shifted even by half an inch, you can’t rely on the initial calculations.

So, inspect the equipment and vehicle in detail before moving the ramp as close to the vehicle as possible to begin the unloading process.

Unload the chains and binds slowly, paying close attention to their state as a snapping chain/bind can hurt those around.

After you’ve released all of them, move the machinery down the ramp slowly, careful not to make any sudden movements and pose a threat to others.

Voilà, you’re all done!

Conclusion

Heavy equipment transportation is a process that starts long before you load the equipment onto the vehicle and set out on your journey.

The process consists of four equally important phases: preparing the equipment and vehicle for loading, loading the equipment onto the vehicle, transporting the equipment using the vehicle, and unloading the equipment from the vehicle upon arrival to the destination.

Each of these stages has its own safety considerations that you need to consider.

Hopefully, you’ll remember the advice we’ve offered in this article for each step of the heavy machinery transportation process, and take some of it with you to your next transport assignment!