Key Takeaways:

- Asset identification boosts workflow visibility and leads to better equipment utilization and productivity.

- Labeling frequently stolen tools with unique IDs deters theft and increases the chances of recovery.

- Linking assets to maintenance logs and usage data supports proactive maintenance and enables timely replacement decisions.

Effective asset identification powers smoother operations, helping construction teams maximize equipment usage, cut downtime, and stay compliant.

It’s no surprise that more than half of the companies in one study reported a significant ROI from asset tracking in under a year.

This article outlines five key benefits that show why asset identification is a smart, low-cost move with high-impact results.

In this article...

Maximizes Asset Utilization

Proper asset identification unlocks real-time visibility into your equipment’s movement and usage, helping you make the most of it.

This process involves assigning unique identifiers to each asset for easy differentiation and accurate tracking across multiple construction sites.

Construction companies that label their tools and machinery gain the necessary agility to effectively (re)deploy these assets as needed.

That kind of agility is what many large-scale projects lacked, including the infamous Montreal Olympic Stadium.

A well-known Canadian journalist, Allan Fotheringam, recalls how dozens of cranes were brought in to speed up construction at some point.

Illustration: GoCodes Asset Tracking / Quote: Engaged Scholarship

Despite deploying dozens of cranes to speed up progress, many ended up sitting idle or interfering with each other.

While the stadium was a unique case, the takeaway is universal: equipment that isn’t tracked can easily become a liability instead of an asset.

Asset identification changes that.

In fact, 53% of firms across construction, transportation, and related sectors reported a strong ROI within a year of implementing asset identification and tracking tools, according to research by Automotive Fleet.

Illustration: GoCodes Asset Tracking / Data: Automotive Fleet

Where does this return come from?

For starters, continuous tracking allows you to pinpoint which assets are over- or underutilized and redeploy them efficiently.

Beyond that, asset identification and tracking also help cut unnecessary maintenance costs—something CEM Leigh Dennis notes is often triggered by usage hours.

Illustration: GoCodes Asset Tracking / Quote: Construction Equipment Magazine

Without accurate tracking, excessive idling can result in over-servicing and wasted costs.

But that’s not the only hidden cost that you can address through asset identification.

Komatsu America’s former manager, Craig McGinnis, raises another issue regarding inflated hour-meter readings, and that’s lower resale or trade-in value:

“Perhaps the highest cost of extended idling is the hour-meter reading when the machine is traded for a new machine or sold privately, or taken to auction. Lower-hour machines command higher prices than high-hour machines of the same vintage.”

Asset identification helps mitigate these risks.

Combined with predictive analytics, it also enables smarter planning around future usage, ensuring your fleet works efficiently, retains more value, and meets business needs without overspending.

Enhances Productivity

Productivity improves significantly when workers spend less time hunting for tools and more time using them.

With asset identification, you can quickly and easily locate the right equipment at the right time, eliminating delays and keeping your projects moving forward.

Instead of searching for a missing item or dealing with misallocated resources, field teams and managers gain real-time visibility into asset location and usage.

This streamlining of daily workflows directly contributes to better on-site execution, which McKinsey identified as one of the key drivers behind 50–60% productivity growth in construction.

An Autodesk/FMI survey reinforces this, revealing that 57% of construction professionals invest in field tech like asset tracking specifically to boost productivity.

Illustration: GoCodes Asset Tracking / Data: Autodesk & FMI

Tagged tools and automated movement tracking help companies reduce downtime while enhancing decision-making for managers.

Tom Richter from Nokia explains that asset tracking is a crucial component for streamlining workflows, which immediately impacts productivity.

Illustration: GoCodes Asset Tracking / Quote: Manufacturing Digital

That’s because asset identification lays the foundation for better coordination between workers and equipment.

Take a simple check-in/check-out system.

Beyond tracking who’s using what and where, it also provides insights into task progress and workforce allocation.

This added layer of visibility promotes accountability, reduces tool hoarding, and keeps everyone aligned toward project goals.

Larger assets like vehicles and heavy machinery benefit, too.

With GPS tracking and usage data, managers can assess which machines are idle, which are active, and where to redeploy them for maximum impact.

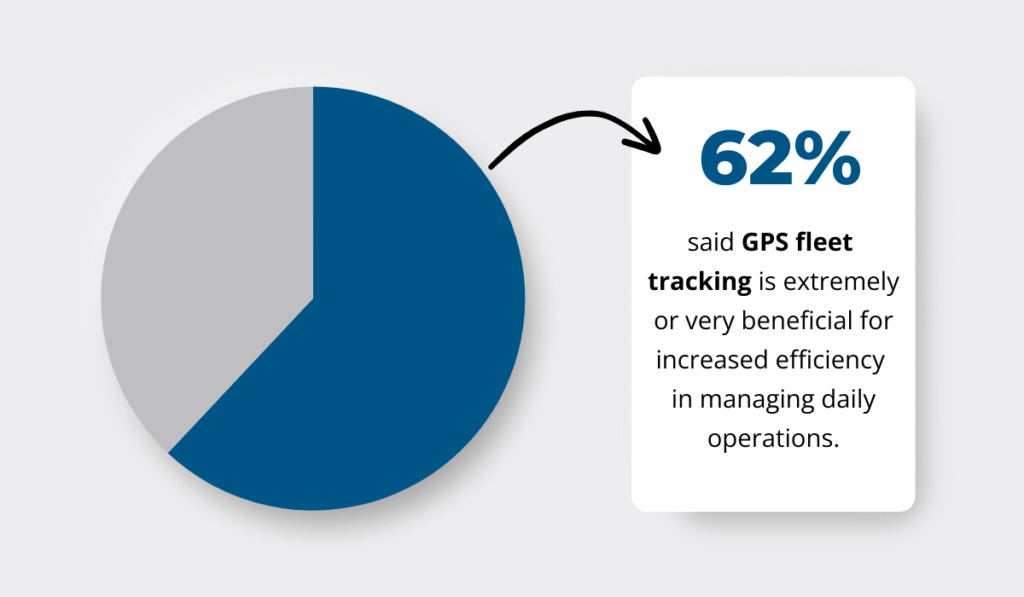

In fact, according to the previously cited Automotive Fleet research, 62% of fleet professionals report that GPS tracking is extremely or very beneficial in improving operational efficiency.

Illustration: GoCodes Asset Tracking / Data: Automotive Fleet

The bottom line is this:

With asset identification at the core of your operations, you’ll continuously drive productivity gains across the board.

Reduces Equipment Loss

Asset identification plays a key role in preventing equipment loss by making it easier to monitor inventory, deter theft, and recover missing items.

Since valuable tools and mobile equipment constantly move between crews and locations, loss is unfortunately common on busy construction sites.

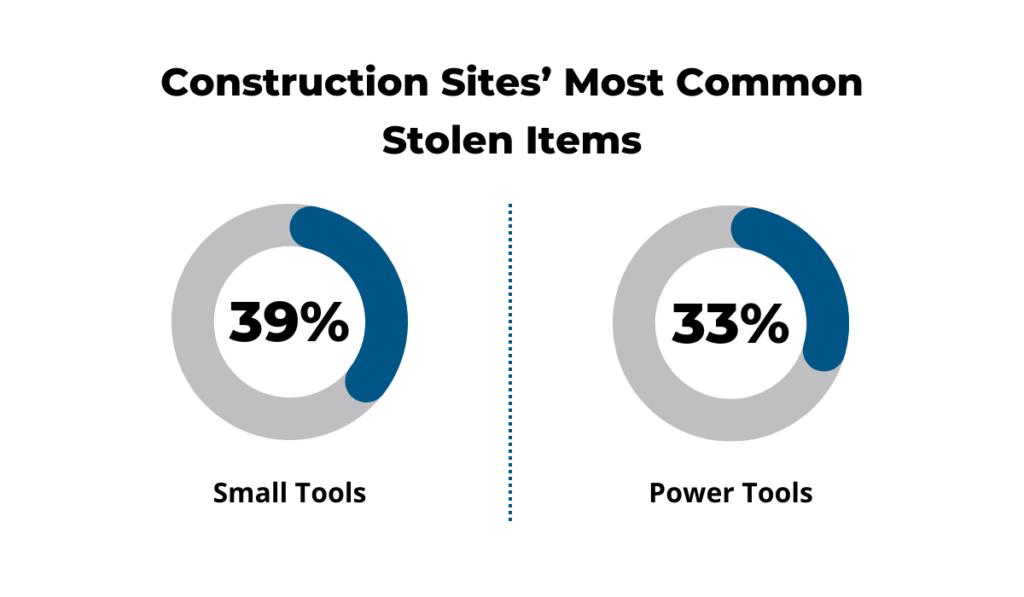

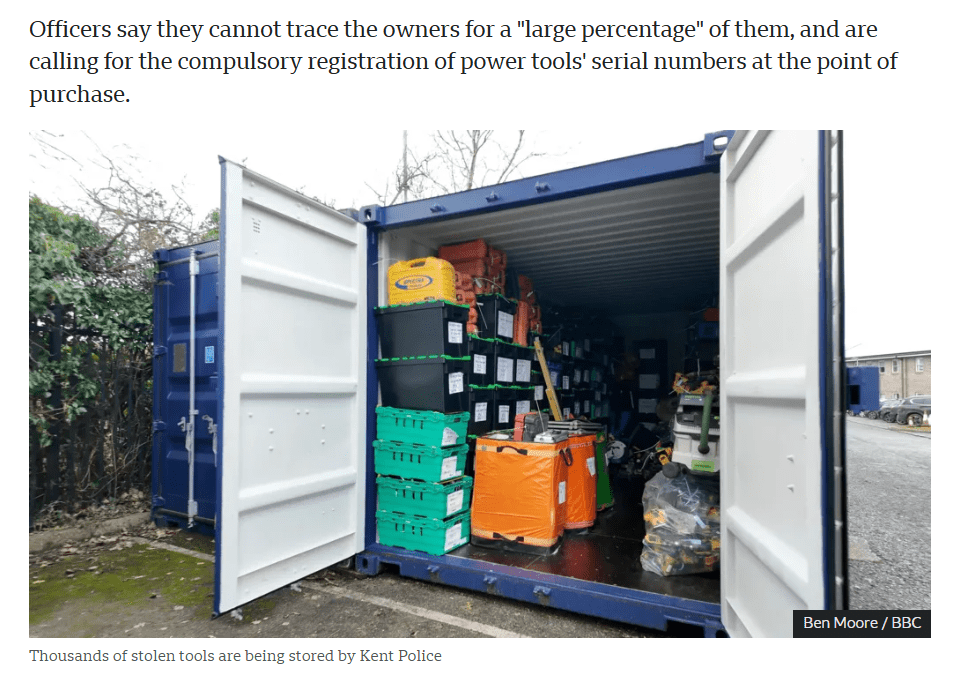

And according to BauWatch’s 2024 construction crime report, handheld and power tools remain prime targets of both organized groups and opportunists, including insiders.

Illustration: GoCodes Asset Tracking / Data: BauWatch

While heavy machinery theft does occur, smaller items are stolen far more often, mainly because they’re easier to conceal, resell, or simply go unnoticed for longer periods.

The sheer volume of tools on a jobsite makes it difficult to detect when something is missing, and the problem only escalates when tools aren’t tagged or tracked.

After all, smaller items rarely justify the cost of GPS trackers, which means they often go unprotected even if businesses invest in fleet management solutions.

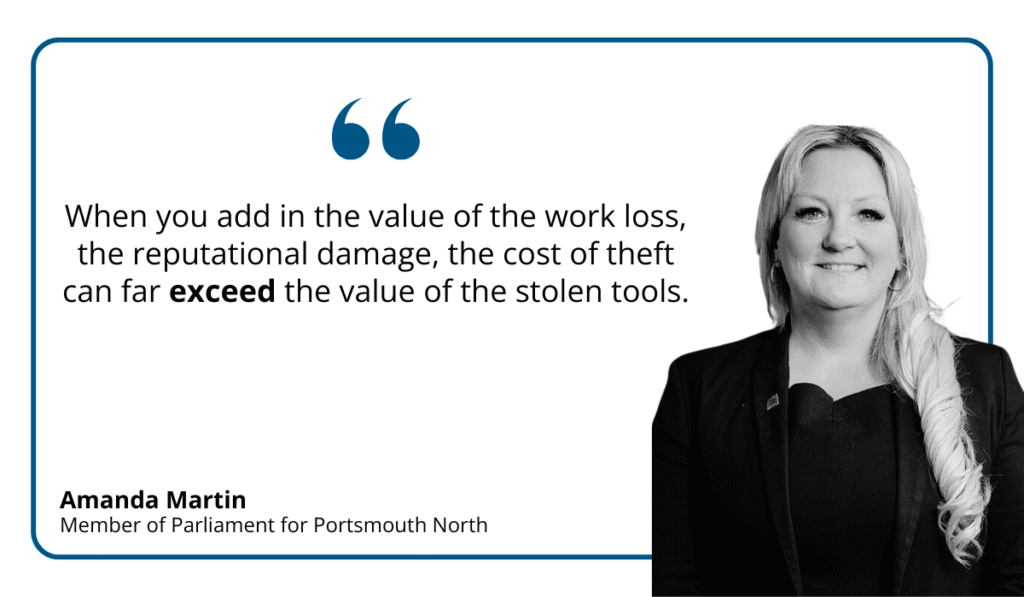

Commenting on the recent spike in tool theft across the UK, Parliament Member Amanda Martin highlights that the consequences of equipment loss extend far beyond replacement value.

Illustration: GoCodes Asset Tracking / Quote: BBC

For tradespeople and companies alike, recurring losses can derail schedules, inflate budgets, and erode trust between teams and clients.

Fortunately, asset identification can change that.

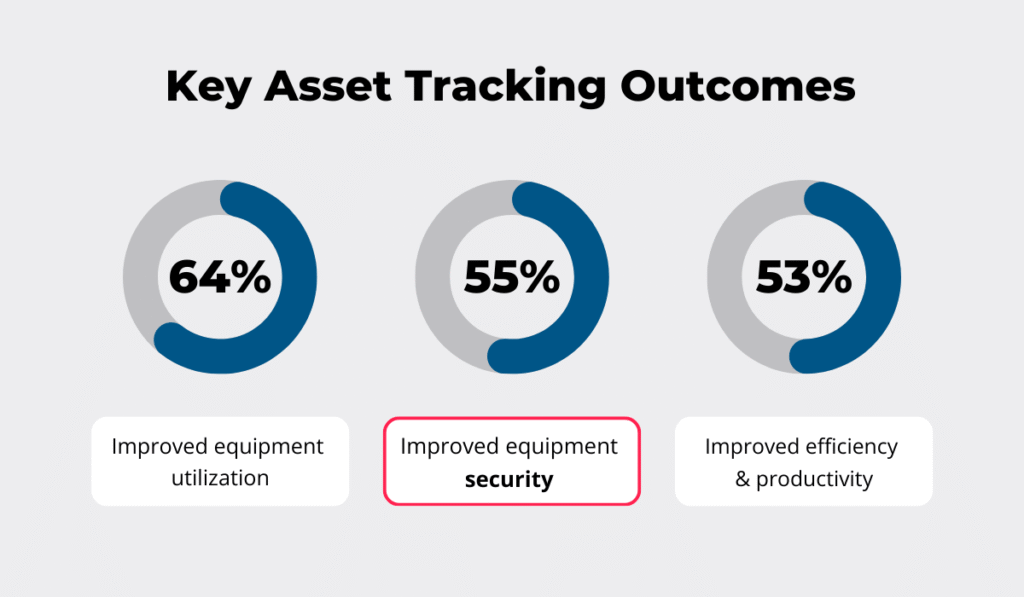

Research by Automotive Fleet shows that improved equipment security is one of the main outcomes of using dedicated asset tracking systems.

Illustration: GoCodes Asset Tracking / Data: Automotive Fleet

Following best asset tagging practices and marking each tool or piece of equipment with a durable, hard-to-remove label creates a comprehensive digital record that improves visibility and accountability.

Whether through QR codes, barcodes, or RFID, these systems go beyond identifying assets and toward establishing a clear chain of custody.

Moreover, with visual ownership markers in place, your equipment is not only less likely to “walk off” unnoticed, but you can retrieve it more easily in case it’s recovered by law enforcement.

This means avoiding a common scenario where police are unable to trace the tools back to their owners.

Source: BBC

With check-in/check-out records and visual ownership markers in place, your gear is less likely to “walk off” unnoticed and more likely to be recovered if it does.

In short, asset identification reduces the risk of loss while giving you the oversight you need to protect your investments.

Improves Maintenance Management

Asset identification isn’t just about knowing what you have—it’s also about knowing when and how to take care of it.

By linking assets to their service histories and maintenance schedules, you can move from reactive fixes to proactive upkeep.

That means fewer unexpected breakdowns, less downtime, and longer equipment life.

Here’s why it matters: maintenance and replacement decisions are closely tied to equipment usage.

Let’s say you own 10 forklifts—but only three are used constantly, while the others sit idle.

Without proper tracking, those three may wear out faster and rack up higher maintenance costs, while the rest are underutilized.

Asset identification changes the game and unlocks data-driven decision-making.

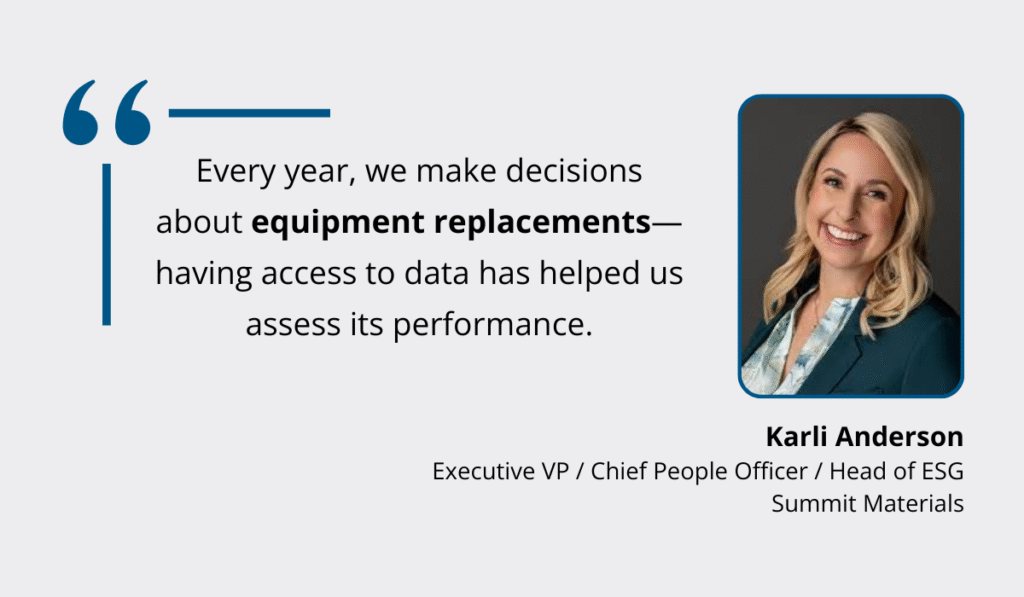

Karli Anderson, an executive at building material company Summit Materials, highlights how access to performance data helps them make more informed equipment replacement choices.

Illustration: GoCodes Asset Tracking / Quote: Samsara

Comprehensive asset management solutions combine telematics and inventory management features to provide exactly the kind of data you need to make these decisions.

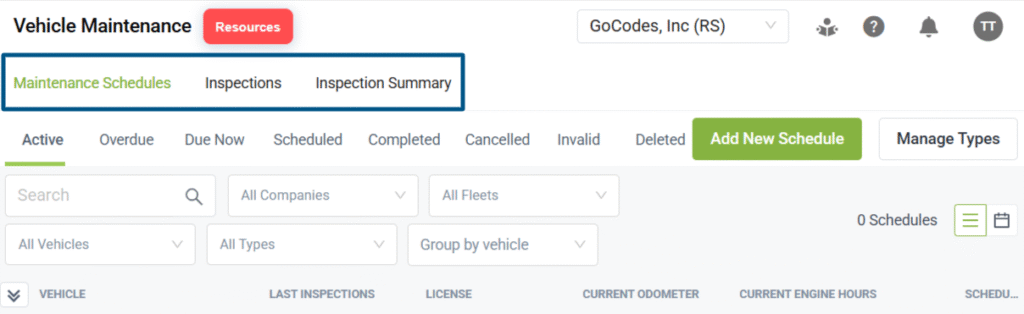

For instance, here’s a glimpse of GoCodes Asset Tracking’ vehicle maintenance dashboard, offering total visibility into scheduled maintenance, inspection summaries, and real-time condition insights.

Source: GoCodes Asset Tracking

The filters allow you to search through overdue, upcoming, and completed inspections, as well as group insights by fleets, vehicle types, and more.

Beyond vehicle insights, you can also generate reports on utilization and check related documentation with ease.

But it’s not just for fleets.

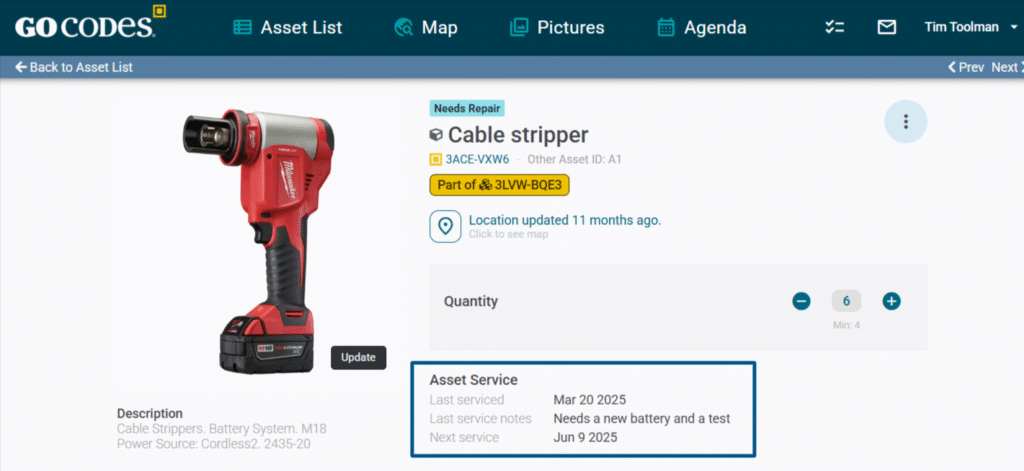

Whether you’re managing heavy machinery or hand tools, GoCodes Asset Tracking offers a single access point for records, so crew members can check important info at a glance.

As you can see below, crew members or equipment managers looking up cable strippers can see the most important information on each piece.

Source: GoCodes Asset Tracking

This is especially useful for managers overseeing larger amounts of equipment.

And that kind of visibility can pay off immediately.

As pointed out by the CIO of E.K. Services, Shawn Beinhower, if a technician in the field discovers an issue under warranty, having the documentation on hand can result in immediate savings.

Illustration: GoCodes Asset Tracking / Quote: For Construction Pros

Ultimately, when you pair asset identification with telematics and maintenance tracking, you reduce costly mistakes and keep your equipment in top shape, without the guesswork.

Streamlines Regulatory Compliance

Asset identification makes it easier to monitor inspection dates, certification status, and safety checks for each piece of equipment.

By assigning a unique ID to every asset, companies simplify reporting and ensure that each piece of machinery complies with both workplace safety standards and legal obligations.

These are the essential elements of regulatory compliance in construction.

Advanced asset tracking technologies further strengthen compliance efforts.

Authors of one academic study note that systems rooted in asset identification create robust documentation and audit trails, helping businesses demonstrate accountability during safety audits and investigations.

Illustration: GoCodes Asset Tracking / Quote: Scientific Research Archives

For example, machinery that requires periodic load testing or electrical inspections can be scheduled and verified through the asset’s digital record.

The same goes for cleanliness and hygiene standards, particularly for safety equipment like harnesses, helmets, and respiratory gear.

Adam Cambareri, an experienced OHS/IMS coordinator and consultant, points out that maintaining the hygiene of safety equipment is just as important as conducting regular inspections.

Illustration: GoCodes Asset Tracking / Quote: LinkedIn

Asset identification systems ensure every procedure is followed consistently and logged accurately while increasing transparency for compliance officers who are looking into individual assets.

With a structured, digital approach, you can minimize common errors and oversights, like forgetting a scheduled check or unknowingly using uncertified gear.

That kind of accountability is critical in high-risk environments, where compliance gaps can lead to serious consequences.

By linking every asset to a detailed inspection and compliance history, you also help reinforce a culture of safety, one with measurable business benefits:

| Legal compliance | Conducting efficient safety audits helps you comply with various safety regulations and avoid costly fines and penalties. |

| Fewer accidents and injuries | Identifying potential hazards and implementing corrective actions can significantly reduce the number of on-site injuries or fatalities. |

| Cost savings | Having fewer accidents and injuries lowers the costs associated with medical expenses, compensation claims, and potential delays. |

| Higher employee morale | Improving overall safety also contributes to higher job satisfaction, leading to improved employee morale and productivity. |

In short, when every asset is labeled, traceable, and regularly inspected, compliance becomes less of a burden and more of a competitive advantage.

Conclusion

Manually tracking your equipment works—until it doesn’t.

Sudden breakdowns and lost tools slow down processes while pushing costs ever higher.

That’s where asset identification changes the game.

By giving every asset a unique digital identity, you unlock real-time visibility, simplify maintenance, streamline compliance, and boost productivity, without adding more admin work.

Construction companies that embrace dedicated, field-ready asset identification systems gain tighter control over their equipment, faster insights, and fewer costly surprises.

Whether you’re scaling up or just trying to keep daily chaos in check, investing in smart asset identification is a crucial step toward smoother, more cost-effective operations!