Ensuring your construction equipment stays in top-notch condition is crucial for your company’s success.

It not only prevents costly breakdowns and project delays but also safeguards your workers from potential accidents caused by faulty equipment.

However, effectively tracking equipment maintenance isn’t always a walk in the park, especially if you fall prey to mistakes.

Today, we’ll outline the five most common ones. If you do find yourself making any of these slips, don’t worry—we’ve got you covered with solutions to steer clear of these pitfalls.

Let’s jump straight into the first mistake on our list.

In this article...

Failing to Accurately Document Maintenance Activities

If you don’t properly document equipment maintenance activities, it’s as though you haven’t performed maintenance at all.

And yes, we’re serious about this.

When standardized procedures for tracking maintenance activities are absent—such as maintenance dates, tasks performed, parts replaced, and personnel involved—the result is nothing less than inconsistencies and errors in maintenance records.

These inconsistencies can lead to serious consequences:

| Inability to demonstrate compliance with regulatory requirements or industry standards related to equipment maintenance. |

| Lack of proper documentation leads to overlooked maintenance tasks, increasing the risk of equipment failure and workplace accidents. |

| Without accurate records, it’s challenging to track maintenance history and identify patterns of wear or potential issues, leading to decreased equipment performance and productivity. |

| Inefficient maintenance scheduling and failure to address issues promptly can result in higher repair costs and increased downtime. |

| Manufacturers may require documented proof of maintenance for warranty claims, and if you can’t provide this documentation, it could result in denied claims and additional expenses for repairs. |

| In the event of accidents or injuries, inadequate maintenance documentation may expose you to legal liabilities and financial penalties. |

| All of the above can also damage your company’s reputation, which means no trust and less work for your business. |

As you can see, the consequences of failing to document maintenance activities are too severe to ignore.

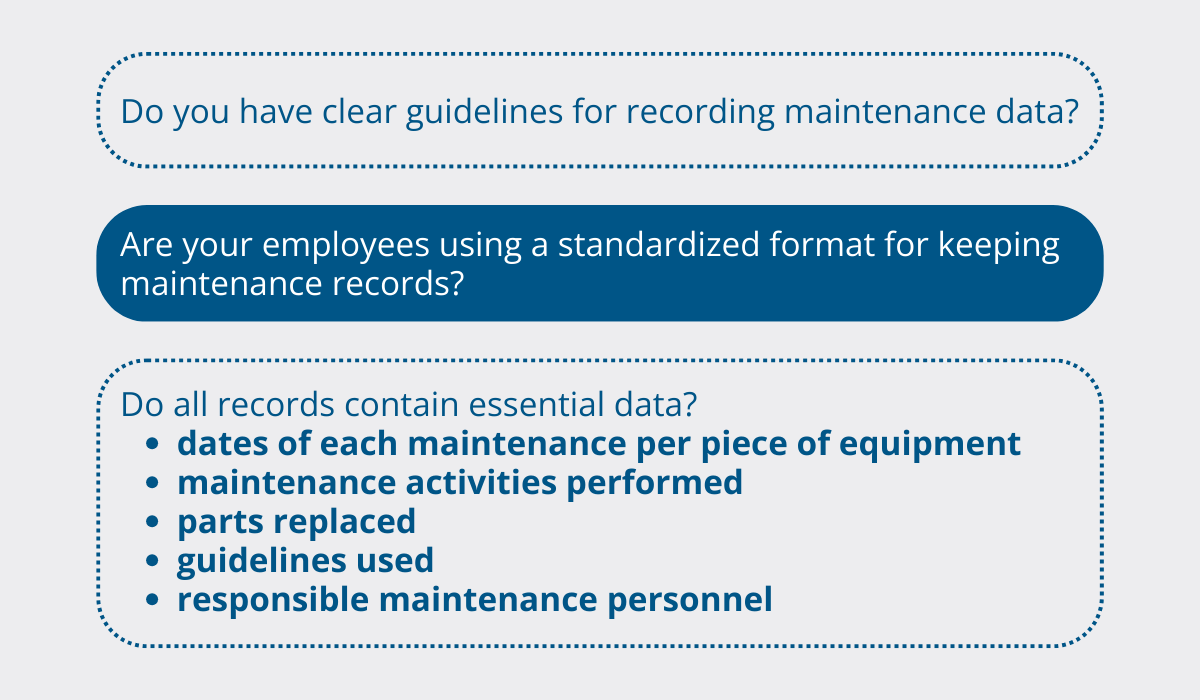

Even if you do keep track of equipment maintenance records, it’s essential to ask yourself the following three questions:

If you’re unsure or the answer is no, it’s time to reassess your maintenance data tracking and recording methods.

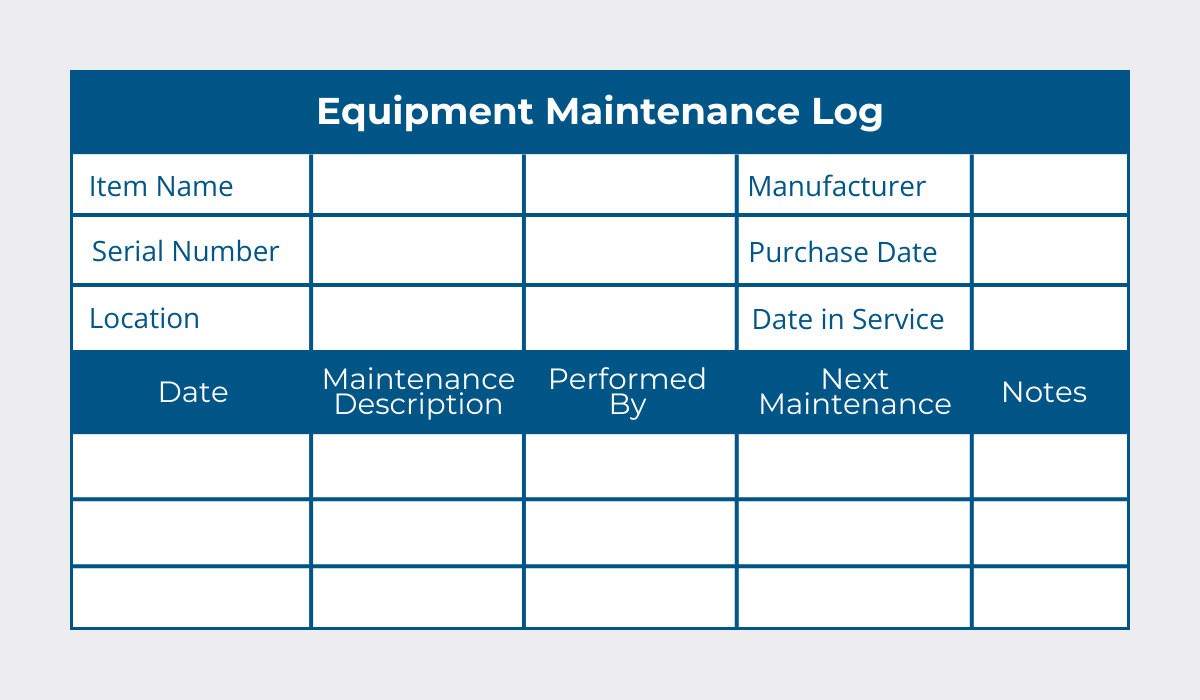

One solution that will help you track your equipment maintenance accurately is a standardized maintenance log template, like the one in the image below, or a digital form for recording maintenance activities.

It goes without saying that you should also train employees on how to fill out the form correctly, including the proper format for dates, the level of detail required for each activity, and any specific maintenance guidelines to follow.

And, of course, teach your employees how important it is to keep records accurately to demonstrate compliance with regulatory requirements, ensure equipment safety and reliability, and mitigate legal and financial risks.

Otherwise, you and your team may find yourself repeating this mistake.

Not Prioritizing Maintenance Activities

Another critical mistake often overlooked in equipment maintenance tracking is failing to prioritize maintenance activities.

When you neglect to prioritize tasks based on equipment criticality, usage patterns, and operational needs, inconsistencies or gaps in tracking maintenance activities can occur.

Also, without clear prioritization, determining which tasks should be recorded and tracked first becomes challenging, leading to incomplete maintenance records where crucial activities may be overlooked or not properly documented.

For instance, consider an incident where a crane collapsed in New York, causing extensive damage and injuries.

Investigations suggest a hydraulic fuel leak as the cause, which could result from various factors such as wear and tear, damaged components, or improper maintenance practices.

While the exact cause is still under investigation, it’s plausible that inadequate maintenance—including the neglect of regular inspections or failure to replace worn-out parts— may have contributed to the incident.

In other words, this crane’s maintenance may not have been prioritized.

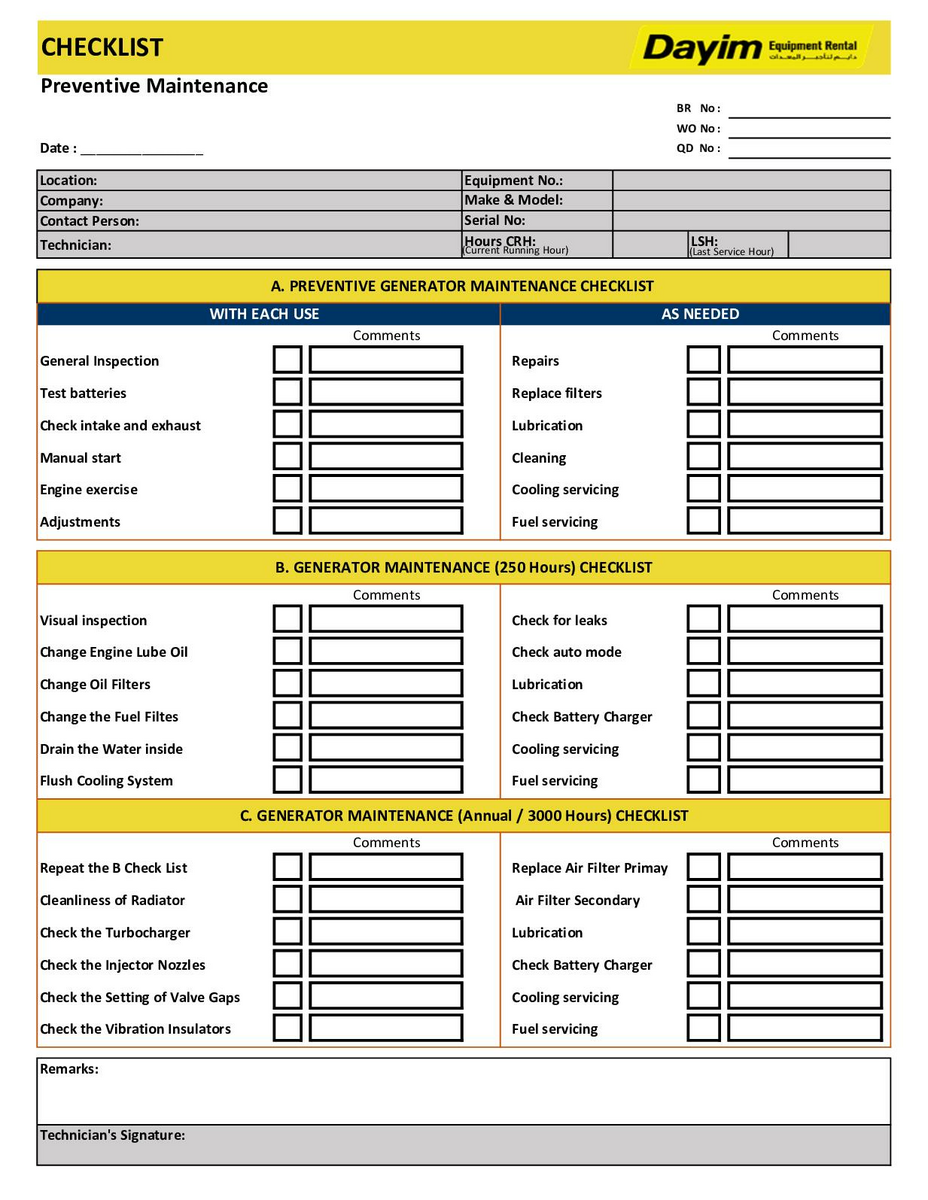

A preventive maintenance checklist proves invaluable in addressing this issue, as it aids in prioritizing tasks based on their importance and urgency.

By utilizing such a checklist, technicians can quickly identify high-priority tasks requiring immediate attention, ensuring efficient allocation of time and resources.

Such a proactive approach minimizes the risk of accidents and equipment failures by promptly addressing critical maintenance activities.

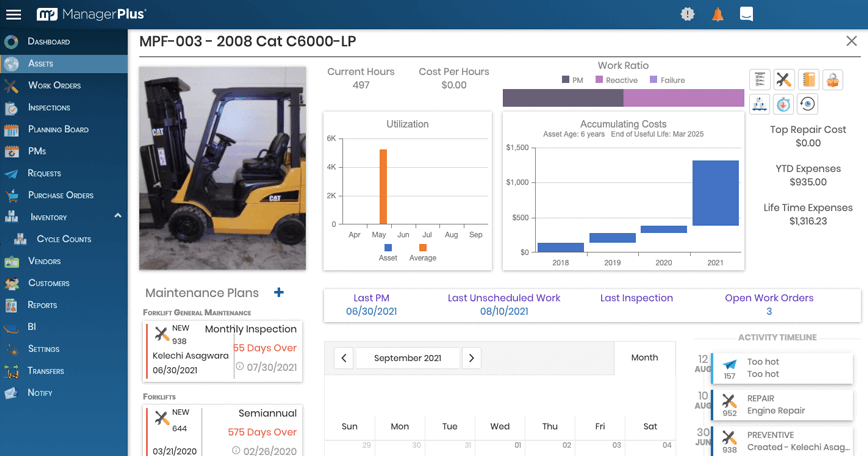

What’s more, consolidating all maintenance data in a single accessible platform (or software) facilitates effective task prioritization and could, therefore, be a smart solution to avoid this mistake.

When you can see all maintenance records and upcoming tasks at a glance, you can make informed decisions about which activities require immediate attention.

This enhances equipment safety and also prolongs its lifespan, ultimately ensuring a safer working environment.

In essence, failing to prioritize maintenance activities can have dire consequences and lead to safety hazards.

To avoid such incidents, it’s necessary to implement a structured approach to maintenance prioritization, leveraging preventive maintenance checklists and centralized maintenance tracking systems.

Relying on Manual Data Entry

Are you still manually entering maintenance data in the system? Or—are you keeping maintenance records in paper form?

If so, it’s time to shed light on the inherent risks of such data handling.

Manual data entry poses a significant challenge in maintaining accurate and reliable maintenance records for your equipment.

Here’s why.

Manual data entry is prone to human errors such as typos and transcription mistakes.

These errors can lead to inaccuracies in maintenance records, compromising the reliability and usefulness of the data for decision-making purposes.

Manually entering maintenance data is also a time-consuming process.

It requires you and your team to spend valuable time on data entry tasks that could be better utilized for more critical activities.

In other words, manual data entry impacts your overall productivity and efficiency.

On top of that, paper-based maintenance records are often stored in physical files or binders, making them less accessible than digital records.

Retrieving specific information from paper records can also be time-consuming and cumbersome, especially when quick access to maintenance history is crucial.

For example, in an equipment breakdown, having to sift through physical files to find relevant maintenance records could delay troubleshooting and repair efforts, leading to extended downtime.

Fortunately, the mistake of relying on manual data entry can be easily solved.

Instead of manually keeping track of equipment maintenance, you can invest in automation solutions such as QR codes or RFID tagging systems or utilize maintenance tracking software with data validation features to minimize manual data entry errors.

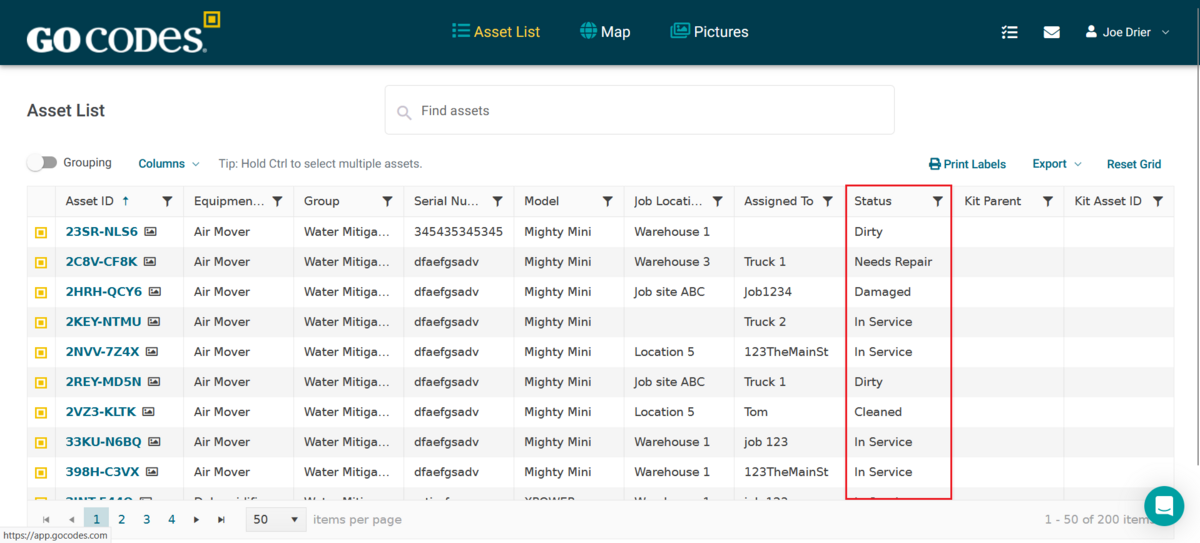

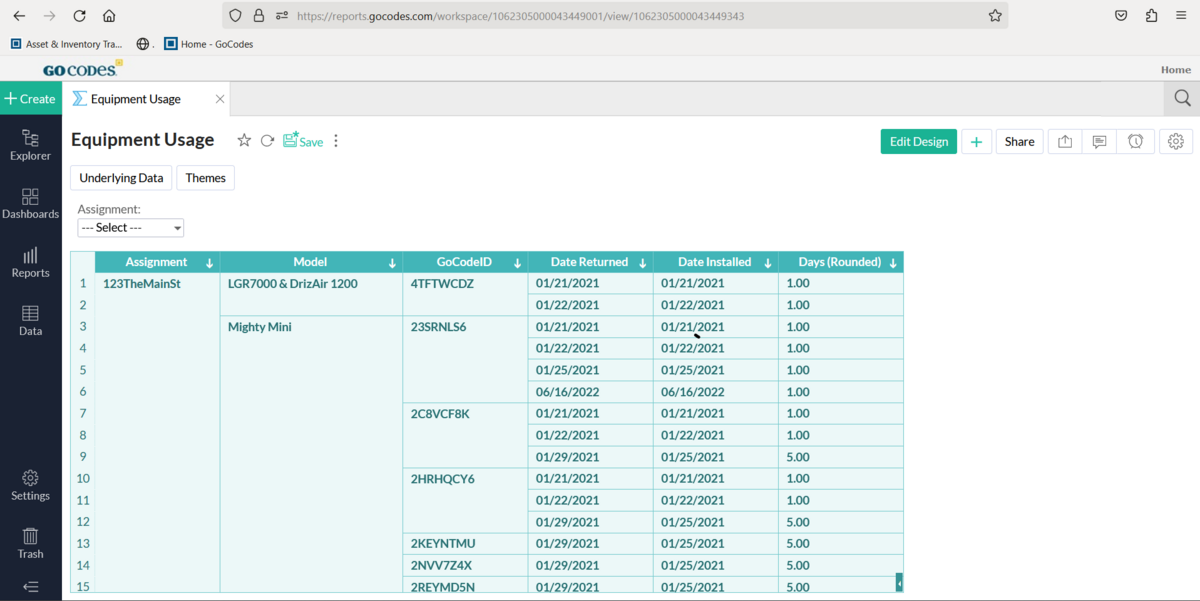

One such automation solution is our asset tracking software, GoCodes Asset Tracking.

GoCodes Asset Tracking uses QR code tags that you attach to your equipment and then scan with a mobile phone app scanner.

Whoever has to use that piece of equipment can easily scan the QR code and see in which condition it is—whether it’s safe to use or if it is waiting for maintenance.

Also, with GoCodes Asset Tracking, you have all your asset data—including maintenance records—in one centralized location, from where you can automatically send out work orders and assign maintenance tasks.

Since you can do this in just a few clicks, you avoid manually entering data, save time, and ensure that the person who needs the information in question gets it immediately.

That’s extremely important for maintenance workers.

When performing maintenance activities, technicians can conveniently scan the QR code affixed to the equipment using a smartphone or QR code scanner and instantly access the asset’s maintenance history, equipment manual, and other relevant documents directly from the system.

This lets them quickly review past maintenance tasks, identify recurring issues, and ensure the correct procedures are followed.

In summary, relying on manual data entry for equipment maintenance tracking introduces various risks and inefficiencies.

From increased error rates to limited accessibility, manual entry hampers the effectiveness of your maintenance tracking efforts and compromises overall operational efficiency.

It’s time to replace it with automation.

Overlooking Regulatory Compliance Requirements

In the US, adherence to Occupational Safety and Health Administration (OSHA) guidelines is crucial for ensuring workplace safety, especially in construction.

And many of their guidelines cover various regulations on heavy machinery operations, including regular inspections and maintenance.

Overlooking or neglecting these requirements can expose you to compliance issues, fines, and legal liabilities.

However, the most tragic consequence of overlooking regulatory compliance is the potential loss of life.

A recent incident involving John Oliveira & Sons Stamp Concrete Inc., a Massachusetts-based contractor, highlights the dire consequences of neglecting regulatory compliance in equipment maintenance.

Following a worker’s death, OSHA investigated the company’s safety practices and found alarming lapses.

An employee’s fatal accident occurred when removing a soil screen from a conveyor without disabling the power source.

OSHA discovered that the company lacked proper equipment and energy control plans to identify and minimize hazards, as required by regulations.

Additionally, essential safety hardware, such as locks and tags, was missing, leaving machines and equipment vulnerable.

On top of this, the inadequate maintenance of the soil screener further uncovered that the company was negligent in upholding regulatory compliance.

All these led to a loss of life and $ 201,000 in penalties for the company.

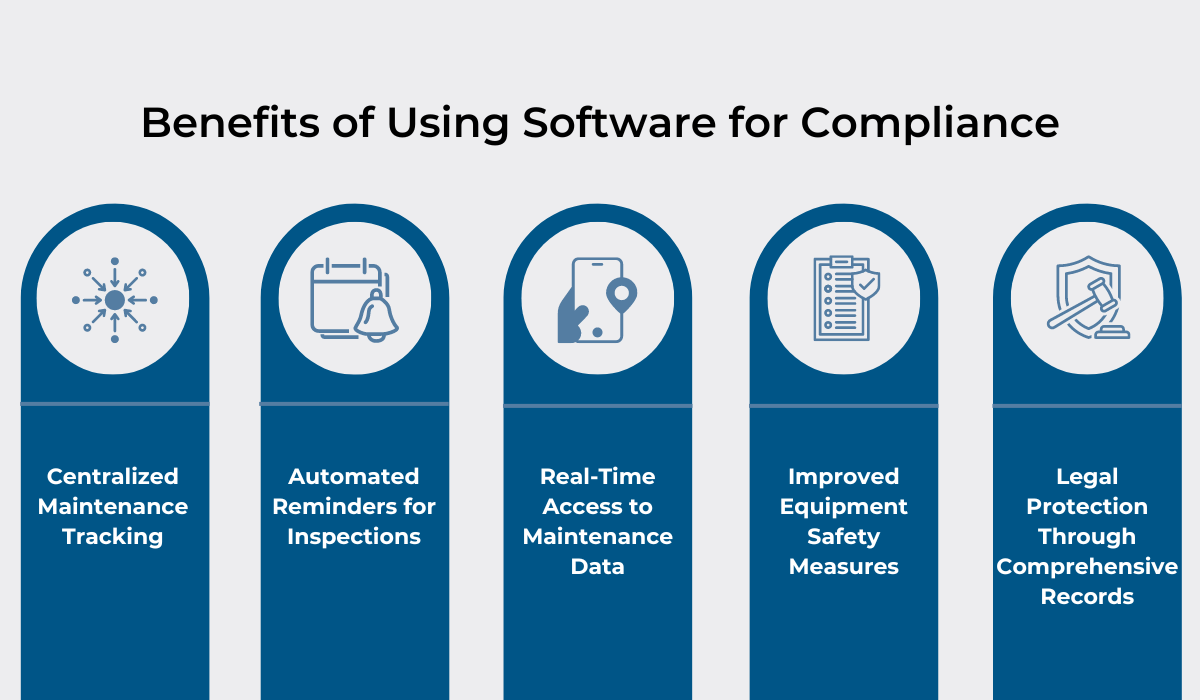

To prevent similar tragedies and ensure your construction company complies with regulations, consider implementing cloud-based software for equipment maintenance tracking.

This software allows you to store maintenance data for each piece of equipment, including regulatory standards, in one place.

It ensures that all relevant information is readily accessible to technicians during their work.

Furthermore, software with preventive maintenance functionality can schedule recurring safety-related tasks, such as equipment inspections and calibrations, to address potential hazards and prevent accidents to the highest extent possible.

While these tasks may not entirely eliminate the risk of incidents, they are essential for identifying potential hazards early on and implementing measures to mitigate them.

In simpler terms, such proactive maintenance will improve overall job site safety.

And last but not least, when you have a comprehensive log of equipment maintenance activities stored in such software, it is evidence of proactive maintenance practices during audits and inspections.

So, it can also protect you from a legal point of view if it comes to incidents.

The key takeaway is this: regulatory compliance should never be overlooked when it comes to equipment maintenance because it’s not just about avoiding legal fines and reputational damage.

You risk someone’s life, too.

Failing to Analyze Maintenance Data

Another common mistake that construction companies make is failing to analyze maintenance data.

If your company falls into this category, you’re missing out on valuable insights that could optimize your maintenance strategies and enhance operational efficiency.

This mistake becomes even more critical when manual data entry is involved, because without digitized data and analytical tools, identifying areas for improvement or predicting future maintenance needs becomes cumbersome and less accurate.

But there’s a solution to this.

Remember the first mistake we discussed—failure to document maintenance activities accurately?

Well, fixing that mistake puts you halfway towards resolving this one.

Why?

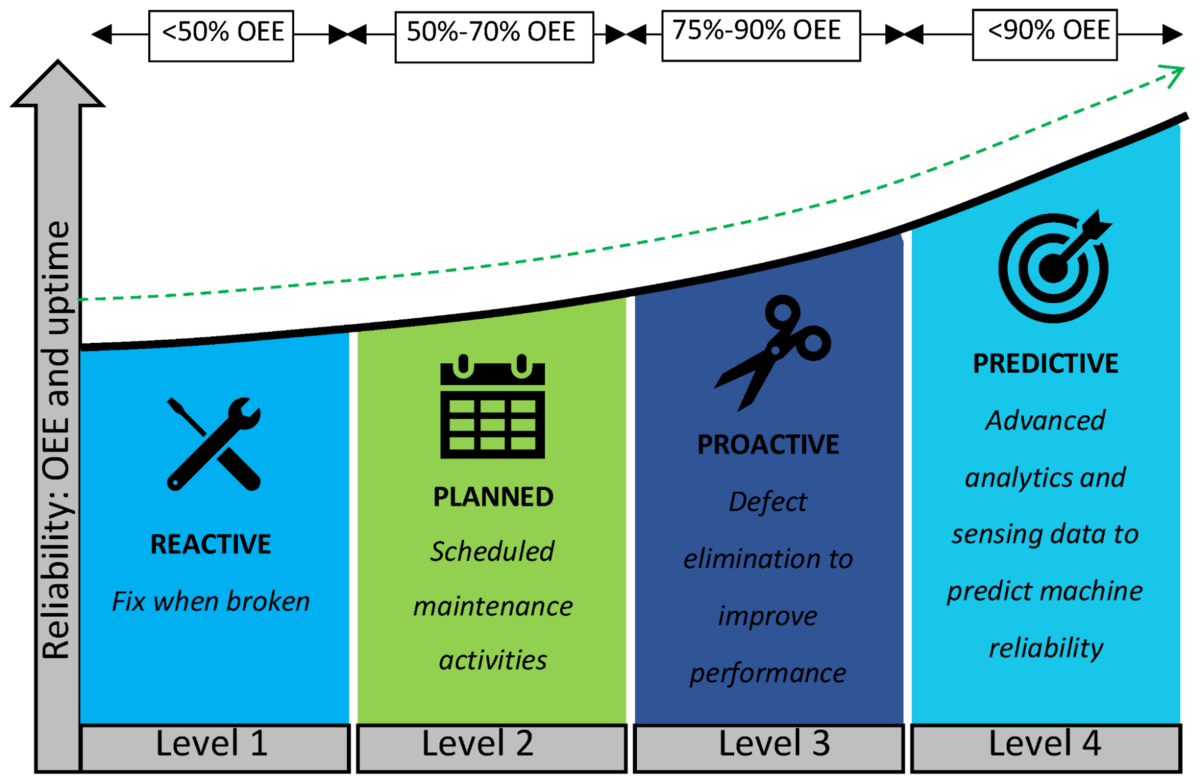

Proper documentation of maintenance activities creates a database of maintenance history, which is the foundation for predictive analytics.

Predictive analytics involves using historical data together with statistical modeling and machine learning algorithms to predict equipment failures before they occur.

By analyzing patterns and trends in maintenance data, predictive analytics can forecast potential issues, allowing you to take measures to prevent breakdowns and reduce downtime.

In other words, to implement predictive and proactive rather than reactive maintenance.

Source: MDPI

Predictive maintenance can also be possible if you use sensors or other monitoring devices to access real-time information on the functioning of your equipment, such as engine temperature, fuel consumption, and hydraulic pressure.

This real-time visibility allows you to identify potential issues before they turn into serious problems causing expensive downtime.

If you don’t go into full predictive analytics mode immediately or don’t use such sensors, you can still make use of data that you already have in your asset management system.

Let’s illustrate this.

As you know, different equipment requires different maintenance scheduling.

For example, a bulldozer is better off maintained based on its usage patterns rather than adhering strictly to a calendar plan.

So, you can use its usage time data and data on previous maintenance, analyze it, identify patterns, and then schedule its maintenance.

Of course, this will only work if you properly train your team on how to analyze and interpret data.

Investing in ongoing training and skill development for your team should, therefore, be a priority.

In summary, adequately documenting maintenance activities and embracing data can improve equipment reliability, reduce downtime, and optimize maintenance costs.

All this can, ultimately, prolong your equipment’s lifespan and improve your company’s bottom line.

Conclusion

And that brings us to the end of this article.

Equipment maintenance tracking can, indeed, seem challenging or even pointless if you keep making the five mistakes we outlined today.

But, as you saw—each of them can be easily avoided with the right approach.

And the solution is almost always going digital and using some sort of tool or software that will help you track maintenance more easily and store data in one place where it can be accessible to both teams who schedule maintenance and those who perform it.

So, take a moment to reassess your current approach to equipment maintenance tracking and consider the solutions we’ve presented here.

With the right tools and strategies in place, you’ll be well-equipped to avoid these mistakes.

Good luck!