In construction, keeping track of your assets is essential.

Tools and equipment are constantly in use and circulating from one construction site to another, so it is important to be aware of their location and status at all times.

This can be achieved with the help of asset tags.

In this article, we are going to take a look at different types of asset tags and offer insight into the purposes they can serve.

If you’re a construction manager looking to find out more about how your business can benefit from implementing asset tags, this post is for you.

In this article...

What Is an Asset Tag

Asset tags are a key component of asset tracking and management.

They are labels that serve the purpose of identifying assets with the help of serial numbers and are used in conjunction with asset tracking software.

In order to better serve their purpose, asset tags should contain key information about the construction company, but also about the asset itself.

Including company information such as the company name and logo can be beneficial in cases of loss or theft of tools and equipment.

You also need to be able to access information about the asset itself, which can be achieved by including the asset ID number.

We encourage you to assign a unique identification number to each individual asset.

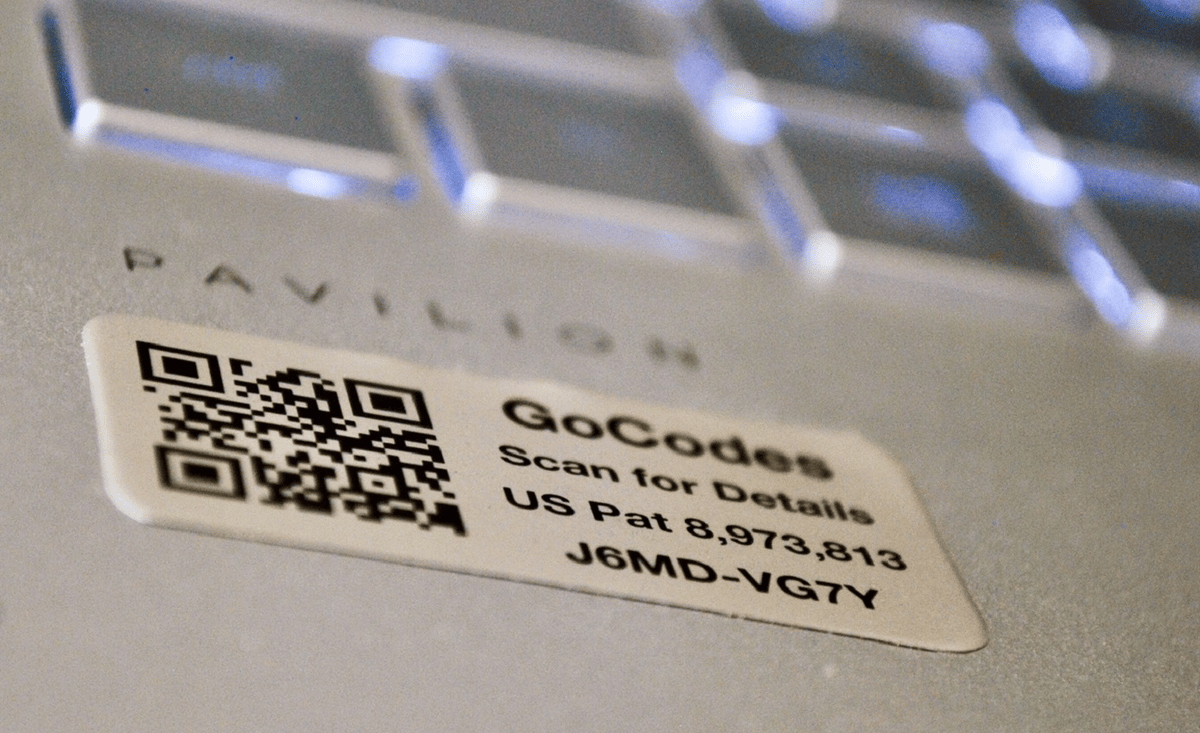

To make this easy, GoCodes Asset Tracking has developed a QR code technology where each of our labels comes with a unique and randomized 8-character code that will be associated with the asset you attach it to throughout its lifespan.

Types of Asset Tags

Now that you have an idea of what asset tags are, it is time to look into four different asset tag types: QR, barcode, RFID, and BLE asset tags.

Given that there are many asset tag options, you may feel unsure about what to look out for once you start doing your research.

One of the key factors to consider is the work environment, advises Tina Huff, Marketing Director at Avery Products Corporation.

Once you determine the conditions your assets will be used in, you can make an informed decision about the asset tag types that are the best fit for your needs.

QR Asset Tags

QR (quick response) code asset tags are a popular choice when it comes to tracking construction tools and equipment because they are easy to implement and use.

All you need to do is open the camera on your smartphone and scan the code from any angle to instantly identify the asset.

This technology makes access to asset information quick and convenient.

Not only are QR codes quick to scan, but they can also hold a large amount of asset information, seeing as they are two-dimensional.

This is especially useful in construction, seeing as it is going to allow you to store more data about the asset—from the manufacturer name, asset model, location, and status, to the user manual for it.

QR asset tags are a safe choice, thanks to the fact that they can be used for both big and small assets, indoors and outdoors, as well as in harsh environments.

Even if some of the boxes on the QR code tag get scratched, you will still be able to scan it and obtain asset information from another part of the tag.

Barcode Asset Tags

Barcodes are well-known and widely used for tagging assets in various industries.

These identifiers, consisting of vertical lines of different widths, might seem like a good option because they are easy to use and cost-effective.

Nowadays, you no longer need a barcode scanner in order to read the code—you can simply use your smartphone for that purpose.

However, regardless of their accessibility, affordability, and ease of use, barcodes aren’t always the best choice when it comes to tagging assets in the construction industry.

Unlike QR codes, barcodes are one-dimensional, thus storing less asset information.

Thanks to this one-dimensionality, they are also less convenient to scan, given that they need to be in the direct line of sight for you to be able to scan them properly.

RFID Asset Tags

RFID (radio-frequency identification) is a technology that has gained popularity in the field of asset tracking and management over the last couple of decades.

RFID tags are small devices, usually made of plastic, that contain microchips which store data about the asset.

When scanned, they transmit a signal which is then read by an RFID reader, providing information about the asset they are attached to.

RFID tags also have a higher level of security thanks to the fact that they can be password-protected or encrypted.

WiseTrack’s program manager Todd Edmondson believes that RFID tags are the barcodes of the future:

Unlike barcode asset tags, they don’t require a direct line of sight in order to be scanned and can store large amounts of asset information.

Many RFID readers have the ability to read multiple tags at once, so they are a great choice for locating tools and materials indoors, such as in your warehouse.

However, since they aren’t able to provide geographical information about moving assets, they aren’t ideal for tracking assets outdoors.

BLE Asset Tags

BLE (Bluetooth Low Energy) is a technology that was introduced in the last decade and has been gaining popularity in the field of asset tracking and management.

Let’s take a look at the definition of BLE technology:

The BLE technology stands out due to the fact that it consumes very little energy.

BLE asset tags have a built-in battery that can last for several months or even years, thus enabling continuous and real-time asset tracking.

The BLE beacon tags are placed on assets, and they then communicate with BLE receivers in order to track the location of assets.

To actually see your assets in real-time, you also need an asset tracking system that stores asset information the BLE receivers have collected from the tags.

Take a look at the GoCodes Asset Tracking BLE beacon below:

Apart from the classic QR code asset tags, GoCodes Asset Tracking now also offers BLE beacons for tracking and managing your assets and inventory.

The GoCodes Asset Tracking G-100 Bluetooth Beacons have a 100M range and don’t require you to scan the label, thus making locating and managing your assets quick and easy.

What Are Asset Tags Used For

Asset tracking is a powerful and convenient tool that can help you remain aware of the location, availability, and mechanical health status of your assets.

Having access to this information will ensure your construction business is running smoothly and your assets are performing at an optimal level.

Asset tags, in combination with asset tracking software, have various functionalities, some of which we are going to explore in more detail.

Tracking Company Assets

Tracking assets—primarily tools and equipment used on the construction site—is one of the key functionalities of asset tags.

Soeren Brogaard, the CEO of Trackunit, states that construction workers spend 10% of their time each day looking for tools.

This negatively impacts worker productivity and can cause delays in the project timeline.

By tagging your assets, you can significantly reduce the amount of time your workers spend trying to find out where the tools they need are and whether they are already in use.

Asset tracking provides quick access to asset information by scanning the asset tag using a smartphone.

Using asset tags in conjunction with an asset tracking system can help you stay in the know about the whereabouts and availability of your assets at all times, thus making sure you remain well-organized.

Managing Company Inventory

Apart from keeping track of your tools and equipment, you can use asset tags to manage your consumable items.

Having a clear overview of all of your materials will give you control over how you purchase and store them.

While you can track your inventory manually, using a combination of asset tags and asset management software can save you a lot of time and effort.

You can automate the inventory management process by placing asset tags on your consumables and then scanning them to get information about their status from the asset tracking system.

This way, you will instantly know whether certain items are low in stock, how soon you need to repurchase them, and whether you have enough room in the warehouse to store them.

Additionally, managing your inventory this way is more reliable.

Given that all of the data is securely stored and backed up, you don’t have to worry about losing information that is crucial to the success of your business.

Preventing Asset Theft

According to the National Equipment Register’s latest available Annual Theft Report, the annual estimate of the cost of construction equipment theft is in the range of $400 million.

These numbers serve as confirmation for construction businesses that it is important to prioritize strengthening their on-site security in order to prevent theft.

Apart from installing remote video surveillance, fencing, and lighting, it is recommended to properly tag all of your construction site assets in order to deter equipment thieves.

When potential perpetrators see that the item is traceable, they will be less likely to steal it.

The task of tagging your valuable assets might be time-consuming, but it pays off in the long run.

Without keeping an accurate inventory of all of your tools and equipment, you can’t be sure whether an asset got stolen or misplaced.

Tagging all of your assets will give your team the ability to check them in and out so that you always know exactly where they are being used.

If despite all your efforts, an asset does get stolen, a tag containing your company information can help the authorities confirm ownership and make sure it’s returned to you.

Monitoring Maintenance Schedules

When it comes to planning and scheduling the maintenance of your tools and equipment, you may feel like this is something you can keep track of manually.

However, if the maintenance log gets misplaced and servicing isn’t carried out according to schedule, issues with the project can ensue.

A simple way to combat this is to automate the maintenance management process with the help of asset tags and asset management software.

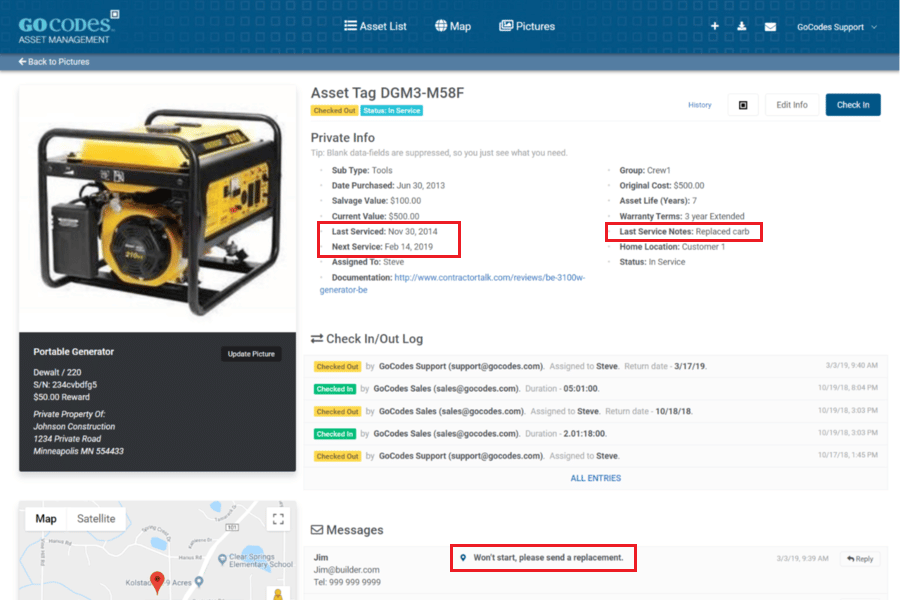

This is what maintenance information looks like in the GoCodes Asset Tracking asset management system:

An asset management system is going to allow you to centralize all information related to your assets, including details about their condition.

Tagging your assets not only lets your team scan the tag and check whether the tool they need is performing well but also helps you organize preventive maintenance in order to avoid potential issues.

Preventive maintenance is key for avoiding unnecessary downtime caused by serious tools and equipment breakdowns.

You can set up your asset management system to send you notifications whenever an asset is due for preventive maintenance, thus recognizing and solving issues as soon as possible.

Conclusion

Using asset tags in conjunction with an asset management system is going to help you organize and track your assets and inventory with ease and accuracy but also aid in preventing asset theft and equipment breakdown.

Regardless of what type of asset tags you opt for, make sure that they are suitable for the conditions in which the tagged assets will be used. Lastly, take the time to assign a unique ID number to each asset.

That way, you are making sure that you and your team have access to accurate and up-to-date information about the status of individual assets.