The construction industry is often labeled as one of the greatest modern-day polluters.

Moreover, some building materials, like concrete, are so widely used that the adverse effects they have on the environment cannot be overstated.

As the awareness of this issue grows, more and more sustainable construction materials are being created.

This article will present the top 18 sustainable materials you should look out for.

In this article...

Recycled Steel

Steel is already the most reused material in the world, since it retains its strength when recycled. Its low cost and ease of recycling are also an advantage.

Steel is an alloy made of iron and some carbon that boosts its strength and resistance. It’s used everywhere: infrastructure, buildings, ships, cars, trains, machinery, and electrical appliances.

Let’s go over its pros and cons.

| PROS | CONS |

| Can be endlessly recycled without losing strength | Transport costs and emissions (going to recycling centers) |

| Recycling saves energy and resources (less mining) | Energy costs and emissions for recycling steel |

| One of the easiest materials to recycle |

As you can see, while the costs and environmental impact of processing are still substantial, recycled steel offers strength and durability on a par with regular steel, which makes it a viable solution for many construction companies.

Recycling is becoming more present in the construction industry, so join the trend and try to source recycled steel for your building needs.

Rammed Earth

This technique has been around for ages, but it’s recently been gaining momentum as a sustainable building method, and for good reason.

Let’s take a closer look at how rammed earth is used in construction.

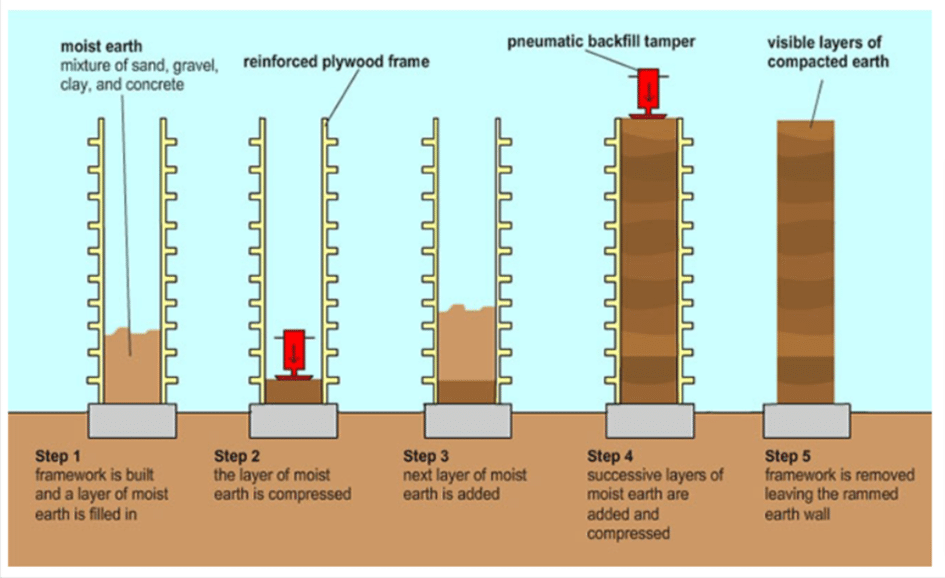

Damp earthen materials (sand, gravel, clay) are layered and compacted into a formwork, with a binder (stabilized) or without (raw).

Once all the layers are in place and they’re compressed enough for the structure to be stable on its own, the frame is removed.

The graph below shows how rammed earth walls are erected.

The benefits of this building technique are numerous and outweigh the faults, so it’s easy to see why it has persisted over centuries.

| PROS | CONS |

| Low cost | Labor-intensive (mechanical tampering helps) |

| Materials can be locally sourced | Building regulations not up to speed |

| Durable and versatile | |

| Fire- and pest-resistant | |

| Good thermal and acoustic insulation | |

| Non-toxic |

As the old saying goes, if it works, why change it? Rammed earth could be a much-needed answer to material shortages and environmental strain the world has been experiencing a while now.

Reclaimed Wood

With deforestation being a growing concern, reclaimed wood is a promising option in green construction and remodeling.

Wood is one of the most widely used building materials, so reclaimed or recycled wood has an important role in lowering demand for new timber.

However, while reclaimed wood undoubtedly offers many benefits for the environment, there are still some hindrances to its adoption.

| PROS | CONS |

| Environmentally friendly | Can be more expensive than new wood |

| Multiple uses: from flooring and wall panels to furniture | May contain leftover toxins, pests, or old nails |

| Strength and quality: reclaimed wood is usually harder than virgin wood | Due to its popularity, some dealers may claim the wood they use is reclaimed when it’s not |

As you can see, in the future, more comprehensive regulations will have to be put in place to ensure the quality of reclaimed wood in construction, but this material already presents a sustainable option for contractors.

Environmentally-friendly construction methods will need to rely on materials that are already there, ready to be put to service. Boosting reclaimed wood use is a step in that direction.

Sheep’s Wool

Same as wood, sheep’s wool has been with us for a long time, but environmental trends have found novel uses for this material.

It’s totally renewable and perhaps the most environmentally friendly type of insulation. Look at the ceiling in this picture. Believe it or not, it’s insulated using sheep wool fibers.

This sustainable material offers many advantages, with comparatively few drawbacks.

| PROS | CONS |

| Eco-friendly, even more so if locally sourced | Cost—more expensive than other insulation materials |

| Non-flammable | Use of chemicals for wool disinfection and treatment |

| Absorbs and releases moisture—good for damp environments | |

| Easy to install (no glass fibers) |

Wool is a rather unconventional natural material to be implemented this way. However, prioritizing sustainability breeds innovation and opens up many possibilities.

Cork

Although cork is an eco-friendly renewable material, it’s still a few technological advancements away from being more widely used outside the wine industry.

According to Thérèse Brinkcate, Ecosystems Partnership Manager for WWF-South Africa:

“Cork for wine bottle stoppers accounts for almost 70% of the total value of the cork market.”

So there’s definitely room for growth when it comes to other industries making use of this material.

It’s harvested from cork oak trees that can be sustainably and ethically sourced. As it’s made by hand-peeling the bark, no trees need to be cut down when it’s extracted. And the trees can live up to 300 years, like this one in Portugal.

The material offers many possibilities to the construction industry.

| PROS | CONS |

| Circular economy in action—trees regenerate the bark, no cutting down necessary | Sensitive to temperature and humidity, can expand or curl up |

| Excellent and affordable insulator | Cork flooring is prone to damage and fading |

| Easy to install, maintain and refinish | Cork floors need to be recoated with water sealant at least once a year |

| Hypoallergenic and antimicrobial |

As you can see from our consideration above, cork is especially suitable for flooring, with hopes for finding more uses elsewhere.

Straw Bales

Building a straw-bale house can prove to be an affordable and energy-efficient solution coupled with minimal environmental impacts.

As straw is an agricultural by-product usually burned as waste, its repurposing in construction prevents carbon emissions.

Because of its versatility, straw has been a mainstay in permaculture design for years, but the construction mainstream has sometimes struggled to catch up when it comes to its adoption:

| PROS | CONS |

| Fully recyclable and biodegradable | Building codes lagging behind |

| Affordable, easy to work with, and energy-efficient | Pests during construction or due to poor maintenance |

| Can be locally sourced | |

| Due to being tightly packed, straw bales don’t burn easily |

You can see how a straw-bale house is built here.

Clearly, the old ways are still with us, and they’re ready to enter a new era of sustainable building.

Bamboo

Bamboo is a biodegradable and sustainable material with many applications as a building material. You’ll find it in wall coverings, flooring, and countertops.

Bamboo is the fastest growing plant in the world (it is actually a type of grass), can grow on degraded land, and produces 35% more oxygen than trees.

Building with bamboo is highly rewarding in many respects, but the material can be rather high-maintenance.

| PROS | CONS |

| Entirely sustainable | Can easily deteriorate if not treated correctly |

| Affordable | Can be vulnerable to natural elements (insects, fungus) |

| Durable and strong | Lack of regulation can result in quality differences |

| Easy to install |

Bamboo usually conjures up images of Eastern Asia, but we’re bound to see a lot more of it in the West.

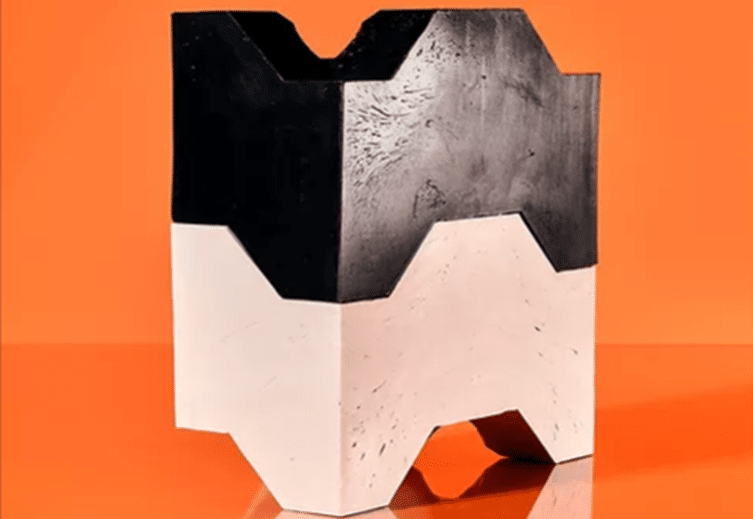

Recycled Plastic

As plastic is everywhere and takes a huge amount of time to decompose, recycled plastic is increasingly used in the construction industry as an efficient, durable, and cost-efficient alternative to other materials.

For example, waste plastics can be added to fortify concrete, make high-quality roofing tiles or even bricks that can turn home construction into a LEGO-like experience.

And while the material is versatile and durable, many of the reservations about the use of plastic continue to apply to its recycled counterpart. Therefore, its negative impact has to be offset with responsible practices.

| PROS | CONS |

| Robust, waterproof, lightweight and recyclable | Toxic emissions |

| Low-cost alternative to other construction materials | Harmful by-products |

| Reduces plastic waste (plastic sequestration) | Negative environmental impacts (ocean contamination) |

Plastic is slowly being phased out of wide use, and that’s a good thing. But there’s still merit in using the plastic that’s already around instead of creating more.

AshCrete

What is AshCrete? It’s a cost-effective way of making concrete with fly ash instead of cement.

Fly ash, a by-product of coal combustion, is mixed with other chemicals to create Ashcrete, a stronger and more durable alternative to concrete that continues to “catch” carbon from the air.

Here are some qualities that make Ashcrete an attractive and sustainable option for the construction industry, as well as some of its downsides:

| PROS | CONS |

| Higher resistance to acid, fire, temperature changes and corrosion | Mainstream use could drive coal combustion up |

| Made of 97% recycled materials | Serious health concerns about the inhalation of coal ash |

| Water saver: requires less water for hardening |

Just like plastic, global efforts should be focused on phasing out coal. But while it’s still here, it’s good to know that its by-products can be used in a sustainable way.

Ferrock

Ferrock is another environmentally-friendly alternative to concrete, this time made of waste steel dust and silica from ground-up glass.

It was invented by Dr. David Stone, who experimented with iron dust at the University of Arizona. The dust attains rock-like properties like concrete after it hardens, and comes with a number of advantages.

Let’s look at some of them, as well as some other considerations contractors should take into account when contemplating the use of this material.

| PROS | CONS |

| Eco-friendly – contains 95% recycled materials | Hard to find on the market |

| Cheaper as it uses a by-product (steel dust) | Mainstream use could raise the prices of waste materials |

| Stronger and more flexible (earthquakes) | |

| Can be used in saltwater or sewage water without deterioration |

The use of this material is still in its inceptions, but the available information makes it seem very promising.

Hempcrete

Hempcrete is another facet in the rise of hemp as a renewable resource and its future seems bright.

It’s one of the few materials that continue to absorb carbon after being used in construction.

Hempcrete is a sustainable building material made of hemp fibers and lime.

The fibers are mixed with a binder that hardens hempcrete in the form of blocks and panels, or it can be sprayed in layers like in this new-build in Paris, France.

It offers a wide array of advantages, although some of its disadvantages are not negligible, either.

| PROS | CONS |

| Zero-carbon construction technique | Poor mechanical performance—not used as a load-bearing material |

| Lightweight, saves energy in transport | Still not widely available on the market |

| Good thermal and acoustic insulation | |

| Absorbs moisture, useful in humid climates | |

| Fire- and pest-resistant | |

| Resistant to cracking (earthquakes, extreme weather conditions) |

Hempcrete is one of the few materials that continue to absorb carbon after being used in construction, and that’s reason enough to keep an eye on it in the future.

Plant-Based Polyurethane Rigid Foam

An insulation component increasingly used in green architecture is Plant-Based Polyurethane Rigid Foam. It’s made from hemp, bamboo and kelp, some of the fastest-growing plants on this planet.

It can be considered an environmentally-friendly substitute for petroleum-based products that cause environmental concerns.

Although still some way to go from becoming mainstream, this material offers many possibilities.

| PROS | CONS |

| Made from non-toxic and natural components | Not as strong as rigid polymer foams |

| Resistant to moisture and mold | |

| Good thermal and acoustic insulation |

As these materials are made from the most sustainable plants, their future looks promising.

Enviroboard

Enviroboards are fire-resistant boards made of cellulose waste fibers (like rice, or wheat straw, sugar cane or elephant grass, or even old newspapers), magnesium and sawdust. They are used as wall or ceiling lining.

After the source material is naturally dried and cured, the final product—boards—is created.

This is a great way to reuse and repurpose all kinds of byproducts and waste materials, so enviroboard definitely checks all the boxes on our sustainability list.

| PROS | CONS |

| Lightweight | Can shrink under certain conditions |

| Good thermal and acoustic insulation | |

| Non-combustible | |

| Fungus and pest resistant | |

| Water-resistant |

This could very likely become a material of the future, but more research and development is needed before that happens.

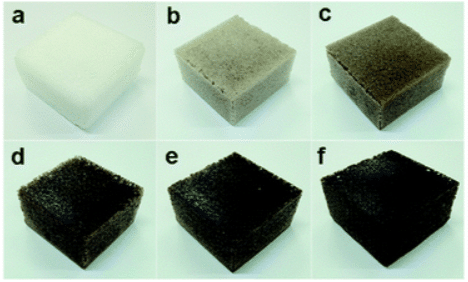

Mycelium

Fungi as a building material? Really?

Yes, it’s possible. Actually, mycelium has been explored as a potential building material in recent years.

Mycelium can be described as the connective tissue of fungi and mushrooms. The idea is to encourage it to envelope other natural materials in molds.

After mycelium is dried, it becomes very strong and durable. Thus, it has the potential to create strong and lightweight bricks (or other shapes).

| PROS | CONS |

| Organic, compostable and biodegradable | Availability—still under development |

| Natural, non-toxic and insulating | |

| Quickly regenerates | |

| Resistant to water, fire and mold |

After relying on synthetic material for so long, it’s interesting to think we might soon be “growing” structures with materials like this.

Unfired Clay Bricks

Unfired clay bricks are just like ordinary bricks, but they’re air dried instead of fired. This method provides certain environmental benefits like easier recycling and disposal.

Unlike, let’s say, monolithic rammed earth walls, unfired bricks are built in a typical fashion, i.e., they are bonded together with mortar.

The resulting material offers many of the same benefits as regular bricks.

| PROS | CONS |

| Can be reclaimed or recycled | Lower strength, not used as a load-bearing material |

| Inexpensive and durable | Lower moisture resistance |

| Good thermal and sound insulation | |

| Fire protection | |

| Better humidity control |

The key takeaway here is that sustainability isn’t all about creating new materials. Sometimes, existing materials can be optimized and upgraded with sustainability in mind.

Timbercrete

Timbercrete is another alternative to concrete with a low carbon footprint.

As a mixture of waste sawdust, wood chips and cement, Timbercrete is lighter than concrete, which reduces transportation costs and emissions.

When water is added, Timbercrete can either be poured or sprayed, or can be shaped into bricks, blocks, or pavers.

Its fire resistance has met U.S. regulatory requirements—the Building Code and the Fire Code, making construction professionals more willing to test out its many benefits.

| PROS | CONS |

| Lighter, thus offering financial and environmental savings in transportation | Not as strong as traditional concrete |

| Locally sourced from wood waste | Mass ratio of 80% cement and 20% sawdust |

| Improved insulation properties |

To build on a previous point, this is another interesting case where new, more sustainable options are created using familiar materials.

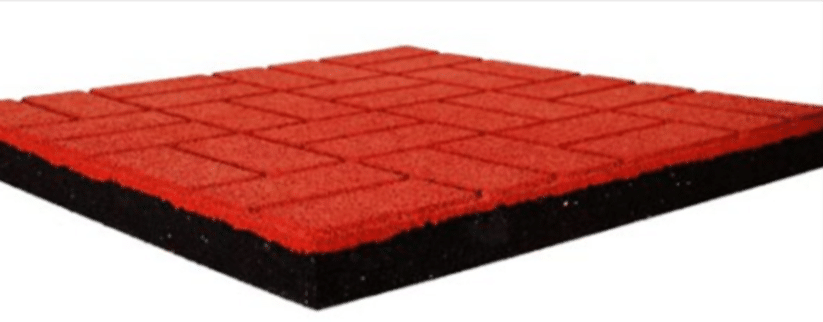

Recycled Rubber

Recycled rubber mulch, flooring tiles and mats are becoming increasingly popular in construction due to their low maintenance and resistance to the weather.

Such materials are often used in playgrounds as they reduce the risk of injury and have many other useful qualities.

| PROS | CONS |

| Low maintenance | Higher initial costs than, for example, wood mulch |

| Weatherproof | Decomposes slowly over time – not a permanent solution |

| Resistant to flooding | Fading |

| Pest resistant | Rubber mulch requires weeding by hand |

| Controls weed growth | Can release toxic chemicals and volatile organic compounds (VOCs) |

The use of recycled tire mulch in U.S. playgrounds is being reconsidered. However, new processing and manufacturing procedures might help this well-known material stay.

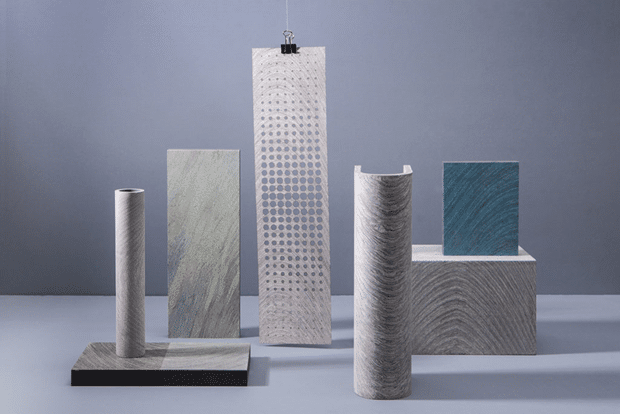

Newspaperwood

This innovative material reverses the paper production process and brings paper back to its roots—wood.

Developed in 2003 by Dutch designer Mieke Meijer, NewspaperWood combines special layering techniques and solvent-free glue to create wood-like structures such as furniture, pottery or even clothes.

Thanks to the innovations in the production process, its thickness can range from paper-thin to extra thick.

Its characteristics lend themselves to certain uses in the construction industry, although further developments will be necessary.

| PROS | CONS |

| 100% recyclable and biodegradable | Strength—limited use as a structural component |

| Waterproof and flame-retardant | Size—only wide as a newspaper, which limits its use in larger applications |

This is another promising material, but we’re still waiting to see if it can handle large-scale production.

Conclusion

As we’ve come to the end of our list of eco-friendly building materials, let’s just stress their importance again.

Sustainable building materials can go a long way in improving our own and our planet’s health. For a safe and livable future, it’s important that we keep exploring sustainable materials and start switching to them as soon as possible.