Key Takeaways:

- A single disruptive event in construction can trigger up to ten times more indirect productivity loss.

- Poor tool tracking creates delays, drives hidden costs, and creates mistrust among crew members.

- A field-first, easy-to-use tool management solution ensures accountability among crew and simplifies tool checkout.

- Comprehensive software like GoCodes Asset Tracking adapts as your construction business grows.

On construction sites, tools are the most commonly stolen equipment, accounting for more than half of the total thefts.

But that’s just a part of the tool management struggle. Misplaced drills, untracked repairs, and inefficient checkouts all add up to lost productivity and unnecessary costs.

For builders, managing tools does much more than increase visibility or accountability.

Let’s explore how software solutions can protect your margins and keep projects running smoothly!

In this article...

Why Builders Struggle with Tool Management

Tool management is frustrating for builders and construction managers because it creates problems on several levels, including time, cost, and overall accountability.

A single misplaced drill or saw can snowball into a project setback, and research confirms why this is no exaggeration.

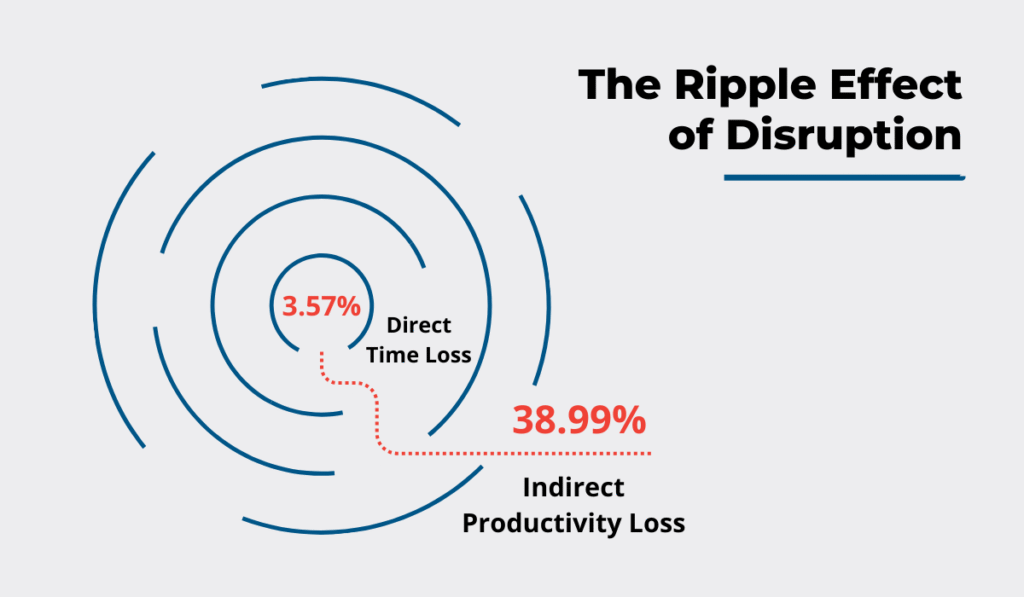

One study shows that while a disruptive event directly accounts for 3.57% of lost time, its ripple effects can cause overall productivity losses of up to 38.99%.

Illustration: GoCodes Asset Tracking / Data: Google Books

On a busy jobsite, tools are often borrowed informally between crews, without any record of the handoff.

Multiply this by the number of active jobsites, and tracking the movement of assets becomes even more difficult, complicating resource management.

One obvious outcome is unnecessary spending on equipment replacements, but there are also far more serious consequences.

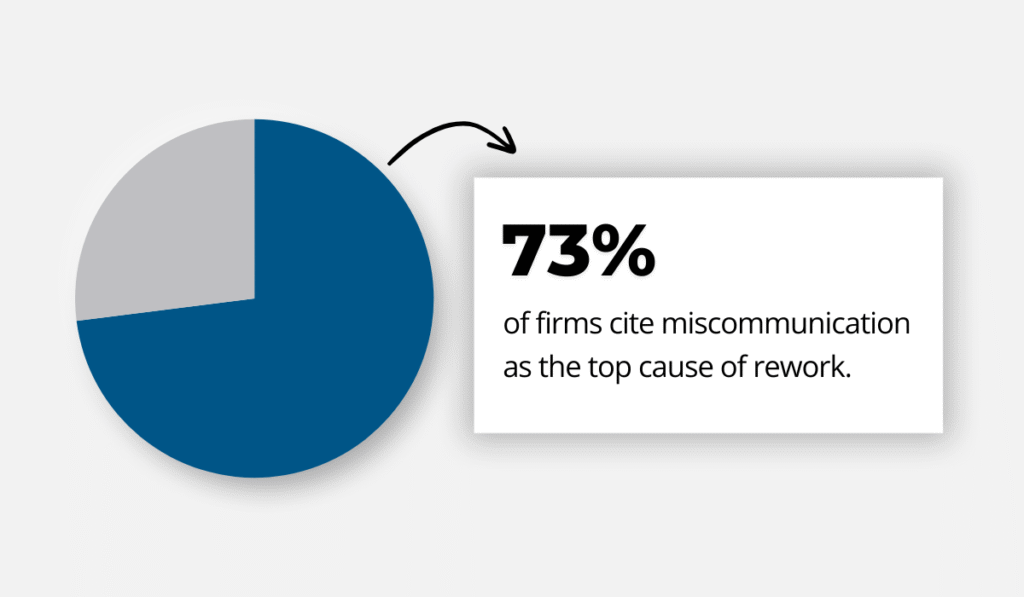

Uncertainty over who has which tool fuels miscommunication, which is cited by 73% of firms as the leading cause of rework.

Illustration: GoCodes Asset Tracking / Data: Newforma

Rework itself is one of the top drivers of costly delays and project frustration.

But the lack of accountability deepens the issues caused by existing operational gaps.

While workers often bring their own small tools, the larger and more specialized equipment is typically allocated by managers to crews depending on the job.

This mix makes it difficult to know exactly who has which tool at any given moment.

And what happens when tools start disappearing?

On industry forums, tradespeople often share stories of suspecting their coworkers of “borrowing” tools permanently, asking for advice on what to do.

Source: Reddit

If the issue is actual theft, and not forgetfulness, this adds another dimension to the problem.

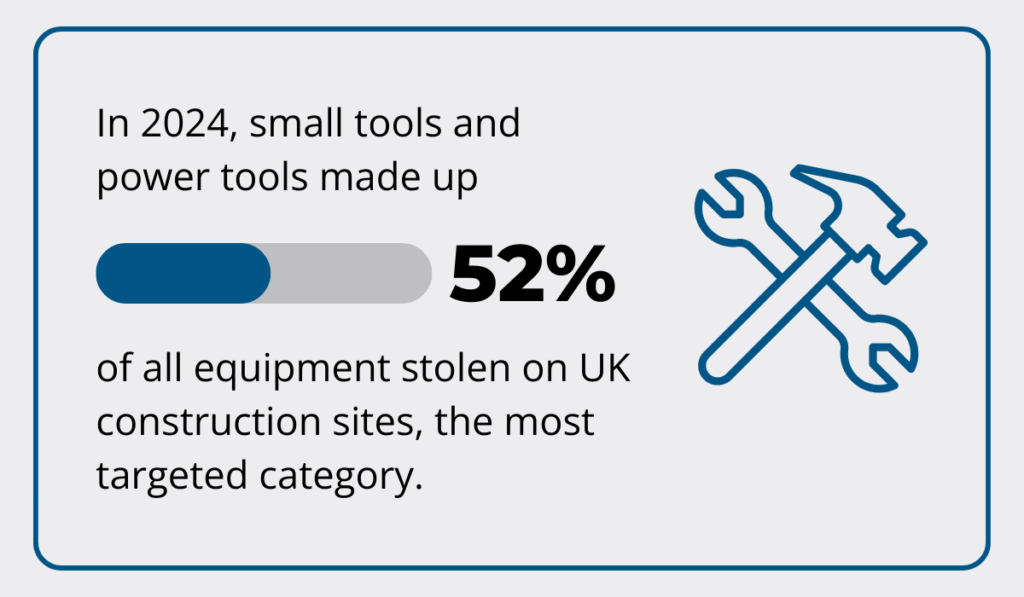

According to BauWatch’s 2025 report, small tools and power tools account for 52% of all equipment thefts on UK construction sites, making them the most targeted category.

Illustration: GoCodes Asset Tracking / Data: BauWatch

Alarmingly, about 25% of these crimes involve insider assistance.

And for builders, this is more than a security issue. It’s a reminder that trust, culture, and financial stability are on the line all the time.

Misplaced tools, blurred responsibilities, theft… All these challenges compound one another to create unnecessary costs and mounting frustration.

And while they may feel like part of the job, the truth is they don’t have to be. There are remarkably straightforward ways to restore order and accountability across your sites.

Why Builders Need a Tool Management Solution

Tool management solutions restore order at the jobsite, helping you avoid issues such as lost tools and blurred accountability, while streamlining processes.

Are they essential, though?

The thing is, the challenges we’ve covered can’t be solved by adding more shelves or tightening control at the tool crib.

As noted by Roy Little, a certified Safety Manager and Trainer, tool cribs are valuable for daily checkouts and general monitoring:

“An example that works well for monitoring is a comprehensive, fully stocked tool crib where equipment and tools are checked out daily. Doing this enables daily inspections, records location, tool condition, and forces employee accountability.”

However, they can’t keep up with the reality of tools constantly changing hands on active jobsites.

What happens once a tool leaves the crib?

In practice, hammers, drills, and saws often switch hands during shifts, travel between crews, or even move across different sites.

Without complete visibility, managers are left guessing where assets are, who is using them, and whether they have been stolen or just misplaced.

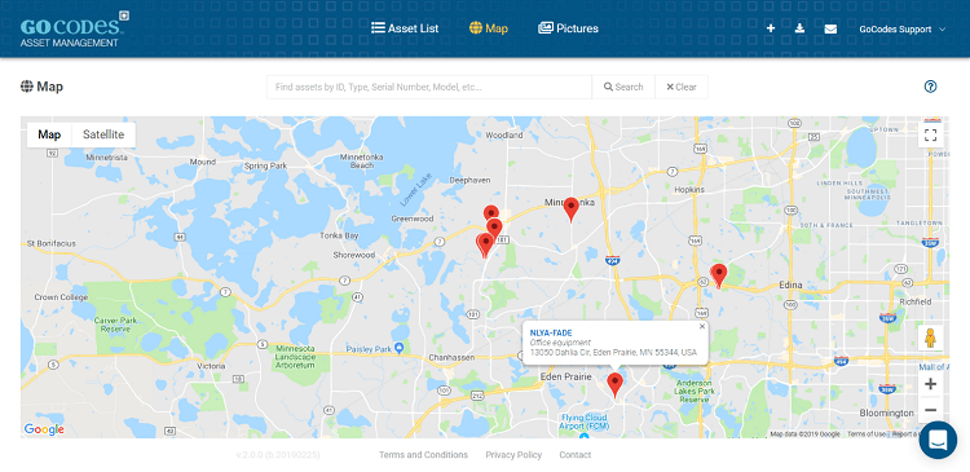

Tool management software fills this gap by creating a live map of your assets, as pictured below.

Source: GoCodes Asset Tracking

Managers can see which tools are on-site, which are checked out, and which are idle.

This visibility translates directly into efficiency, with crews spending less time hunting for gear and more time building.

The benefits go beyond equipment availability and use, and toward improving maintenance scheduling practices and asset lifecycle management.

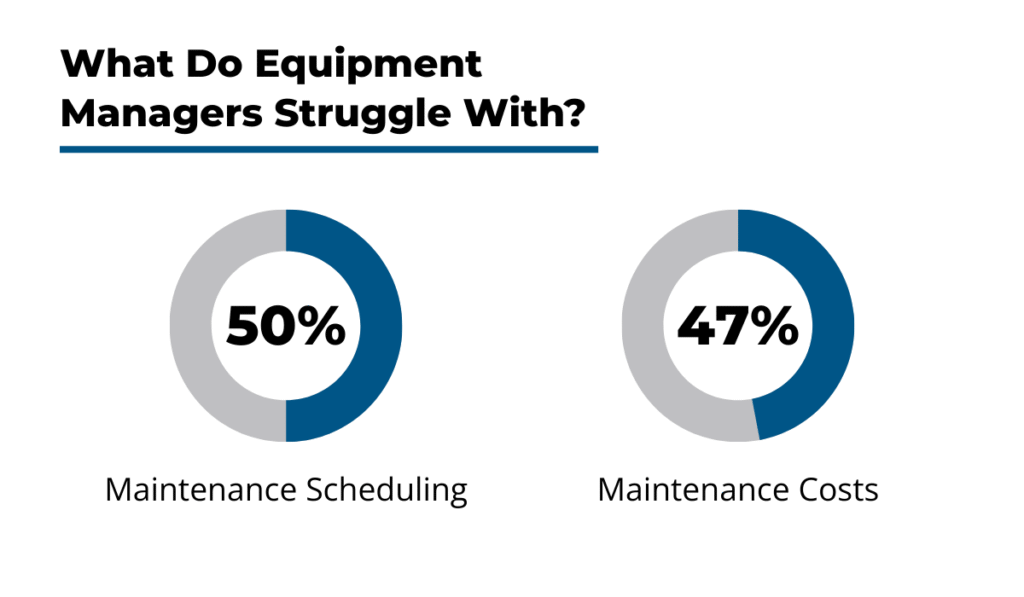

According to Teletrac Navman’s 2025 report, 50% of construction companies struggle with scheduling equipment maintenance, and 47% struggle with rising costs.

Illustration: GoCodes Asset Tracking / Data: Teletrac Navman

When tools aren’t tracked, it’s easy to miss inspections and defer essential care. Over time, this increases the risk of asset breakdowns and even accidents.

In one OSHA inspection reported by The Gazette, a worker’s fall was attributed to improper ladder placement and poor safety practices in general.

Source: The Gazette

However, the ladder in question showed severe corrosion on its bottom rungs, which significantly raised the risk of falls.

The same level of risk is attached to any tool that stands neglected for a little too long.

Without proper tracking, tools can’t be flagged for inspection, serviced on time, or kept in compliance with safety standards.

But when managers have a clear record of usage history and guarantees that maintenance was conducted, they can assign tools to individual workers or specific teams with peace of mind.

In return, there’s less waiting time and friction among crews, not to mention unnecessary replacement expenses.

Ultimately, a dedicated tool management solution delivers a level of control that can make the difference between projects that run smoothly and ones that bleed costs.

What to Look for In a Tool Management Solution

Choosing the right tool management software means you can address the day-to-day realities of construction work.

In practice, this translates to ensuring seamless operations today while leaving room for future growth.

Let’s take a look at key considerations that should drive your choice of software.

Mobile Accessibility

Mobile accessibility on jobsites is essential because no one has time to run back to an office computer just to update tool records.

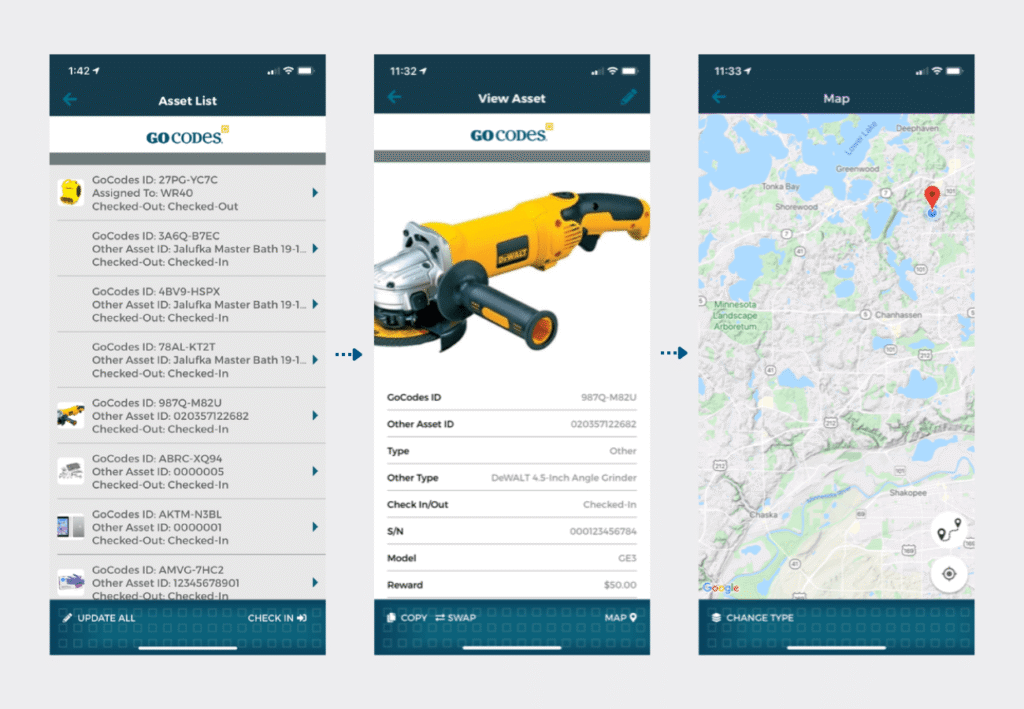

As such, a strong tool management solution should allow crews to check tools in and out using their smartphones, no matter where they are.

Imagine a foreman on Site A needing a rotary hammer that just arrived back from Site B.

With sufficient accessibility or a dedicated mobile app, he can access the entire database and easily view individual asset details and their exact location.

Source: GoCodes Asset Tracking

Instead of wasting hours on calls or manual logs, the tool is put to use the same day.

Mobile dashboards provide instant visibility to both crew members and managers, acting as a bridge between field and office.

Managers can see which tools are active, which are idle, and where bottlenecks might be forming, all without leaving their current project.

This keeps communication clear, decisions fast, and crews productive.

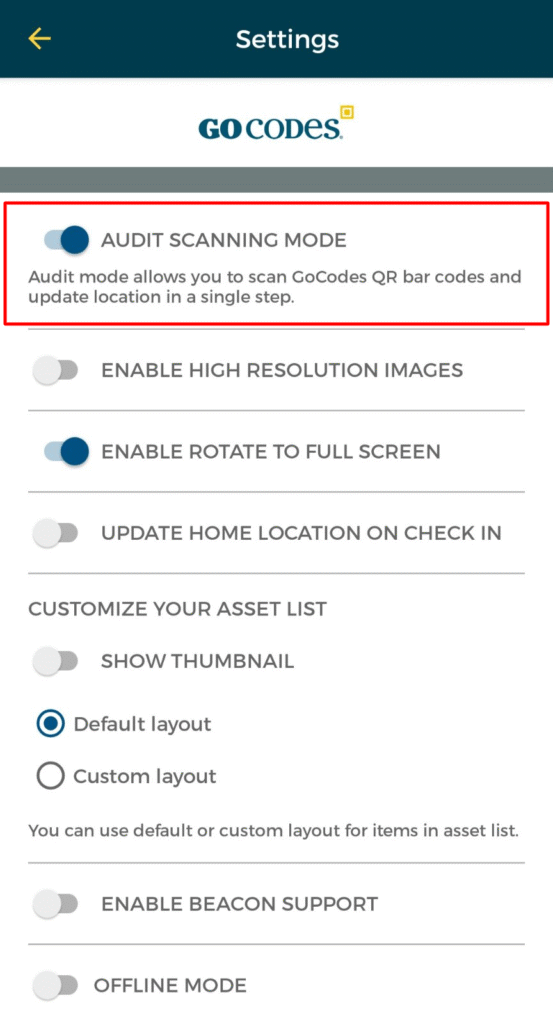

Keep in mind that discrepancies can and will happen, but this is where mobile scanning features in digital asset tracking systems really shine.

With dedicated audit tools, managers can quickly reconcile records, confirm tool locations, and resolve issues on the spot.

Source: GoCodes Asset Tracking

The result is a mobile-enabled system that stays accurate and reliable, no matter how hectic the jobsite becomes.

Easy-to-Use Interface

Even the most advanced tool management system won’t deliver results if your crews don’t know how to use it.

A clunky platform means longer onboarding, more mistakes, and low adoption, and builders need a solution that is straightforward and intuitive.

When it comes to tool management systems in particular, they’re only effective if all the staff can quickly access the information they need.

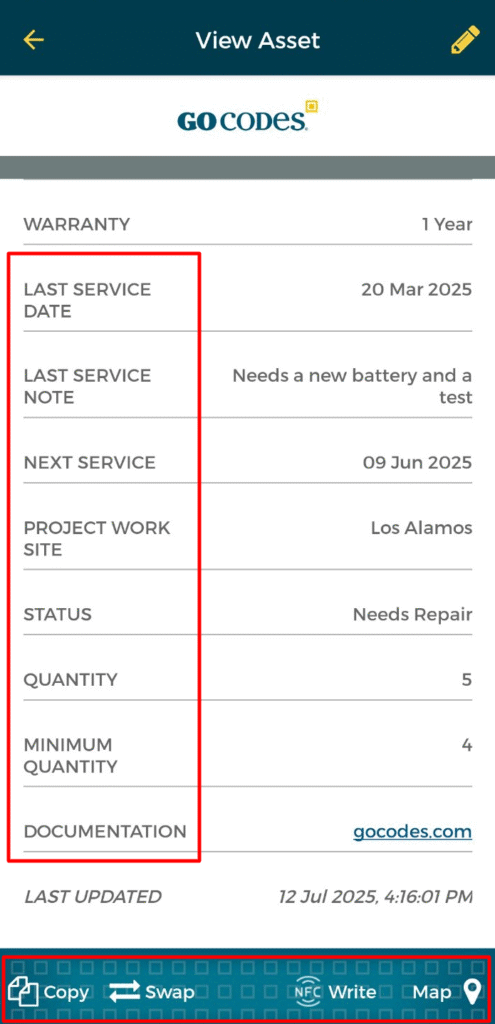

An intuitive interface like the one below lets users view key details at a glance, from last service date, upcoming maintenance, current status, quantity on hand, and project location.

Source: GoCodes Asset Tracking

By ensuring that the critical information is always available, you’re saving an incredible amount of time that would otherwise be spent searching through logs or spreadsheets.

Meanwhile, features like copy, swap, or mapping tools allow teams to coordinate movements and assignments efficiently across multiple sites.

This keeps the projects moving smoothly day after day, because no one wastes time figuring out how to record usage or track down missing tools.

To sum up, the simpler the platform, the more consistently it’s used, giving your construction crews all the actionable information they need.

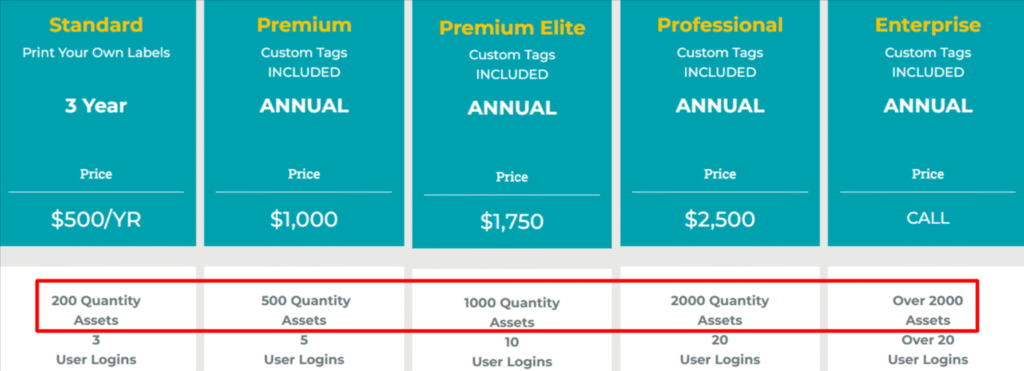

Scalability for Growing Teams

Construction companies rarely stay the same size for long. As you take on bigger projects or expand to multiple sites, the number of tools in circulation multiplies quickly.

Without a scalable system, the very software you rely on can become a bottleneck.

So, instead of switching platforms every few years, you can simply expand your existing system as your needs evolve, adding new assets.

But scalability isn’t just about the number of tools.

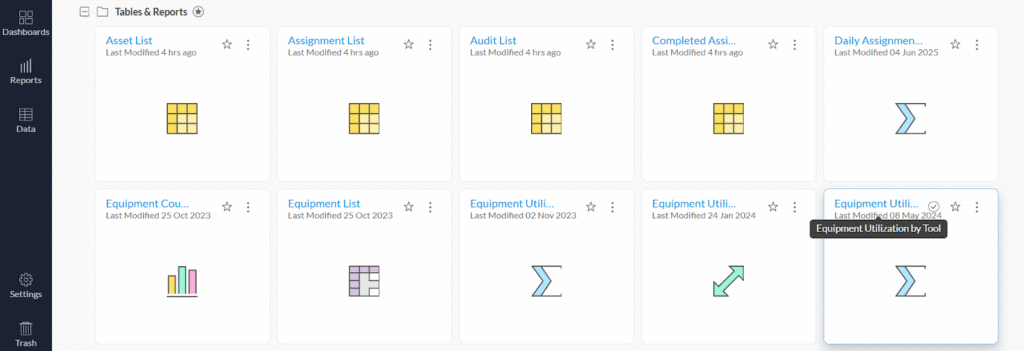

As construction companies grow, reporting needs often shift from simple usage logs to more complex insights, such as cost allocation, fleet management, or general utilization trends.

Source: GoCodes Asset Tracking

In other words, a reliable tool management system needs to handle both the basics and the advanced analytics that support long-term decision-making.

The pricing schemes should reflect this growth as well, adjusting offerings for different team sizes/number of assets owned.

Source: GoCodes Asset Tracking

By framing the pricing around asset quantity levels, your company can easily upgrade on a per-need basis.

Ultimately, a system designed for growth reflects that in both features and pricing, supporting more strategic decision-making.

How GoCodes Asset Tracking Can Help

GoCodes Asset Tracking provides builders with an all-in-one tool management solution built for the realities of construction work.

From fast-paced jobsites to multi-crew operations, the platform helps managers and workers alike stay in control of their tools without adding administrative headaches.

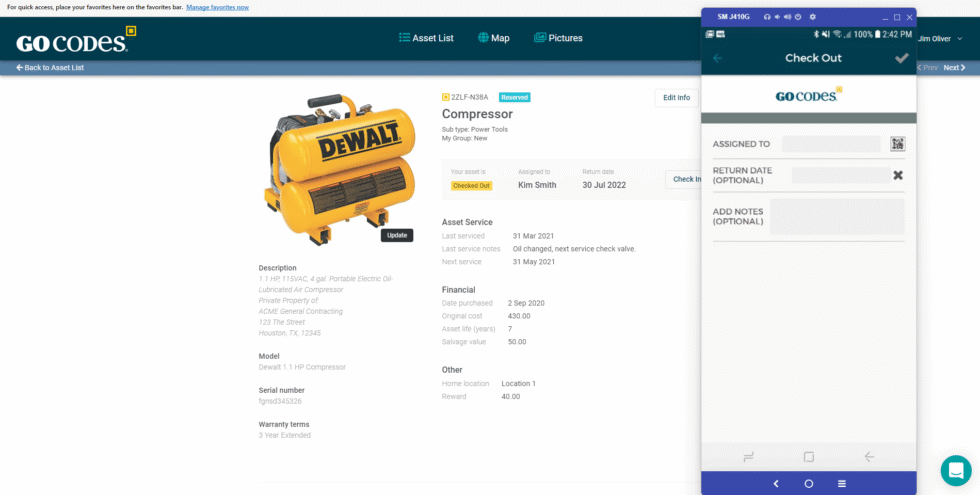

At its core, GoCodes Asset Tracking combines durable QR code tags with a simple, mobile-first app.

Source: GoCodes Asset Tracking

Crews can check in and check out tools in seconds by scanning a tag with their smartphone: no special hardware is necessary.

Moreover, managers can directly assign specific tools to crews, detailing return dates and leaving relevant notes.

Source: GoCodes Asset Tracking

This ease of use is one of GoCodes Asset Tracking’ biggest strengths.

Unlike paper logs or even tool cribs, there’s no lag between when a tool is borrowed and when it’s recorded.

Plus, QR code labels are GPS-enabled, meaning that software automatically records the location every time a tool or piece of equipment is scanned.

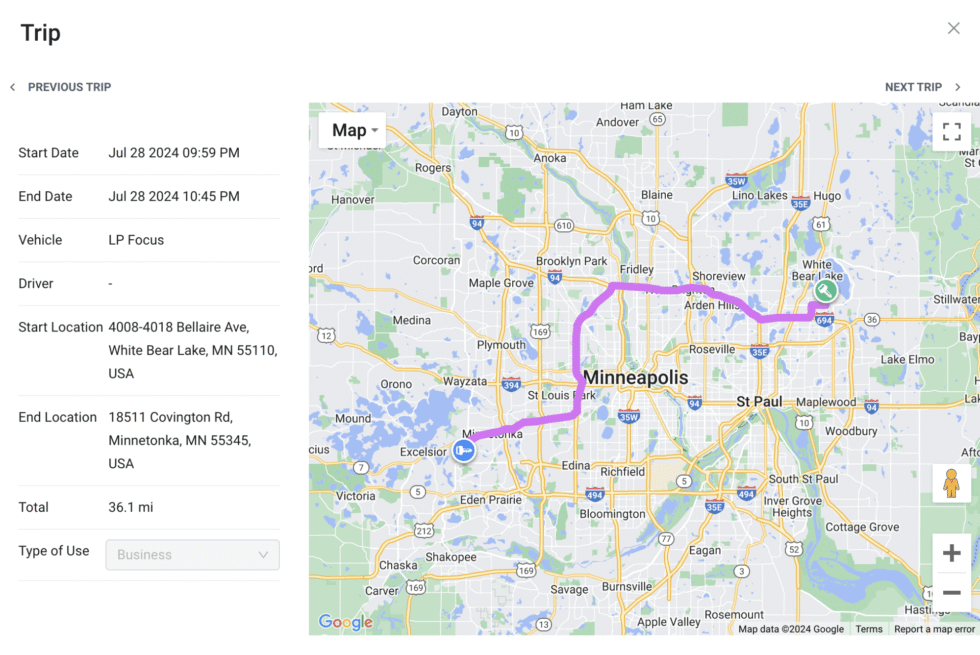

On top of that, you can combine QR tags with powerful real-time GPS trackers to ensure real-time monitoring of larger tool transfers and other fleet movements.

Source: GoCodes Asset Tracking

This visibility not only reduces theft and loss but also frees up crews from wasting time searching for misplaced equipment.

Additionally, you don’t have to look for a separate solution for tracking your vehicles and heavy machinery.

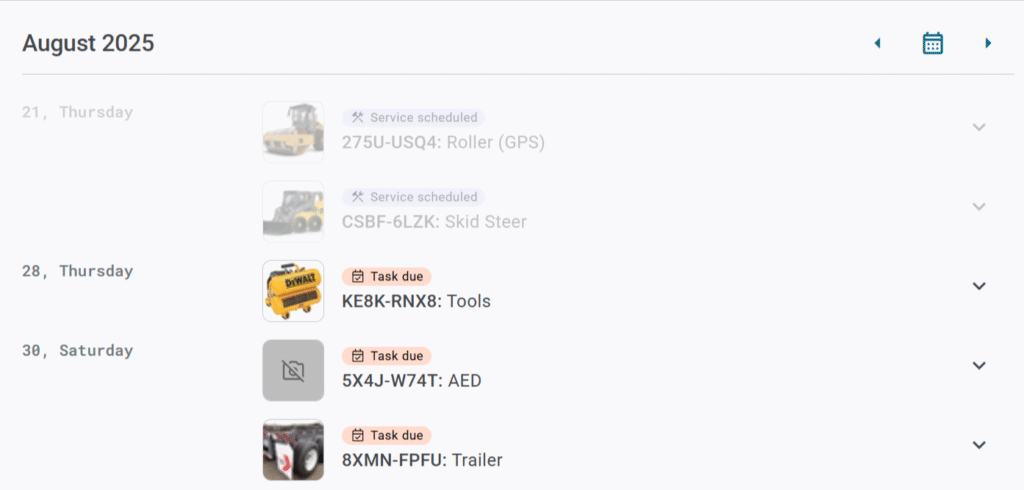

Beyond availability, GoCodes Asset Tracking helps builders take control of tool care and maintenance.

The system makes it easy to schedule inspections, log repairs, and receive alerts before service is overdue.

You can check the upcoming tasks from an individual asset, or go to Agenda View for a more general overview.

Source: GoCodes Asset Tracking

By staying ahead of maintenance, companies avoid costly downtime and reduce the risk of breakdowns or injuries caused by neglected equipment.

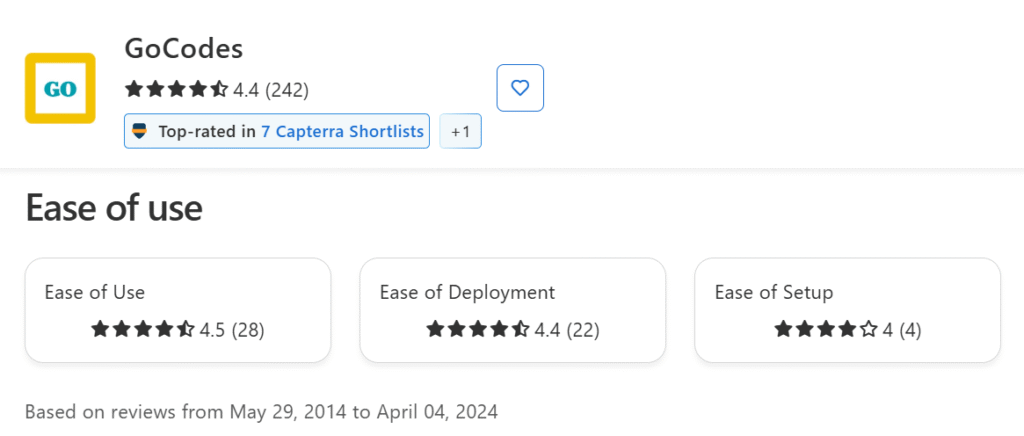

Most importantly, all these features have earned GoCodes Asset Tracking a consistently high rating for ease of use, deployment, and setup on sites like Capterra.

Source: Capterra

All in all, GoCodes Asset Tracking Asset Tracking is a dependable, plug-and-play choice for construction crews, which makes lost assets and other tool management struggles a thing of the past.

Conclusion

Tool management doesn’t have to be complicated.

With the right software, you get full visibility and insight, reducing losses, enhancing upkeep, and helping your teams stay productive without slowing them down.

The bottom line is to look for a solution that’s built for the field, easy to deploy and appealing to crew members, and flexible enough to scale with your business.

Don’t wait until missing tools derail your projects. Invest in tool management now and give your company a competitive edge in an industry where every margin counts.