With supply chain frustrations still plaguing the construction industry amid a building boom, some contractors mind find themselves renting equipment more often than usual to meet project deadlines and uphold client satisfaction.

That means it’s best to subject your fleet, whether owned or rented, to asset tracking.

In order to make the most of your system, it’s important to perform regular inventory audits.

Automating rental equipment tracking also creates more efficiency in your workspace, and deciding on a consistent identification system is key.

Finally, once all of these decisions and details are in place, tagging your equipment will set your equipment tracking system in motion.

In this article...

Perform Regular Inventory Audits

Carrying out regular inventory and equipment audits offers many benefits to construction companies.

Whether you rent out equipment to others or undertake rentals for your own team, inventory audits can make sure they have an accurate account of all of their assets.

Inventory audits have several functions. They verify financial data, help you schedule equipment and raw material orders, and provide a benchmark of financial stability.

The most effective audits are performed with integrity and confidentiality. This is easier to achieve with long-term and vetted employees.

While counting inventory manually is an option, this form of audit is slow, inaccurate, and even expensive, as sometimes it’s necessary to bring in temporary workers to help out.

What is more, the average frequency of human error in such repetitive tasks presents the potentially costly reality that you will never truly know how many highly necessary assets your company has on hand.

Conversely, using a digital asset tracking system like our own solution, GoCodes Asset Tracking, increases speed and accuracy.

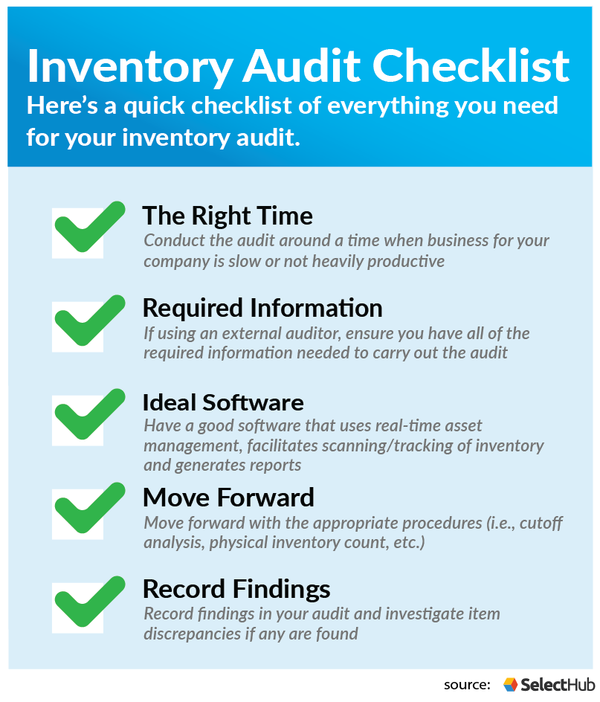

Since inventory audits can quickly become complex, here are a few essentials for undertaking an effective one:

Note that this checklist emphasizes the use of quality software. GoCodes Asset Tracking is a fitting system, as it offers asset management in real time and provides secure data storage in the cloud, authorized employee access, and much more.

GoCodes Asset Tracking also assists in undertaking audits regularly.

It offers the ability to schedule such actions, and can draw up data-driven graphics for easy year-to-year comparisons in just a few clicks.

When equipment and inventory audits take place periodically instead of randomly, it is easier for your construction company to assess risk management, theft issues, and replenishment protocols.

Regular audits also offer your team the ability to target and eliminate potential problems in the early stages, before they fester throughout the entire company.

In addition, they provide a data trail for compliance and financial documents while also allowing all of your employees the opportunity to plan for such events.

Automate Rental Equipment Tracking

Now you know the importance of conducting regular inventory audits, but manually keeping track of equipment can be tedious and prone to human error.

The best way to address this is to automate the process of rental equipment tracking.

Automated rental equipment tracking offers countless benefits.

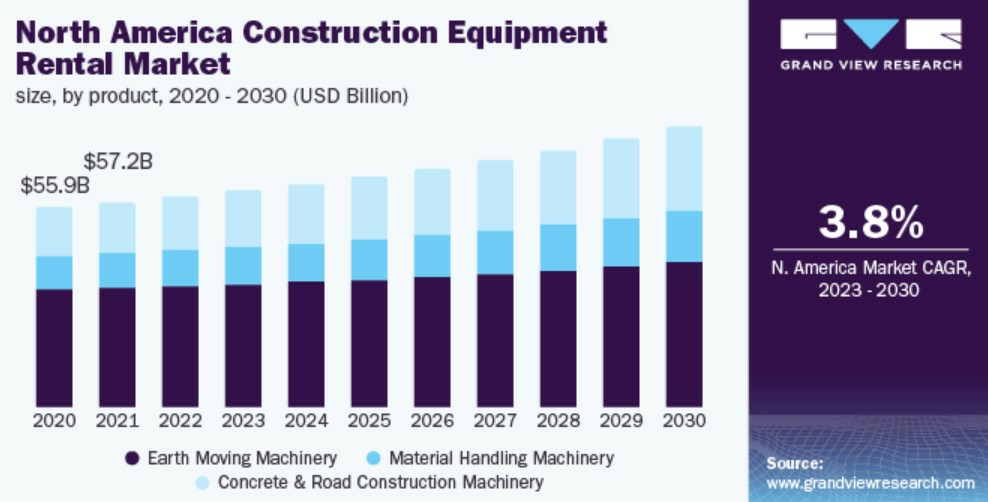

For example, it helps you to take advantage of current conditions in the construction rental market.

This bar graph demonstrates that projections for the North American market have nowhere to go but up:

In addition, automated rental equipment tracking offers access to real-time information about the status of each asset, making it easier to plan equipment management.

Your team can easily and securely see when your assets are available, and for how long, in real time.

This not only contributes to your organization’s efficiency, it also eases the process of renting your construction equipment to clients.

Making the most of renting out your equipment to others or leveraging data to find the best arrangement for renting from others is a smart way to grow and maintain your construction business.

Whether you are renting out your own equipment or using the assets of others, instituting a tracking system is vital for security and equipment retrieval.

Asset tracking is also a significant customer service bonus when it comes to working with maintenance requests.

Your client can easily and instantly alert your customer service staff in the event of a breakdown or mechanical question.

If the rental equipment is your own, a robust tracking system helps to manage the ongoing and crucial maintenance process.

Investing in a system with GPS tracking is, therefore, advisable.

Using GoCodes Asset Tracking for rental inventory management offers security, reliability, and real-time updates for your maintenance workflow.

This helps to extend the life of your valuable construction equipment while also easing communication among team members and clients.

Decide on an Equipment Identification System

Finding an effective equipment identification system helps guarantee that each piece of equipment is accounted for, through, for instance, assigning unique identification numbers for each asset.

This is most easily achieved with asset management software.

Even small businesses will benefit from a system providing automatic access to easily changeable data that is easily scalable as your company changes and expands.

An asset tagging system like that of GoCodes Asset Tracking offers a quick overview of information such as a chain of employee or vendor custody.

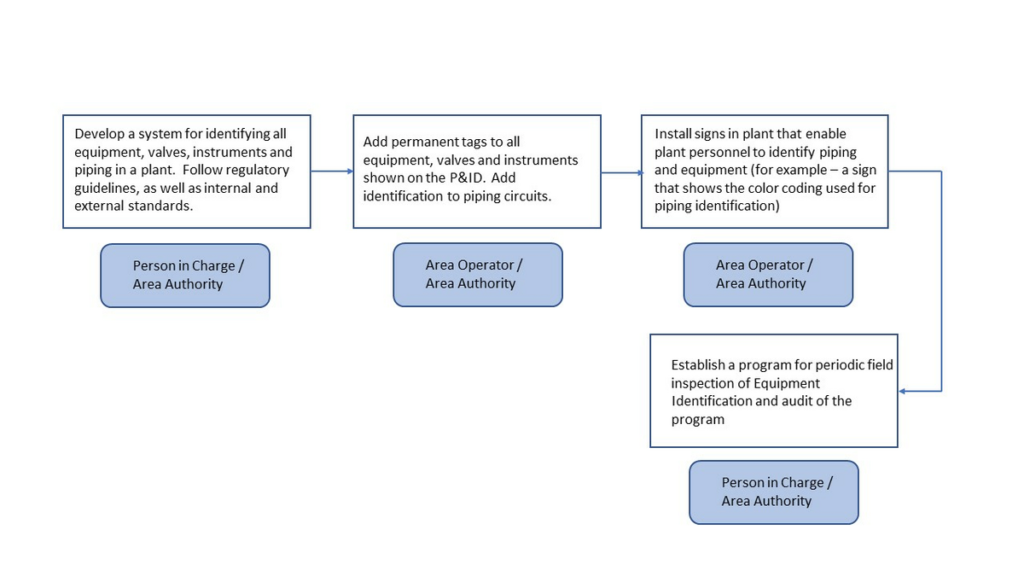

Understanding the steps to tracking your construction tools before you begin is an important part of installing a successful system.

This flow chart provides an idea of how your construction company can begin the process:

Whether your company decides to use QR codes, RFID tracking, or traditional barcodes to keep track of each asset, scanning takes mere seconds.

Most systems use smartphones or tablets– technology on which your employees are likely already relying.

Your equipment identification system can sync automatically with your company’s data plans.

Such a format is far more secure, safer, and even cheaper than traditional paper methods.

Using spreadsheets or manual entries leaves room for inaccuracies and can take up a great deal of office space.

Paper records are costly to store and constantly at risk of loss due to fire, water damage, loss, or even theft.

Your rental equipment will likely have a longer lifespan if you decide on an equipment identification system capable of dealing with work orders and managing automatically updated work flows.

Such a system should facilitate quickly accessing such important information as vendor contact, dates of last repair or preventive maintenance, operators manuals, and much more.

The right system can send alerts for overdue maintenance actions, equipment moved without authorization, assets late for rental return, and employee or client possession chains.

All of this data helps to secure, study, and optimize your assets.

Tag All of Your Equipment

Tagging your equipment is the backbone of your rental equipment tracking system.

Combined with rental equipment tracking software, using tags for rental equipment helps provide a more comprehensive overview of its status.

Employees can then scan the tags when checking out rented equipment, as well as when checking it back in, allowing decision makers to determine whether a particular piece is in use and where, as well as when it can be expected to be available again.

When it comes to choosing what type of tag is best, it’s best to look at the type of asset you are using and the environment in which it is kept.

Construction equipment is usually made of rugged materials and exposed to all kinds of weather.

Extreme temperature changes, heavy moisture, severe vibrations, and extended exposure to corrosive materials can all present themselves on a daily basis to construction-related assets.

Therefore, adhesive anodized aluminum metal foil or polyester adhesive tags, while appropriate for such items as books or personal computers, would not last long on assets such as earth movers or cement mixers.

However, metal tags that are welded directly onto heavy steel last as long as the asset does, so they are more suitable for construction equipment.

All of these options are available with a GoCodes Asset Tracking equipment tracking system. GoCodes Asset Tracking offers a wide variety of tags, each of which is designed for durability and longevity.

Above is a graphic denoting the various aspects of a heavy-duty GoCodes Asset Tracking metal tag.

As you can see, this option is durable and well-protected. It is sealed to protect the QR code and other information from the elements.

Finally, the base of the tag is designed to stay with construction equipment subjected to the harshest of conditions.

Conclusion

Rental equipment tracking is best accomplished with a robust system such as GoCodes Asset Tracking.

It is important to perform regular inventory audits to discover and verify the location, number, and condition of each construction asset.

Automating retinal equipment tracking is the best way to keep track of the availability and location of each item.

The equipment identification you decide upon should include a unique ID system that supports real-time GPS location and maintenance requests.

Finally, your equipment’s asset tags should provide a comprehensive overview of the equipment in an appropriate tag.