Key Takeaways:

- Real-time locating system alerts help prevent safety incidents and protect both assets and workers on construction sites.

- Nearly half of supply chain professionals consider real-time inventory visibility crucial—RTLS delivers the data they need.

- RTLS enhances asset health and optimizes resource allocation by tracking utilization data in industries like manufacturing and healthcare.

While safety and efficiency are critical in industries like construction, warehousing, manufacturing, and healthcare, it often feels like you have to trade one for the other.

Real-Time Locating Systems (RTLS) offer a solution, delivering both of these benefits and so much more.

In this article, we’ll explore four key RTLS use cases to optimize workflows, improve safety, extend equipment life, and reduce costs and risks.

In this article...

Construction Site Monitoring

RTLS is ideal for construction site monitoring, as these systems enhance both worker safety and overall site security.

Real-time tracking and continuous monitoring are essential for any industry with high injury and fatality rates.

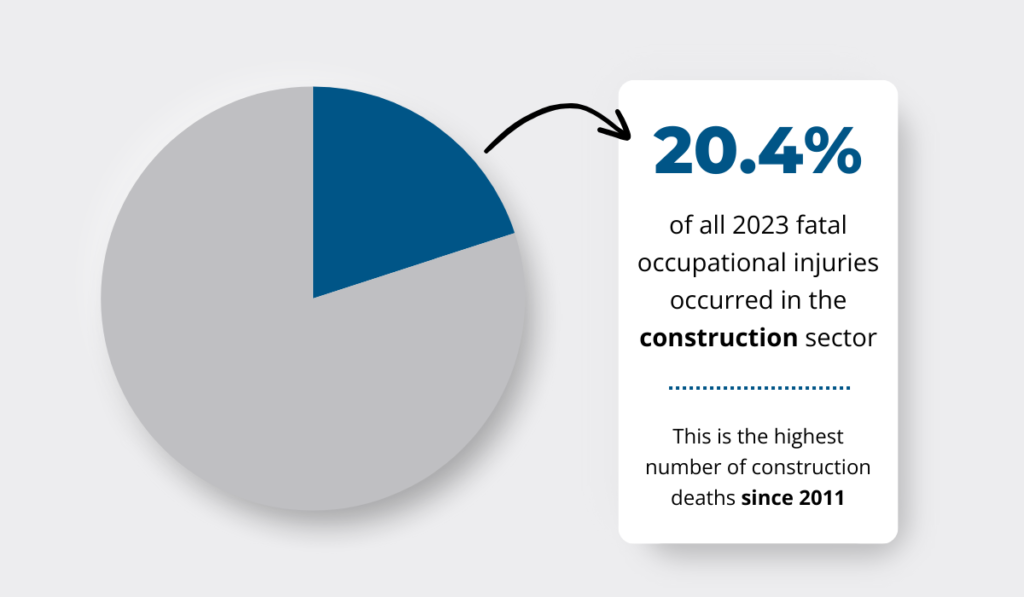

Based on the latest reports, construction had the most fatalities (1,075) among all industry sectors in 2023, which translates to roughly one-fifth of all fatal occupational injuries in the U.S.

Illustration: GoCodes Asset Tracking / Data: U.S. Bureau of Labor Statistics

With the number of construction deaths reaching the highest level since 2011, it’s clear that businesses need to do more to improve jobsite safety.

Fortunately, real-time locating technology offers a surefire way of enhancing safety.

A 2019 study on RTLS applications in construction safety highlights multiple key areas of use, including:

- Safety monitoring

- Accident prevention

- Behavior-based safety

- Safety alerts and warnings

- Physiological status monitoring

- Ergonomics analysis

- Communication-based safety

- Performance evaluation

- On-site safety training

Safety monitoring is one of the most widely used applications that involves real-time tracking of equipment and personnel on-site.

For instance, one of Litum’s solutions is specifically designed to enhance the safety of employees working in remote or high-risk areas.

Source: Litum on YouTube

This solution enables construction companies to address emergencies more effectively, improving response time thanks to key features like:

- Automated alerts – falls, inactivity, panic triggers

- Geofencing – restricted zone monitoring and safety violation triggers

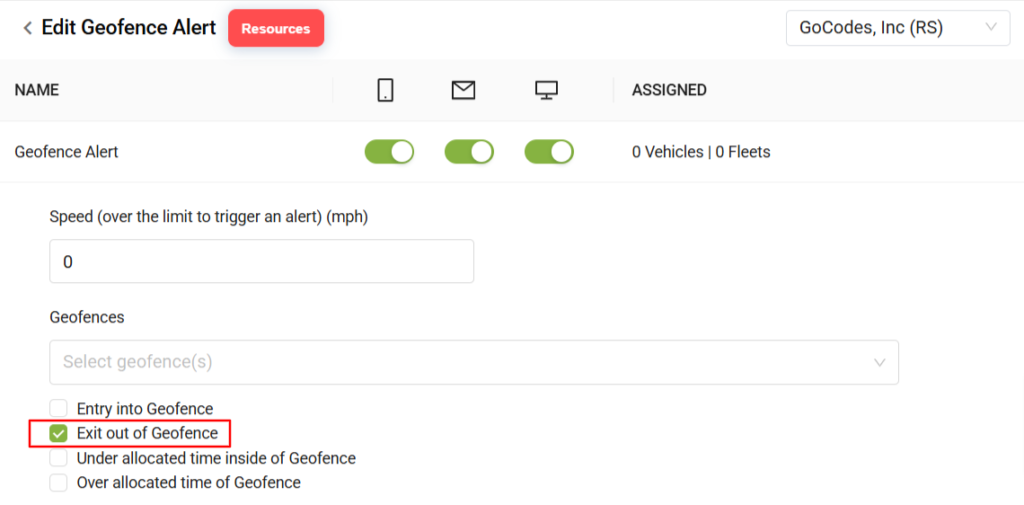

Geofencing is a key RTLS capability that enhances monitoring through virtual boundaries.

You can set up geofences around hazardous areas and receive alerts as soon as an asset or a worker crosses the established perimeter.

UK-based safety technology provider Tended relies precisely on geofencing technology—and a variety of wearables—to improve the safety of construction crews and trackworkers.

Siemens Mobility partnered with Tended to make their expansive, 70-mile worksite safer by monitoring the movement of several road rail vehicles (RRVs) and preventing workers from straying beyond safety limits.

Jules Reed, Head of Behavioral Science at Tended, explains just why this technology makes a difference:

People will lose situational awareness […]. It’s not humanly possible to stop it, so we can’t give them rules to get them out of the situation. What we’ve got to do is […] bridge the gap between workers and their fallibility and their safety. Technology is the perfect solution because it’s reliable, it’s consistent, and it doesn’t get tired.

Besides helping you define safe working zones and access points, geofencing technology excels at preventing unauthorized access and minimizing risks of theft.

If any asset equipped with real-time GPS trackers moves outside the predefined zone, the relevant staff is notified immediately and can swiftly investigate the matter.

As long as you configure the relevant geofence alerts, you’re good to go!

Source: GoCodes Asset Tracking

Deploying RTLS technology helps businesses prevent occupational fatalities by providing a vital layer of protection and security in high-risk environments.

Want to protect both your workers and assets? Then don’t hesitate to explore this technology!

Warehouse Inventory Optimization

Modern warehousing relies on real-time locating technology to boost accuracy and optimize inventory management.

You can improve your warehouse operations by introducing vertical storage solutions or mobile racking systems, but RTLS plays a key role in automated storage and retrieval systems.

The ability to track the movement of any item within a facility enhances visibility and control across industries, helping businesses optimize stock levels and speed up order fulfillment.

As such, it’s no wonder that nearly half of surveyed supply chain professionals cite real-time inventory visibility as a crucial component of success.

Illustration: GoCodes Asset Tracking / Data: Standvast

RTLS technology automates location updates and minimizes manual input, which drastically reduces human error and improves lead times.

This makes it far less likely that essential components or incoming material shipments will be misplaced—even within a vast storage network.

In other words, relying on these systems enables you to streamline operations while helping you handle both increased demand and unexpected disruptions.

It all goes back to having instant access to real-time data, as noted by Nokia AIMS’ General Manager, Paul Heitlinger.

Illustration: GoCodes Asset Tracking / Data: Supply Chain Digital

Since automated asset tracking provides instant access to updated information, it’s far easier for managers to quickly spot and respond to discrepancies when they occur.

Want to know the best part? It’s not just about tracking inventory.

RTLS is highly versatile and enables you to:

- Monitor valuable assets

- Navigate special equipment or vehicles indoors

- Track employees’ clock-in/clock-out and access to restricted areas

The video below showcases how ELOcate’s highly precise indoor tracking helps users optimize route planning and control vehicle movement within specific zones.

Source: ELOKON Group on YouTube

For instance, you can enhance safety by using the system to automatically limit vehicle speed in certain areas and warn nearby workers about incoming traffic.

Moreover, the ability to restrict access to certain areas and be notified of any breaches increases safety while reducing security risks.

RTLS solutions are commonly integrated with warehouse management systems (WMS) to provide a more comprehensive overview of warehouse activities.

By combining inventory control and asset tracking with order management and shipping logistics, you can optimize entire workflows and enhance operational efficiency.

For instance, warehouse labeling systems create a strong foundation for tracking.

However, introducing RTLS will quickly elevate operations, as demonstrated by the example of fashion group and textile producer TB International.

Managing Director of Logistics and IT, Johannes Rudenko, explains that TB International partnered with RTLS provider Inpixon.

This partnership enabled the company to analyze its processes and find a use case for RFID tags, resulting in a substantial efficiency boost.

Illustration: GoCodes Asset Tracking / Quote: ThinkWIoT

Although not mentioned explicitly, a sharp increase in efficiency is likely to have generated cost savings and improved customer satisfaction.

The bottom line is that RTLS connects all warehousing processes, allowing you to eliminate inefficiencies while unlocking new growth opportunities.

So if you haven’t already, now is the time to explore how this technology can transform your operations.

Manufacturing Asset Tracking

Another prominent use case for real-time locating systems is asset tracking and equipment management.

RTLS benefits manufacturing and similar sectors by enhancing the way you manage tools and machinery, helping you:

- Easily locate equipment

- Reduce equipment idle time

- Efficiently plan equipment maintenance schedules

Knowing where your assets are improves operational efficiency and resource allocation while establishing a clear chain of custody for better compliance.

However, one of the key values of RTLS lies in capturing comprehensive equipment usage records.

Equipment utilization rates serve as guideposts for operations managers, helping them optimize performance and improve maintenance scheduling to maximize efficiency.

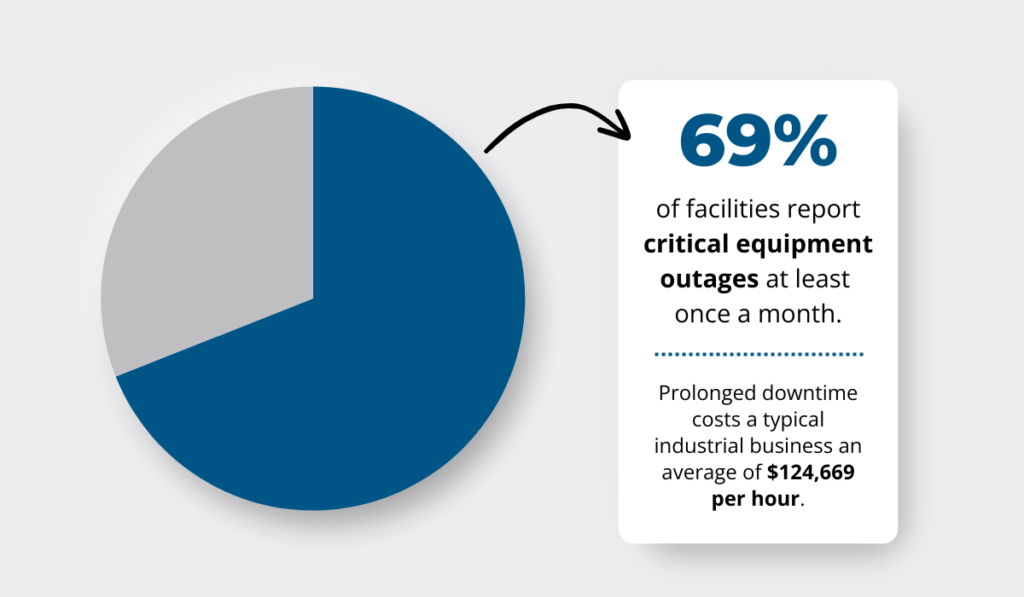

These insights also help prevent unplanned downtime, which research identifies as a common and costly problem.

Illustration: GoCodes Asset Tracking / Data: JLL Technologies

Considering the high costs of unplanned equipment outages, many industrial businesses make it a point to move away from reactive maintenance and adopt more preventive strategies.

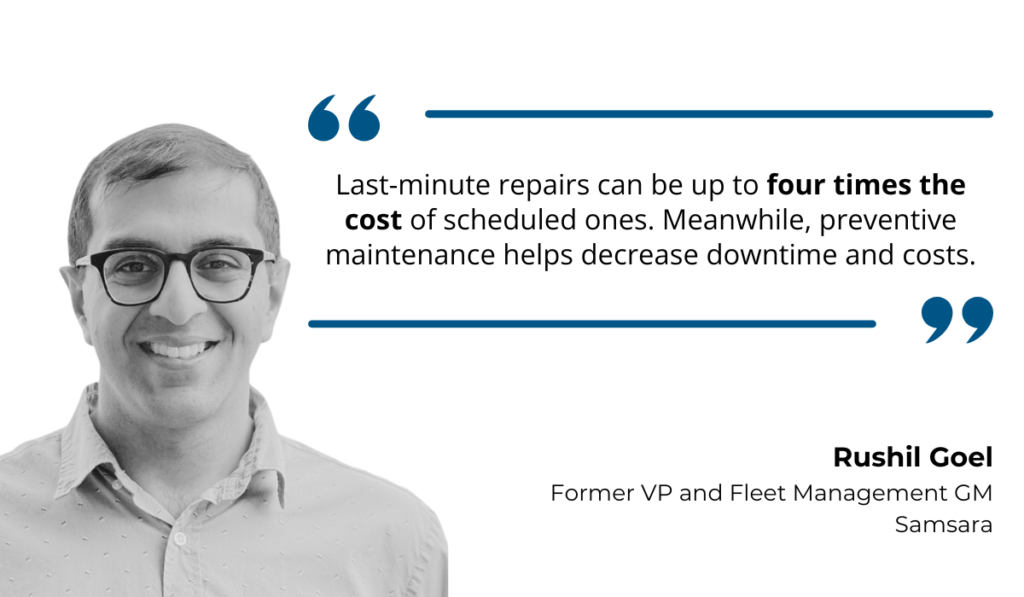

Rushil Goel, former VP and Fleet Management GM at Samsara also highlights the difference between the two, both in terms of costs and overall impact.

Illustration: GoCodes Asset Tracking / Quote: Work Truck Magazine

Various academic studies support Goel’s claim, including a 2021 report.

It shows that while preventive maintenance may lead to higher direct maintenance costs, it also reduces defects (78.5%) and unplanned downtime (52.7%), ultimately lowering total costs.

So, how does RTLS fit into all this?

Simply put, it enables organizations to implement proactive maintenance practices.

By monitoring asset conditions in real-time, you can collect historical data and adjust maintenance schedules based on actual operating conditions and usage patterns.

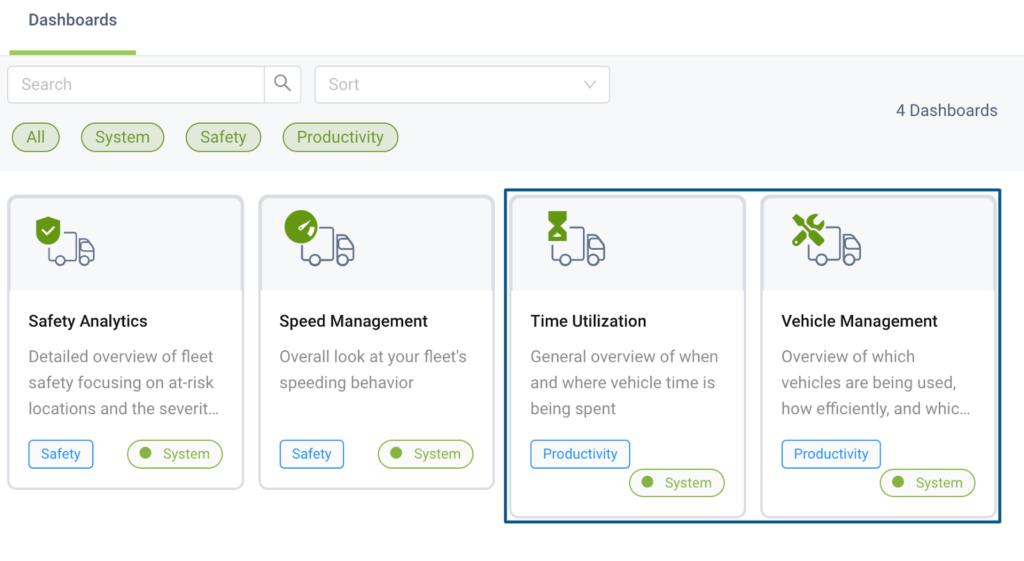

For instance, tracking systems like GoCodes Asset Tracking can measure key telematics of your movable assets to detect anomalies, predict failures, and schedule timely maintenance.

Additionally, you get access to comprehensive reports shown below.

Source: GoCodes Asset Tracking

This approach goes beyond mere location tracking, empowering maintenance teams to make informed, data-driven decisions.

Let’s take a forklift as an example.

If it’s scheduled for maintenance every 500 hours, real-time tracking ensures that service happens precisely when needed, based on odometer readings.

In contrast, relying on reactive maintenance could stretch this interval to 700-1,000 hours or more, increasing the risk of unexpected breakdowns, costly repairs, and operational delays.

Real-time locating systems are a staple of preventive maintenance efforts, helping manufacturers mitigate failures and optimize overall performance.

Medical Equipment Tracking

RTLS technology is crucial for addressing the challenges of medical equipment tracking today.

Healthcare facilities have long relied on real-time locating systems to track medical equipment and staff, while more recent applications include patient monitoring and access control.

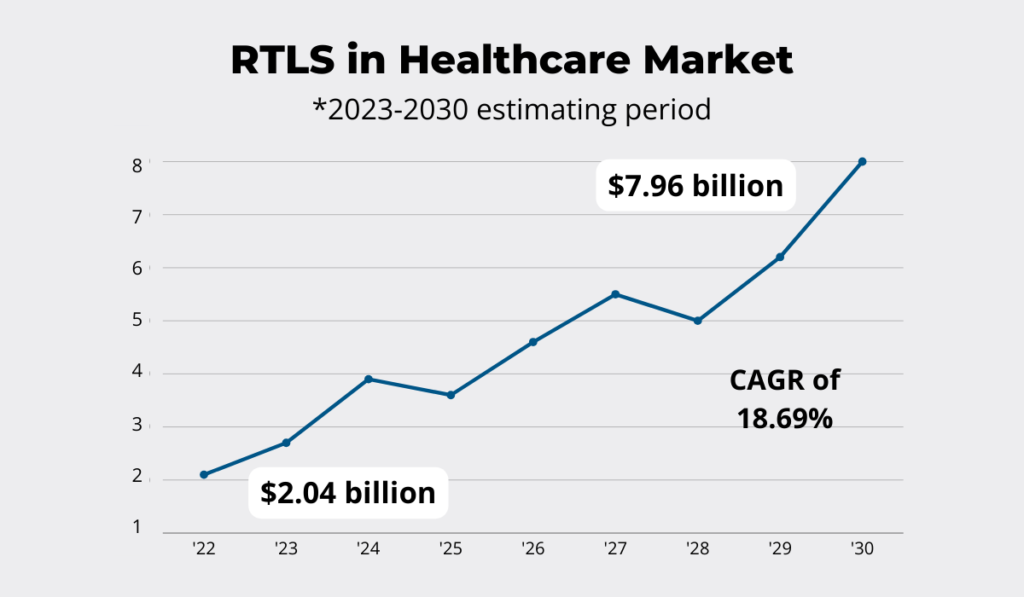

Still, asset tracking remains a leading driver behind the growth of the RTLS healthcare market, which is expected to reach $7.96 billion in value by 2030.

Illustration: GoCodes Asset Tracking / Data: Grand View Research

Healthcare facilities are increasingly adopting RTLS to improve resource allocation and operational efficiency, thereby reducing additional purchases of medical equipment.

It’s not just about tracking high-value assets or reducing equipment replacement costs.

The inability to locate surgical instrument kits and ensure that critical equipment is sterilized and available at the right moment can drastically impact patient care and lead to fatal outcomes.

Fortunately, RTLS solutions play a crucial role in supporting sterilization tracking and compliance monitoring by streamlining complex workflows.

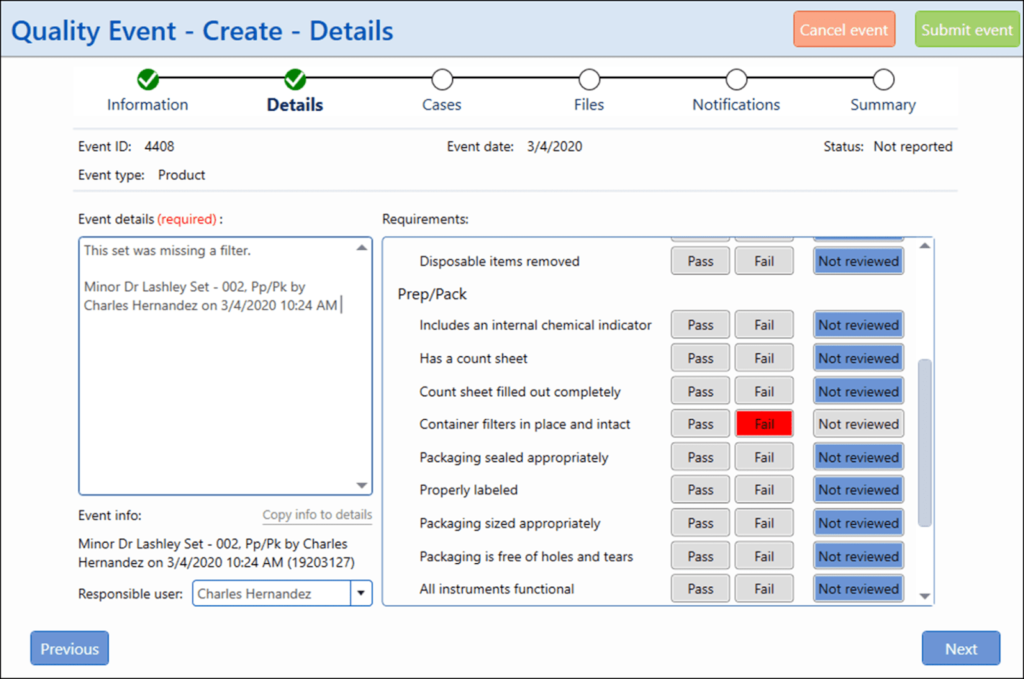

Consider Steris’ instrument tracking software.

This solution leverages RTLS to ensure seamless movement of instruments between storage facilities, CSSD, the operating room, or anywhere else.

In addition to tracking, the system incorporates various quality assurance features and a comprehensive set of checks to ensure that the equipment meets strict cleanliness standards.

Source: Steris

Moreover, configurable workflows within the system guarantee that only trained technicians are authorized to complete specific tasks.

This significantly reduces the risk of contamination and negative patient outcomes.

The end result? You don’t have to worry about the availability or condition of critical equipment.

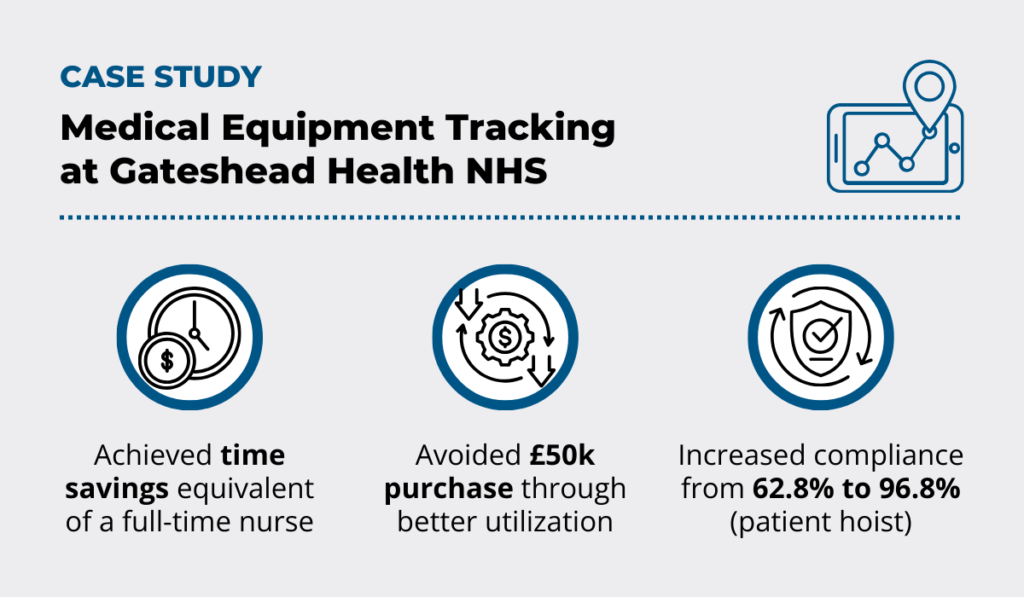

The Head of Medical Engineering and Equipment Services at Gateshead Health NHS Foundation Trust, Michael Crowe, explains this is a perennial healthcare challenge that erodes both patient care and the bottom line.

No matter if the assets are misplaced or simply poorly utilized, the inability to rely on key equipment puts pressure on staff.

In turn, this results in frequent requests for replacement sets that aren’t truly necessary.

To try and address these problems, Gateshead turned to a hybrid RTLS solution that combines Bluetooth trackers with UHF RFID tags.

The time and cost-saving benefits speak for themselves.

Illustration: GoCodes Asset Tracking / Source: Medstrom on Youtube

Precise tracking increased equipment visibility, preventing time-consuming manual searches and additional purchases.

The organization also improved maintenance efforts to ensure specific equipment like patient hoists comply with safety standards and regulatory requirements.

In summary, RTLS enhances medical equipment tracking by providing real-time visibility and improving workflow efficiency.

Medical facilities that want to control costs while providing exceptional care know that their best option to do both is to adopt RTLS-based asset tracking software.

Conclusion

RTLS ensures better asset tracking, personnel monitoring, and inventory management, transforming the way businesses optimize operations.

By integrating real-time location data, you’re sure to stay ahead of potential risks, optimize workflows, and protect both people and equipment.

No matter the industry, adopting RTLS unlocks significant efficiency gains and cost savings, while supporting compliance and quality.

Ready to unlock the full potential of your operations?

It’s time to turn to RTLS and reap the benefits of reliable, real-time tracking across your organization!