Key Takeaways:

- Real-time locating systems (RTLS) help companies stay ahead of unexpected operational challenges.

- IoT-enabled RTLS optimize maintenance schedules, cutting downtime and repair costs.

- Instant tracking and geofencing enhance equipment security.

- RTLS deliver a strong ROI.

Keeping track of your equipment in a fast-moving environment like construction often feels like an uphill battle.

Luckily, real-time locating systems (RTLS) quickly bring order to the chaos.

From tracking down $500,000 worth of stolen equipment to optimizing maintenance, RTLS does much more than capture your assets’ locations.

Eager to see how you can redefine efficiency and security, and cut down on construction costs with RTLS?

Then let’s get started!

In this article...

Enhanced Asset Visibility

Real-time locating systems provide precise tracking, significantly improving asset visibility.

By combining real-time tracking devices with software, companies can monitor equipment movement across multiple jobsites in real time.

This improved visibility is driving the rapid adoption of RTLS technology.

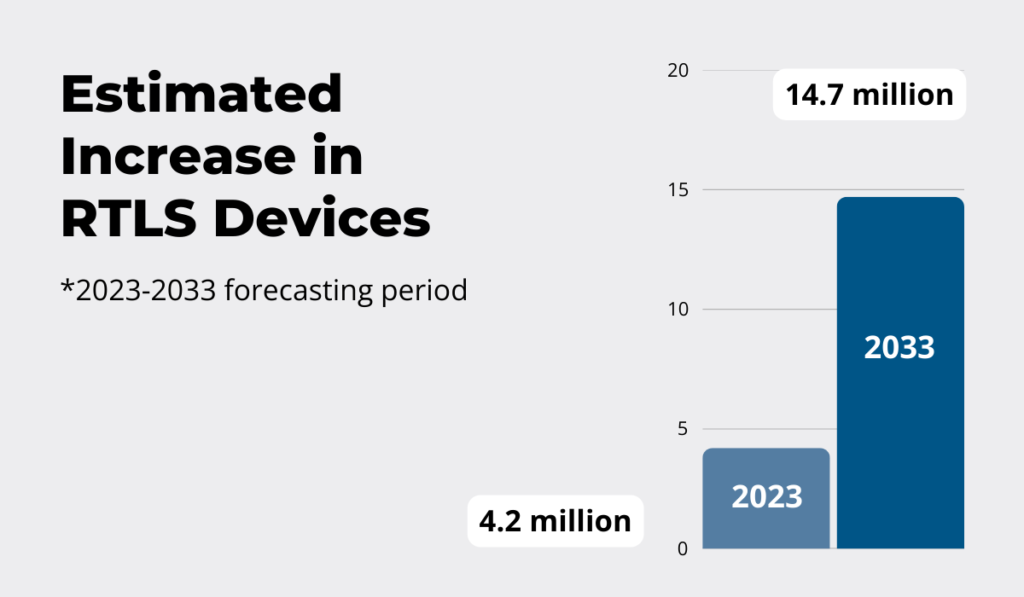

According to Transforma Insights, the number of RTLS devices is projected to grow from 4.2 million in 2023 to 14.7 million by 2033.

Illustration: GoCodes Asset Tracking / Data: Transforma Insights

Naturally, with greater asset visibility, you gain more benefits.

For instance, you can successfully prevent tool misplacements while minimizing the time your workers spend locating what they need in their day-to-day work.

On a bigger scale, managers who rely on RTLS are in a better position to effectively allocate resources across several projects.

With each piece of equipment accounted for and used optimally, there are fewer chances you’ll be making unnecessary purchases instead of simply making adjustments.

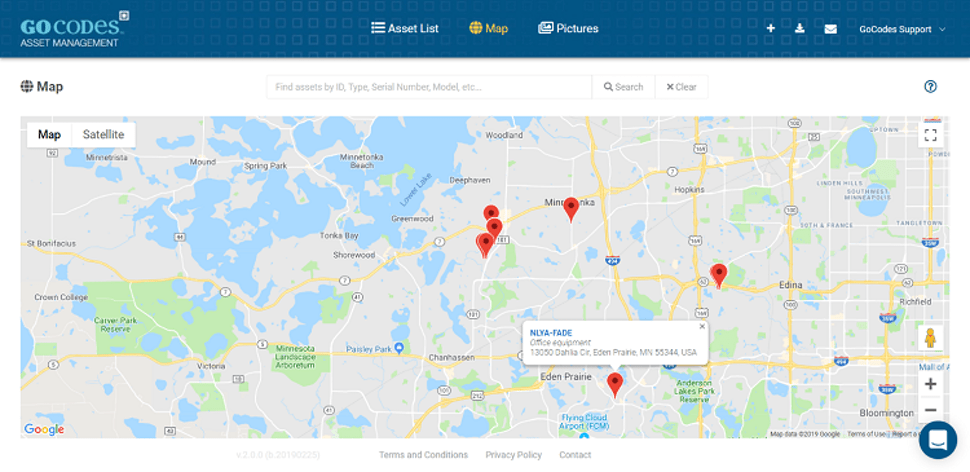

A quick look at the map like the one below, and you have the key insights on each asset’s location and current use.

Source: GoCodes Asset Tracking

While these systems make a difference for any organization looking to track numerous assets, it’s particularly beneficial if you’re expanding your operations.

One example is the Parkland Health & Hospital System’s RTLS implementation.

Parkland’s 2018 move to a new campus, which was double the size of the previous facility, meant a huge increase in the number of medical devices that required precise tracking.

With 60,000 assets moving across the premises, deploying RTLS technology was the only way to cut losses and increase overall visibility.

Matthew Kull, Parkland Health and Hospital System’s Senior VP and CIO at the time, remarked that this move resulted in substantial savings and paved the way for greater efficiency.

Illustration: GoCodes Asset Tracking / Quote: Healthcare Innovation

Such increased visibility has a similar impact across different industries, especially those like construction, where assets frequently move between several jobsites.

In other words, if you want more visibility over your construction equipment, RTLS is the way to go.

Improved Operational Efficiency

RTLS technology promotes better planning and agile decision-making, which immediately impacts overall operational efficiency.

Real-time locating systems eliminate the inefficiencies of manual asset tracking by enabling companies to locate equipment instantly and streamline workflows.

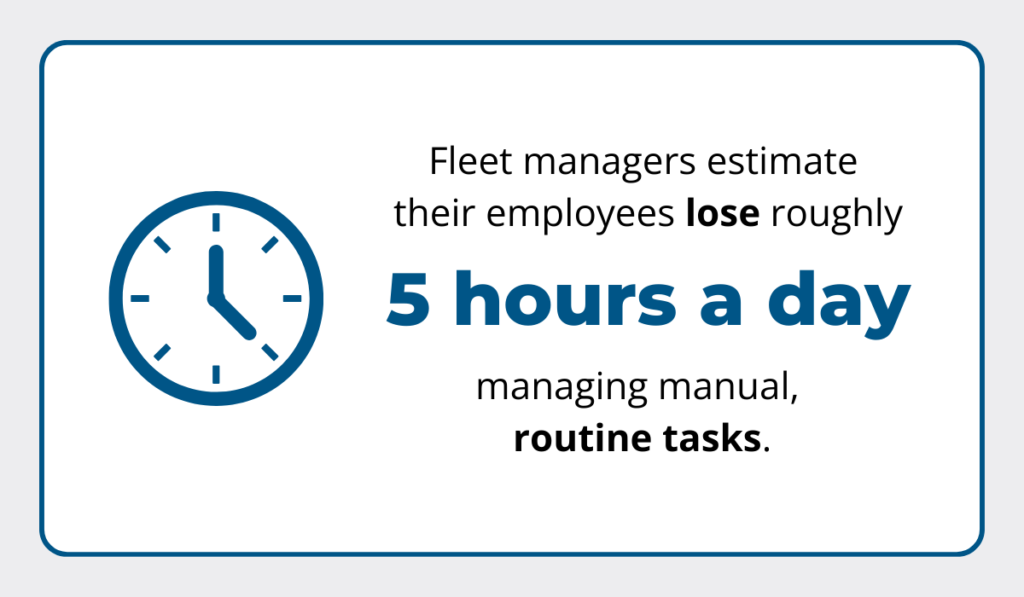

Motive’s recent survey of 1,000 fleet managers found that employees lose more than half of their time on manual tasks, including tracking down misplaced equipment.

Illustration: GoCodes Asset Tracking / Data: Motive

This inefficiency leads to downtime, project delays, and increased operational costs.

Automating asset tracking with RTLS provides instant access to real-time data, enabling companies to respond proactively to challenges.

One key application is route optimization for fleet management.

RTLS-integrated platforms like DispatchTrack help operators map the most efficient routes, improving material handling and logistics.

RTLS also enhances agility in the face of unexpected disruptions.

If a shipment is delayed, managers can quickly reroute available materials to prevent downtime.

Similarly, during weather-related emergencies, real-time tracking allows teams to move equipment to safer locations, mitigating damage risks.

Fleet management expert, Erin Gilchrist Rugg, emphasizes that having all data in one place enables teams to quickly identify and address critical issues, such as off-route vehicles or incomplete inspections.

Illustration: GoCodes Asset Tracking / Quote: IntelliShift

This visibility allows companies to focus on the most urgent risks, improve response times, and enhance overall efficiency.

To sum up, by integrating RTLS, companies can streamline workflows, reduce inefficiencies, and focus more on high-value tasks rather than tracking down misplaced assets.

Strengthened Equipment Security

Construction equipment is a prime target for theft, which makes real-time locating systems all the more important.

And it’s more than knowing where your equipment is at all times.

Placing a real-time tracking device on your high-value machines discourages theft while improving your chances of recovering the stolen asset(s).

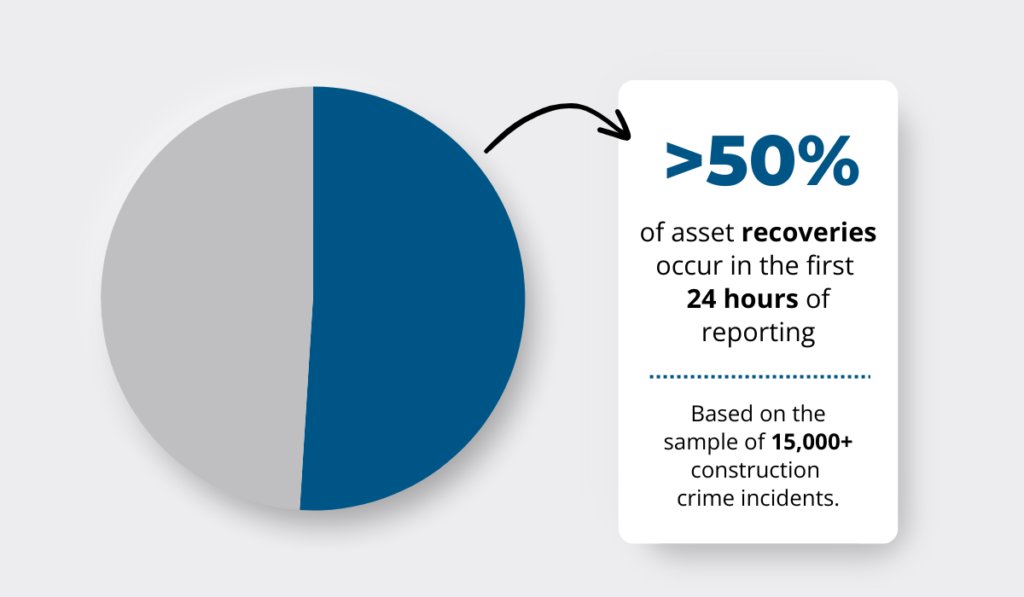

An extensive study of construction crime incidents shows that over half of recoveries occur when the theft is reported within 24 hours.

Illustration: GoCodes Asset Tracking / Data: Associated Schools of Construction

In other words, the more time passes, the less likely it is you’ll recover your stolen property.

Fortunately, implementing RTLS technology is the surest way to improve reaction time.

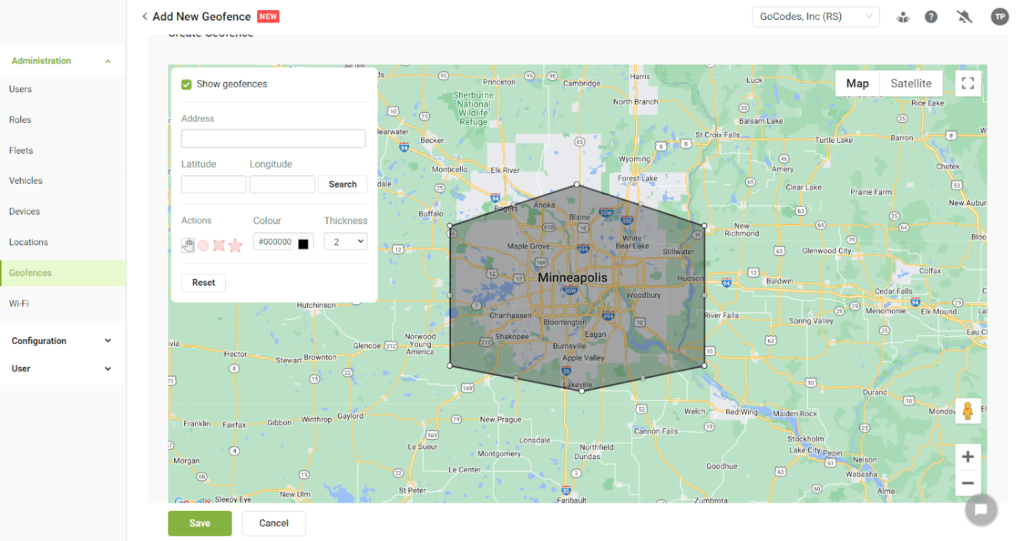

These systems can help you flag any unauthorized equipment movements thanks to powerful geofence-enabled GPS trackers.

Geofences act as virtual boundaries, so any suspicious movement, such as crossing the geofence during after-work hours, triggers an instant alert.

Source: GoCodes Asset Tracking

GoCodes Asset Tracking and similar systems come equipped with automated notifications that are pivotal in recovery efforts and are highly customizable.

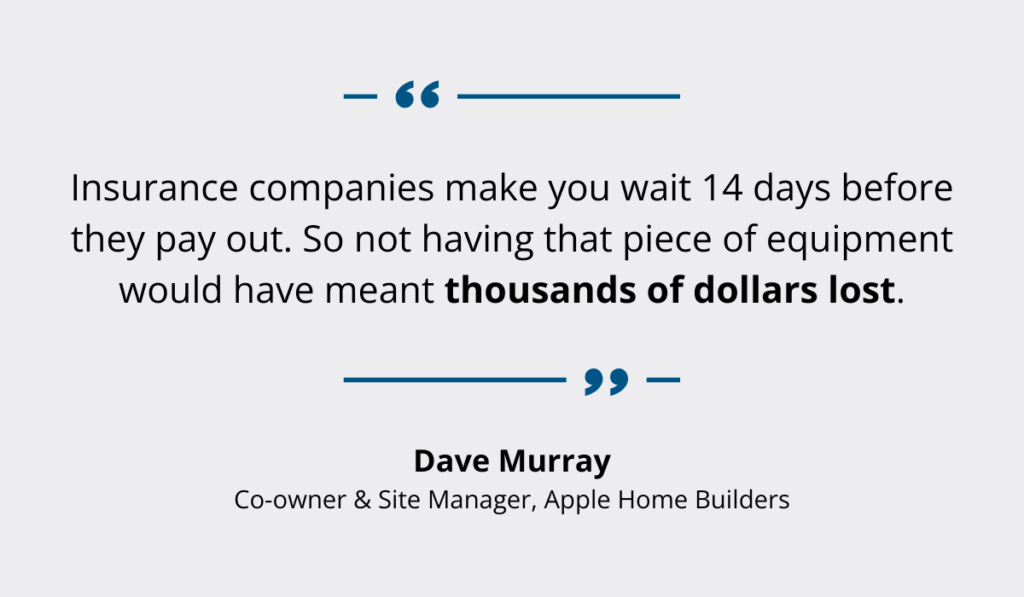

The value of these instant alerts is best seen in the case of Apple Home Builders.

Namely, the company decided to introduce CloudHawk’s asset management solution to combat theft and ended up retrieving a stolen excavator while also uncovering $500,000 worth of stolen machinery.

Dave Murray, the company’s Co-owner and Site Manager, explains that real-time tracking and automated alerts proved critical in locating the equipment and guiding law enforcement.

Illustration: GoCodes Asset Tracking / Quote: CloudHawk

Without this system, it would have been near impossible to pinpoint where the asset was, let alone do it within an hour of the incident.

So, if you’re looking to bolster on-site security and protect your assets, it’s time to invest in real-time locating systems.

Optimized Maintenance Scheduling

RTLS technology also plays a key role in optimizing maintenance scheduling, especially when combined with IoT capabilities.

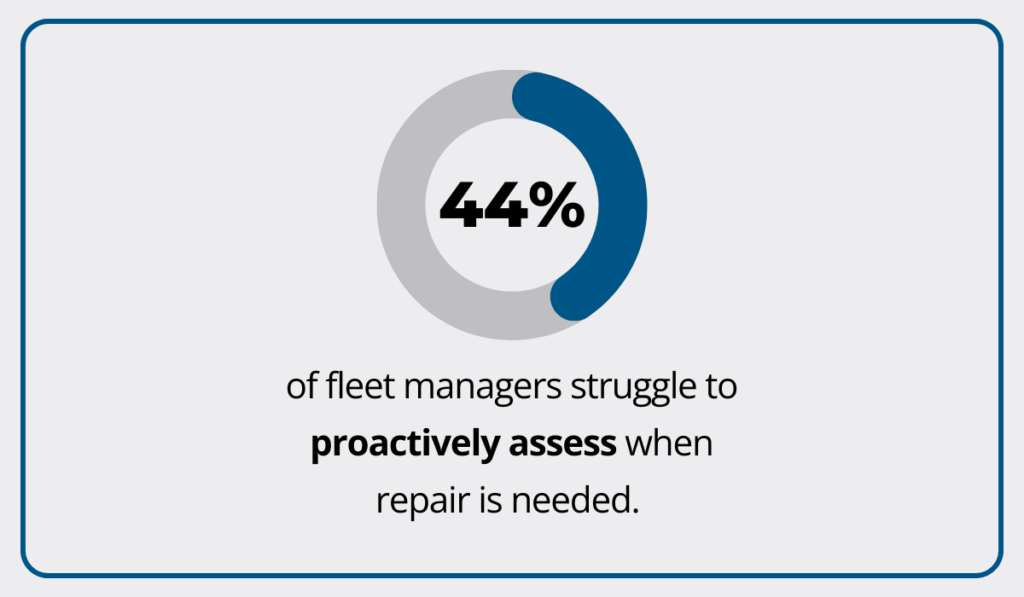

Due to tight deadlines and manual processes, strategic maintenance remains one of the top equipment management challenges.

J.J. Keller’s 2024 study confirms this, with 44% of fleet managers reporting difficulties in proactively assessing repair needs.

Illustration: GoCodes Asset Tracking / Data: J.J. Keller

Real-time locating systems combined with IoT sensors can change that.

By integrating RTLS with IoT sensors, companies can track both equipment location and usage patterns, allowing for data-driven maintenance decisions.

Instead of relying on fixed schedules, companies can perform maintenance based on actual operating conditions, preventing both over-servicing and unexpected failures.

For example, if a compactor is scheduled for maintenance every 300 hours, real-time tracking ensures that service occurs precisely when needed—whether the equipment has been used more than expected or is underutilized.

This approach to maintenance extends equipment lifespan, prevents downtime, and reduces maintenance costs.

Keep in mind that although location insights come second compared to odometer data, they’re still vital for planning maintenance.

As Field Maintenance Foreman Ryan Kennedy explains, real-time location data allows technicians to plan their service schedules more efficiently, covering multiple assets in the shortest time possible.

Illustration: GoCodes Asset Tracking / Quote: Construction Equipment

Ultimately, using RTLS for maintenance scheduling reduces downtime, lowers repair costs, and enhances overall equipment reliability.

Improved Compliance

RTLS-powered tracking systems help construction companies maintain compliance with regulatory requirements.

By accurately recording asset locations and usage, these systems help ensure construction equipment meets safety and operational standards both on-site and during audits.

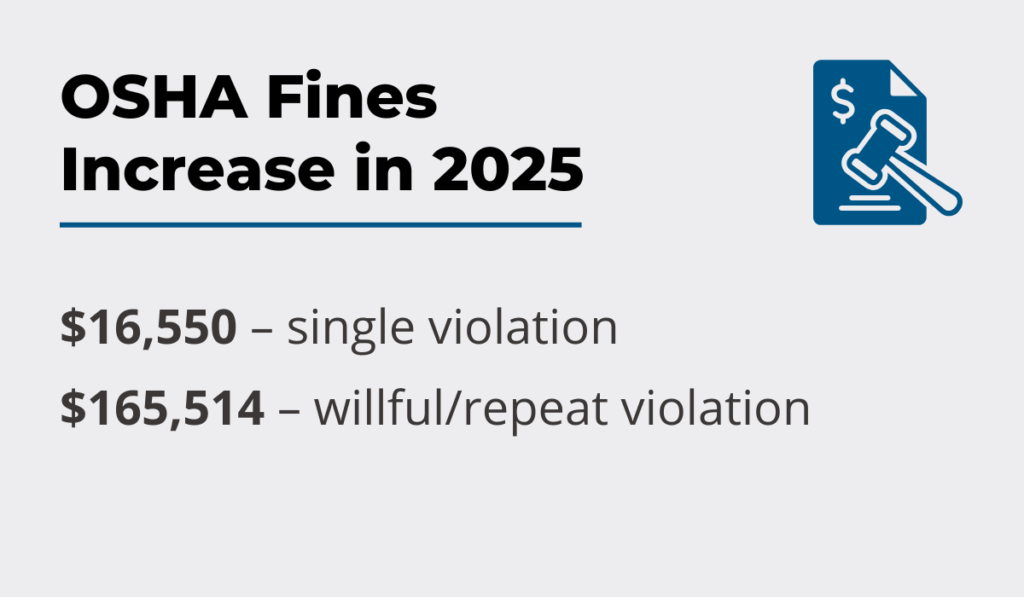

Construction companies have plenty of reasons to prioritize safety and compliance, including the hefty price tag of recently increased OSHA fines.

Illustration: GoCodes Asset Tracking / Source: OSHA

So, how does RTLS help ensure compliance?

It boils down to minimizing legal risks through automated record-keeping.

RTLS conveniently logs the movement history of all tracked assets, which can then be used as proof of compliance during inspections.

For instance, if an OSHA inspector requests detailed documentation on all crane inspections, the system can easily provide time-stamped records of all conducted inspections.

Moreover, RTLS movement history helps you establish a clear timeline of events, which is crucial for investigating safety incidents and mitigating liability risks.

In its simplest form, RTLS helps companies enforce safety measures by ensuring assets remain in designated areas.

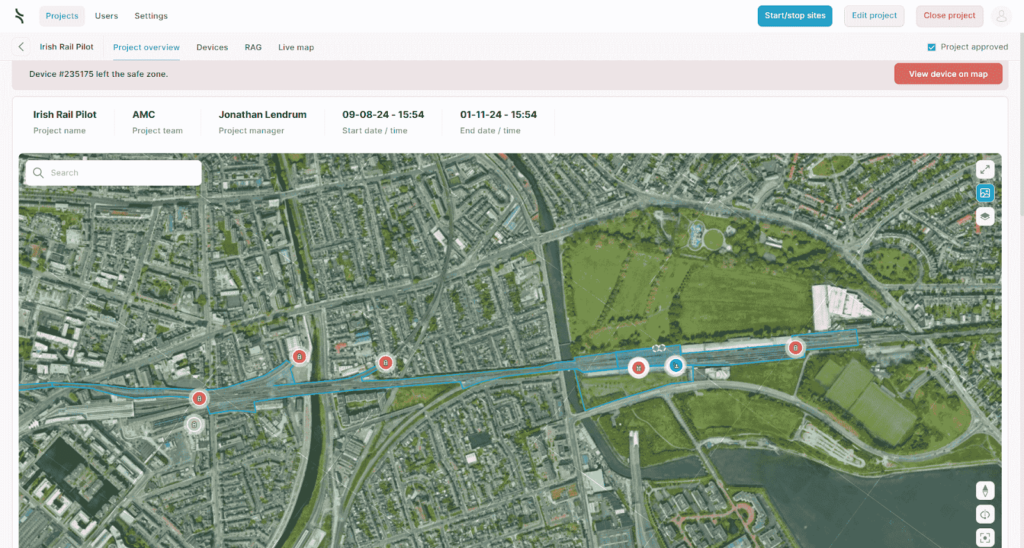

Take Tended’s solution as an example.

The green areas typically show the designated safe zones while red alert icons highlight locations where compliance issues may have occurred.

Source: Tended

RTLS also helps prevent unauthorized use of assets and avoid both fines and safety incidents.

You can track who accessed and operated high-risk tools, such as concrete saws, to ensure that only qualified personnel use specific equipment or enter restricted zones.

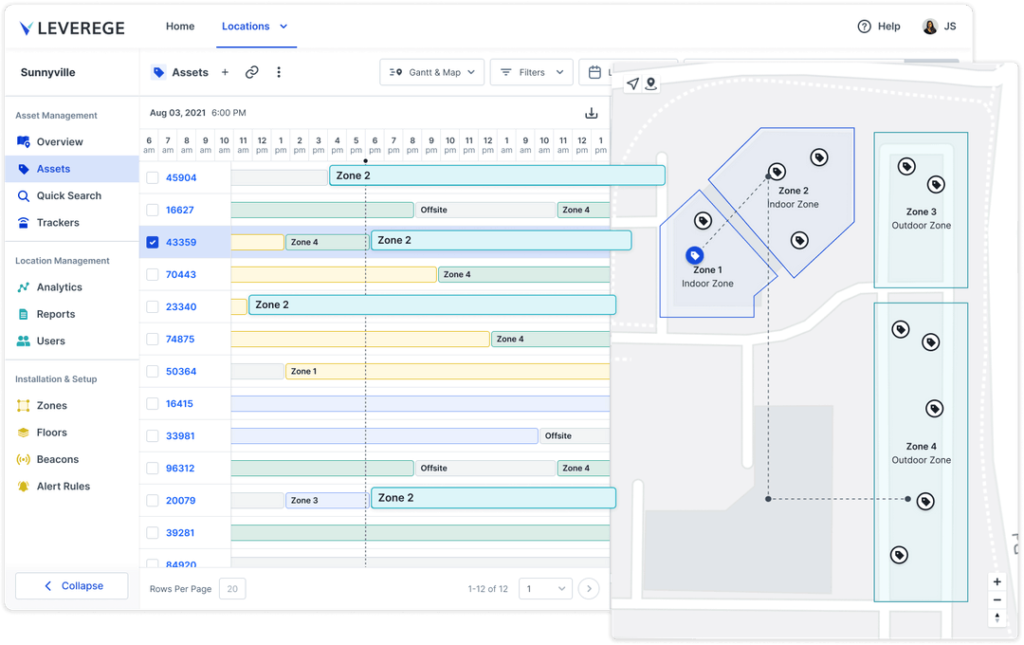

Here’s what this zone-based monitoring looks like when using solutions like Leverege.

Source: Leverege

As shown in the image above, by dividing areas into specific zones, companies can closely monitor movement between those zones.

In the end, gaining access to detailed movement histories as well as real-time tracking is invaluable to any company that wants to maintain accurate audit records and minimize legal risks.

Reduced Operational Costs

Finally, adopting RTLS software is a key cost-reduction measure.

When we take into account all the benefits listed previously, this is hardly a surprise.

Real-time locating systems contribute to cost savings in several ways, including:

- Cutting labor expenses related to manual tracking

- Reducing asset loss and replacement costs

- Minimizing downtime

As we’ve already established, workers in companies without RTLS waste time tracking down misplaced or improperly stored equipment, with lost minutes turning into hours over time.

Moreover, using paper-based documentation or Excel sheets over dedicated asset tracking solutions means that employees must physically verify asset locations, eroding efficiency.

Minimizing asset loss leads to even more significant and measurable cost savings.

Let’s briefly go back to Apple Home Builders’ successful asset retrieval story.

Namely, the reported $500,000 in stolen assets didn’t account for the additional costs of asset loss, including replacement expenses and costly downtime.

Apple Home’s Site Manager noted that the stolen excavator would have cost $80,000 to replace, with the losses piling up further due to slow insurance payouts.

Illustration: GoCodes Asset Tracking / Quote: CloudHawk

Payout delays create cash flow challenges, which, in turn, slows down asset replacement and creates an even more devastating impact on all operations.

On the other hand, investing in real-time locating systems can quickly turn things around, no matter the industry.

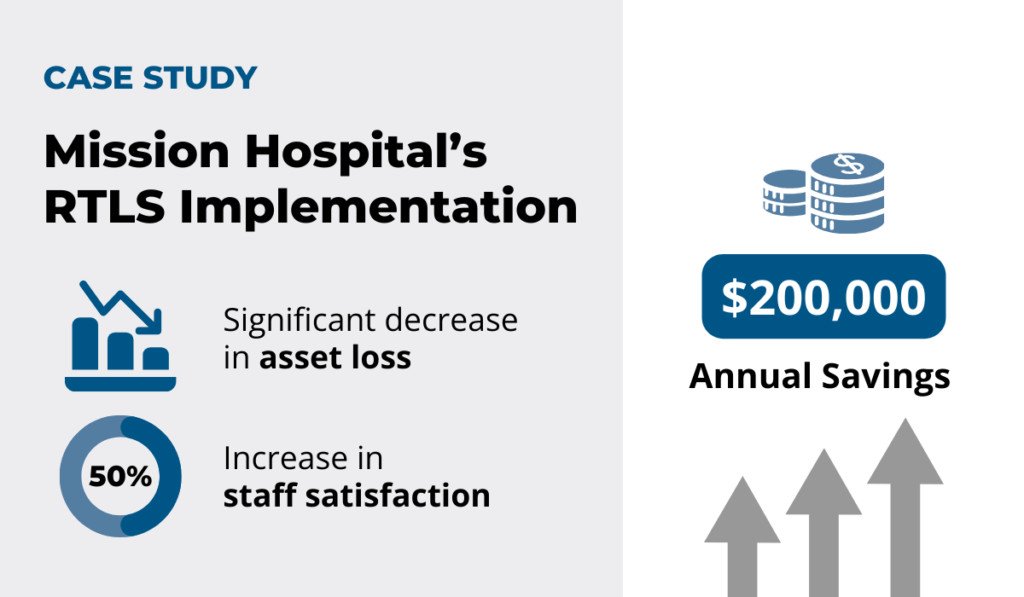

Take the recent example of successful RTLS technology adoption at the Mission Hospital.

Leveraging RTLS reduced asset loss while simultaneously improving overall efficiency and employee satisfaction.

Ultimately, the annual cost savings amounted to $200,000.

Illustration: GoCodes Asset Tracking / Source: Health IT Answers

The high ROI of RTLS in both healthcare and construction is most evident in how it empowers better decision-making through actionable data.

By automating routine, low-value tasks and providing valuable insights, companies can map inefficiencies and streamline workflows in a way that optimizes asset usage.

The result?

Long-term improvements in operations and cost savings.

In the end, that’s the true value of RTLS across industries—unlocking savings by driving continuous improvements.

Conclusion

Real-time locating systems bring multiple benefits.

In an industry where you’re one delay away from losing profit margins, RTLS helps you reduce uncertainties and regain control over your equipment.

This reliability extends across all your operations, no matter how many projects you’re managing at once.

The question isn’t whether you need RTLS technology—it’s how soon you can implement it.

Future-proof your operations with this tracking technology, and you’ll see immediate efficiency gains while securing long-term success and cost savings.