Personal protective equipment is the cornerstone of successful construction work. When contractors supply their workers with personal protective equipment, they keep them safe from life-threatening hazards.

On the other hand, failure to comply with PPE safety requirements will disrupt your construction operations and put your workers at risk.

After reading this article, you’ll understand what the essential pieces of PPE are and how they contribute to a safer and more productive construction site. Let’s get started.

In this article...

Hard Helmets

When we think about construction sites, hard helmets are often the first thing that comes to mind.

There is a good reason why hard helmets are synonymous with construction sites. They play a crucial role in preventing workers from suffering severe injuries to the head, concussions, as well as bone and spine fractures.

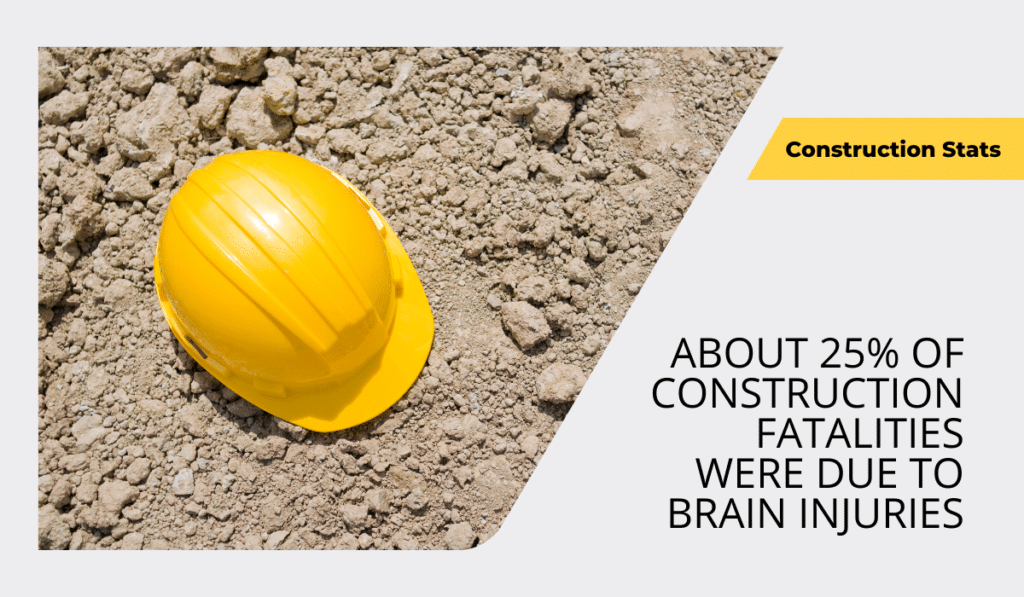

Are you aware that the construction industry has the highest occurrence of traumatic brain injuries of all occupations?

According to a scientific study published by the National Institute of Occupational Safety and Health, roughly 25% of construction fatalities were due to brain injuries.

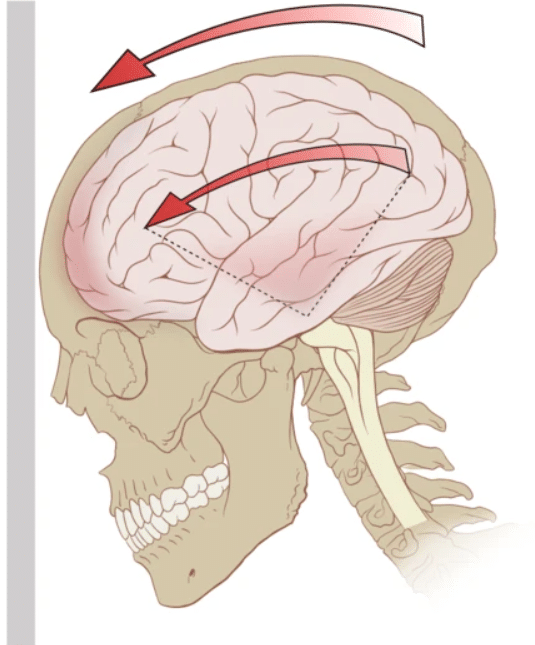

When a person falls and hits the side of their head, the impact produces rotational acceleration, the leading cause of concussions on worksites. One more study of brain injuries found that about 15% of Swedish and 27% of German contractors suffered concussions.

It’s safe to assume that concussions are unfortunately common in the worksite, and without hard helmets to absorb the force of the impact, there would be more head injuries.

And how much do head injuries cost laborers and their companies?

According to the CDC, the workers who do not need physical therapy after sustaining a head injury still have an average medical cost of $17 893.

A mild traumatic brain injury that requires rehabilitation efforts costs $85 000 on average. If the brain injury is severe, the costs can ramp up to $3 million.

Providing your construction workers with quality hard helmets is an absolute necessity.

Safety Gloves

Construction is hard manual labor, so safety gloves are critically important for protecting the hands of your workers.

As part of their job, contractors often work in high-risk situations where they can easily suffer serious injury if they’re not provided with protection for their hands.

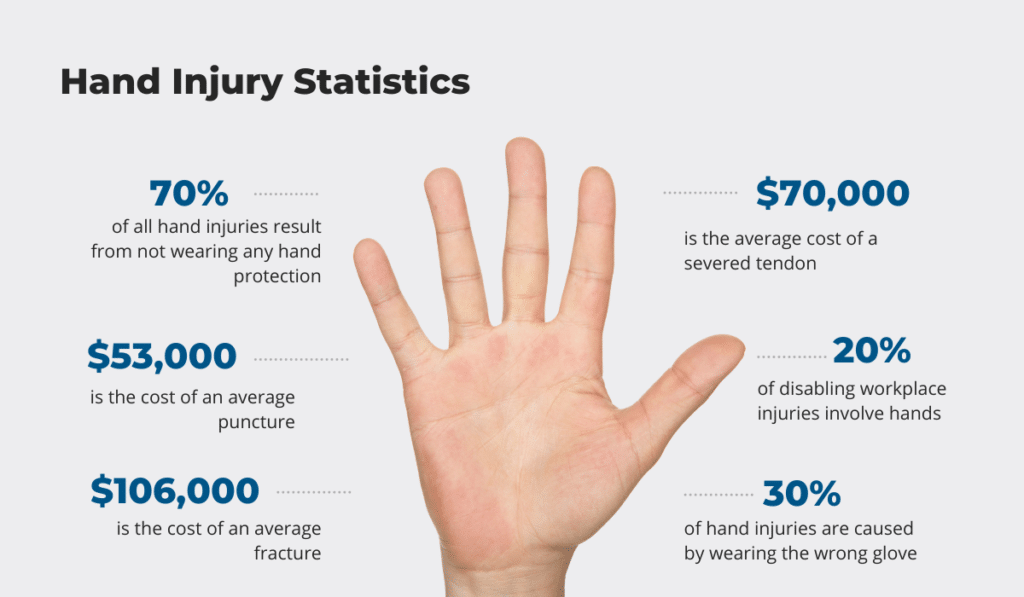

Have a look at the data from the Energy Workforce report.

The numbers are thought-provoking, to say the least.

Around 20% of disabling workplace injuries involve hands. That’s one in five work-related injuries.

To make things more serious, 30% of those were caused by workers wearing the wrong type of protective gloves. If the workers had been provided with PPE gloves fit for a particular task, the number of disabling injuries could have been reduced.

Naturally, contractors work with many rough and hazardous materials that require delicate handling. Different site operations require specific safety gloves.

For example, this is how a contact injury from working with chemicals looks like.

Contact injuries like these happen when contractors are not provided with safety gloves resistant to chemical burns.

High-Visibility Vests

High-visibility vests are a mandatory piece of PPE on construction sites where workers have to be spotted easily.

As you know, construction work also includes conducting repairs on bridges and roads alongside inbound traffic. If the drivers are unable to see the construction workers on time, a moving car can hit a contractor on the scene and cause a fatal accident.

However, when contractors wear high-visibility vests, they are noticeable even during nighttime construction.

In fact, the National Academies of Sciences, Engineering, and Medicine recommend using high-visibility vests for productive and safe nighttime construction work.

High-visibility vests must provide a 360° full-body coverage, so workers are visible in all viewing directions.

Color stripes on visibility vests are in contrast to the background colors to make the wearer stand out even more. In addition, visibility vests are covered with a fluorescent material, which is particularly useful when it’s dark.

High-visibility vests significantly reduce the likelihood of accidents and contribute to safety in construction.

Safety Eyewear

The workers’ eyes are highly vulnerable during an array of contracting activities. Therefore, if they are not appropriately protected with safety eyewear, there is a risk of potentially disabling injuries.

According to OSHA’s PPE standard annual training program, 90% of eye injuries could be prevented with suitable eyewear. Workers in construction can injure their eyes with airborne chemicals, debris, dust, and forceful impact.

So, wearing safety eyewear directly contributes to preventing vision impairment.

Anne Summers, an ophthalmologist and clinical spokesperson for the American Academy of Ophthalmology (AAO), said that it takes surprisingly very little effort to protect a person from worksite hazards that can cause an injury that leads to blindness.

She also urges workers and employers not to drop their guard when it comes to eye protection.

Of course, the safety eyewear workers need depends on the specific hazards they face.

We can single out 3 different types:

- Safety glasses with side shields for workers exposed to flying particles

- Goggles for construction tasks that involve the use of chemicals

- Specially designed safety eyewear for specific tasks, like welding

Non-specialized safety eyewear is very affordable, starting at prices as low as $10. With that in mind, there’s no point in exposing workers and their employers to unnecessary risks.

Foot Protection

There are many things at the construction site that can cause serious injuries unless the workers are provided with adequate foot protection.

Foot protection is an essential piece of personal protective equipment designed to shield the workers’ feet from injuries that stem from the poor footing or other causes.

Proper footwear is a significant factor in the safety of construction sites.

First, it provides protection from crush injuries. Construction material and other heavy objects can easily drop during transport and fall on the workers’ feet. Therefore, their shoes are plated to prevent crushing injuries.

Second, such footwear protects workers from slipping and falling. As you can imagine, slips are common at sites with difficult working conditions, which is why the soles of the workers’ shoes also include an anti-slip grip.

It’s important to note that the rubber sole also keeps workers safe from floor electrocution.

And finally, adequate foot support keeps workers from straining their muscles and developing poor posture in the long run.

Safety Harness

Safety harnesses (or safety belts) are life-saving pieces of personal protection equipment. They’re designed to keep workers from falling when contractors are completing tasks in heightened areas.

Site employees working at over 6.5 ft of height are required to wear a safety harness. Safety harnesses are strong enough to carry 5000 lb of weight, making them more than adequate to prevent fully-equipped workers from falling.

Unfortunately, one-third of construction site fatalities were a direct result of falls from great heights. According to OSHA, these deaths would have been entirely preventable had there been adequate PPE available.

Safety harnesses are essential because falls from height are more likely to be life-threatening than other types of worksite accidents.

A construction site accident usually affects a single part of the body, while falls damage multiple body parts and vital organs.

To make things worse, not providing contractors with fall protection remains the most frequent violation of safety standards, according to Dillon Holewinski, a strategic risk advisor for construction industries.

Hearing Protection

If you don’t provide your site workers with hearing protection, they can develop long-term hearing loss.

It goes without saying that construction sites are some of the loudest workplaces out there. Heavy machinery makes a lot of noise, and working close to it can have a negative effect. Many contractors are struggling with hearing damage because of it.

A study published by the CDC has revealed that 23% of US workers that are occupationally exposed to loud noise developed hearing difficulties afterward.

To make matters worse, another 15% of workers develop tinnitus. Tinnitus causes a person to hear ringing in their ears, without the noise being caused by an external sound.

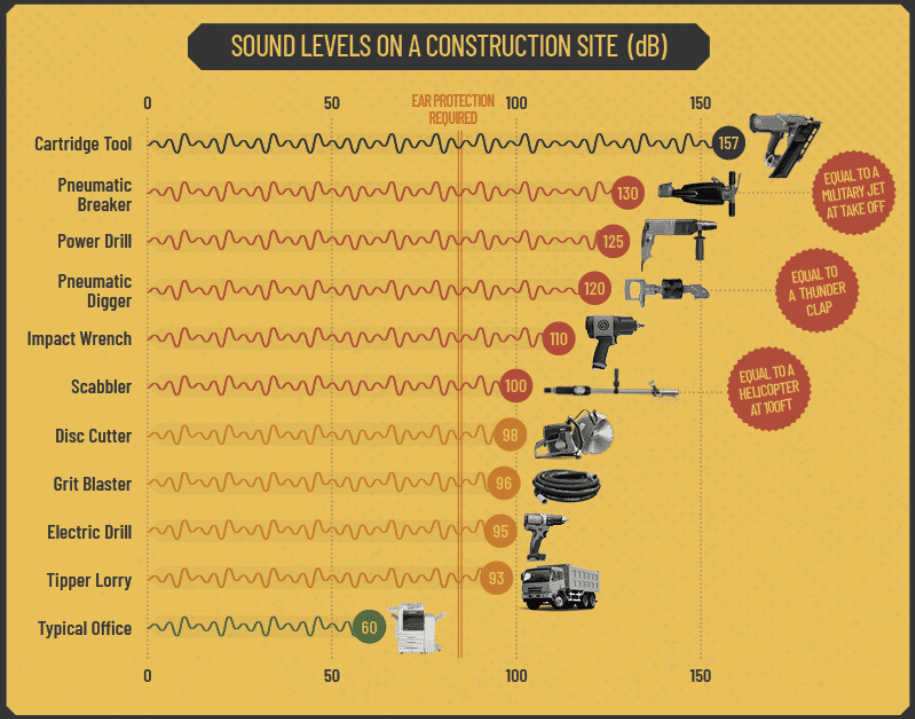

Keep in mind that hearing damage is irreversible. It occurs when workers experience long-term exposure to the noise around 85 decibels for 8 hours. In addition, for every 3-decibel increase, hearing loss occurs in half the time.

So if the noise level is over 91 decibels, hearing damage can occur in 2 hours.

To put these numbers into perspective, an electric drill registers about 95 decibels of noise. Just think about how much noise the rest of your heavy construction equipment is making.

Elizabeth Masterson, the study’s co-author, has stated that hearing loss is entirely preventable if the workers are provided with proper hearing protection. Providing your workers with noise-canceling headphones or earplugs will keep their hearing intact.

Respirators

Construction sites often have compromised air that’s not safe for breathing.

There are too many construction operations to count involving dust, carbon monoxide, fumes, or hazardous gasses. If workers are not provided with adequate protection, they’re bound to develop respiratory issues and potentially life-threatening illnesses.

Take silica dust, for instance. Silica dust is a small particle found in a wide array of construction materials, such as cement, steel, clay, or sand.

Workers release and breathe it during high-energy operations. However, doing so leads to developing progressive lung disease, kidney failure, or lung cancer.

Unfortunately, 8 out of 10 workers have been exposed to silica dust work in the construction industry. To keep workers safe, contracting organizations have to provide them with proper respirators.

There are 2 different types of respirators that are utilized alongside reusable half-masks.

Filtering facepiece respirators are made from filter material covering the worker’s mouth and nose, and they filter the particles from the air they’re breathing in. They are more suitable for mild construction operations and filter out 67% of dust the worker breathes in.

Powered air-purifying respirators are powered by a battery and they cleanse 99.97% of the air. They are the most effective respirators available and protect contractors from breathing in silica dust or other substances during operations on hazardous sites.

Depending on the specifics of the construction sites, organizations can use either one of them.

Wearable Protection Tech

Thankfully, the construction industry is ripe with innovative tech solutions that make construction sites a safer place to work.

Wearable protection tech monitors the vital signs of the contractors so that construction site supervisors know where the employees are and what their current health condition is.

If it picks up on any irregularities or signs of a potential site accident, the tech immediately requests emergency help. Providing medical attention on time can be the deciding factor in a life or death situation.

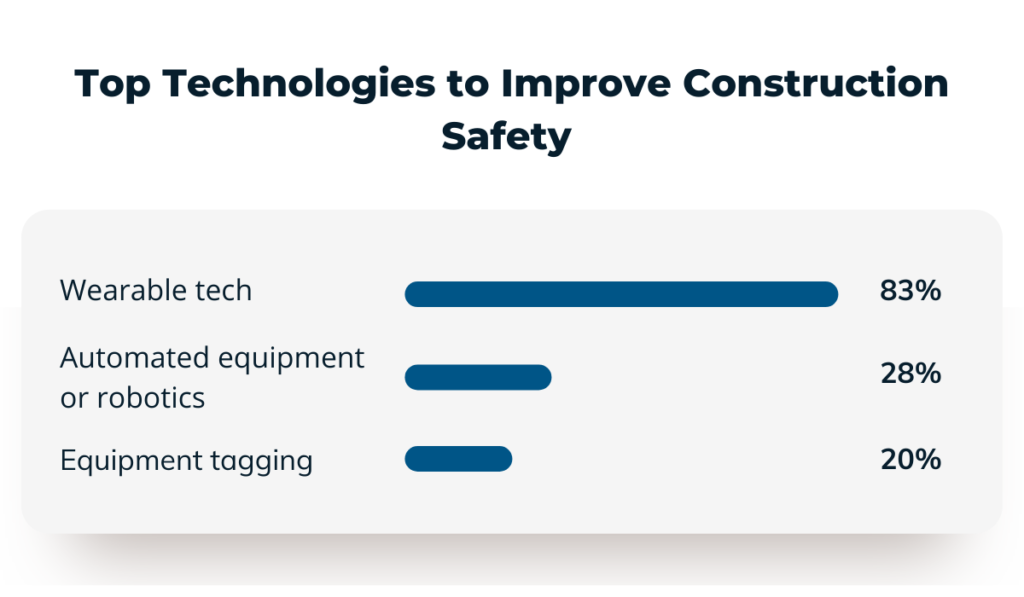

A report by the US Chamber of Commerce discovered that as much as 83% of contractors believe wearable technology will improve safety on construction sites.

There appears to be a widespread consensus among the construction industry that wearables are the way to go.

The same report estimates that 23% of construction companies will use wearable tech by the end of 2021. That’s almost four times as much as in 2018, when only 6% of organizations used such technology.

Popular examples of PPE wearable tech include:

- Smartwatches

- Smart boots

- Hard helmets with sensor bands

- AR glasses

It’s safe to say that wearable protection technology will become an essential part of personal protection equipment in the coming years.

Specialized Protective Clothing

It’s also important to note that, besides your usual PPE, construction sites can have particular operations that require specialized equipment.

For instance, if construction workers complete tasks in environments where electrical or fire injuries are possible, providing them with flame-resistant clothing will significantly improve their personal safety.

Or, if your workers use equipment that uses laser technology, such as laser levels, you should provide specialized eyewear that matches the power and frequency of the beam and protects the wearer from irradiation.

Depending on the specifics of your construction operations, you should re-evaluate your practices with a construction site safety manager and identify which tasks require specialized protective clothing.

Providing your employees with specialized PPE for specific tasks will improve their safety and ensure that your worksite is in compliance with necessary regulations.

Conclusion

Personal protective equipment will remain an integral part of construction site safety. As time moves on, industry professionals will find new ways to protect themselves from safety hazards prone to the construction industry.

Until then, it’s up to contractors to make sure every piece of PPC equipment is in place.

A fair question to ask is: how does your construction company stand with personal protective equipment?

If you want to ensure your workers are protected from all hazards, evaluate your PPE inventory and find adequate solutions to keep them safe.