Key Takeaways:

- Unique IDs prevent mix-ups and simplify multi-site asset tracking.

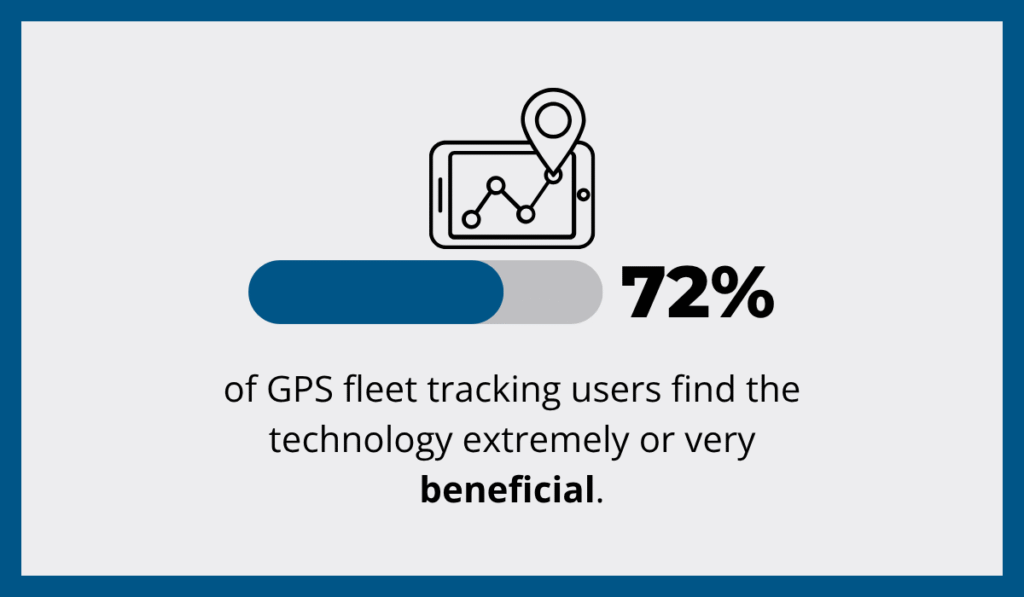

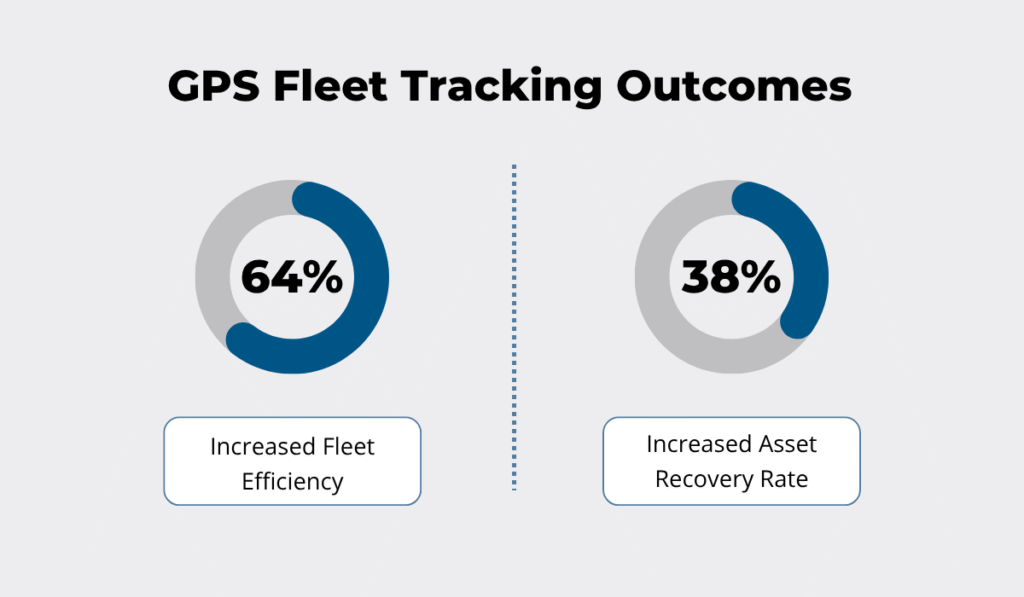

- 72% of GPS fleet tracking users consider it extremely or very beneficial.

- Standardized transfer processes reduce disputes and equipment losses.

- Centralized, real-time data keeps crews and managers aligned without the need for constant check-ins.

A single missing tool can derail a jobsite, but what if you multiply that risk by five, ten, or twenty locations?

Without a system for tracking equipment across multiple projects and locations, the costs will rise and schedules will slip.

In this guide, we’ll give you five practical tips to enhance asset visibility across multiple jobsites and keep your projects moving.

Let’s dive right in!

In this article...

Assign Unique IDs to All Equipment

The foundation of effective equipment tracking is clear, consistent asset identification.

If you’re running multiple construction sites, relying on visual checks or serial numbers alone isn’t enough.

Every piece of equipment, from heavy machinery to portable tools, needs a unique identifier that’s easily scannable and understood by your team.

Unique IDs allow you to differentiate identical assets and instantly access accurate information about each one’s location, status, and history.

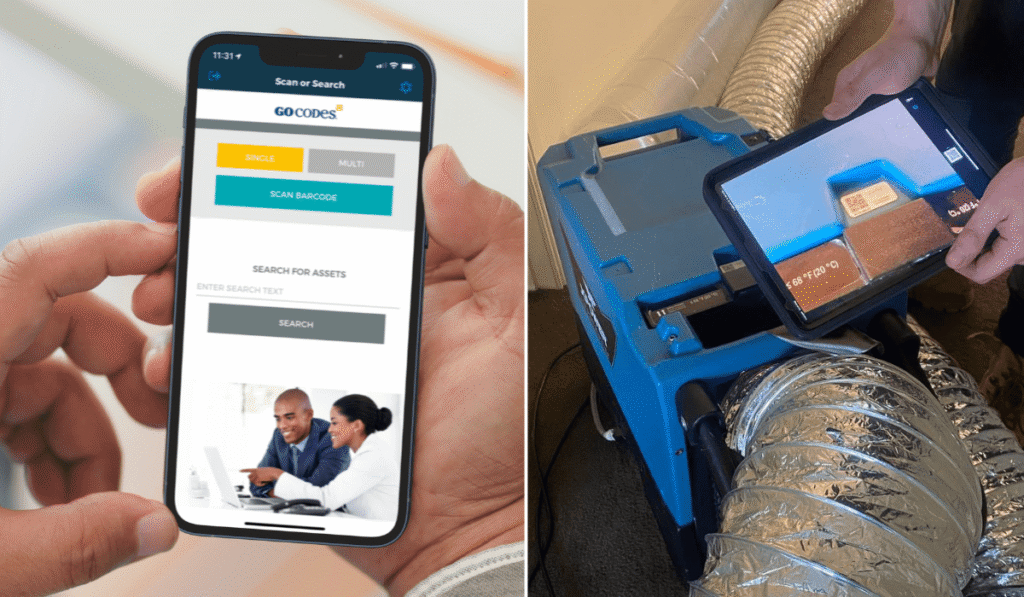

There are several effective ways to track and identify assets, including barcodes, QR codes, and RFID tags.

Source: GoCodes Asset Tracking

Each one helps reduce mix-ups during equipment transfers, inspections, or maintenance.

They also come with different advantages, depending on your budget and work conditions:

- Barcodes and QR codes are affordable and easy to set up.

- RFID tags allow hands-free scanning and are more durable, making them ideal for rugged environments.

What doesn’t work?

Relying on manufacturer serial numbers.

Yes, they’re unique—but they’re not integrated into your workflow, and they’re hard to scan or search in the field.

Instead, you need a digital system that ties every ID to a complete asset record.

This gives you visibility across all jobsites and helps boost both productivity and profit, as Antwan Houston, Maintenance Manager at United Rentals, points out:

Illustration: GoCodes Asset Tracking / Quote: Construction Equipment

Accurate, automated tracking eliminates confusion and prevents data mismatches across your sites.

GoCodes Asset Tracking, our own equipment tracking solution, makes this process remarkably simple.

GoCode’s cloud-based system lets you create unique QR code labels for everything from drills and ladders to generators and attachments.

The labels come in a range of sizes and materials, so you can choose the right type for different environments.

A thick polyester label will work perfectly in indoor settings, while a rugged metal tag is the best fit for your outdoor machinery.

Once applied, anyone on your team can scan the label with a smartphone or tablet to instantly pull up that asset’s information, right from the jobsite.

Source: GoCodes Asset Tracking

Need to check the asset’s current location, maintenance history, or user guide? It’s all at your fingertips.

In short, if you’re serious about maintaining visibility and control across several locations, unique IDs backed by a reliable system should be your starting point.

Use GPS for Real-Time Visibility

GPS tracking gives you real-time visibility over high-value equipment and vehicles across multiple sites.

No more chasing down team members for updates, or finding out hours later that a critical asset has gone missing.

GPS tracking is one of the most effective ways to reduce downtime and improve coordination.

According to Automotive Fleet’s 2025 report, 72% of GPS fleet tracking users consider it extremely or very beneficial.

Illustration: GoCodes Asset Tracking / Data: Automotive Fleet

While you won’t tag every tool on-site, GPS trackers are ideal for:

- Loaders and excavators

- Jobsite vehicles

- Toolboxes and storage containers

- Material shipments that move between sites

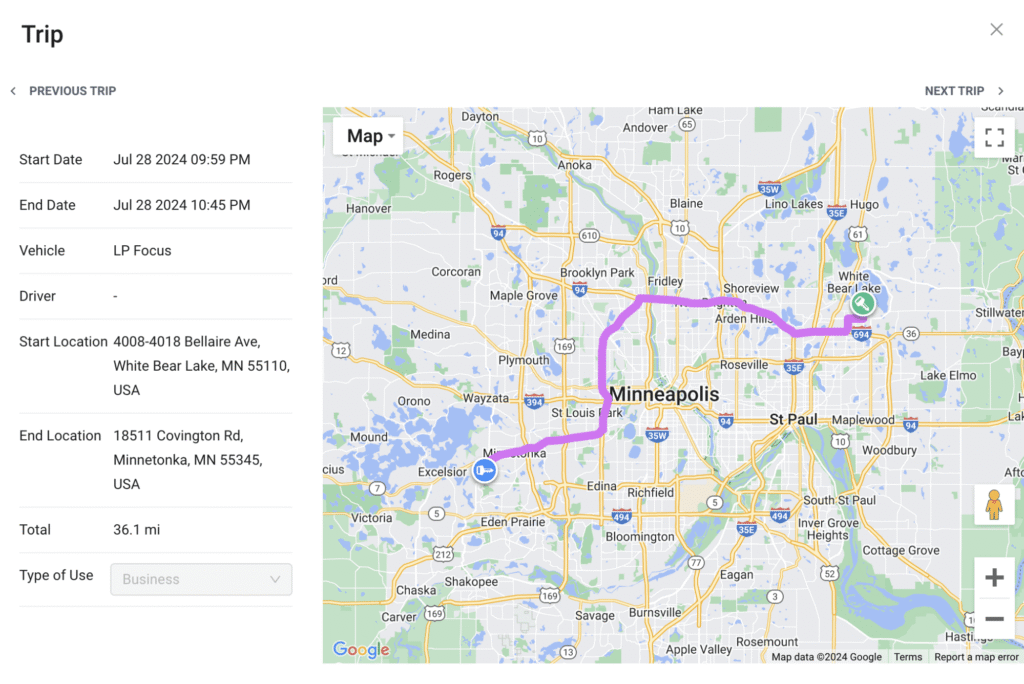

Take a loader, for example.

A real-time GPS device can report its location every 10 minutes.

Whether it’s heading to a different site or shifting areas within the same project, you’ll always know where it is, without making a single call.

Source: GoCodes Asset Tracking

However, not all GPS devices work the same way.

Passive devices log location data for later retrieval, while active trackers use cellular or satellite connections to report positions in real time.

That difference matters.

Real-time data helps you manage resources more effectively, reduce project delays, and act fast if something goes missing.

Going back to the Automotive Fleet report, companies using GPS tracking saw a 64% improvement in overall fleet efficiency, and a 38% increase in asset recovery rates.

Illustration: GoCodes Asset Tracking / Data: Automotive Fleet

As you can see, the benefits extend beyond operational efficiency.

Construction theft is a serious and growing problem, and recovering stolen assets is rarely easy.

Just consider a recent case in the UK where thieves made off with £250,000 worth of construction equipment in two separate break-ins.

Source: BBC

The company didn’t realize anything was wrong until Monday morning.

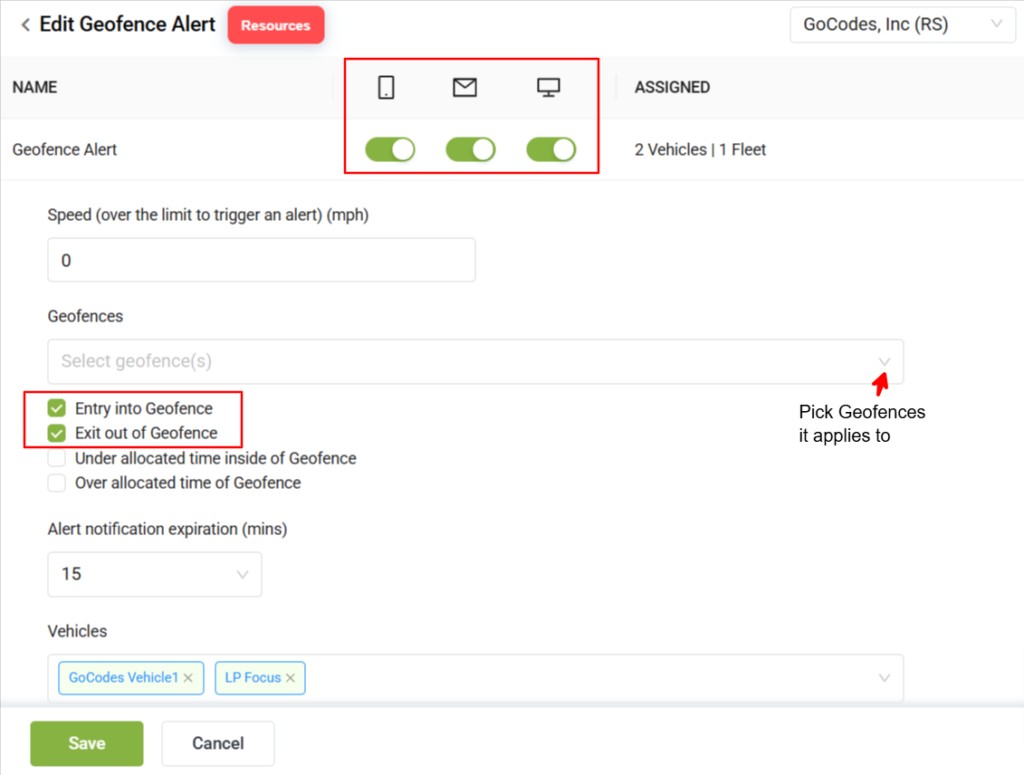

Cases like these highlight why geofencing matters.

With geofence-enabled trackers, you can set up virtual perimeters around storage areas, yards, or the entire site.

If a tagged asset crosses that boundary, the system sends an instant alert.

That means you can quickly check if it’s a scheduled move or something suspicious, and take action fast, including notifying law enforcement if needed.

The best part?

Geofences are easy to set up.

Just draw a zone on the map, adjust a few settings, and decide who should get alerts and on which devices.

Source: GoCodes Asset Tracking

Bottom line:

GPS tracking gives you full visibility and peace of mind.

Whether you’re managing two jobsites or twenty, it helps you stay in control of your equipment—anytime, anywhere.

Standardize Transfer Processes Between Sites

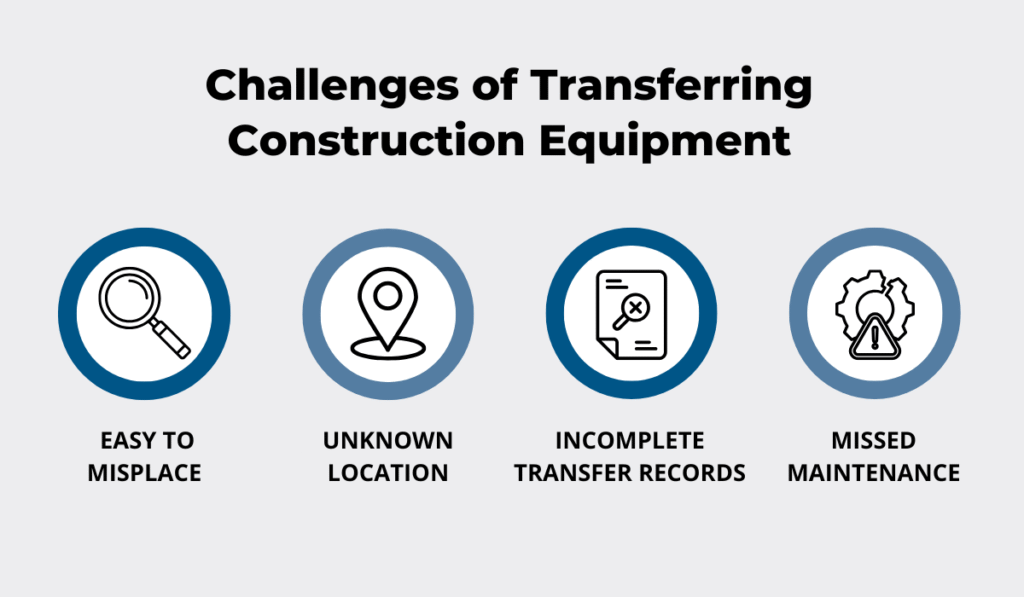

When you’re running multiple jobsites, equipment transfers can quickly become a major blind spot.

Without a clear process, tools and machines can go missing, maintenance checks can be skipped, and finger-pointing over damage or availability becomes common.

Source: GoCodes Asset Tracking

Over time, these small issues lead to real consequences: project delays, higher costs, and wasted time.

Transferring construction equipment between sites requires planning, preparation, and a work culture rooted in accountability.

The good news is that you can avoid most of the common headaches by putting a simple, structured system in place.

Here’s what that looks like in practice:

| Key Practices | Why It Matters |

|---|---|

| Log every handoff | Creates a clear trail of who had what and when. |

| Inspect and record asset condition | Prevents disputes over damage or missing parts. |

| Assign clear responsibility | Makes crews accountable for pickups and returns. |

| Use digital tracking whenever possible | Ensures no tool or machine moves without being properly logged. |

Even with larger equipment, a simple, structured handoff process can make a big difference.

Here’s a short video showing how physical transfers work in the field.

Source: Equipment & Contracting on YouTube

Of course, the process may vary slightly depending on the asset.

But to improve efficiency, reduce errors, and track usage accurately, a digital system is your best bet.

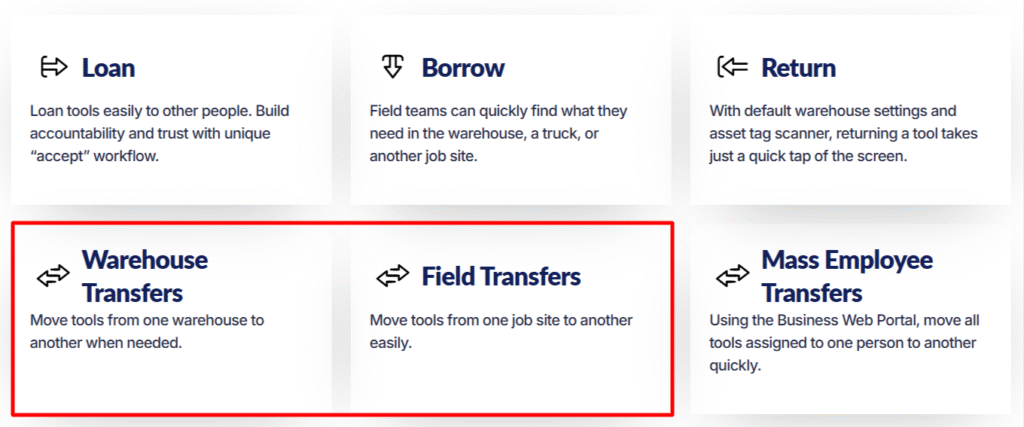

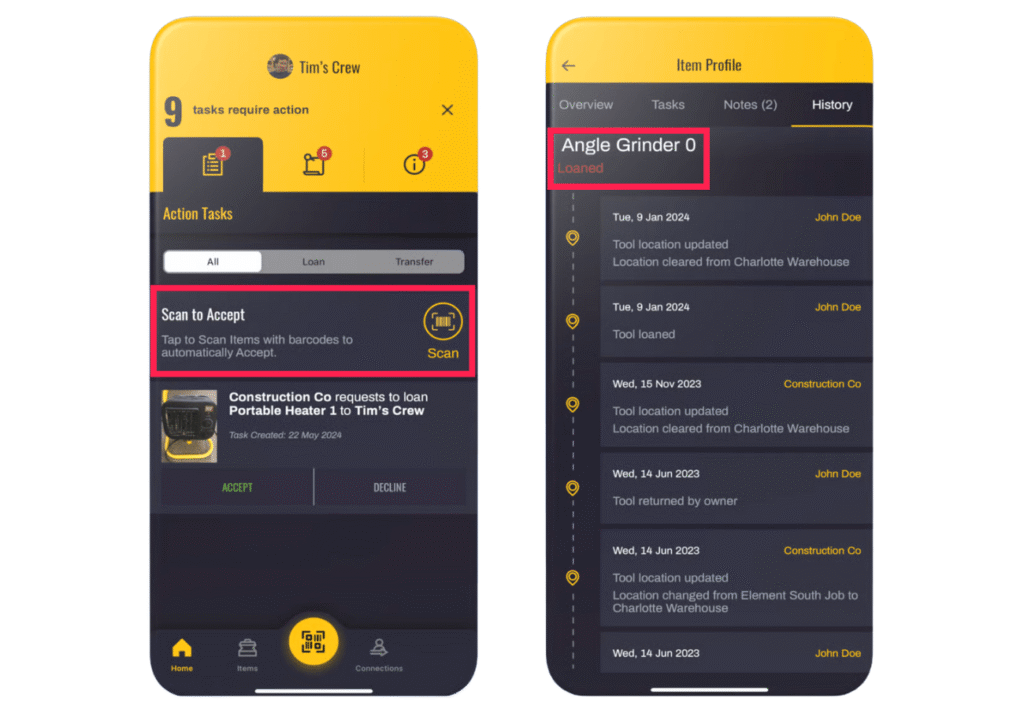

Take ShareMyToolbox, for example.

Their platform offers dedicated features for warehouse and field transfers.

Source: ShareMyToolbox

Let’s say a generator is being moved from Site A to Site B.

If the operator logs the transfer via the mobile app, the system immediately prevents double-booking.

Source: G2

At the same time, if the generator goes missing or is returned damaged, it’s easy to trace the issue through the digital record.

You’ll know who last had it and when—no guesswork involved.

All in all, standardized transfers help your teams stay organized and accountable.

And when everyone follows the same system, you’ll see fewer delays, lower risk of loss, and smoother coordination across all your sites.

Centralize All Asset Data in One Platform

Managing equipment across multiple sites is hard enough.

Doing it with scattered spreadsheets or outdated records makes it even harder.

A centralized platform gives your team a single, reliable source of truth, keeping asset data synced in real time and accessible from anywhere.

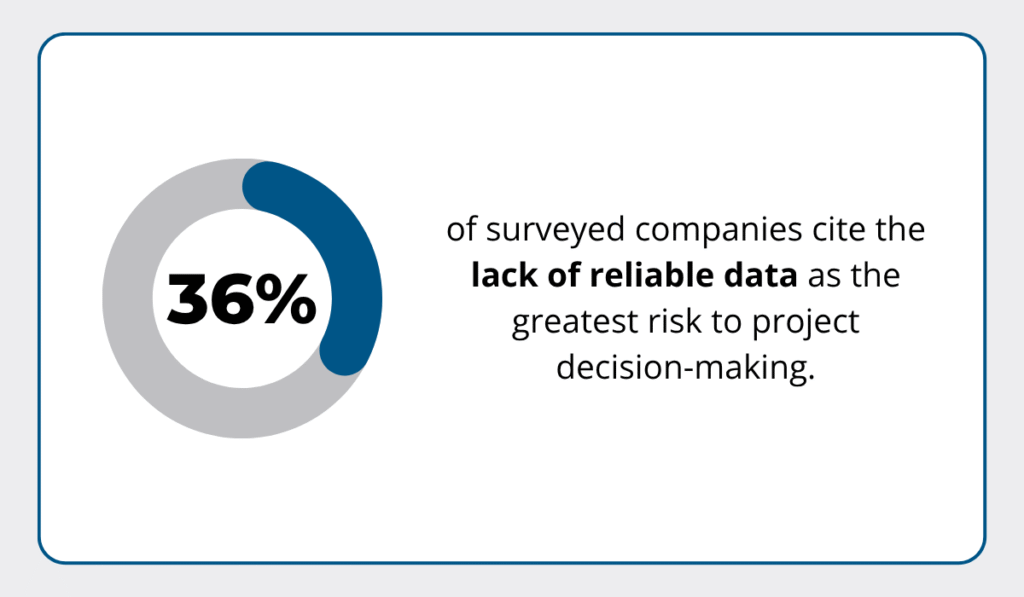

In a 2022 survey by FMI, one-third of U.S. construction companies said unreliable data posed the biggest risk to decision-making.

Illustration: GoCodes Asset Tracking / Data: Autodesk & FMI

Yet only 37% stored their data in a shared environment, leaving many projects exposed to delays, errors, and poor coordination.

So, why does centralized data matter?

It ensures field teams can instantly locate assets without involving the office.

Meanwhile, managers can access reliable information for scheduling, dispatch, and decision-making.

In other words, you’re connecting office and field operations in real time.

As Christopher Lindsay, Head of Sales at Senzit, explains:

“If you can take all this data—equipment on site, equipment en route, equipment being serviced and repaired […] and plug that into a system that spits out an answer for you in a second, then you can spend more time ensuring […] the engine on jobsite X that’s due to be on jobsite Y is replaced, serviced and trucked over there.”

To achieve this, your chosen platform has to include at least the following features:

- Mobile access

- Location and status filters

- Usage and availability reports

- Maintenance alerts

- Multi-user permissions

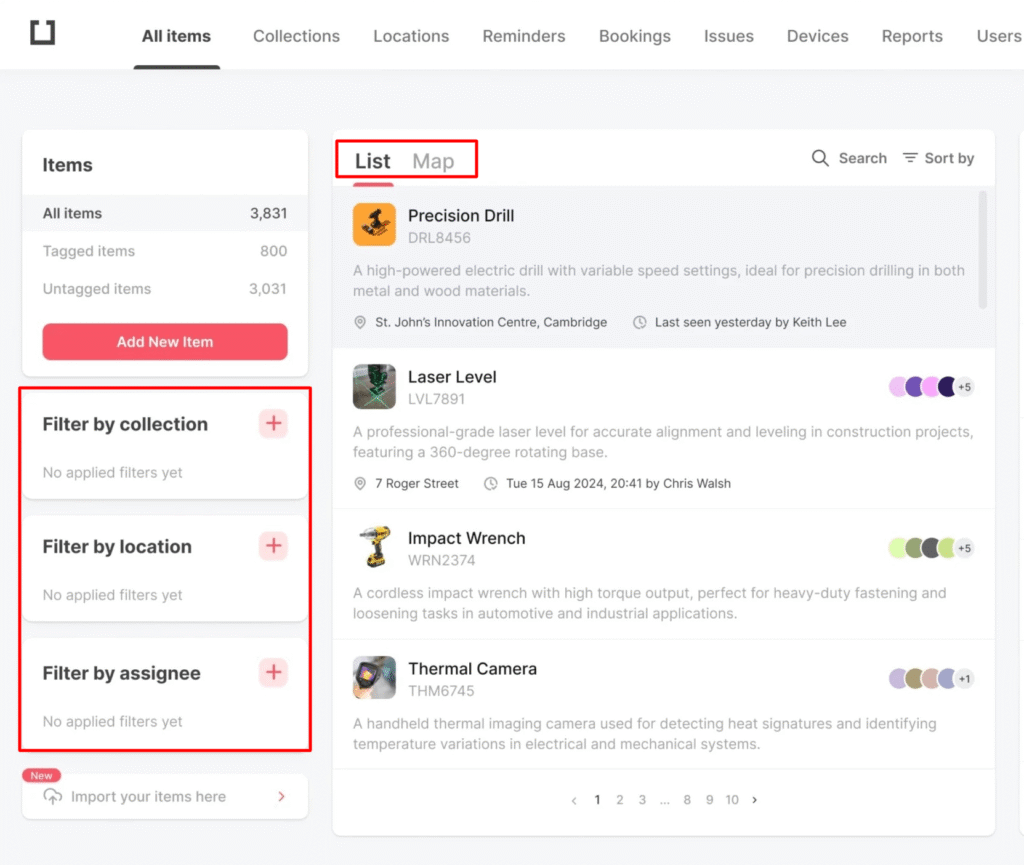

Take itemit, for example.

Their dashboard lets users switch between list and map views, and filter assets by location, collection, or other custom tags.

Source: itemit

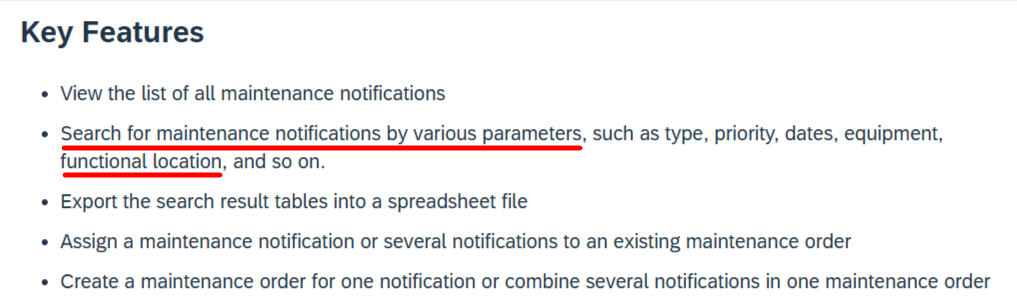

Maintenance alerts are just as important.

While not all systems offer robust tracking, some, like SAP Ariba, make it easy to filter overdue tasks by site, asset type, or urgency.

This ensures nothing critical slips through the cracks.

Source: SAP

The result:

All your equipment information is in one place, up to date, and easy to act on, making multi-site equipment management far more efficient.

Automate Maintenance Scheduling

Manual maintenance is tough to manage on one jobsite—let alone across five, ten, or more.

That’s why automated maintenance scheduling is essential for keeping your equipment fleet reliable, efficient, and visible across locations.

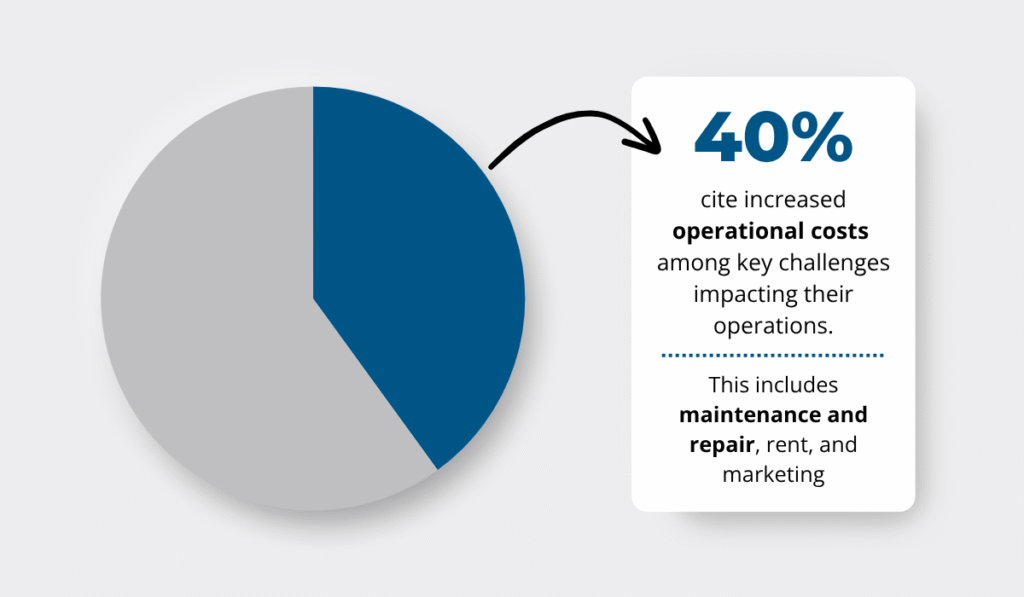

According to joint research by Autodesk and Deloitte, 40% of respondents cited increased operational costs, including maintenance and repairs, as one of the top 3 challenges impacting business performance.

Illustration: GoCodes Asset Tracking / Data: Autodesk & Deloitte

So, how do you address these costs?

One possible approach is to reduce unplanned downtime by automating service schedules.

Instead of relying on static calendars or waiting for breakdowns, smart systems use real-time data—like engine hours or mileage from GPS and telematics—to trigger service tasks automatically.

Tom Richter, the Head of Industrial Verticals at Nokia, explains that real-time tracking not only improves efficiency but also directly optimizes service intervals and boosts uptime.

Illustration: GoCodes Asset Tracking / Quote: Manufacturing Digital

This means a generator might automatically trigger a service task after 100 hours, or a bulldozer might alert the fleet manager when it hasn’t been serviced since its last assignment.

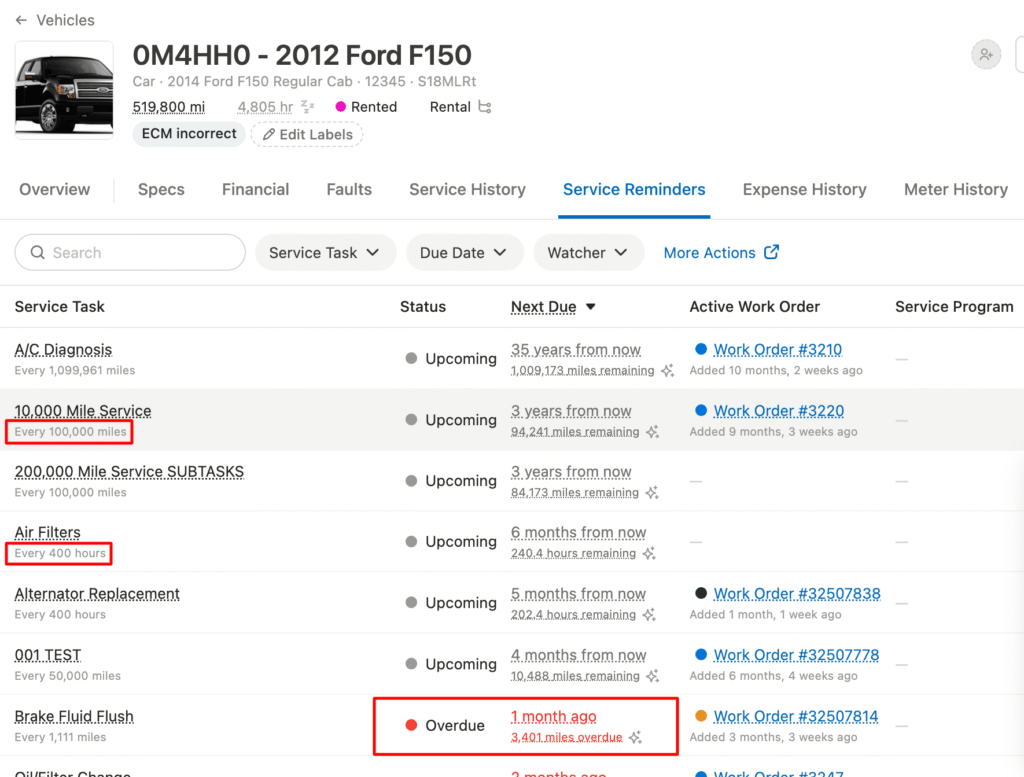

Systems like Fleetio make this even easier by linking service tasks directly to data like hours run or miles driven.

Source: Fleetio

This kind of automation ensures timely servicing, helping your company save time, avoid costly breakdowns, and improve uptime across busy jobsites.

Most modern systems let you set maintenance triggers based on:

- Usage (e.g., hours or miles driven)

- Time (e.g., every 30 days)

- Event (e.g., job completion or inspection results)

- Breakdown (as a fallback, not the norm)

The common thread is that no one has to manually check individual service reminders—the system tracks it all and issues alerts automatically.

And the benefits extend beyond increased reliability and uptime.

Karli Anderson, former Executive Vice-President at Summit Materials, noted that by anticipating maintenance needs and performance issues, companies unlock additional gains.

Illustration: GoCodes Asset Tracking / Quote: Samsara

By partnering with Samsara, Summit saved around $1.8 million per year on fuel costs alone, enabling the company to direct these funds elsewhere.

Ultimately, automating maintenance scheduling improves efficiency, lowers operational costs, and keeps projects on track, no matter the number of sites you’re managing.

Conclusion

Tracking equipment across multiple sites is not an easy task, but it doesn’t have to be complicated either.

With clear processes, centralized data, and real-time tracking tools, you can reduce downtime, prevent losses, and simplify equipment management.

Start by integrating digital platforms where they make the biggest difference.

Automate alerts, streamline transfers, and build a system that works across every jobsite.

Soon, you’ll see how a few changes pay off in efficiency, cost savings, and better control across your every site and project!