Key Takeaways

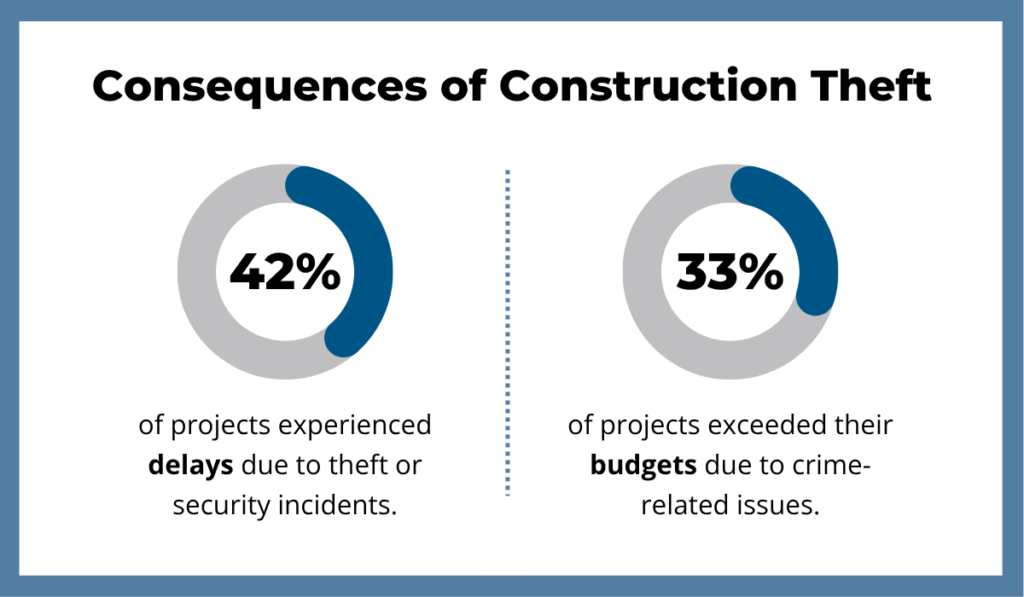

- Equipment theft has a direct impact on deadline (42%) and budget (33%) overruns.

- Smart tracking can cut fuel consumption by up to 16%.

- Real-time visibility into equipment location and usage enhances resource management.

- Automated, data-driven maintenance can save you thousands of dollars in downtime and repairs.

Heavy equipment keeps your construction projects moving, but it can also be one of the biggest drains on your budget and time.

Without efficient management, costly theft, wasted fuel, and unexpected downtime can quickly pile up.

Luckily, tracking technology flips the script, turning hidden risks into actionable insights.

Join us in exploring how these tools can transform heavy equipment management and help you protect your assets while boosting productivity.

In this article...

Prevented Equipment Theft

When your heavy equipment is tracked, you have the peace of mind that it won’t get stolen.

Heavy equipment can get quite costly, but it’s never just the equipment itself.

BauWatch’s 2025 report outlines several consequences of stolen equipment, with the most impactful ones being deadline (42%) and budget (33%) overruns.

Illustration: GoCodes Asset Tracking / Data: BauWatch

In other words, one stolen loader can stall an entire project.

And when crime happens, it’s often too late to act, especially since the loss of heavy equipment typically creates the largest operational disruptions.

Here’s one case in point.

When thieves broke onto a site managed by Gibby’s Construction Inc., this family-owned business lost roughly $6,000 in direct damages.

But as explained by one of the owners, the bigger blow was the weeks of workflow interruptions that followed.

Source: KOAA 5 on YouTube

They had CCTV and a fence, but no tracking system, which meant that recovery relied solely on grainy footage and the hopes that someone would recognize either the thieves or the stolen assets.

While most stolen items are small tools, 16% of all stolen construction equipment is large machinery.

As Ryan Shepherd, Director General and General Manager of Crime Analytics and Supply Chain Solutions at Verisk, explains, two factors determine risk: mobility and value.

Illustration: GoCodes Asset Tracking / Quote: Construction Briefing

The logic is simple: why take hundreds of power tools when you can tow away a single unguarded excavator worth far more?

And once your machine is gone, the hopes of recovery are dim.

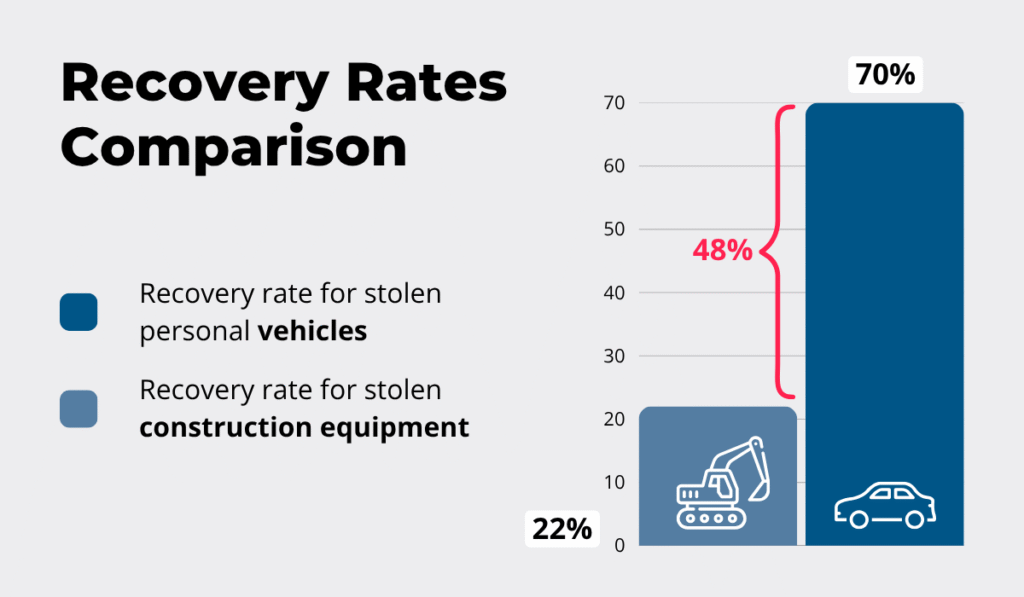

Shepherd highlights that the recovery rates for construction equipment (22-24%) are still poor compared to those of personal vehicles (70%).

Illustration: GoCodes / Source: Construction Briefing

One key reason is that most modern cars now have factory-installed GPS or telematics systems, whereas heavy machinery often doesn’t come with built-in tracking.

And this is where GPS tracking changes the equation.

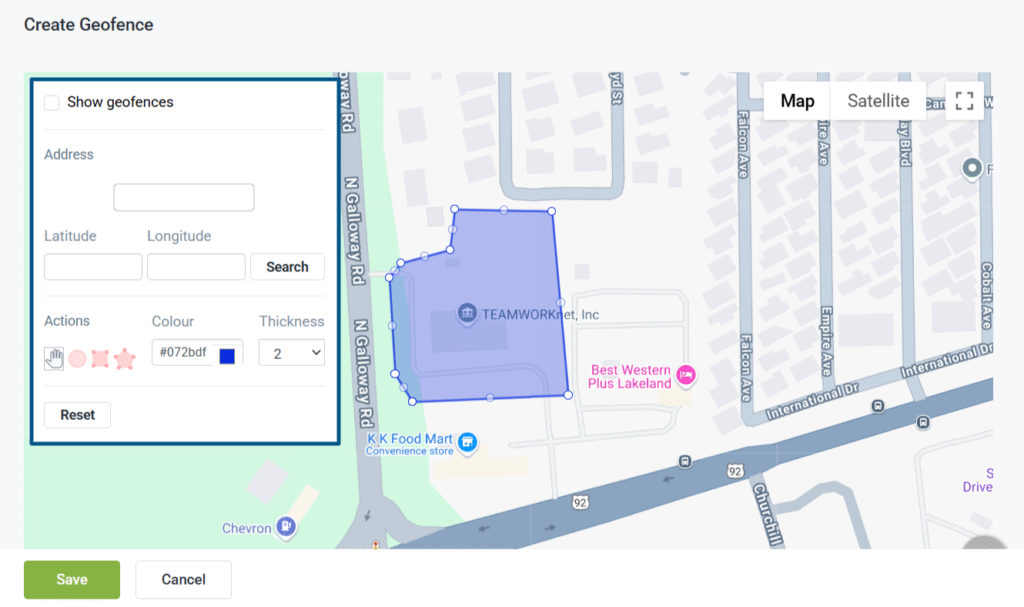

Modern real-time trackers provide global coverage, are hard to remove, and, when geofence-enabled, send instant alerts if equipment crosses a predefined boundary.

The process of setting up geofences is easy and straightforward, while the benefits are huge.

Source: GoCodes Asset Tracking

That immediate notification not only boosts recovery chances but also speeds coordination with law enforcement.

With tracking in place, you don’t have to hope that thieves will somehow pass up on your heavy equipment. You’re actively stacking the odds in your favor!

Less Fuel Waste

Tracking your heavy-duty machinery puts a firm plug on fuel waste.

Fuel has always been one of the biggest line items in fleet budgets.

In the 2024 Teletrac Navman report, half of the surveyed fleet managers ranked it as their top expense.

And recent market volatility has only pushed fuel management further up the priority list.

Just look at Fleet Owner’s recent headline—diesel prices dropping while gasoline climbs.

Source: Fleet Owner

Luckily, technology has a proven track record in cutting fuel costs.

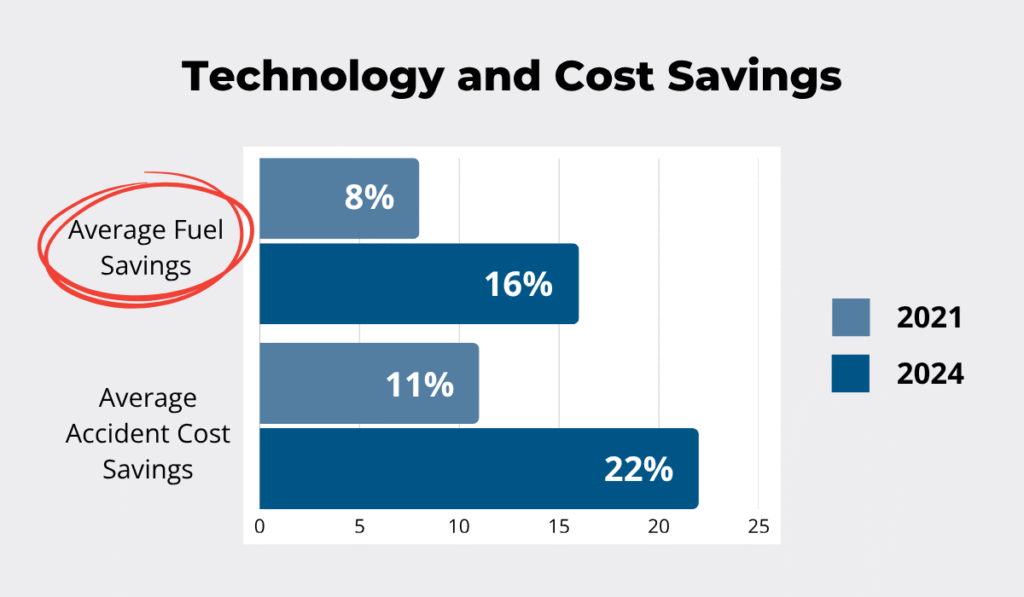

According to Automotive Fleet, average fuel savings from 2021 to 2025 doubled from 8% to 16%, with GPS tracking alone driving those gains.

Illustration: GoCodes Asset Tracking / Data: Automotive Fleet

Interestingly, accident-related cost savings also doubled (11% to 22%), but that’s where GPS and telematics work in tandem.

GPS provides location and movement data, while telematics collects and integrates that data with onboard sensors to monitor performance, fuel consumption, and driver behavior.

The result is a single, connected system that captures and analyzes every factor affecting fuel use.

Telematics operates on several levels:

- Vehicle performance monitoring – tracking fuel economy, idling, and engine diagnostics

- Route optimization – identifying the shortest and least fuel-intensive routes

- Driver behavior tracking – logging patterns like speeding or harsh braking

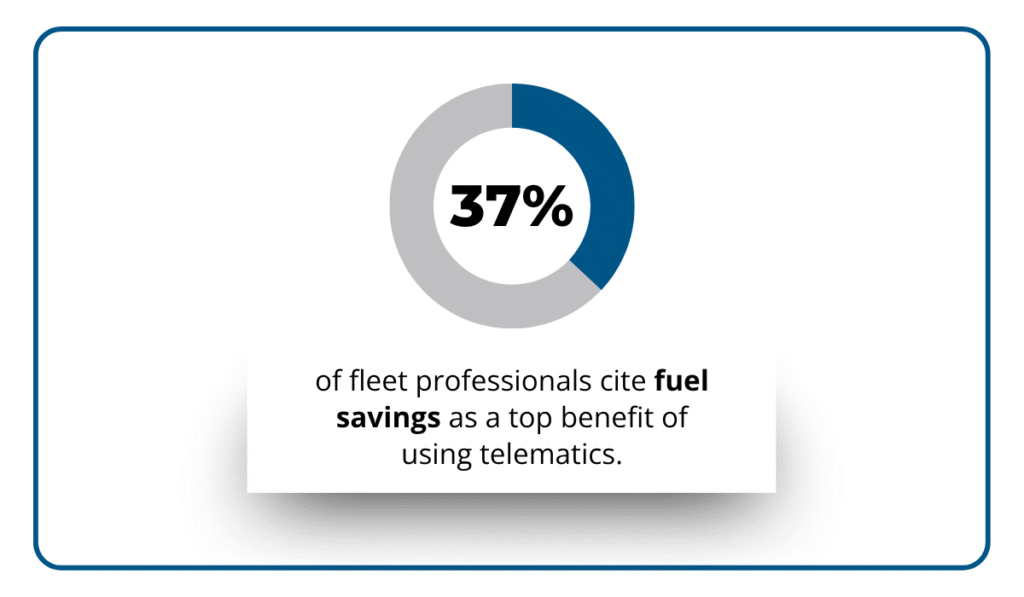

Fuel management is consistently cited as a top benefit of telematics, with 37% of fleet professionals surveyed by Teletrac Navman ranking it first.

Illustration: GoCodes Asset Tracking / Data: Teletrac Navman

And it’s all due to these systems’ robust capabilities.

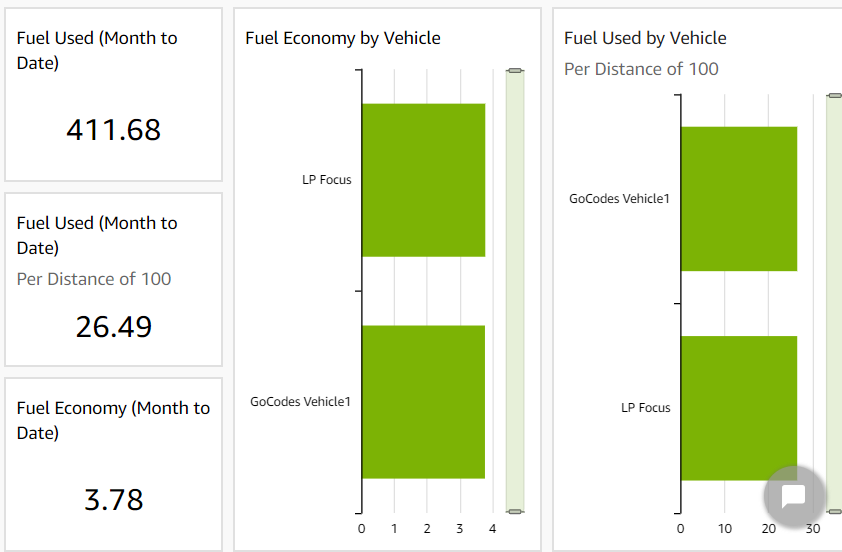

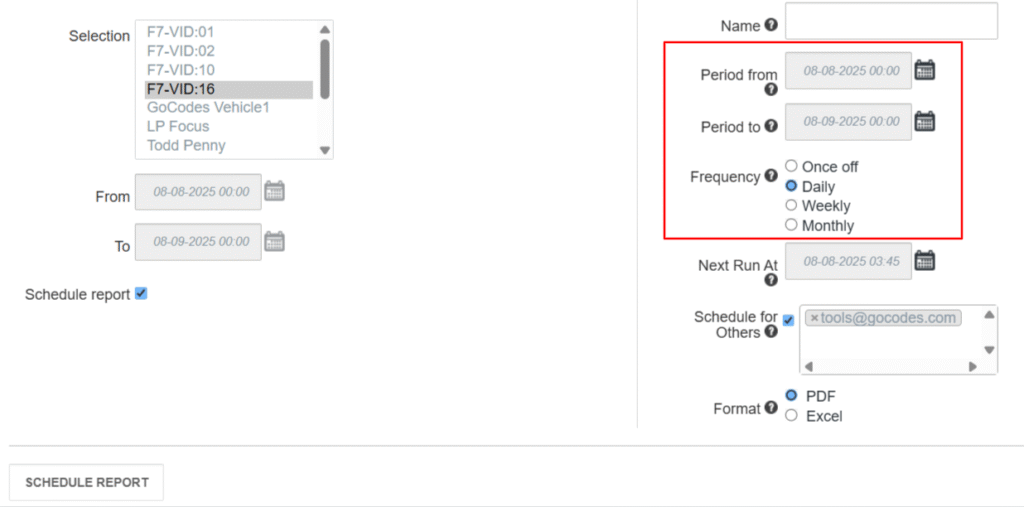

With a dedicated dashboard or automated reports, you can instantly see fuel usage per vehicle, over any distance or period of time, and spot trends in overall fleet fuel economy.

Source: GoCodes Asset Tracking

However, the often overlooked savings opportunities come from monitoring driver behavior.

Speeding, harsh acceleration, and aggressive braking are all major fuel wasters.

As noted by Liam James, the Head of Business Development at Novuna Vehicle Solutions, these and similar habits impact fleet productivity on several levels.

Illustration: GoCodes Asset Tracking / Quote: Fleet News

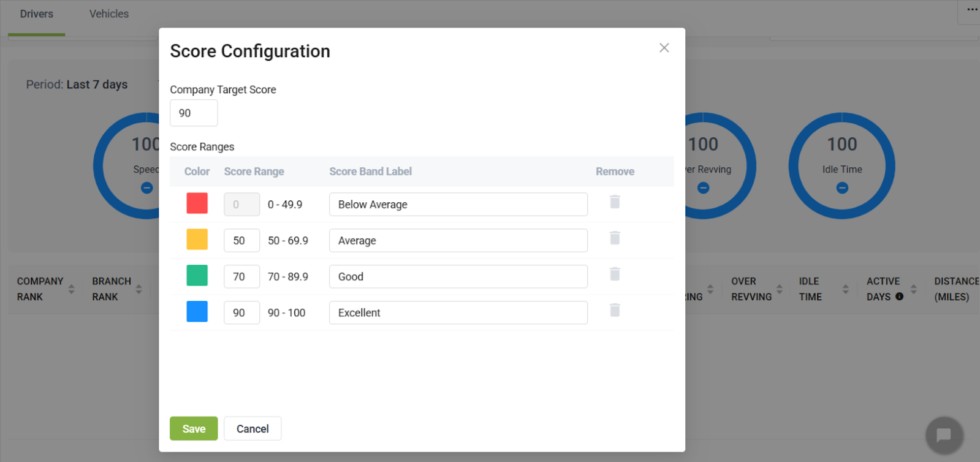

With dedicated tracking software, you can flag repeated harmful behaviors and coach drivers based on their accumulated performance scores.

While driver scorecards differ in looks and functionalities, you can always set your own thresholds, as well as escalation rules to promote swift corrective action.

Source: GoCodes Asset Tracking

In the end, proactive fuel management won’t just save you money.

The insights captured by tracking systems simultaneously increase the overall safety and efficiency of your whole operation.

Better Schedules and Equipment Use

Continuous tracking delivers a crucial benefit for construction companies: you always know where your equipment is, how it’s being used, and when it’s available.

This real-time visibility prevents delays, balances workloads across the fleet, and keeps projects moving even when your resources are spread across several jobsites.

Why does this matter so much? Because wasted time and misplaced assets have a lasting impact.

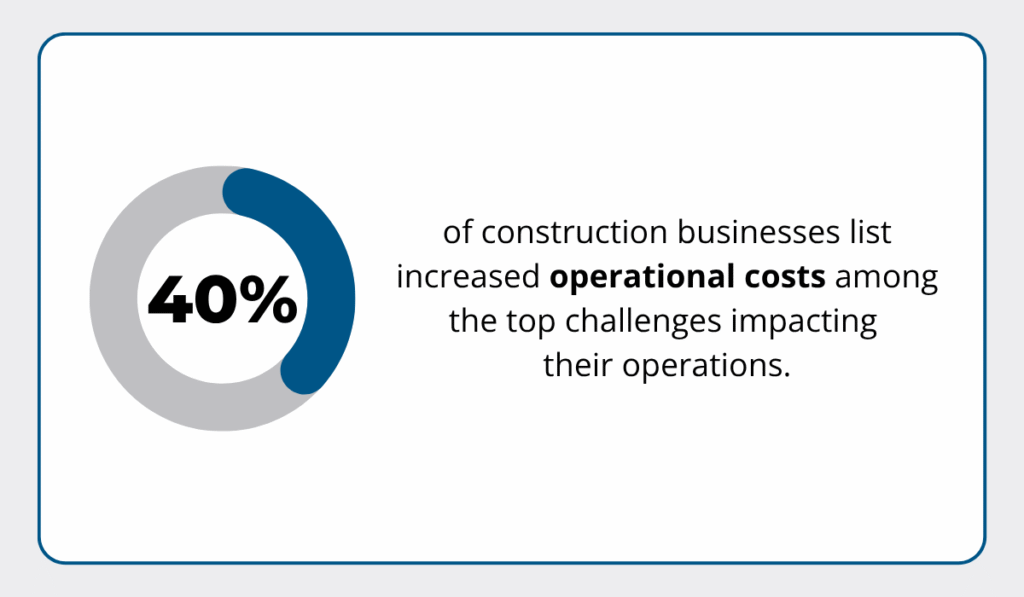

Autodesk and Deloitte research shows that 40% of construction businesses list increased operational costs among their top operational challenges.

Illustration: GoCodes Asset Tracking / Data: Autodesk & Deloitte

With location and usage data at your fingertips, you can quickly spot underused machines and reassign them to where they’re needed most.

That means fewer idle hours, reduced unnecessary rentals, and a more efficient distribution of resources across sites that boost productivity.

Source: GoCodes Asset Tracking

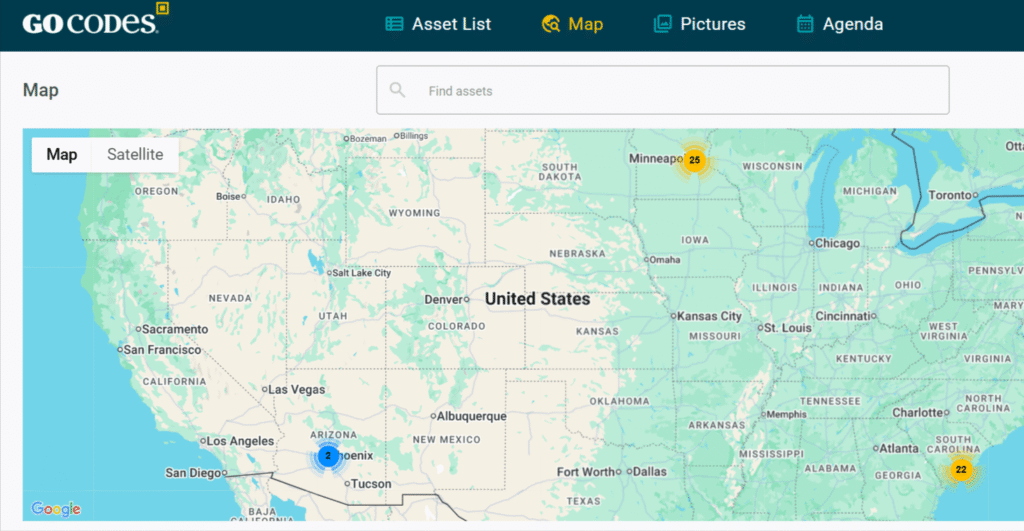

One example of this in practice is our very own GoCodes Asset Tracking, a comprehensive asset management solution built for construction.

Suitable for tracking equipment across multiple jobsites, you can instantly locate and monitor all asset movement via a live map view.

Source: GoCodes Asset Tracking

To achieve complete visibility and cost efficiency, the GoCodes Asset Tracking system pairs GPS trackers for heavy machinery with QR code tags or Bluetooth beacons for smaller tools.

Regardless of the asset type, everything is stored in a single, centralized database accessible directly from the field.

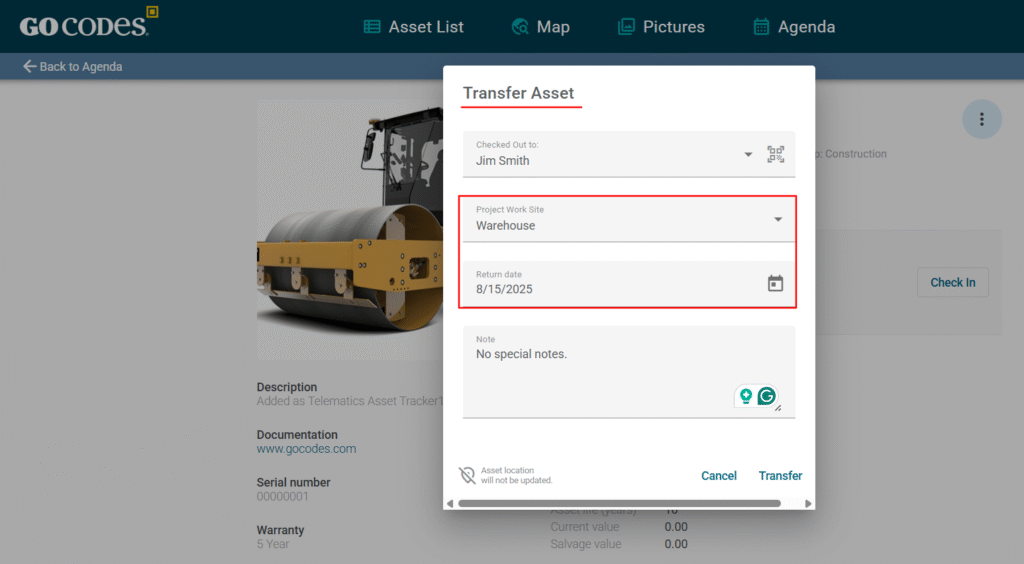

Each asset entry contains not only essential details, but also check-in/check-out logs for precise usage history.

From there, you can quickly perform actions such as scheduling transfers or updating status in real-time.

Source: GoCodes Asset Tracking

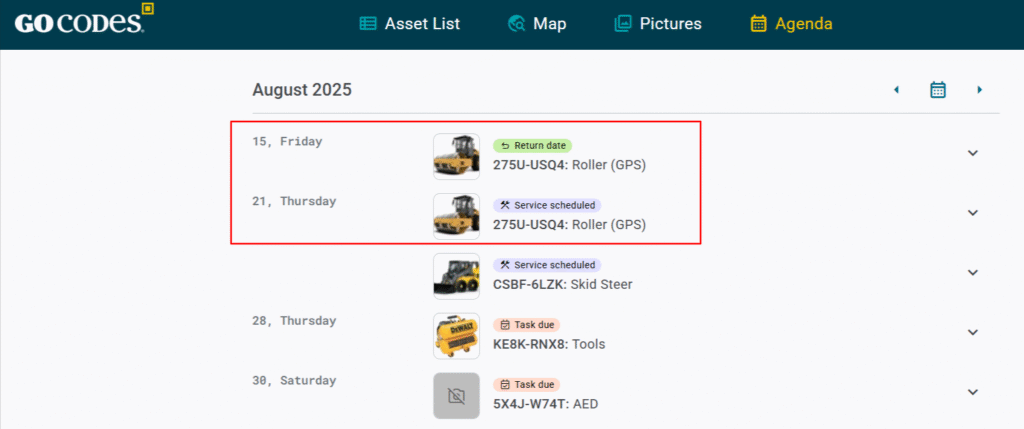

The platform’s agenda view lets you plan around upcoming return dates, scheduled services, and other deployment-affecting events.

Tasks are color-coded for your convenience, making it easy to scan a month’s worth of tasks at a glance and make swift adjustments without losing track of maintenance or availability.

Source: GoCodes Asset Tracking

Instead of scrambling to find a machine or arranging last-minute rentals, you’re managing a balanced, predictable flow of resources.

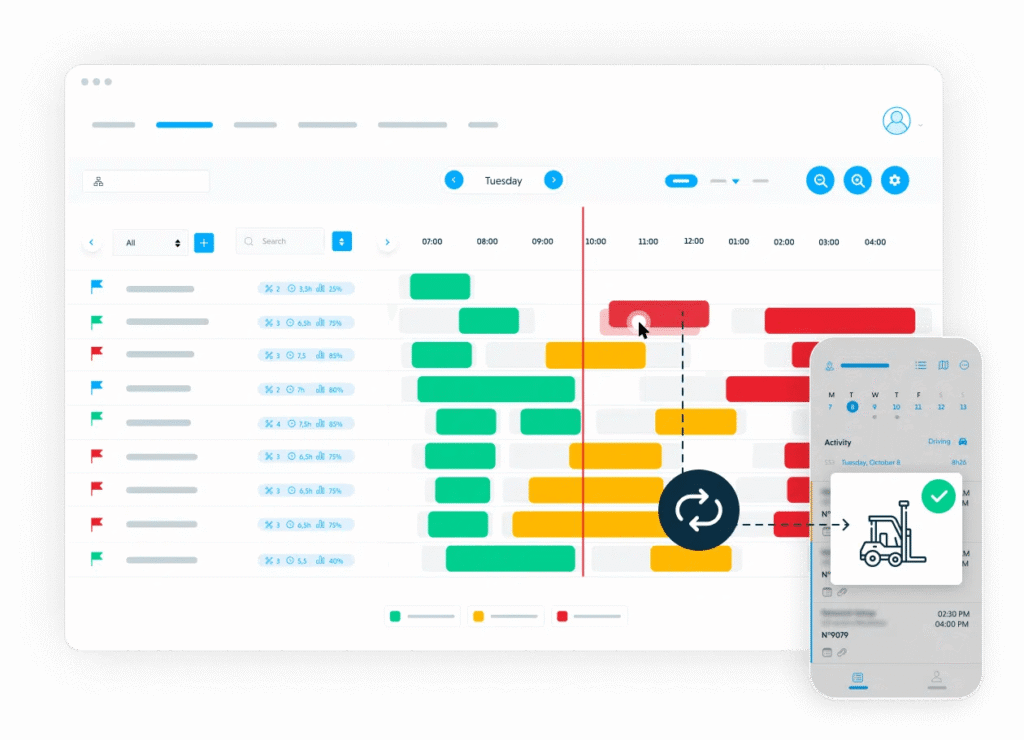

And for businesses that deal heavily in rentals, Praxedo’s Field Service Management (FSM) software offers an additional layer of control.

In addition to handling delivery and pickup logistics for heavy-duty rental equipment, this solution has integrated maintenance scheduling to ensure every piece of machinery is ready for its next assignment.

Source: Praxedo

Ultimately, this level of organization simplifies scheduling in a way that traditional spreadsheets or ad-hoc communication can’t match.

Combine the right tracking tools with disciplined scheduling, and you’ll move from reacting to shortages and delays to proactively managing your fleet.

Less Downtime with Smarter Maintenance

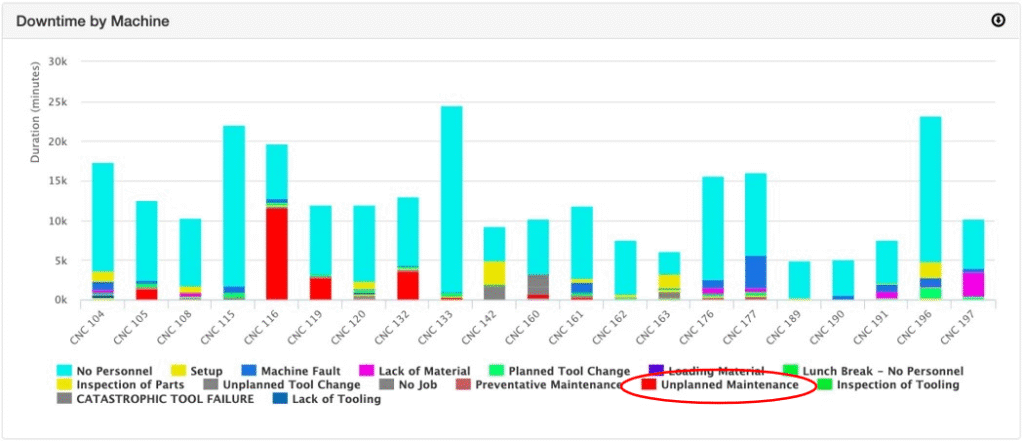

Another major benefit of heavy equipment tracking is reduced unplanned downtime.

Downtime in construction can stem from many sources: absent personnel, faulty systems, tool changes, or unplanned maintenance, to name a few.

Source: MachineMetrics

One of the most common causes is skipped service work because “everything seems fine,” and the cost feels unnecessary at the time.

The aforementioned Fleet News contributor, Liam James, explains that, while it’s tempting to skip maintenance to save money, attending to smaller issues is less expensive in the long run.

Illustration: GoCodes Asset Tracking / Quote: Fleet News

Without smaller interventions, you’re increasing the risk of equipment failure, which is far more disruptive to project schedules.

Fleet vehicles are particularly vulnerable. Since they’re used daily for hauling, deliveries, and crew transport, minor wear can quickly turn into major mechanical issues.

A transmission or a brake system failure can take out an asset for days at a time.

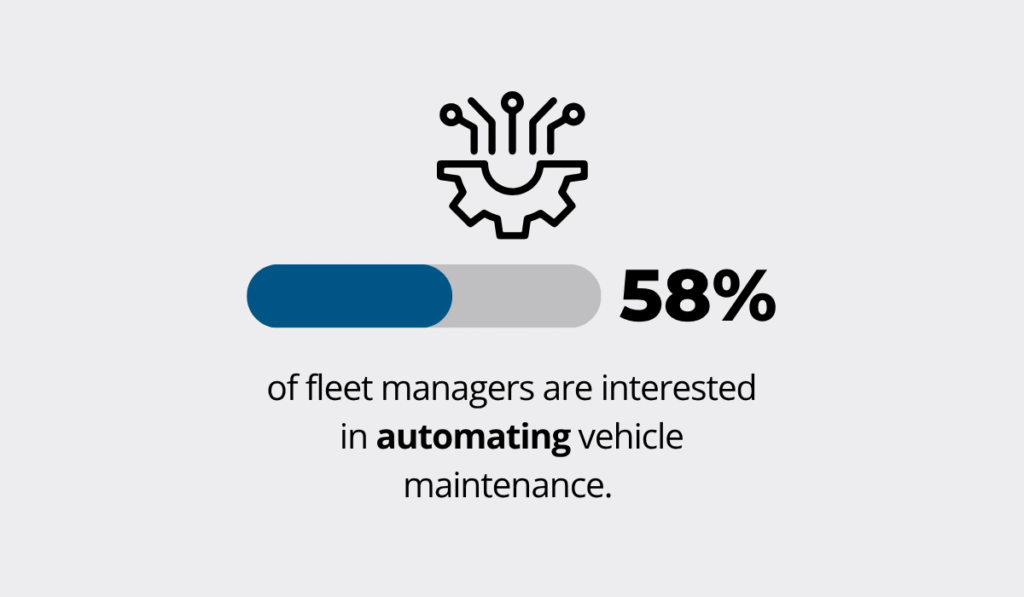

So, it’s no surprise that 58% of fleet managers in Motive’s survey identified vehicle maintenance as a key target for automation.

Illustration: GoCodes Asset Tracking / Data: Motive

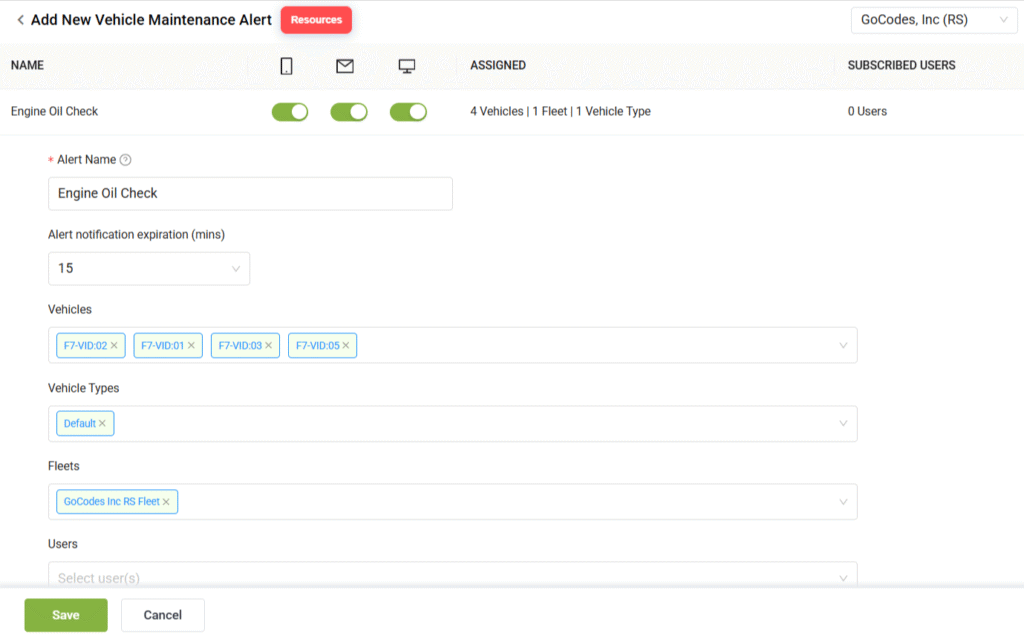

Automation can take many forms: scheduled service reminders, usage-based alerts, and dashboards that track health metrics for all machinery, from excavators to compactors.

Even simple, configurable reminders for oil changes or tire checks can have an outsized impact when they’re easy to access and set up using an intuitive interface.

Source: GoCodes Asset Tracking

Tracking technology goes beyond basic reminders.

Some solutions integrate AI diagnostics or connect with specialized downtime tracking platforms like MachineMetrics.

These tools monitor equipment in real-time, identify patterns, and help diagnose issues before they cause prolonged delays.

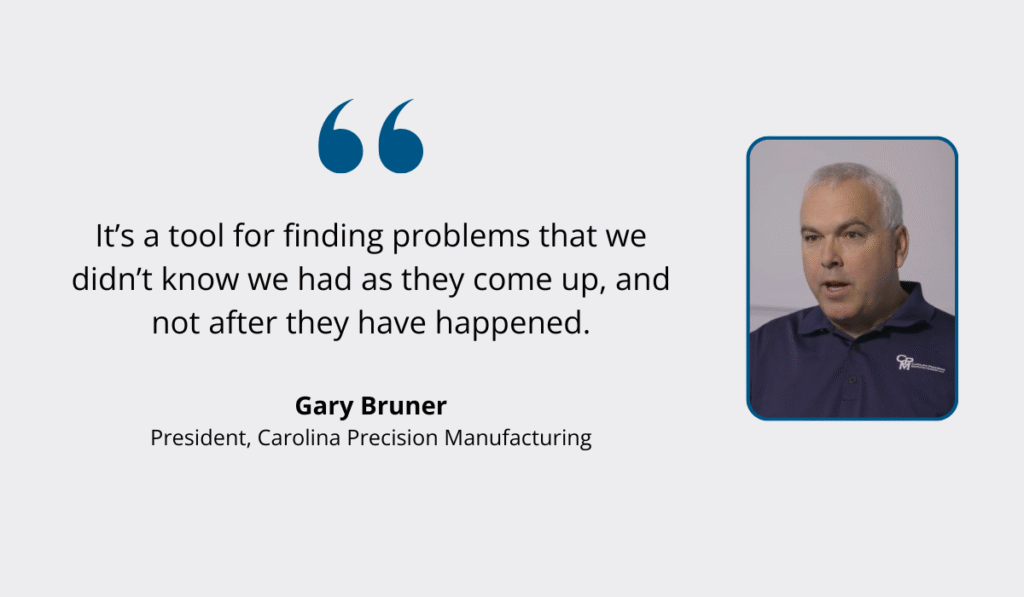

Gary Bruner, President of Carolina Precision Manufacturing, one of MachineMetrics’ clients, summed up the impact of this approach:

Illustration: GoCodes Asset Tracking / Data: Motive

For Carolina Precision Manufacturing, this translated into the following benefits:

- A 20% increase in shop productivity

- An ROI in 11 days

- 688 additional operating hours per machine on average

- Saving 2 hours per day on administrative work

While this is a manufacturing example, the principle applies directly to construction: the sooner you detect and address equipment issues, the less time your projects spend waiting on repairs.

To conclude, in an industry where schedules are tight and margins are thin, smarter maintenance enabled by tracking is a direct investment toward keeping every job on track.

Data-Driven Decision-Making

As we’ve established, the usage data you collect through heavy equipment tracking reveals which machines are overworked and which sit idle.

In turn, these insights directly inform smarter investment and resource decisions.

In a 2022 FMI survey, one-third of U.S. construction companies said unreliable data posed the biggest risk to project decision-making.

That risk extends to one of the costliest aspects of any job: equipment.

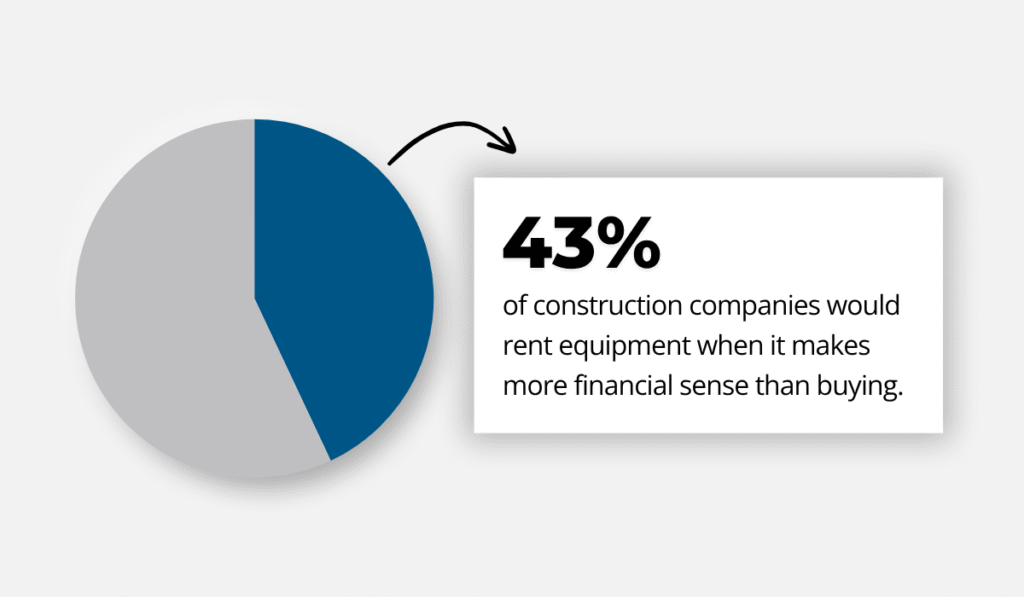

A recent Equipment Watch report found that owning and operating construction equipment can account for up to 50% of project costs, which is partly why 43% of companies opt to rent when it makes more sense than buying.

Illustration: GoCodes Asset Tracking / Data: Equipment Watch

After all, why spend $150,000 on an excavator you don’t fully need when better scheduling or redistribution could solve the problem? But it’s not just a buy-versus-rent decision.

Maximizing asset value means knowing when to replace, retire, or repurpose machines.

These choices depend on calculating the whole life cost of each asset from taxation, insurance, and fuel to servicing and depreciation.

However, usage insights in particular mean a great deal when deciding what to do with an asset.

Usage data is especially valuable here.

Tracking metrics such as engine hours, idle time, fuel consumption, utilization rate, and maintenance history gives you a clear picture of an asset’s true cost and performance.

You can run under-utilization reports on demand if you suspect an issue, or schedule them at regular intervals for ongoing oversight.

Source: GoCodes Asset Tracking

These capabilities are part of why telematics and real-time data monitoring rank among the key technologies transforming fleet management.

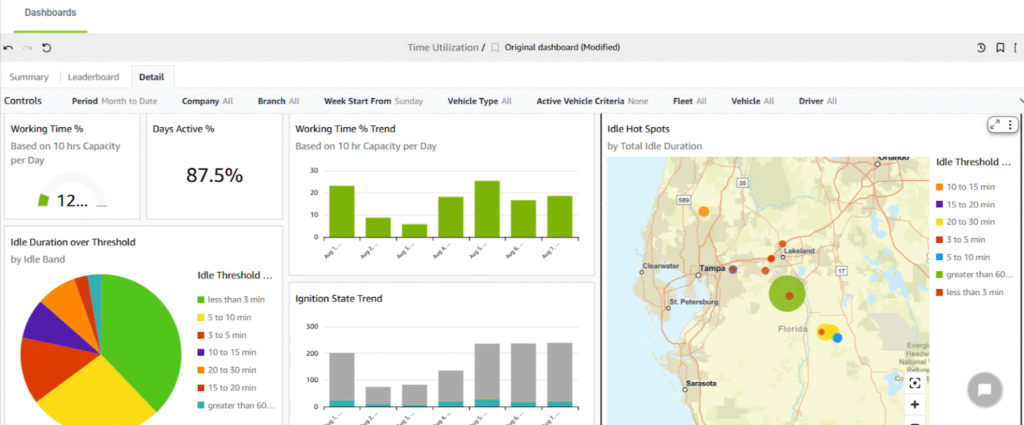

Most modern tracking platforms offer dashboards and visual reports that pinpoint usage patterns and highlight whether inefficiencies stem from the machine itself or operator behavior.

For example, the interface below shows detailed records of idling time and idle hot spots, allowing you to investigate causes and make targeted improvements.

Source: GoCodes Asset Tracking

The truth is that when you have accurate, timely, and actionable usage data, you’re enhancing both day-to-day asset deployment and long-term planning.

In construction, where margins are thin and equipment is costly, data drives key decisions while safeguarding profitability.

Conclusion

At a surface level, heavy equipment tracking helps you capture key information. In reality, it enables you to run your projects smarter.

With the right technology, you won’t be chasing down misplaced machines, skipping maintenance, or paying for equipment that’s sitting idle.

Your decisions and resulting success will be rooted in real data.

The sooner you introduce tracking and automate your workflows, the sooner you cut waste, protect your gear, and keep projects moving in the right direction.

So, what are you waiting for?