To complete most construction projects, you’ll likely need the help of some type of heavy equipment.

Every construction site will feature various pieces of heavy equipment, fit to complete different tasks.

In this blog post, we’ll be going over the ten pieces of heavy equipment most commonly found on construction sites.

Let’s dive in!

In this article...

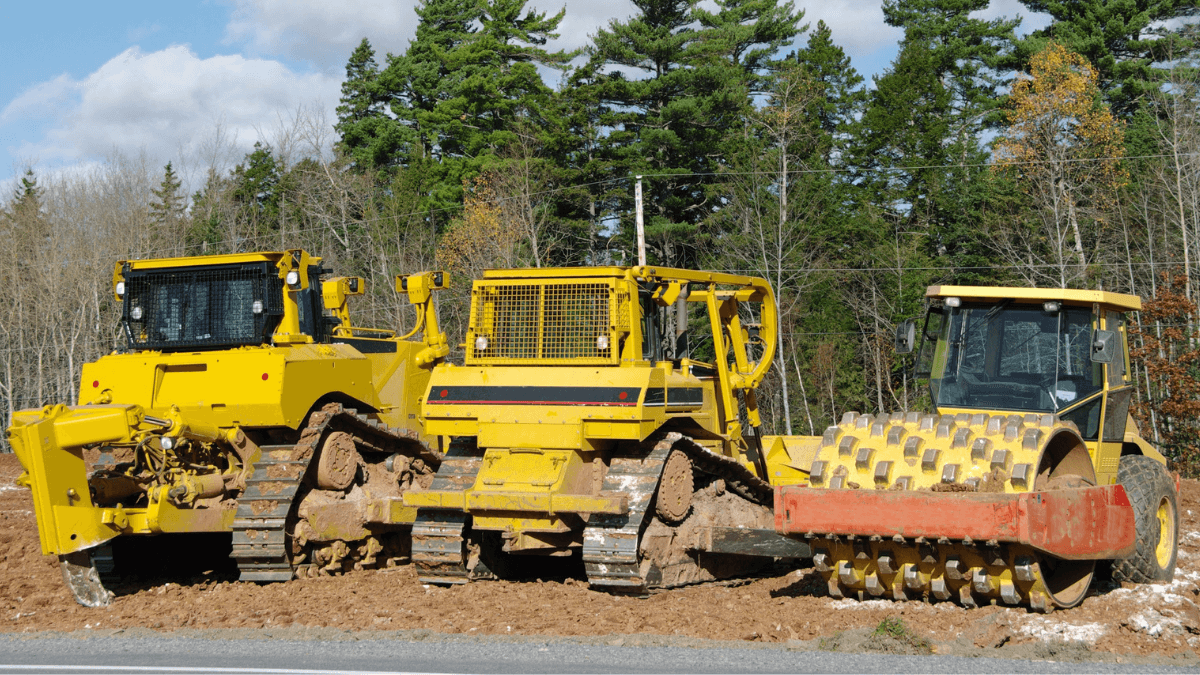

Bulldozer

When people think about construction sites, bulldozers are usually the first piece of heavy equipment that comes to mind.

Their most distinctive feature is the steel blade or plate mounted at the front, which is lifted or pushed down during operations.

Bulldozers, or dozers, typically move on heavy metal tracks designed to maneuver through rough terrain. Those models are not suitable for usual concrete roads.

Conversely, some models come with four-wheel drive instead, allowing them to move around concrete roads, but those are less suitable for rugged areas.

The most common purpose of this type of machinery is to push and move material around the construction site.

Besides maneuvering soil or construction debris, interchangeable blades also allow contractors to clear waste or vegetation before digging a foundation for the building.

Bulldozers are also often paired with other heavy construction site equipment.

Backhoe

Backhoes have two distinguishable features: the loader bucket at the front of the machine and the digging bucket at the end of its two-part arm.

The backhoe loader can push large masses of debris and soil from one location to another, either to clear the site or to fetch the material. It can even be used for removing snow.

Contractors use the digging bucket on the two-part arm for excavation. Depending on the backhoe model, the arm can pivot left and right, with a rotation radius of 180 to 200 degrees.

The quick turn rate allows contractors to use the loader and the digging bucket simultaneously, which is a significant advantage.

Backhoes also have a great range of attachments, which makes them very versatile.

Since they’re smaller than other similar pieces of equipment, such as excavators, backhoes are more maneuverable. They can also be driven on roads, which is a significant advantage, especially if you conduct operations across multiple worksites.

Excavator

Excavators are large construction machines built for excavation, lifting, and digging.

While they are similar to backhoes in some regards, there are a few key differences.

Unlike backhoes, they only have one feature: the digging bucket at the front of the machine, typically much larger than the one found on backhoes.

It can also fit multiple attachments.

The digging bucket on the excavator is purposely built to handle tasks that demand increased power and strength.

Because of their power, they’re often used for demolition jobs as well.

In addition, excavators can make complete 360 degree turns.

As for movement, they’re available as wheeled or tracked vehicles. Since they’re large and heavy, they’re not as mobile as backhoes, nor can they travel on roads.

However, their sheer strength makes them indispensable for heavy-duty projects found on major construction sites.

Let’s talk about loaders next.

Loader

Loaders are tractor-type pieces of heavy machines used in a broad range of construction site operations.

Their key feature is the wide square bucket on the end of the moveable arms that can lift large masses and move material around.

Contractors rarely use loaders as standalone heavy equipment. Instead, as their name suggests, they rely on them to load material into other heavy machinery, like dump trucks, for instance.

Since the bucket can usually store around 3 to 6 m³, its load capacity is far greater than that of the backhoe.

Loaders are ideal for transporting building material around the site, such as pipes, bricks, or construction tools.

Also, unlike bulldozers, they usually move on wheels. Having wheels instead of tracks allows them greater mobility, and they can move faster without damaging roads.

Nevertheless, loaders with tracks are standard on construction sites where sharp materials can damage the tires.

Since we’ve mentioned them, let’s discuss the role of dump trucks.

Dump Truck

Dump trucks are critically important heavy machines.

They’re used to move large amounts of waste and construction debris to the designated areas in the construction site.

Without them, it would be near impossible to keep large building sites tidy.

A standard dump truck is equipped with an open box bed for dumping construction waste.

Once contractors fill the bed and the truck arrives at the designated dump location, a hydraulic ram under the box bed lifts it from a horizontal to a vertical position, dumping the waste.

They come in various sizes, depending on the specific needs of the construction site in question.

For example, there are:

- Side dump trucks that can spill waste to the left or right of the truck

- Super dump trucks can carry extreme amounts of waste, up to 6.5 tons

- Off-highway dump trucks for strictly off-road dumping operations; not allowed on roadways

Dump trucks complement the operations of the rest of the construction site excavation machines.

Drum Roller

For successful operations, construction sites need stable, flat grounds to work on.

Drum rollers are heavy construction machinery used to flatten and compress the road, remove air pockets, and secure flat foundations.

Their most recognizable feature is the massive drum roller that flattens the soil or tarmac.

However, the drum rollers commonly appear in two types; single or double drum rollers.

Single drum rollers have a heavy drum roll mounted in the front and wheels in the back. The wheels ensure the front drum is more maneuverable.

Single drum rollers are ideal for creating site foundations and paving roads.

Double drum rollers are mounted with one additional drum roll in the back. They don’t rely on wheels for movement and are twice as effective in flattening surfaces.

The downside is that the lack of wheels makes their movement limited. Contractors use them for flattening asphalt roads.

Paver

Pavers are essential heavy equipment for residential and road construction.

Their function is to lay asphalt flat on the surface and to provide minor ground compaction.

Pavers have two distinctive features.

The first is the feeding bucket, which is continuously loaded with asphalt as the paver moves forward. The second is the paver screed at the front, which disperses the asphalt mass evenly.

Modern pavers can increase the width of the screed to cover larger areas. They can also monitor the paver’s fuel consumption.

For effective performance, they need to maintain a consistent speed and supply of materials.

Contractors support them with other heavy equipment on the construction site. Dump trucks help load their feeding buckets, and drum rollers pass over their tracks to compact the surface.

The result is a smooth paved road.

Soil Compactor

Similar to drum rollers, compactors are heavy machines vital for road works and residential construction.

Compactors rely on their massive wheels for movement. They have a bulldozer-like plate or drum mounted in front of the vehicle.

The heavy front attachment applies pressure and vibratory force to the soil to remove air pockets.

By doing so, it makes the ground compact and ready for construction.

There are many sizes and shapes available for soil compactors.

The type of compactor you’re going to use on a job depends on the terrain of the construction yard.

Contractors typically use soil compactors with a plate attachment and spiked wheels for landfill sites with granular soil. The spiked wheels apply pressure and vibration to the ground while the plate pushes the soil forward.

If the construction terrain consists of cohesive soil, like silt or clay, soil compactors with drums are ideal. The drum flattens the ground and removes the excessive air.

Soil compactors with drums are typically faster than those with a plate, which means they can cover more terrain in the same amount of time.

Tower Crane

If a construction company is building a tall structure like a skyscraper, materials like steel and concrete need to be delivered to the structure’s upper levels.

Tower cranes can move heavy weight safely and efficiently.

The heavy foundation can withstand the weight of the entire crane and support the tower.

A typical tower crane can lift to 18 tons of weight thanks to its robust structure.

They can reach 265 ft in height. As the height increases, the crane’s grounds need to be heavier.

Tower cranes can move loads in a radius of 220 ft, which enables contractors to cover the entire construction area.

When construction companies are deciding on the tower crane size, they choose based on:

- the scope of the construction site

- the required weight capacity for materials

- the height of the planned structure

Finally, let’s talk about the smallest piece of heavy equipment on the list.

Forklifts

Contractors use forklifts to transport heavy materials across the site in a safe and fast manner, which makes them vital supporting vehicles on construction sites.

Since interior construction materials like wood, tiles, and bricks are delivered in pallets, forklifts are the ideal machinery for handling them.

When such materials arrive at the site, forklifts quickly pick up pallets and move them across paved surfaces.

If the construction terrain is uneven and difficult to maneuver, contractors use rough-terrain forklifts.

In addition to the standard features, rough-terrain forklifts are equipped with pneumatic tires that enable superior traction in off-road conditions.

That way, the vehicle can move over rocks and maintain stability while carrying the load.

They also lift heavier objects, with load capacities from one to 20 tons, depending on the specific model.

How to Track Heavy Equipment

Heavy equipment is expensive and requires careful handling.

The best way to do so is to use asset management software to track your machinery and construction equipment.

Tracking solutions allow you to pinpoint the GPS location of your heavy equipment and determine who is using it at the moment.

If you’re operating on multiple sites, you can track which equipment is present on which site. You’ll eliminate delays and mix-ups that cause unnecessary expenses.

You’ll keep your costly machines safe from theft at all times.

First, connect your equipment to asset management software. This allows you to send data to a centralized cloud system.

From there, office administrators can quickly check up on assets and equipment from a PC or a smartphone.

You can add more equipment to the cloud by tagging items with generated QR codes.

Since most smartphones nowadays come with QR scanners, this solution is simple to use and implement for all onsite workers.

Tracking heavy equipment is essential if you want to run an efficient construction site.

Conclusion

Managing heavy equipment has always been a challenging task for construction companies.

Understanding which heavy equipment is most demanding to maintain is essential for achieving top performance.

If you’ve had difficulties on your construction sites in the past, think about deploying new solutions to improve your operations.