Did you know that equipment needs to weigh at least 5,000 pounds to be in the heavy category? That is 25x the weight of an average American male.

An excavator’s median weight is a little less than 70,000 pounds or 350x more than the average male. The point is: humans don’t stand a chance if they are struck by or caught in or between heavy machinery.

This is just one of many reasons why construction equipment can be deadly to workers.

This article will explain what heavy equipment poses the most danger to construction workers and causes the most common accidents and injuries. We’ll also go over what leads to construction equipment accidents and when they’re most likely to happen.

If you’re interested in making your workplace a safer place, this is the article for you.

In this article...

The Most Dangerous Types of Heavy Equipment

Heavy equipment can be hazardous if you don’t know how to operate it safely.

Let’s face it: some companies don’t invest in equipment training as much as they should.

As a result, unskilled operators end up handling machinery that weighs well over 5,000 pounds. It’s the equivalent of a bull in a china shop—accidents are just waiting to happen.

Let’s see what the most dangerous type of construction equipment is, as this data can help you work on detailed employee training.

Knowing what machinery causes the most accidents can ensure that your operators receive extensive instructions on the proper use of said machinery.

Heavy equipment involved in most accidents includes:

- Cranes

- Bulldozers

- Dump trucks

- Backhoes

- Excavators

Cranes are number one on the list because of the deadly consequences they can bring about. A typical crane can go up to 265 feet in height and 350 tons in weight, which means that falling from it or having it roll over can be fatal.

In 2019, a crane collapsed in Seattle, killing four people—two workers and two civilians— and injuring another four. In this tragic case, the workers removed the pins that held the construction together too quickly, and it led to the crane falling onto the road.

Bulldozer accidents are just as deadly. Those machines are also known to roll over, which almost always results in a fatality. Last summer, the owner of a construction company was killed in such an incident.

Three months earlier, a worker fell out of a running bulldozer and tried to get back inside to stop it, getting pulled under the tracks and sustaining fatal crushing injuries as a result.

When it comes to dump trucks, employees are most likely to get struck by one or injured if it rolls over or falls.

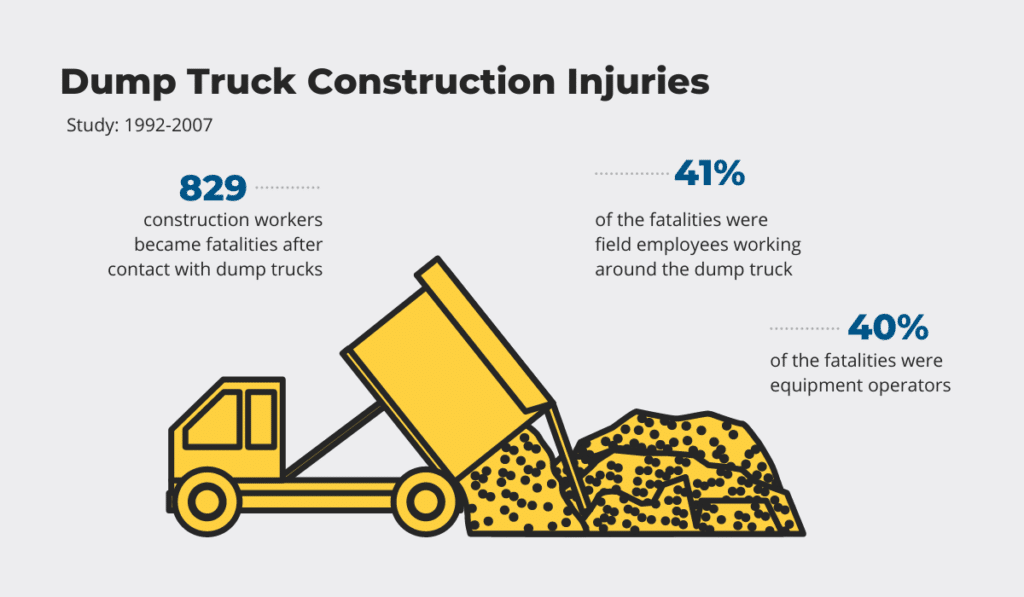

A study covering 15 years (1992-2007) of construction accidents wanted to determine how often fatal dump truck accidents happened.

A staggering 829 workers died in contact with dump trucks, which means there was an average of 55 dump truck-related fatalities a year.

40% of the workers were operators, and 41% were workers on foot. Out of those 343 field employees, ¾ were struck by a dump truck.

The study found that providing training on the importance and the proper use of safety belts would have prevented many of these incidents. An operator wearing a seat belt will not easily fall out of the truck or get injured as gravely in case of a rollover.

What Accidents Are Most Likely to Occur

As mentioned before, getting struck by equipment is one of the most common types of accidents at the construction site.

It’s easy to see why when you remember that many employees have to work around heavy machinery, and the operator doesn’t always have a clear view of their surroundings.

The worksite noise can be loud, which means some workers might not even hear the machine coming.

The Occupational Safety and Health Administration (OSHA) warns about the construction industry’s four most deadly injuries, also known as the Fatal or Focus Four, consisting of:

- falls,

- injuries sustained by being caught in or between pieces of equipment,

- struck-by accidents,

- and electrocution.

These four types account for around 60% of all construction site injuries, year after year. Two of them are directly related to heavy equipment: caught-in/-between and struck-by injuries.

Sadly, construction workers are at high risk when working in proximity to large equipment. They can get caught between the machine and another vehicle or object, they can get pinned down, struck, or crushed by equipment.

In fact, 25% of construction workers die from being struck by a vehicle, which is more than any other occupation.

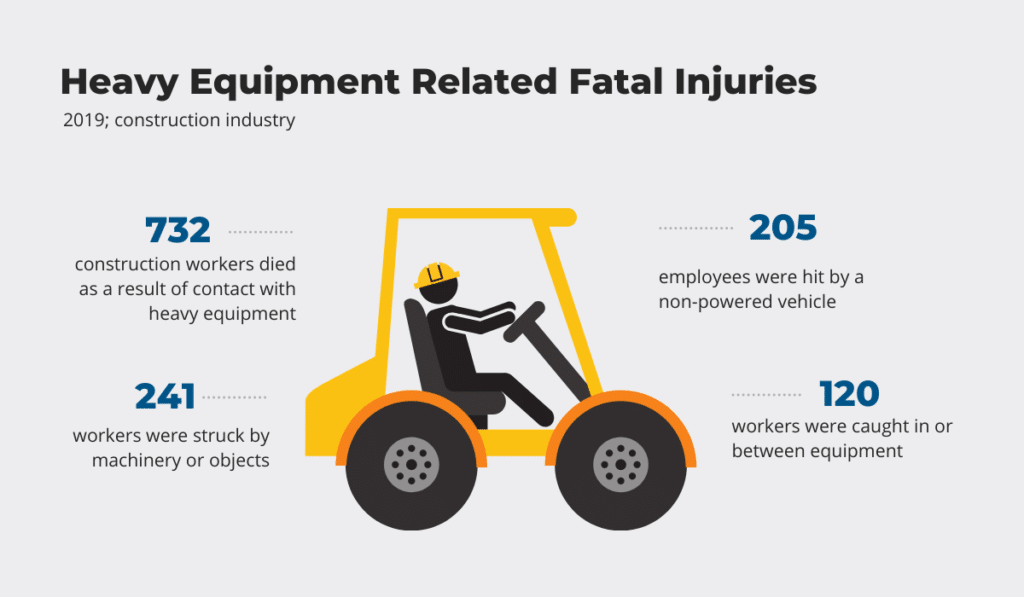

In 2019, 732 workers died after fatal contact with objects and equipment at the worksite. Out of them, almost a third (241) were struck by falling objects or equipment.

Two hundred five workers were hit by a powered non-transport vehicle.

Another 120 were caught in and between equipment or objects, leading to their demise. Additional 83 workers died due to collapsing equipment and materials.

Such incidents happen a lot more than you know, so your goal should be to make safety a priority.

You can include details on heavy equipment in your training to ensure that the employees are well aware of hazards and know how to react if they happen. Proper training on the safe use of equipment for operators will also help you minimize the number of accidents.

When Most Heavy Machinery Accidents Happen

It’s hard to pinpoint when exactly most equipment accidents happen. If that were possible, we’d be able to practically eradicate such incidents.

But, what we do know is that the majority of unfortunate events happen during specific activities, which means you can instruct your team to pay attention when performing them.

These activities include:

- Backing the equipment up

- Loading/unloading

- Working on uneven surfaces

- Getting on or off a vehicle

- Operating near power lines

So, during training, remember to explain the importance of being wholly focused when doing these tasks.

On top of that, the workers who are on foot should steer clear of equipment during these activities to ensure they don’t get hurt if something happens to the vehicle.

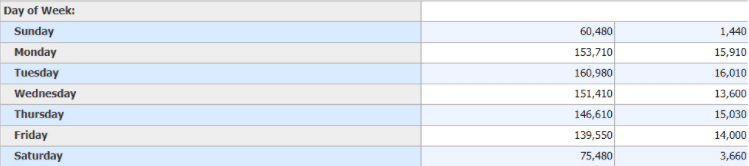

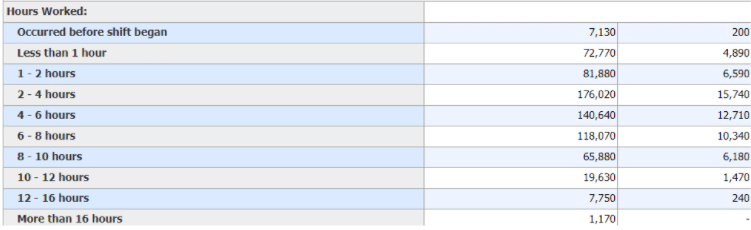

We’ve also analyzed the 2019 US Bureau of Labor Statistics (BLS) reports to see when exactly most accidents involving heavy equipment happened.

Here’s what we found: the large majority of accidents happened during the workweek, specifically on Tuesdays and Mondays, followed by Thursdays.

In total, 74,550 happened on workdays, while 5,100 of them occurred during the weekend.

Of course, since not every construction site works on the weekends, it’s easy to understand why there’s such a disparity.

The beginning of the week seems to be the most dangerous time because that’s when the demanding tasks start.

When you think about it, it makes more sense to tackle an extensive aspect of construction on a Monday and work on it the entire week rather than start it on Friday before leaving the site for two days.

However, such tasks are naturally riskier.

Also, a surprisingly high number of accidents mentioned in the report happened between 8 AM and 12 PM—28,680. This data points to the workers’ rush to complete their tasks before their lunch break.

Vicki Huebler, a corporate director for quality, health, safety, and environment at ION Geophysical, believes that safety suffers when there’s pressure to finish a job quickly.

When analyzing workplace accidents, she found that it’s often the supervisors who pressure people to wrap up quickly.

Other times, though, the workers put pressure on themselves.

BLS reports that around 10,000 fewer accidents happened from 12 PM to 4 PM, and the interval between 4 AM and 8 AM, which is when most construction sites open for work, was in third place.

However, bear in mind that over 20,000 accident reports didn’t include the exact time when the incidents took place, so BLS wasn’t able to include them in the calculation.

Finally, you may want to know how long the worker had been on the job site when an accident occurred.

Do accidents happen when workers just arrive at work, immediately before the break, after one, or after a long day of work?

According to BLS, most equipment accidents happened after two to four hours of work, which is somewhat surprising, but could be, as mentioned earlier, related to rushing to get the job done before a break.

Four to six hours into the shift was the next most common option, followed by six to eight hours.

It’s interesting to note that 200 accidents happened before the shift even began, pointing to safety problems at the worksite.

Common Causes of Heavy Equipment Accidents

What causes heavy equipment accidents?

Firstly, it’s the lack of safety hazard awareness at the worksite. Employees who aren’t aware of the possible dangers won’t keep an eye out for them, putting themselves at a higher risk.

As an employer, it’s your responsibility to train workers on the proper use of the equipment and the importance of safety at the worksite. Otherwise, you’re putting them in direct danger.

Workers who don’t know how to use personal protective equipment (PPE) or safety belts are a lot more likely to become a fatality on your construction site. Why take the risk?

Statistics show that many accidents happen in the first year of working in construction, which points to experience playing a key factor in safety.

Younger workers are more likely to be involved in construction site accidents precisely because of the lack of training and knowledge needed to recognize and avoid safety hazards.

Therefore, your goal should be to improve construction site safety as much as possible.

One of the topics you should focus on is definitely safe equipment operating, including wearing a safety belt, using alarms to warn other employees about the vehicle moving, and knowing what activities create more hazards.

For example, the operator should be highly cautious when loading and unloading the equipment. Almost 50% of driver injuries are related to this activity.

Then, train the workers to recognize safety hazards. The workers should always wear the necessary PPE and follow the protocols, even if it seems that doing so takes longer.

Yes, specific protocols do take a longer time, but following them can save the workers’ lives. Their importance is something you should explain during training.

No time is worth the risk of a construction site accident.

Last year, the second most cited OSHA violation was hazard communication.

In other words, 4,170 companies were fined for failing to warn their workers about worksite dangers.

Another 2,059 companies did not ensure proper fall prevention training for the workers, even though falls are the number one cause of accidents on the construction site.

So, there’s clearly a need for more extensive training and two-way communication regarding heavy equipment.

Only then will you be sure that the employees in the field have all machine-related data and can use the machinery safely.

An excellent way to seamlessly implement safety communication into your professional practice is to use equipment tracking software with the option of leaving comments on the equipment’s page.

We make tool and equipment tracking easy! Try GoCodes Asset Tracking for free

This ensures that all employees are aware of the condition their machinery is in.

The maintenance team can leave warning comments or upload servicing results, making the data available to any employee interested in this equipment.

At the same time, the employees can leave comments on the machine’s condition for the service team.

Common Injuries Caused by Construction Equipment Accidents

When understanding the most common injuries caused by heavy equipment, we shouldn’t forget that not all injuries are reported.

Sadly, a quarter of construction workers have admitted to not reporting an injury to their employer. Sometimes, workers don’t think the injury is a big deal. Other times, they’re afraid of losing their job if they report it.

BLS analyzes all the reported injuries and offers extensive reports on both fatal and non-fatal construction site injuries related to equipment.

We’ve analyzed both and found some interesting data.

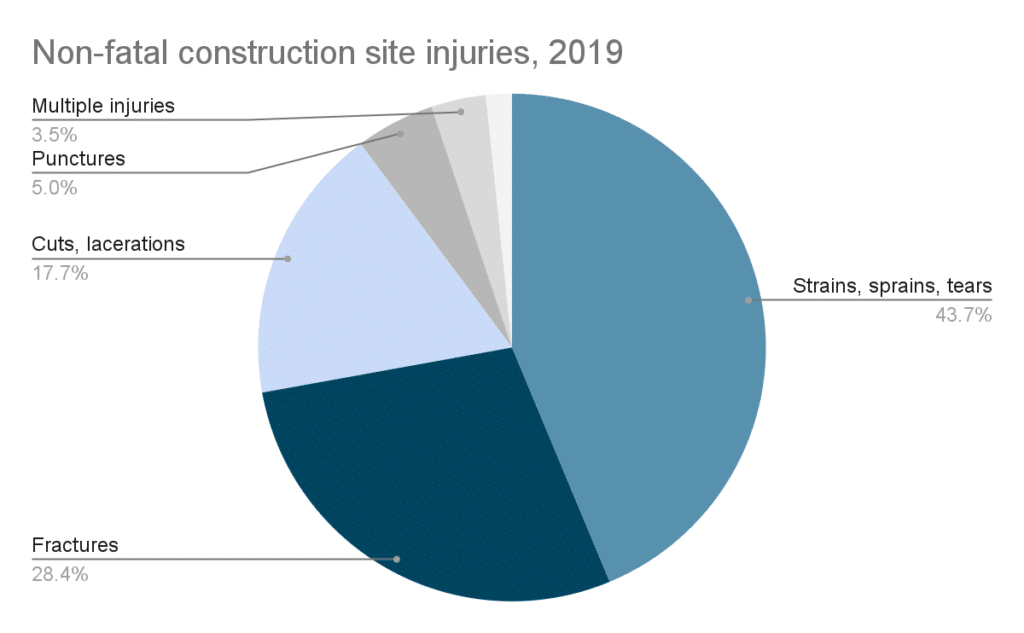

In the year 2019, BLS reported 77,560 non-fatal construction worker injuries.

The most common injuries were sprains, strains, and tears, at a total of 21,180. The second most common type of injury for construction workers was a fracture, which happened to 13,780 workers.

An additional 8,560 workers suffered cuts and lacerations at the workplace, while 2,440 got punctures and 800 people had to go through an amputation.

Finally, 1,690 suffered multiple traumatic injuries. Out of these workers, 490 had fractures, and 600 had sprains.

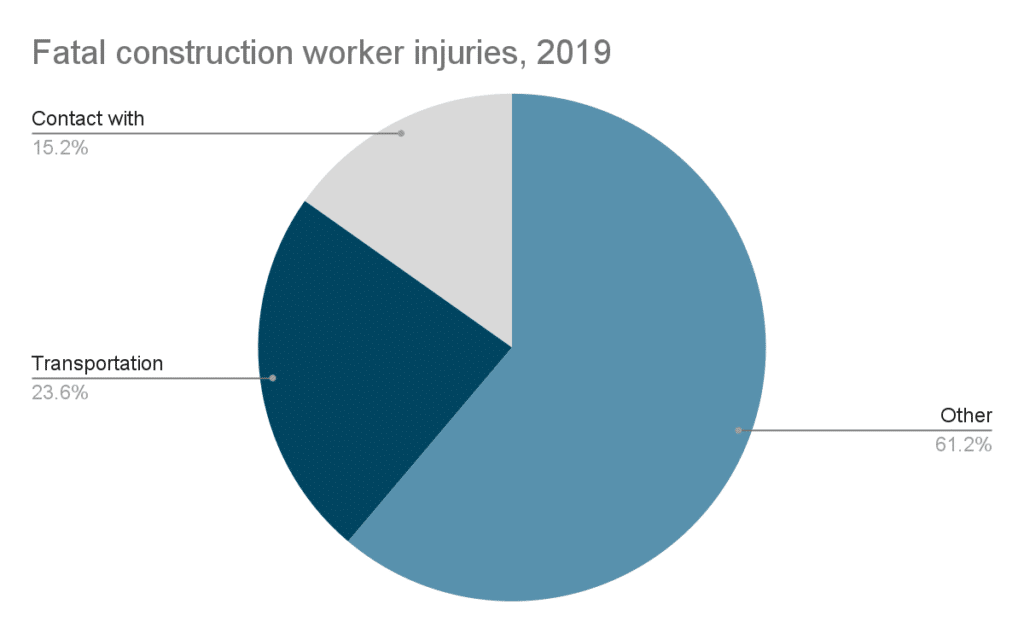

As for fatal injuries, the situation was just as grim. A total of 1,066 construction workers died on the job in 2019.

Out of these workers, 252 or 23% died in transportation accidents, which can easily happen around the worksite.

Another 162 or 15% of construction employees died as a result of injuries caused by objects and equipment found on the worksite.

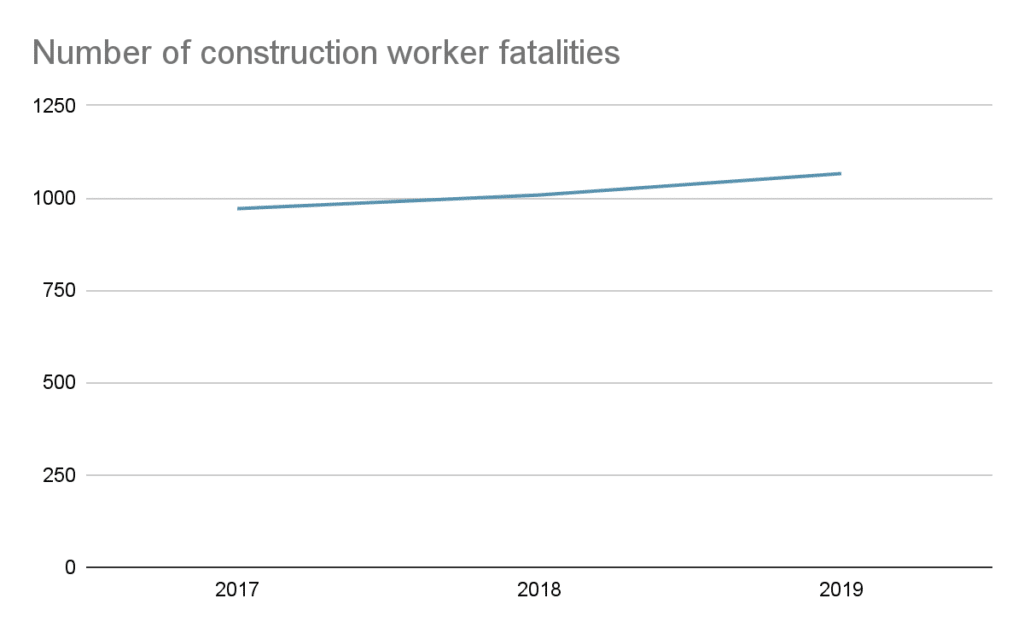

The number of fatalities in construction is growing each year, little by little.

In 2017, 971 construction workers lost their lives at the job site. The following year, that number rose to 1,008.

Sadly, heavy equipment still poses a significant danger to all those working in construction.

In some cases, the hazard can prove fatal, so it should be imperative to promote safety at the worksite as much as you can.

Conclusion

The most important thing to remember about heavy equipment accidents is that they can happen to anyone.

Things can go very wrong when an inexperienced employee operates a powerful piece of machinery or when the equipment is working on uneven terrain. Machines themselves can be unpredictable.

Because of this, you should focus on educating and training your team on understanding the dangers at their workplace. Teach them to keep an eye out for any irregularities.

Only then will you be sure that your workers are protected and safe while working.