When companies begin to organize assets for greater efficiency and control, the first items that come to mind are naturally movable assets, such as hand tools, tablets, and inventory in a supply chain.

These items might be checked out by employees, moved between rooms in the same building, or distributed to far-flung worksites.

However, attention must also be directed towards fixed assets. A fixed asset is an item that stays in place. They require tracking just as much as the items that are never in the same location twice.

So let’s get started.

In this article...

What is a Fixed Asset?

A fixed asset is an item used by an organization to create income. It always remains its installed position. Fixed assets may be more familiar to you under the name of capital assets They are also referred to as PP&E, or “property, plant, and equipment.”

Examples of fixed assets include air conditioning systems, buildings, natural resources, conveyor belt equipment, and land. These are not projected to undergo consumption or sale within the following year.

Some fixed assets are also intangible and can include intellectual property, as well as such growth-oriented investments as mutual funds and stocks. Physical assets, except perhaps for land, suffer from depreciation, but usually not as quickly as movable assets.

A movable asset, on the other hand, generally has a shorter life cycle. Examples include objects like office furniture, nails for construction, day spa equipment, and books. Both movable and fixed assets can be tagged and evaluated.

Fixed Asset Tracking vs. Fixed Asset Management

There’s some difference to fixed asset tracking and fixed asset management.

While GPS tracking and tagging aren’t necessary for a fixed asset—since an asset like that is not going anywhere—it’s still important to tend to it through each stage of its life cycle.

The management of a fixed asset includes more than just tracking. It covers several aspects of predicting its performance along its life cycle while ensuring that the item “earns its keep.”

Fixed assets must continually prove their worth to a company, or it’s time to discuss another solution.

Here are some ways fixed asset management is made possible via tracking:

- Checking the temperature and relative humidity surrounding the item in real time

- Keeping up-to-date preventative maintenance information at hand

- Cloud-based storage of manufacturer recommendations

Why is Fixed Asset Tracking Important

Fixed asset tracking is important for the same reason that movable asset tracking is important: it saves the organization money and offers control and supervision over each aspect of the asset’s performance or valuation.

The ability to gather and analyze this data presents a wealth of opportunities for better understanding an item’s optimal performance conditions.

Where preventative maintenance is concerned, fixed asset tracking passes on information regardless of who tends to the item.

The data offered by regular scanning can alert maintenance crews not only to when filters should be changed or how many RPMs a fan belt is making, but it can also reveal “insider-only” information to specialty crews summoned to work on a fixed asset in the midst of a breakdown.

Several industries might employ the use of identical assets, such as similar-looking industrial buildings or pipe fitting.

When a fixed asset is assigned a unique identifier, it is easy to differentiate the items from one another. This practice avoids confusion, saves time, and allows an effortlessly transferrable information system to subcontractors or temporary employees.

Fixed asset tracking also enables:

- Protection against theft

- Elimination of duplicates

- Insurance against liability in the event of an accident or weather-related disaster

- Measuring the assets’ performance against where it is in its life cycle

- Proof of regulatory compliance

- Instant knowledge of which employee is responsible for its upkeep

- Ensuring the climate surrounding the asset are within manufacturer recommendations or maximum quality standards.

Now that you understand the positive changes fixed asset management can bring to your business, let’s see whether your industry would benefit from it.

Some Industries That Benefit From Fixed Asset Tracking

Nearly every industry can benefit from fixed asset tracking. However, some are more suitable than others.

Logistics and Supply Chains

This might come as a surprise to some, since this industry is most immediately identifiable with movable asset tracking. However, rooting a logistics company in fixed asset tracking provides a holistic view of company data.

By using the same software to keep tabs on such equipment as office buildings, natural resource holdings, and any manufacturing equipment, employees and decision makers will speak an identical tracking language.

Health Care

Doctors’ offices, hospitals, clinics, and med spas seem made for the maximization of fixed asset tracking.

While it’s true that such organizations quickly run through such consumables as bandages, over-the-counter medication, and personal protection equipment, fixed assets like water systems, medical-grade light fixtures, and industrial generators all require constant tracking to ensure their continued proper operation.

Avoidance of breakdown in such items is critical in health care. In addition, regulatory compliance, particularly where pharmaceuticals and regular service are concerned, is much more easily proven with fixed asset tracking.

(IT) Information Technology

Fixed asset tracking is invaluable in managing licensing agreements, as well as gatekeeping where employee access is concerned. Asset tracking software can consolidate data and reinforce credential authentication methods.

What to Track

The benefits of fixed asset tracking are many, but it’s important to carefully choose which aspects of the item to monitor. Otherwise, decision makers might find themselves with frustrating streams of data that require time and effort to assess.

In such circumstances, fixed asset tracking weighs down efficiency rather than improving it. Deciding ahead of time which data to emphasize is essential.

Employee Accountability

For sensitive and massive installments such as power plants in which the “product” is service, operators should know which employee is assigned to servicing, monitoring, or working on a certain fixed asset.

Real-time information about productivity, as well as the instant ability to access scheduling and contact information, is vital in the event of a shutdown or emergency.

Climate Control

In organizations such as museums, archives, or storage units, the careful monitoring of the conditions surrounding certain assets is crucial.

Fixed asset tracking within facilities can alert employees to potentially dangerous changes in temperature, carbon monoxide levels, or humidity.

Purchase Order Information

Your company has its own unique identifiers and methods of tracking, and a third party or contractor might employ a completely different system.

Incorporating tracking data, such as serial numbers, receipt information, and date order references will help save time and ensure accuracy in case you require information or assistance from the manufacturer or vendor.

Methods of Fixed Asset Tracking

One of the most attractive aspects of fixed asset tracking is its flexibility. Fixed asset tracking can take many forms, depending on your company’s needs and structure. Here are a few to consider.

Barcode Labelling

The use of barcodes has been a mainstay of the retail industry for several decades. However, barcodes are also useful in fixed asset tracking.

In this method, a small set of black and white lines are scanned by a proprietary handheld scanner. The use of barcodes is more economical than other forms of tracking and is best when there is no need for large amounts of data storage.

They are usually pre-printed on labels and some are also scannable by smartphone apps. While barcode labels are appropriate for many forms of fixed asset tracking, they very rarely allow for unique identifiers.

To solve that problem, use an advanced version – QR codes.

RFID Tagging

RFID stands for Radio Frequency Identification. Like barcode systems, special equipment is necessary in order to use this kind of organization. RFID tracking makes use of radio waves to transmit data which is encoded digitally.

The tags are attached to the tracked object, and a reading device then picks up the signal and reads the information. While RFID tags might prove more expensive and bulky than barcodes, they provide more security than other methods.

In general, RFID tags are best applied in health care, the hospitality industry, and within organizations with several valuable fixed assets such as museums, theme parks, and tourist operations.

BLE/GPS

GPS (global positioning technology) is best known by consumers in maps and directional aids. Where fixed assets are concerned, however, they can be useful deterrents against theft. They might also be used to help guide contractors, third parties, vendors, and clients to the location of certain assets.

BLE (Bluetooth Low Energy) tracking is another form of technology that is increasingly starting to become integrated into everyday life. Most consumers use Bluetooth to “go wireless” with such electronic products as projectors, headphones, and printers.

However, when applied to fixed asset tracking, BLE is useful in broadcasting beacons that allow devices to communicate with one another. They are most useful when substantial battery capacity is more important than transferring large amounts of data.

NFC Tagging

NFC is short for near-field communications. It is closely related to RFID technology, but the distance it covers is usually much shorter—typically a matter of inches.

NFC tracking is best for organizations seeking to avoid the purchase of specialized equipment; it takes place on a smartphone.

Most are familiar with NFC tracking through the use of point of service payment apps. While NFC offers rapid service, excellent security, and efficient use, it can be more expensive than other forms of fixed asset tracking.

Read more about asset tracking methods in this guide.

Specialized Software: How to Choose the Best Option

Decision makers have many options to weigh when it comes to choosing the best option for fixed asset tracking. The digital revolution means that specialized software is constantly changing and offering more and more features.

Here are some aspects of tracking software to keep in mind when choosing the best form for your company.

The amount of data: Does the fixed asset constantly transmit data, or is only periodic scanning necessary? How much information is exchanged? When the data is uploaded from the asset, how much of it gets sent—simply a temperature reading, or a large amount of information which includes graphics and video stills?

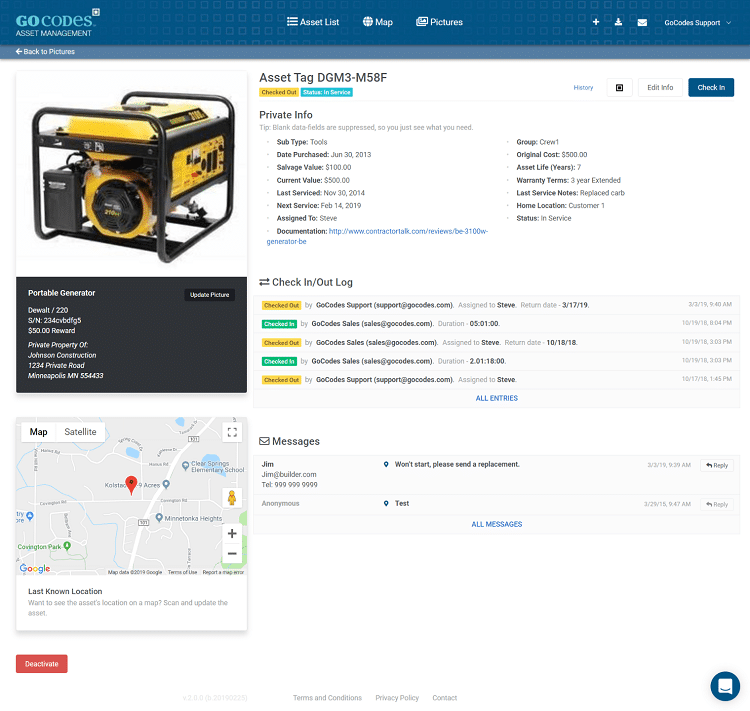

Who is using the asset: Are the employees in charge of the asset changing several times a day, or is this information unlikely to vary for a long time? Is there a check in/check out aspect to the asset? How often is it used in a day—several times sporadically, or is it constantly operating?

Security: Is it necessary to apply several layers of encryption to the data, or is it an asset at low risk for a data breach?

Answering such questions will help you choose not only the right form of fixed asset tracking, but the best kind of software. A hospital will likely need a different form of software than a photography studio.

Best Practices of Fixed Asset Tracking

Once an organization has decided to undertake fixed asset tracking, the system will only work as well as its implementation. Knowing how to maximize the methods and data collection forms of fixed asset tracking will help to rapidly recoup the investment in the system.

1: Knowing What to Track: Narrowing down which items to track, as well as what kind of data to draw from such items, will avoid unnecessary spending and labor on tracking unnecessary information.

2: Maintaining Data Consistency: Employee training and buy-in are vital. If tracking and scanning are not automatic, it’s important to ensure that it becomes a necessary part of an employee’s duties.

3: Creating an Asset Database: The ability to return to data to study patterns and outliers yields better decision making.

4: Keeping Detailed Location Data: This is often vital for monitoring equipment and demonstrating regulatory compliance.

5: Keeping Track of the Life Cycle of the Asset: Keeping tabs on when an asset is likely to be at the end of its life cycle helps to avoid panic buying and increases optimal budgetary planning.

Conclusion

The actual tracking of fixed assets, whether automatic or employee-driven, is a necessary part of understanding the capital in your company. Understanding its importance contributes not only to a strong bottom line but to better information control and employee accountability.

GoCodes Asset Tracking Can Help

We use QR code tags with a unique visual code that you can scan with your smartphone. When scanned, GoCodes Asset Tracking tags provide information about your asset, not limited to its location.

Sign up for a free trial here.