It’s hard to imagine a construction site without an excavator.

Ever since William Otis engineered his steam shovel in 1796 to excavate dry earth, excavators have been indispensable in various construction projects. Digging, clearing, dredging, landscaping, demolition or mining, they’re suitable for anything you can think of.

Still, an excavator would be nothing without the right attachment. They’re the shining stars that allow workers to be more efficient and productive at a worksite.

Switching out attachments can quickly transform an excavator from a jackhammer to a mower and the best part is that there are options for excavators of every size.

Let’s take a look at the essential attachments that give excavators the versatility and flexibility they’re famous for.

In this article...

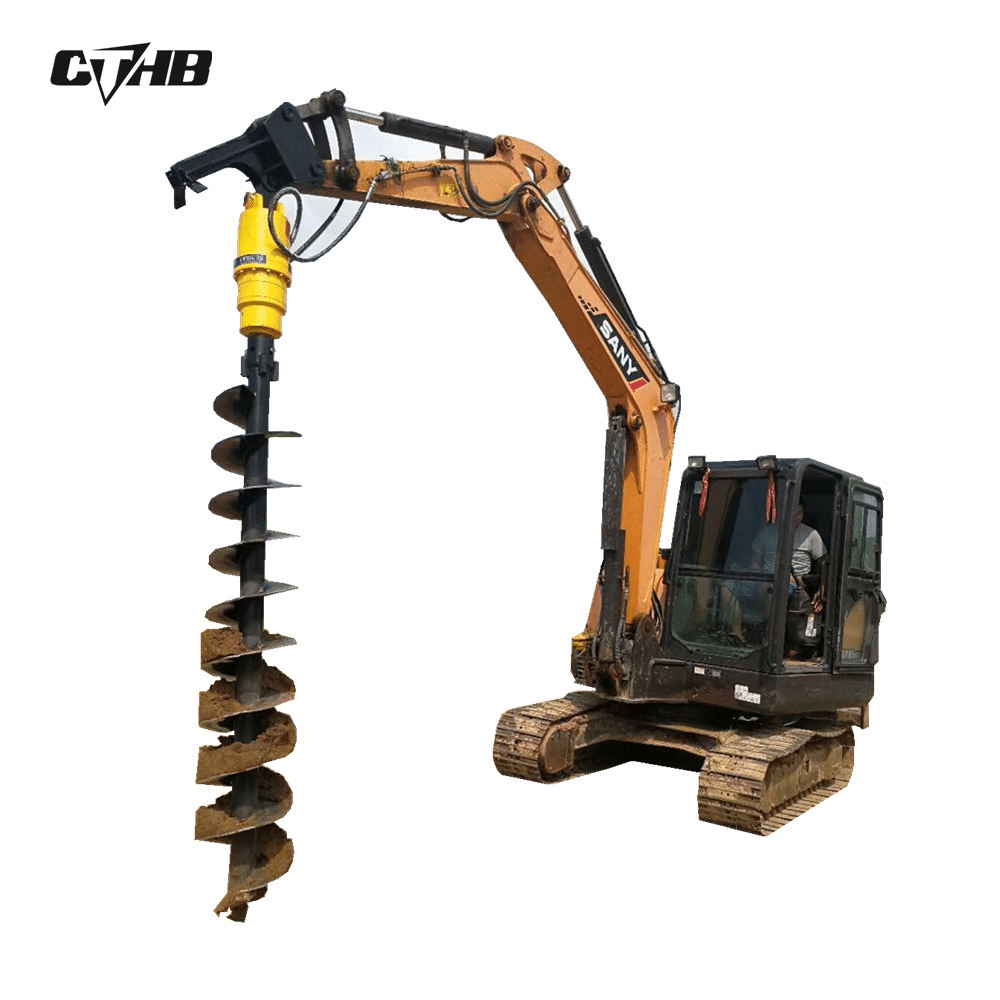

Auger Drills

Auger drills help excavators drill holes in the ground.

They have a spiral design that rotates into the material, and then the blades pull up the material to make a clear hole. Basically, they’re like giant screws that penetrate the ground.

The best thing about auger drills is that they can be used for different types of terrain. Their precision enables you to drill earth, pavement, wood, or even ice.

Furthermore, they’re so versatile that you can find auger drills from 4 inches up to 4 feet in length, and some of them have a digging depth of 33 feet.

This makes them perfect tools for planting trees, drilling holes for pillars, or building foundations.

In the end, the specific design of auger drills makes them capable of most tasks that involve digging straight downwards, so they’re an excellent tool for any construction project.

Buckets

The most common attachment for an excavator is a bucket.

A typical bucket is made from hard steel and has teeth on the front edge to dig into the ground. These attachments are what most people expect to see on an excavator. They’re also highly versatile in shape and size.

While a bucket’s primary use is to scoop and move materials, excavators will be more efficient if you choose the right one for the job at hand. Here are some popular types of buckets:

| General bucket | used for maximum material filling and handling, but also light-duty grading, and leveling |

| Dirt bucket | a durable bucket used for digging, moving rocks and dirt |

| Rock bucket | used for handling stone and gravel where the soil sifts through the holes in the bottom to separate materials |

| Heavy-duty bucket | used for moving sturdy material, but also road construction and leveling rough terrains |

| Light material bucket | used for removing light materials such as snow where you need a higher capacity |

| Low-profile bucket | smaller in size but ideal for tighter spaces; it has a longer lip and a lower back to provide better visibility and precision |

Whether you need to remove rocks or pick up debris, attaching a suitable bucket to your excavator is important. With the right bucket, your operators can benefit from increased productivity and reduce operating costs.

Trenchers

In areas where you need precise digging, using a trencher is often a better choice than a bucket.

Even Lionel Smitka, marketing manager at Digga Australia (Australia’s leading machinery attachment manufacturer), agrees.

When asked about his top recommended excavator attachments, Smitka placed the trencher very high on his list. He explained that using a trencher on an excavator significantly saves time and money.

A trencher’s only job is to dig trenches, so they’re much faster than other attachments you might think to use for that purpose, such as buckets.

For example, you’ll need more time and fuel for two or four excavators with buckets to dig up a trench than for one trencher.

Additionally, the trencher will also make the backfill much more refined so that it can return to the trench without sinkage.

One thing that cannot be overlooked is that trenchers can work close to buildings and other objects, which makes them perfect for tackling difficult trenching jobs.

They can even handle rockier soil types. Therefore, you can use trenchers for jobs such as utility installation, footings, and irrigation systems.

But despite their reliability, Smitka believes that trenchers are one of the most underrated excavator attachments. Contractors still choose to dig up trenches using buckets.

So, if you want to get ahead of your competition, utilize trenchers more often for your construction projects.

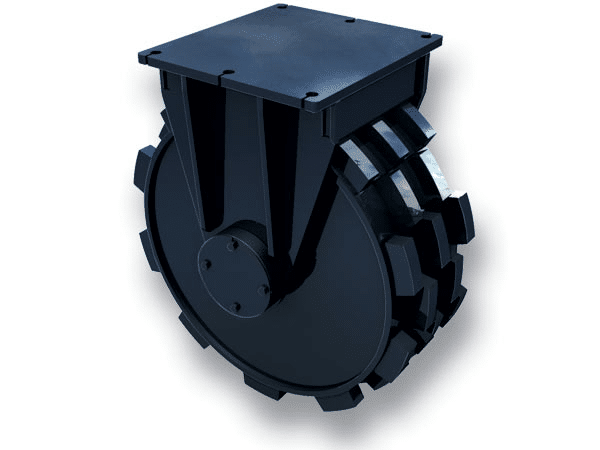

Compactors

When a job requires compressing the ground, the best tool for that is a compactor.

But before you choose the right compactor, you should start with soil identification. The simple reason for this is that each type of compactor (wheel and plate) works better with a specific soil type.

So, in cases where you have granular soil, you’re dealing with sand and gravel.

These particles will crumble easily, but when they’re compacted with vibration energy, there will be less friction, and the particles will find a position that limits their movement.

A plate compactor is better suited for this type of soil.

A typical plate compactor has a flat plate that moves on the ground quickly. These rapid impacts, combined with the plate weight, compress the ground underneath.

Also, they can rotate up to 360 degrees, making them ideal for working in a narrow trench or reaching areas a roller can’t.

On the other hand, when you have a more cohesive soil (i.e., when there’s more clay in it), your best choice is a wheel compactor. This type of soil requires more impact force.

Or in other words, you need to knead out air and excess water to compress the soil further, so it’s best to use a tool with roller bearings like a wheel compactor.

While some contractors choose to do their soil compressing manually, working with a compactor will save time and costs while being more efficient.

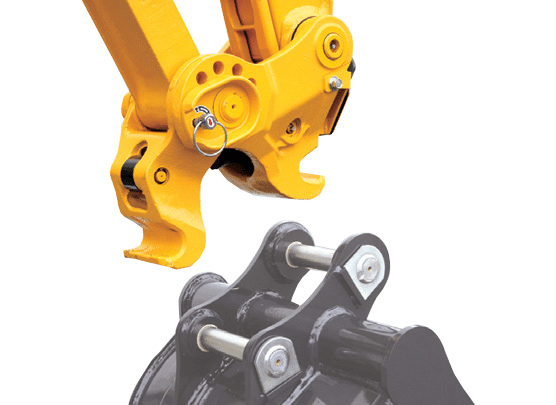

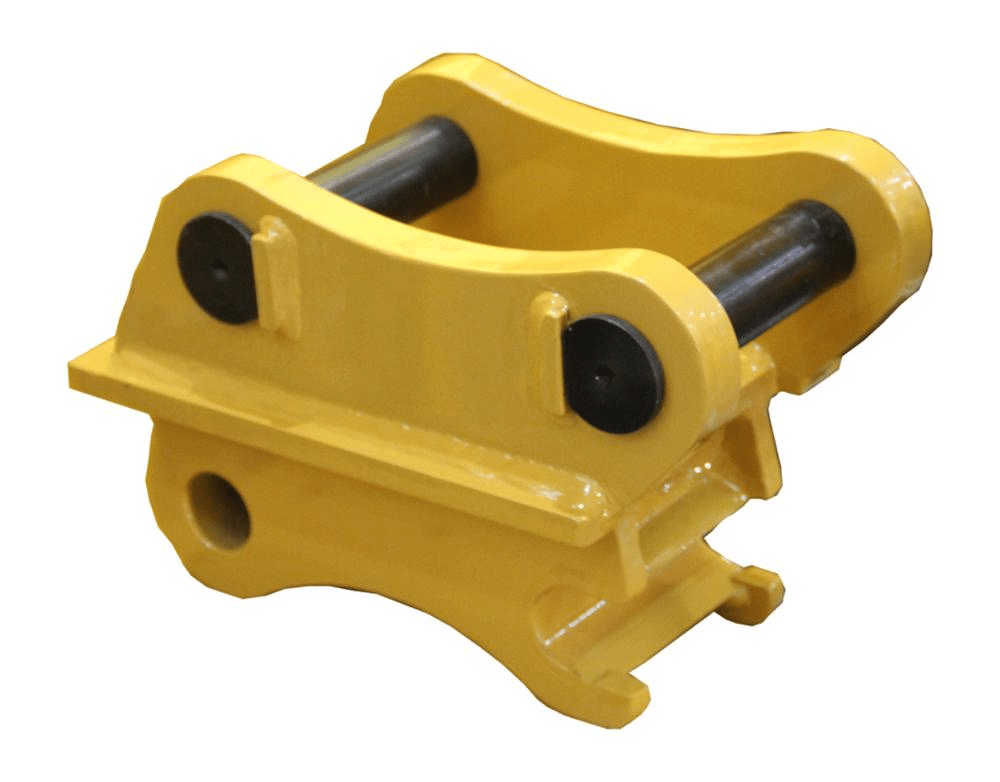

Couplers

For better efficiency at a construction worksite, you must have a coupler.

To begin with, they enable fast attachment changes. So if you suddenly need to replace a bucket with a compactor, a coupler will allow you to do it quickly.

To emphasize this, let’s point out that a glass recycler from South Carolina that uses hydraulic couplers for their heavy equipment saves up to half an hour on changing attachments.

Saving time is especially important for construction projects where such changes occur several times a day.

While hydraulic couplers (also called quick couplers) save time, they also enable operators to work without leaving the cab. Nevertheless, some contractors might find more usability in a mechanical coupler.

For example, if they aren’t in the habit of changing attachments frequently and want to lower their cost, relying on a mechanical coupler makes more sense.

The only downside to mechanical couplers is that the operators have to leave their cab with every attachment change to position the pin into place. This work requires two employees, and the process can become a hassle.

Still, like any other tool, couplers are continuously being developed to ensure better performance and safety.

So deciding between a hydraulic and a mechanical coupler can come down to what makes sense for the company and the scope of a project.

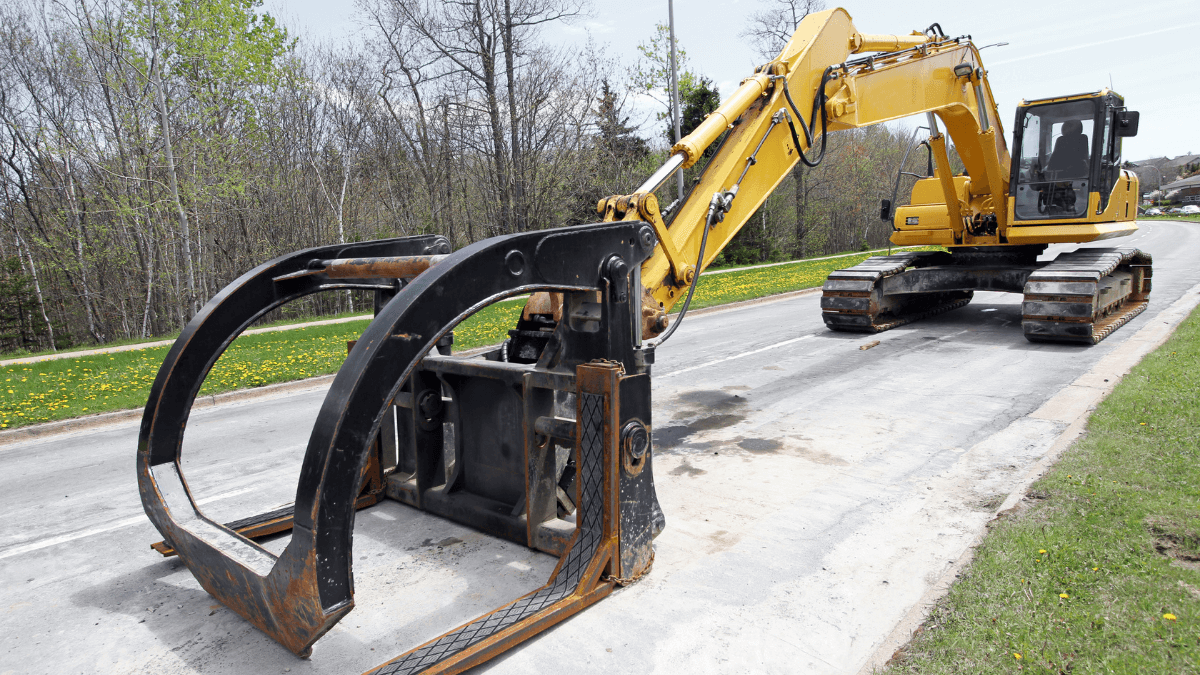

Various Grapples

Even though they’re more common for forestry work, grapples are no strangers to construction sites either.

They have two large claw-like clamps controlled by hydraulics which can rotate and move at an angle. This allows them to lift and move heavy materials of any size and shape.

Their precision and power make grapples useful for demolition, trash removal, and land clearing jobs.

One thing that should be emphasized is maintenance.

Obviously, you should take care of all your heavy equipment and attachments, but grapples require more care. The fingers on the clamp need to be replaced because they get worn out.

If you don’t maintain grapples properly, you risk your attachment losing its grip, which can become dangerous when you’re moving heavy material.

In the end, grapples are great attachments that can handle any type of material and could be used for simple or more aggressive applications.

Hammers

Hammers or breakers are specialized attachments used for breaking up materials.

But they’re not a one-size-fits-all tool. You can choose from different types of hammer attachments, and using the right hammer depends on the material you’re working with.

Here are the three main types:

- Moil

- Chisel

- Blunt

How does each of these work?

First, if you want to break oversized materials with impact breaking, you need a blunt tool. This type of penetration means you need to deliver a high impact over a larger area. That is why blunt tools are the best for large-scale demolition.

Then, you should use a chisel tool for penetration breaking. This is where you need to remove large pieces of material by concentrating energy on a small working area.

This attachment type is more precise because it breaks materials off in chunks. So, chisels are largely used for trenching and utility work.

Finally, a moil tool is most commonly used for the demolition of rebarred concrete. The tool can penetrate through the mesh wires and is useful for breaking concrete buildings and other structures.

So, if you want a precise and controlled demolition, hammers will be there to help you break through the material and allow you to continue excavating.

Flail Mower

When you attach a flail mower to your mini excavator, you can clear any overgrown areas with ease, from highway roadsides to riverbanks. Flail mowers can even handle vegetation growing on hillsides, ditches, and trails.

Basically, any terrain will be cleared with the powerful combination of the long reach of an excavator and the flail knives of a mower.

The best thing about a flail mower is that rotating flail knives bounce off hard objects such as rocks, making them safer to use.

Regular mowers often throw rocks around when they encounter them, which can cause significant damage to people and structures.

Like any other attachment, flail mowers come in various sizes and options, but their main task is to prepare the land by clearing thick trees and shrubbery.

Rakes

Another attachment used for land preparation is a rake.

Like grapples, rakes also have fingers (also known as tines) in various sizes and spacing. Their tines are evenly spaced to smooth out the soil you’re preparing.

With rake attachment, you can clear extra debris and break up large chunks of material to groom the site for any other work you need to do.

Some providers make a distinction between a general-purpose and a land clearance rake. The first type is used to cover a wide area quickly where you don’t need a lot of digging power to break up the soil.

On the other hand, with a land clearance rake, you can find attachments with different gaps between tines. This depends on the type of work you’ll be doing.

For example, when moving large debris such as rocks, it’s better to use thicker tines with larger gaps. However, it’s best to find a rake with a gap between tines that will prevent clogging.

Rake attachments are indispensable for extensive and efficient land clearing jobs, yet they’re very straightforward to use.

Rippers

Rippers make the first tear in the ground when you need to work on tough or frozen terrain.

They are fairly simple attachments that consist of a pointed end that looks like a dinosaur tooth. This shape enables rippers to powerfully cut through any type of hard ground.

Because of this, contractors prefer them when they have to deal with rock, shale, or permafrost.

Another reason why rippers are the contractors’ first choice in breaking the ground is that they’re easy and quick to operate but produce almost no noise.

Dealing with difficult soils is more cost-efficient and productive when you use specialized attachments such as rippers.

A bucket can crack when you try to dig into the frozen ground, so investing in a ripper attachment will be more beneficial in the long run.

Hydraulic Thumbs

For odd-shaped material that doesn’t fit into a bucket, you’ll have to use a hydraulic thumb.

The hydraulic thumb is a large clamp that’s connected to a bucket and holds down the load. This helps transport and remove more material more efficiently, so you’ll significantly improve your productivity.

Hydraulic thumbs are also very easy for operators to handle. They simply use a thumbwheel stick on the joystick to adjust the speed.

Furthermore, thumbs supply extra grip so you can control how much you’re clasping the object without crushing it.

Most importantly, thumbs are incredibly versatile, so you can use them for various jobs.

Whether you’re working in utility installation, landscaping, demolition, road construction, or forestry, hydraulic thumbs will be there to help you grab objects of different sizes.

Conclusion

Excavators are powerful machines capable of handling any intensive construction task.

What enables them this operational efficiency is the right attachments. A single excavator can go from digging to brush cutting with a simple change of the attachment.

Their versatility makes them essential equipment in construction.

So, picking the right attachment for the job is just as important as selecting the right excavator.

Luckily, manufacturers offer a wide variety of excavator attachments, so all you need to do is ask yourself what work you’ll be doing and find what you need.