Key Takeaways:

- Changing regulations increasingly require replacing basic porta-potties with more expensive portable bathrooms.

- Mobile toilets are frequent targets of theft, even on secured construction sites.

- GPS trackers are the most reliable tracking option for outdoor and remote sites.

Portable bathrooms are easy to overlook on busy construction sites, but with rentals costing anywhere between $20 and $50 a week, losing track of them can quickly add up.

This makes asset tracking solutions an investment that quickly pays off.

And it goes beyond the immediate costs, since failing to track portable bathrooms can easily lead to theft, penalties, and dissatisfied crews.

In this article, we’ll break down exactly why tracking portable sanitation matters and which technologies can help you stay in control while drawing maximum benefits.

In this article...

Why You Should Track the Location of Portable Bathrooms

There are several compelling reasons for companies to track the location of mobile bathrooms on or across sites.

Beyond basic inventory management, location tracking improves operational efficiency, protects valuable assets, and ensures timely maintenance.

So, let’s further explore exactly how tracking adds value across your projects.

Optimizes the Deployment of Units

Knowing the exact location of each portable bathroom allows operators to strategically place and relocate units based on real-time demand.

This ensures consistent service coverage on your site while reducing unnecessary travel and fuel expenses.

Investing in optimization also prevents logistical issues, which usually multiply the larger and more complex your projects become.

Dave Peace, an experienced construction project manager, agrees:

Illustration: GoCodes Asset Tracking / Quote: LinkedIn

Securing enough toilets may seem secondary compared to deploying equipment and vehicles.

But imagine bringing together hundreds of workers, only to experience a sanitation mishap.

Before you know it, the entire project can become endangered.

How so?

First and foremost, due to regulatory compliance requirements.

Worker-to-toilet ratios vary by state and jurisdiction, so knowing how many units you have and where they’re located at all times is essential for avoiding fines or site shutdowns.

For example, here’s a breakdown of washroom standards on construction sites for Ontario, Canada:

| Number of Workers | Number of Toilets/Urinals |

|---|---|

| 1-9 | 1 |

| 10-19 | 2 |

| 20-39 | 3 |

| 40-39 | 4 |

| 60-79 | 5 |

| 80-99 | 6 |

| 100-119 | 7 |

| Over 119 | 7+1 for every 30 workers |

But losing track of sanitation facilities goes beyond facing fines, delays, and worker displeasure.

Portable bathroom relocation fees can quickly add up, especially given the sharp increases in fuel prices that put additional strain on construction companies.

Source: Fleet Owner

In such circumstances, efficiency and asset visibility become paramount, and that’s exactly what tracking technology delivers.

With dedicated asset tracking solutions, managers gain more control over the deployment of portable units, making it easier to ensure both compliance and convenience.

Reduces Theft and Loss

Tracking portable bathrooms also deters theft and vandalism while enabling faster and easier asset recovery.

At first glance, portable bathrooms may not seem like high-value targets.

However, even standard polyethylene units can cost over $900 to purchase.

And if you choose to go for accessible models, trailer-mounted units, sinks, and dispensers, the investment becomes substantial, and with it, the appeal to thieves.

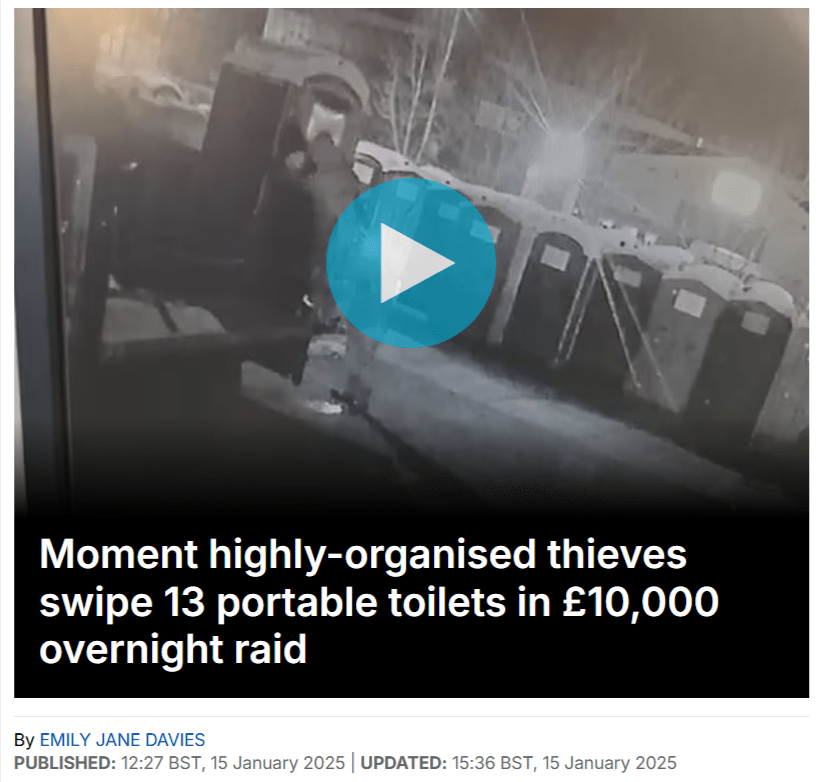

In early 2025, the UK media reported on a string of highly organized thefts, which claimed first 13 and then an additional 25 portable toilets.

Source: Daily Mail

The two thefts resulted in £47,000 in direct damages.

What’s worse is that the consequences for construction companies go beyond finances.

As we’ve already established, inadequate sanitation can trigger regulatory fines or site shutdowns far quicker than missing tools or materials, not to mention impact employee morale and company reputation.

Source: GoCodes Asset Tracking

On the other hand, the consequences for thieves are far less severe.

In one case reported by the Irish Times, thieves made off with over 100 portable toilets, yet faced only light penalties: one man received a 10-month suspended sentence, while his accomplice got six months.

Source: Irish Times

Such light sentences, coupled with the ongoing demand for stolen portable toilets, encourage thieves further, even after you introduce security measures.

Many firms attempt to protect their assets with CCTV and fencing, but according to Mike Dishberger, Vice President of the Greater Houston Builders Association, this is hardly effective:

Illustration: GoCodes Asset Tracking / Quote: Khou

You can weigh or chain down your units, but that’s only a minor inconvenience to a dedicated thief.

And once theft happens, it’s usually final.

Unlike tools or machinery marked with serial numbers or asset tags, most portable bathrooms are unmarked and difficult to trace once removed from a site.

This was also the case with the two convicted thieves—the stolen units were sold to anonymous buyers in the Netherlands, and only three portable toilets could be retrieved.

That’s why location tracking technology isn’t just helpful, but essential.

By equipping mobile units with dedicated trackers, operators can monitor assets in real time, receive alerts for unauthorized movement, and act quickly before losses become permanent.

In the end, where traditional security measures fail, tracking technology acts as a safeguard against a surprisingly disruptive and expensive form of construction site loss.

Improves Maintenance Scheduling

Accurate location tracking also helps operators monitor the usage patterns and movement, which enables smarter, more efficient maintenance scheduling for portable bathrooms.

That means hygiene standards can be consistently met without wasting time and resources on unnecessary visits.

This issue is taking on new urgency in places like British Columbia, Canada, where recent regulations require cleaner, better-maintained facilities at construction sites.

Source: CTV News

The B.C. Labour Minister, Harry Bains, explains that the effective elimination of mobile toilets stems from health and safety issues, and a determination to provide better conditions for construction workers.

Illustration: GoCodes Asset Tracking / Quote: CTV News

As sites adopt more advanced and costly sanitation options, ensuring proper, timely maintenance becomes even more important.

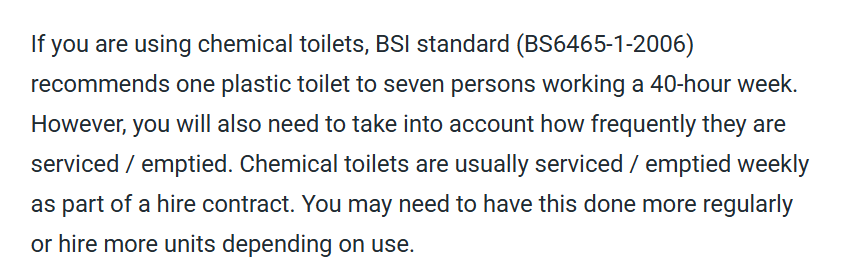

Regular tank emptying, especially for chemical toilets, is a logistical challenge.

According to the Health and Safety Executive (UK), one toilet should serve no more than seven workers per 40-hour week, but actual servicing frequency depends heavily on usage.

Source: Health and Safety Executive UK

So, how does location tracking fit into all this?

For starters, without reliable location and usage data, companies risk either over-servicing bathrooms—thus wasting fuel and labor—or under-servicing them, which invites hygiene problems, environmental fines, and project delays.

This is where location tracking and IoT sensors transform operations.

Beyond GPS or QR code location data, modern connected sensors can:

- Send alerts when tanks reach capacity

- Count door openings to track usage volume

- Monitor movement for unauthorized relocation

As a result, operators can service units when they actually need it, rather than sticking to fixed routes and schedules.

It’s a data-driven way to uphold hygiene standards, reduce downtime, and protect valuable assets.

Robson Gomesuk, an experienced yard and inventory management specialist, shared how he manually worked out servicing needs.

By factoring in 100 workers and knowing each unit held 60–70 gallons for around 200 uses, his analysis showed there was a need for adjustments that enabled business continuity.

Illustration: GoCodes Asset Tracking / Quote: LinkedIn

While effective, this kind of manual estimation is time-consuming and prone to error, especially on larger, multi-site projects.

But with location tracking and smart sensors, those calculations become effortless.

Real-time data on unit location, tank fill levels, and usage volumes turns guesswork into certainty.

Simply put, it’s one more reason why integrating this technology isn’t just convenient: it’s smart business.

Technologies to Use

There’s no single right way to track portable bathrooms. It depends on your budget, environment, and operational needs.

Below are three practical technologies you can use to protect and manage your assets.

QR Code Labels

QR code labels can be easily attached to each portable bathroom, giving workers the ability to scan and update a unit’s status or location using a mobile app.

Source: GoCodes Asset Tracking

While it doesn’t offer real-time tracking like GPS, this method is extremely cost-effective and simplifies inventory checks, especially on controlled job sites or during routine audits.

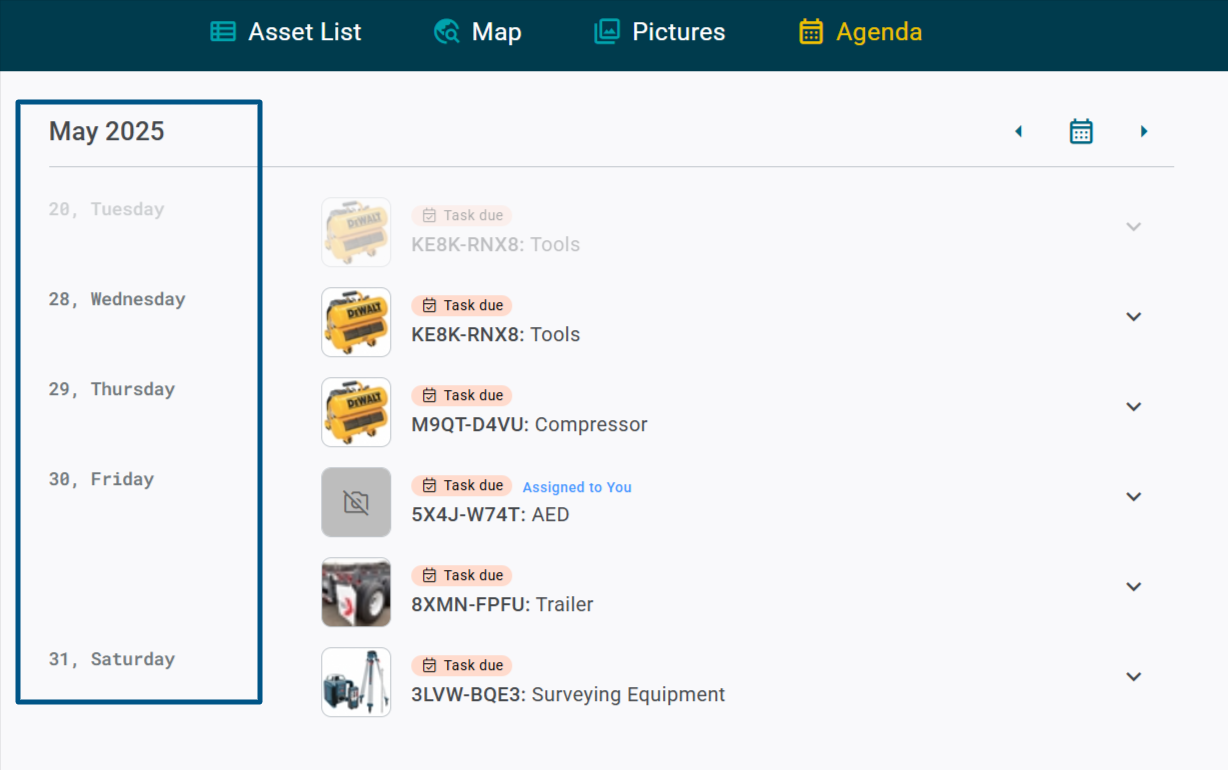

As shown below, maintenance schedules can also be managed through the connected platform, allowing operators to assign cleaning or servicing tasks based on scanned data.

Source: GoCodes Asset Tracking

The biggest limitation is that someone has to physically scan the code for a status update to register.

In other words, the labels can’t detect unauthorized movement on their own, which can leave you vulnerable to theft.

Still, QR codes offer a budget-friendly, scalable option and can be a reliable choice for tracking portable toilet units.

Bluetooth Beacons

Bluetooth beacons provide short-range, automated tracking without the need for manual scanning.

When paired with mobile devices or on-site gateways, they detect proximity and movement, automatically updating asset locations within a localized area.

Source: GoCodes Asset Tracking

BLE beacons don’t require hands-on interaction and scanning, which makes them well-suited for depots, staging yards, or events where portable bathrooms are clustered.

Toms Madžulis, Mapon’s Export Sales Manager, highlights the diverse use cases of BLE trackers, which enable companies to have one solution for both asset and personnel tracking.

Illustration: GoCodes Asset Tracking / Quote: Mapon on YouTube

This can be useful for confirming whether maintenance teams are visiting portable units as scheduled.

However, BLE beacons have limited range, and the lack of infrastructure translates to patchy coverage in open or remote construction sites.

In conclusion, while they’re an upgrade over QR codes, Bluetooth technology still might be better suited for indoor environments.

GPS Tracking Devices

GPS trackers are the most common and the most effective option for asset tracking on construction sites, as well as other open environments like festivals.

These devices use satellite signals to deliver precise, real-time location data, enabling operators to monitor units continuously without relying on scans or proximity.

GoCodes Asset Tracking offers GPS tracking solutions that are specifically built for asset-heavy industries, including portable sanitation.

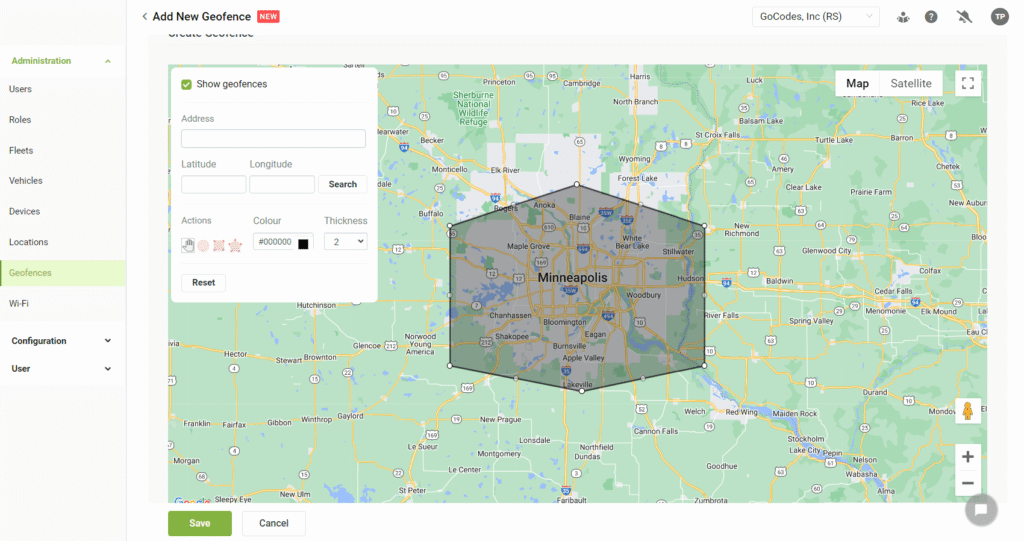

In addition to location data, our system supports geofencing, allowing construction managers to set virtual boundaries around specific areas.

Source: GoCodes Asset Tracking

The best part? You receive automatic alerts as soon as the tracked unit moves unexpectedly, be it the newest excavator model or a portable bathroom.

This makes GPS technology particularly effective at theft prevention, while also facilitating efficient servicing and regulatory compliance.

GPS trackers are a more significant investment than QR codes or Bluetooth beacons, but for high-value or high-risk locations, the added control is well worth it.

Conclusion

Portable bathrooms may not be your highest-value assets, but they play a big role in keeping construction projects compliant, efficient, and running smoothly.

And when these units go missing or aren’t serviced on time, the consequences quickly add up—from regulatory fines and site delays to unhappy crews and reputational risks.

With location tracking technology, however, you’re closing the gap left by traditional security and scheduling.

Investing in smart tracking solutions means protecting your equipment, optimizing operations, and eliminating guesswork when it comes to evolving site requirements.