Checklists are ever-present on efficient and safe construction sites. Project managers should use them just as much, if not more than, their team members.

When construction checklists are an automatic part of life on the site, safety improves and organization is much easier.

While it can be difficult at first to incorporate checklists to a job already underway, once they become an integrated part of the job, accountability, as well as record-keeping, become automatically easier.

Checklists can even uncover problems no one thought to look for.

This information is useful to everyone involved in a construction project: Stakeholders, site employees, administrators, clients, and inspectors.

In this article...

Increasing Accountability

Checklists increase accountability because if a person checks a task off, he or she cannot later say they didn’t do it.

This cause-effect relationship is important in maintaining an orderly worksite and ensuring that all employees can function independently of a manager.

With checklists, employees check themselves, without relying on a person in authority, which helps to instill a routine and maintain safety for teammates.

It is an action item for personal responsibility and specific expectations, and establishes a workflow for specific points in task completion.

There’s a reason why astronauts and ground controllers use them for launches and other high-stakes moments.

Checklists break down complicated tasks into precise steps and act as a backstop to forgetting an action or item.

When filling out a checklist, a person must ask if the item is complete or incomplete, thinking back on past actions, and double-checking for physical items in the proper place.

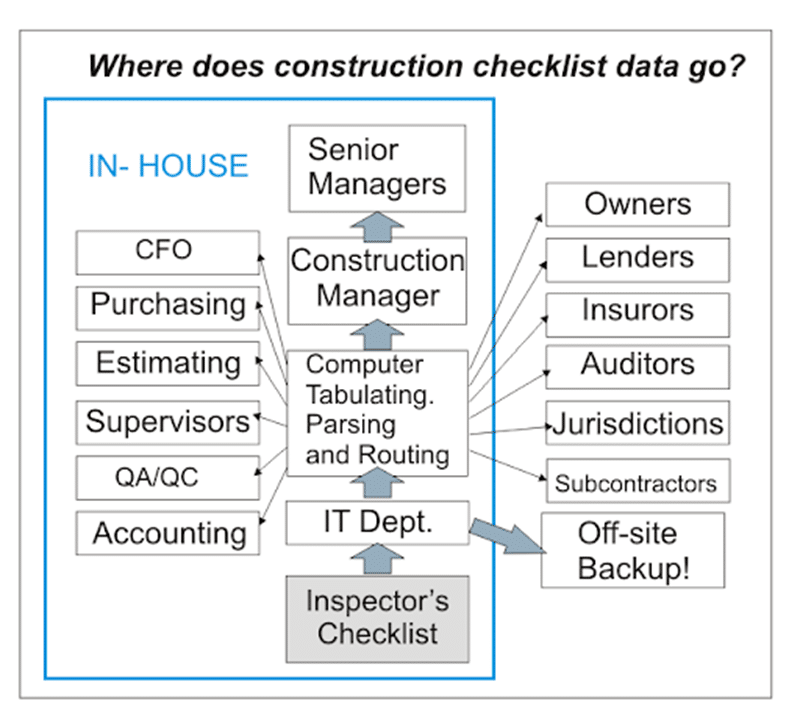

It’s important to impress upon employees that the data they are providing for a checklist is not pointless.

When a team member completes a checklist, it provides valuable information to the entire company and project.

Reminding employees that their participation is the bedrock of this data stream can help to increase accountability:

However, checklists only have the desired effect if they’re immediately applicable to the job at hand.

Asking an employee who runs a cement mixer, for example, to fill out a checklist for grounds maintenance doesn’t make any sense and wastes time.

However, by using digital checklists that are as streamlined and focused as possible, you show that you value the time and attention of everyone on the site.

When employees feel appreciated and responsible for their work, accountability tends to follow.

Improving Workplace Safety

Safety is a constant concern at a construction site. The wellness of the team is paramount.

Sometimes safety checklists can frustrate employees, but these items might have been established as part of a local legal code or union decision.

Moreover, when checklists are the work of more than one person can help prove safety compliance and provide important information to site inspectors.

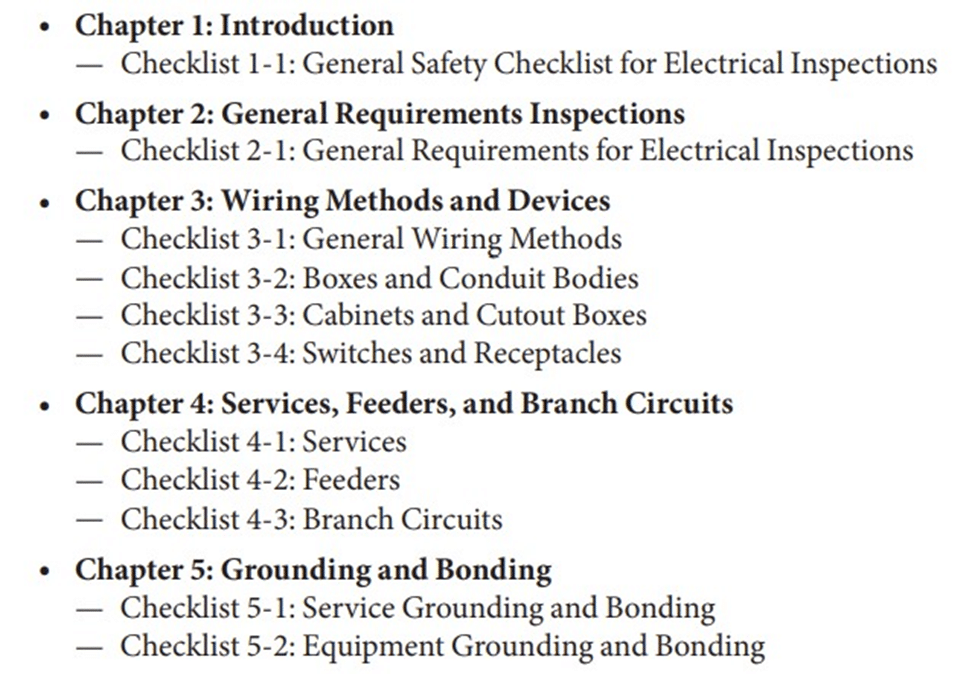

Adhering to workplace safety checklists is especially important when working with heavy equipment, hazardous chemicals, items at great heights, and utilities such as electricity and gas.

These checklists are often highly extensive, as they tend to cover every aspect of a potentially dangerous job.

Here, for example, is just a small part of a general safety checklist for working with electricity:

Moreover, checklists are particularly useful for personal protective equipment, fall protection, and small or emergency tool use.

Revisiting items on a safety checklist on a regular basis can help to ensure that newly discovered problems or code updates are accounted for.

It’s also a good idea to speak to crew members to gather their input on safety concerns—for example, a specific job might provide a hazard that another one might not.

Keeping the safety checklist flexible, relevant, and up to date is best approached as a group project.

Keeping Records to Prove Compliance

Construction worksites are inherently dangerous places. As a result, there are many rules to meet.

The Occupational Health and Safety Administration (OHSA) provides many regulations, and local authorities and unions might demand others.

With so many details to keep track of, checklists are an excellent way to prove that your team is meeting a wide variety of standards:

- Quality

- Safety

- Health

- Environmental

- Legal

- Company/Contractor

When completed and stored digitally, checklists provide a permanent record.

By using cloud storage, this valuable information is maintained off the site, and is far more secure and easy to manage than traditional paper files.

Checklists proving compliance should never have an easy or automatic sign-off.

By signing a checklist as complete, the employee is verifying that quality control was maintained on the site.

There’s no telling when these documents might prove crucial in a legal matter, serving as evidence that certain actions have been performed by your crew.

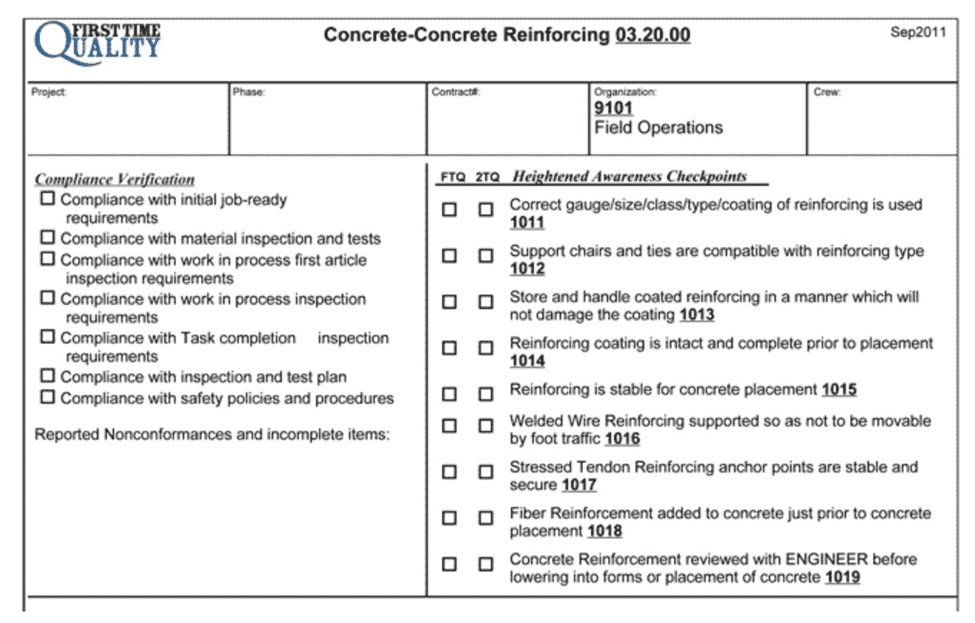

This form referring to concrete reinforcing is a strong example of compliance verification.

It encompasses test plans, inspections, safety issues, and stability checks.

Maintaining specific forms, different for each type of compliance verification, can help avoid redundancies, inefficiency, and employee inattention.

Serving as Reminders

On complex construction jobs involving a wide range of tasks and phases, even across multiple sites, checklists can help each job become manageable.

It might seem daunting to build an entire hotel and conference complex, but it’s less immobilizing to consider what is necessary for a site survey.

Using a checklist to close out a task is an excellent way to ensure that certain tasks are completed.

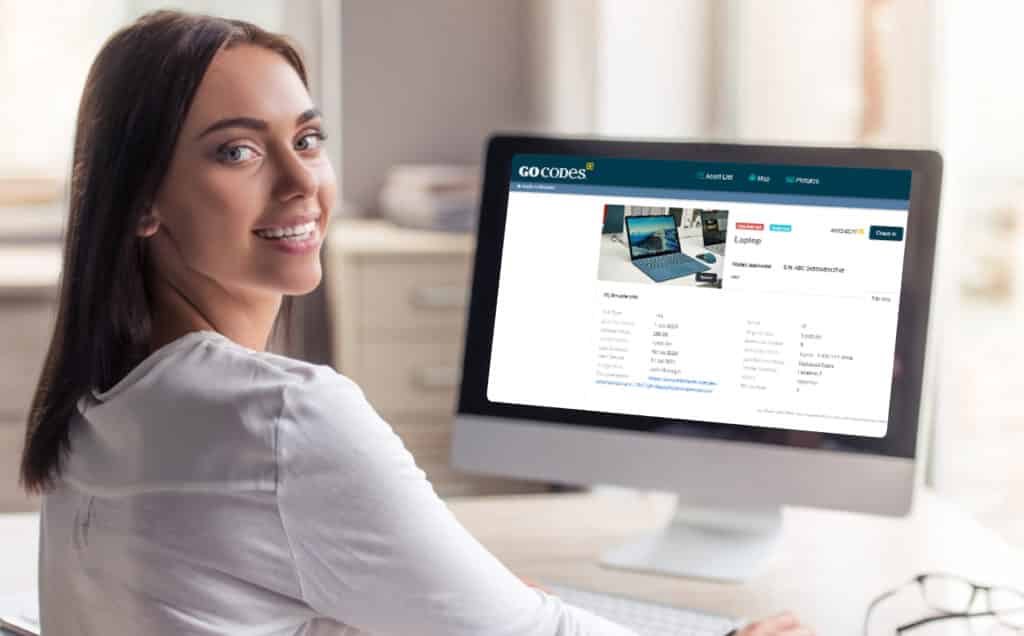

One way to automate checklists is to invest in a flexible and rugged asset tracking system for your company and site.

A trusted asset tracking system can transform an entire company, and certainly a single construction site.

Systems such as GoCodes Asset Tracking can issue pre-set reminders to perform certain actions, and provide valuable information about where items are, as well as when they might come due for maintenance.

Asset tracking systems can send alerts to various personnel as pieces of equipment are moved or shipped, which allows managers to oversee the transit of resources from one site to the next.

GPS systems can even send signals to contractors or site employees to let them know certain items have arrived.

This can easily serve as a trigger to execute certain checklists to integrate the new resource into the worksite, or even check to see which employee handled it last.

Managers can easily integrate such information into refining or streamlining future checklists.

Uncovering Hidden Issues

Construction checklists ensure that you and your team are taking a second look at every aspect of the site at key moments of the day—before starting a shift, when ending one, and perhaps when changing operators.

Running through a checklist on a regular basis can help to detect certain recurring issues with the equipment or other aspects of the construction site, and make the maintenance teams intensify their efforts.

Preventive maintenance is an important aspect of construction.

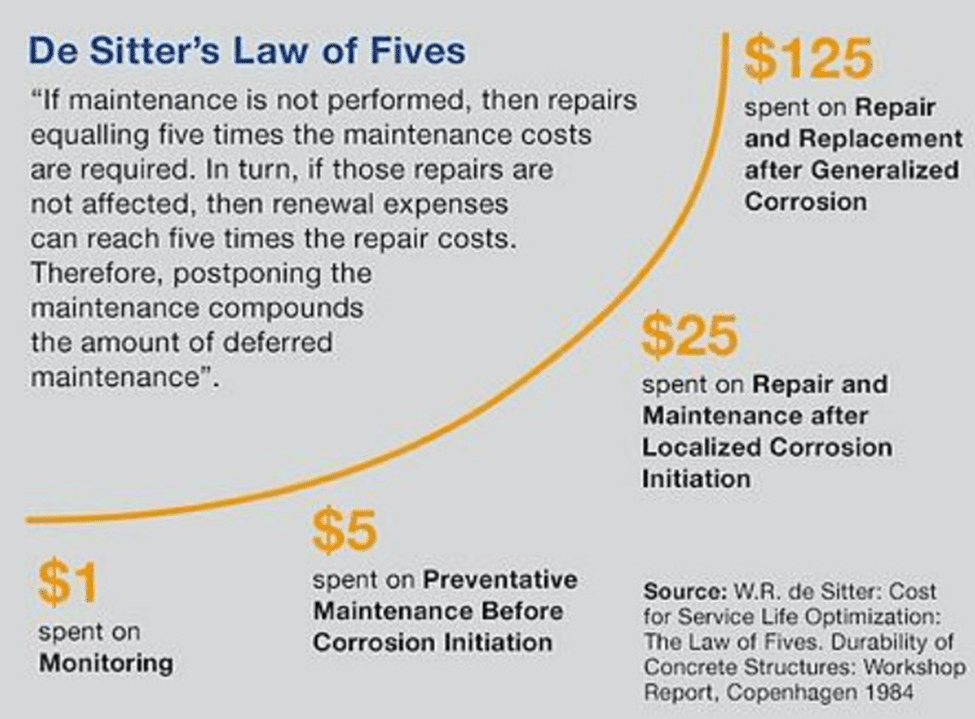

Not only does it keep machines of all sizes in good repair, it can even save a great deal of money, as shown in this illustration of DeSitter’s Law of Fives:

As this shows, it is far cheaper to spend money on monitoring, preventative maintenance, and repair rather than rushing to replace an item or spend time on major repairs.

When potential downtime or the cost of equipment rentals are taken into consideration, these costs can increase even more.

The best way to track preventive maintenance and early repairs is with a solid checklist and employees trained to use them at proper intervals.

Asset tracking systems can contain not only maintenance reminders and checklist alerts, but also operator manuals, warranty information, and vendor contact data.

These are invaluable checklist integrations when it comes to keeping expensive and vital equipment in good repair.

Monitoring Team Performance

Teams work best when they are well-trained, trusted, and given appropriate responsibility in their work.

One of the best ways to track their progress and find ways for them to improve is to monitor performance and share data as necessary.

Checklists are immensely helpful in monitoring team performance.

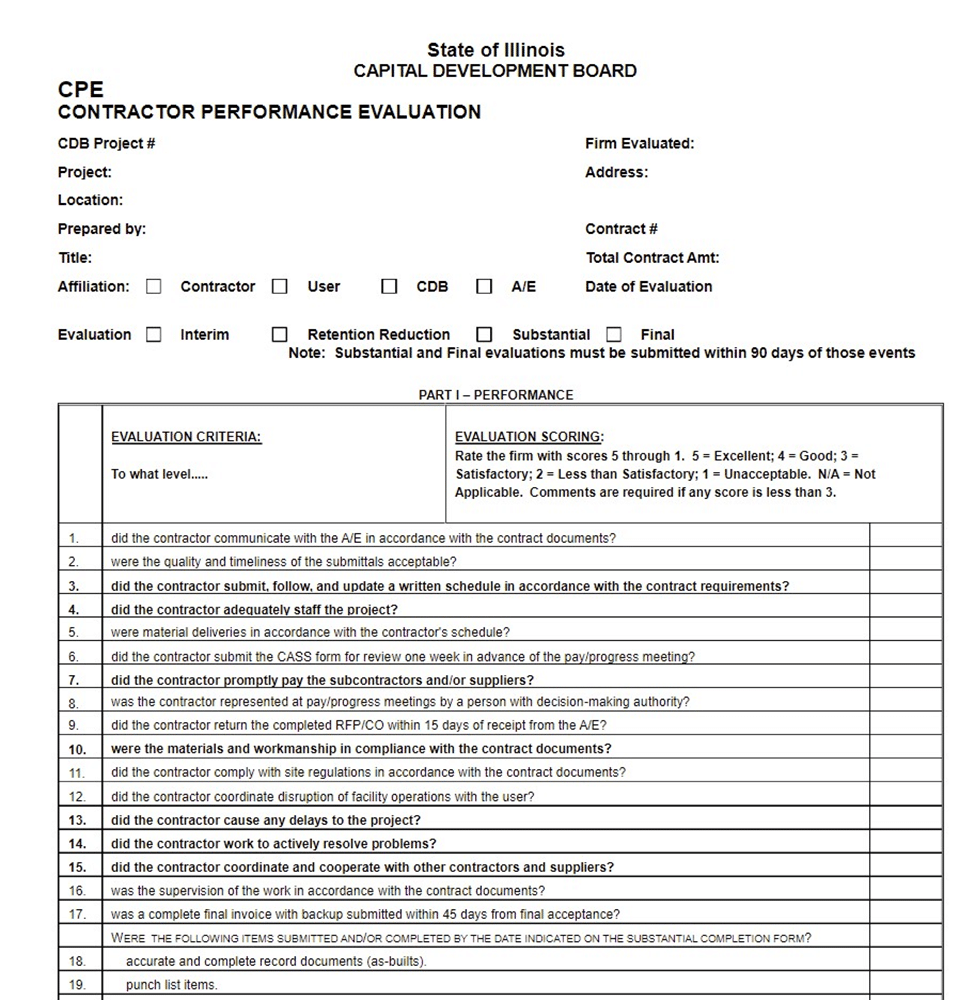

They provide precise areas of evaluation and are easily modified to link performance to task, as this contractor evaluation checklist from Illinois demonstrates:

Transparency with such checklists is essential. Employees deserve to know how they are evaluated, and on what grounds.

This comes into play with especial importance when it is time for a performance evaluation, or if your company is sued for wrongful termination.

In addition, the ability to track and prove performance drops or gains is extremely helpful when amassing data on how to best motivate employees.

The best way to do so in an organized, objective fashion is to meld task and job checklists with team performance.

Conclusion

Several benefits arise from using a construction checklist. They can help a company and specific job run smoother, more safely, and with more accurate data.

A robust asset tracking program such as GoCodes Asset Tracking can contribute greatly to effective construction checklists.

Construction checklists increase accountability and improve workplace safety. They also help to prove compliance and serve as reminders for important tasks.

In addition to helping to uncover hidden issues, construction checklists are also useful in monitoring team performance.

Once you’ve experienced the many benefits of construction checklists, you’ll never stop using them again.