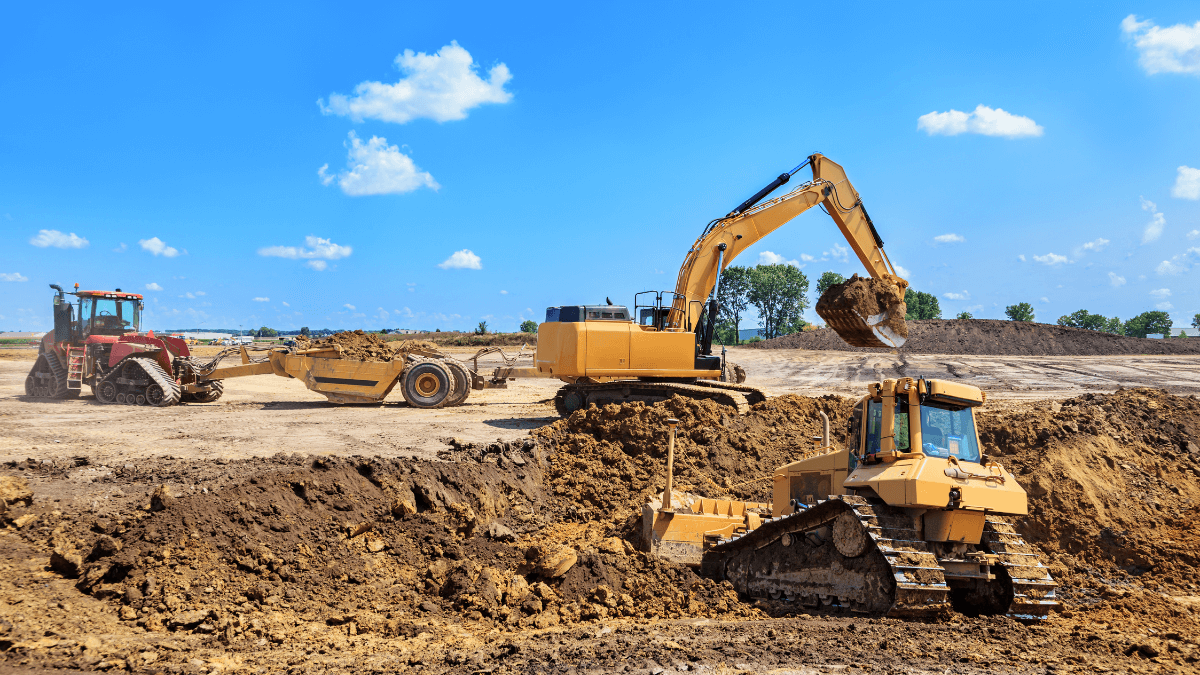

Whether you’re digging trenches, adding an in-ground pool, or removing trees and foliage from the construction site, you are going to need earthmoving equipment to get the job done.

Seeing as there are various types of earthmoving equipment, choosing the right one for the job might seem challenging.

However, in this article, we are going to help you with that.

If you’re wondering what factors you should take into consideration when picking earthmoving equipment for your project, in this article, you’ll find the information you need.

In this article...

Determine the Type of Work You Need Done

When it comes to choosing the right earthmoving equipment for your project, the first question you need to ask yourself is, “What type of work am I going to be doing with it?”

Given that there are various kinds of earthmoving equipment on the market, it is important to properly match the type of machinery with the work that needs to be done.

Earthmoving machines can be used for a wide range of jobs on the construction site—from loading and transporting materials to “mining, grading, digging foundations or trenches, and clearing vegetation”, according to Connect2Local.

So to get the most out of your equipment, it is recommended that you use it for the kinds of tasks it was specifically designed for.

Ross Collard, managing director of HPE Africa, explains:

This means that it would be beneficial to make a list of all tasks your team will need to complete during the project and then determine which earthmoving machines they’ll need to complete them.

For example, you are bound to use an excavator, as this is one of the most versatile earthmoving machines, from drilling holes to moving trees, as well as just excavating.

However, just because one piece of equipment has the ability to perform various tasks, it doesn’t mean that it’s necessarily the best choice for all of them.

That is why it is recommended that you carefully consider what type of work you want to complete before you determine which machines are best suited for those tasks.

Opting for the right piece of equipment is going to help ensure that you get optimal results and maintain construction site safety.

Consider the Size of Your Construction Site

Another factor to take into account when choosing the equipment for your project is the size of the construction site you’ll be working on.

In addition to the kinds of tasks they can complete, earthmoving machines also vary in size.

Therefore, if the construction site they’re supposed to be used on is relatively small in size, bigger machines may not be the best option, as they can damage their surroundings for lack of maneuver space.

This is particularly dangerous if there are gas lines and other pipes on site.

So, what can you do to prevent such issues on sites with limited space and mobility?

According to David Caldwell, National Product Manager of Takeuchi Construction, if you do business on smaller sites, you may want to consider investing in a compact excavator, also known as a mini excavator.

Regardless of their size, mini excavators can perform various tasks without the risk of causing damage.

What is more, compact excavators are becoming increasingly popular and used on larger projects and sites as well, according to Tim Boulds of Kubota.

He says that “the compactness of these powerhouses allows them to be more versatile than the larger conventional full-size backhoe, and also take on larger projects when needed.”

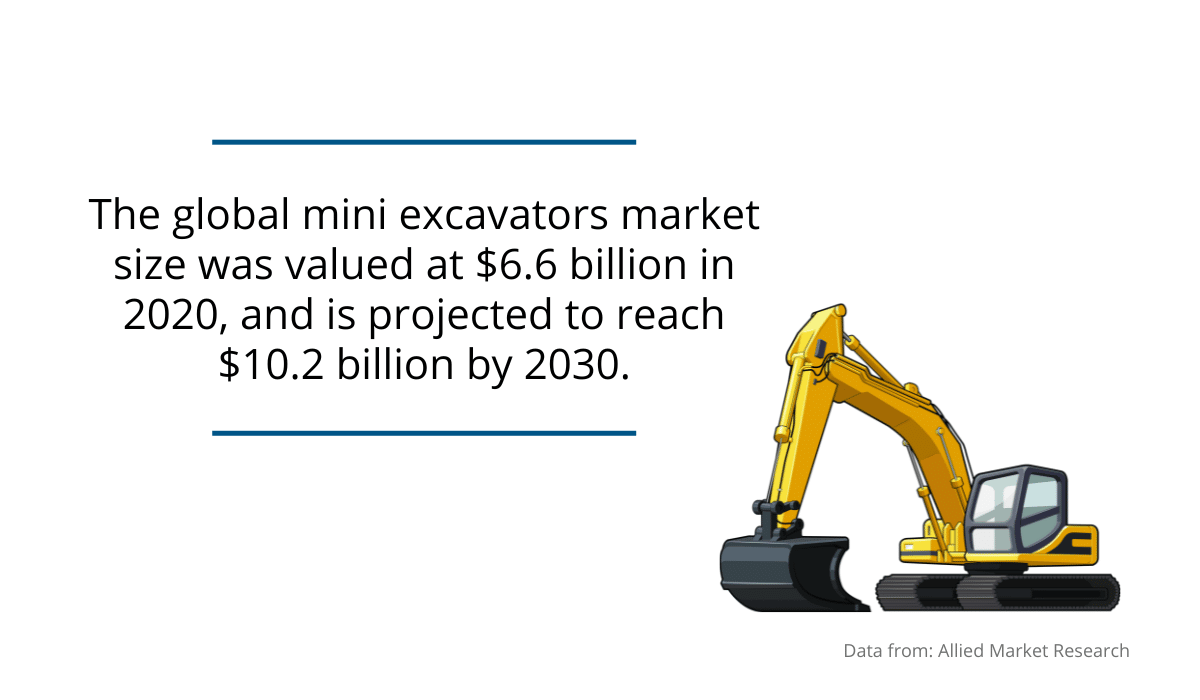

Boulds’s statement about the rising popularity of compact earthmoving equipment can be backed up by research conducted by Allied Market Research:

The bottom line is: whether your projects take place on large construction sites or in tight urban spaces, investing in compact earthmoving equipment that fits the size of the construction site might be a good idea.

Know What Materials You Need Moved

When determining the type of earthmoving equipment you need, you also need to consider what kind of materials you will be moving.

In fact, according to construction industry experts, materials should be your top consideration when deciding which earthmoving machine to use.

With the machines for moving jobsite material, there is no one-size-fits-all—different machines will be suitable for different materials.

It’s important to keep that in mind, because opting for a less-than-ideal piece of equipment can cause damage to the machine itself or prevent you from getting the job done.

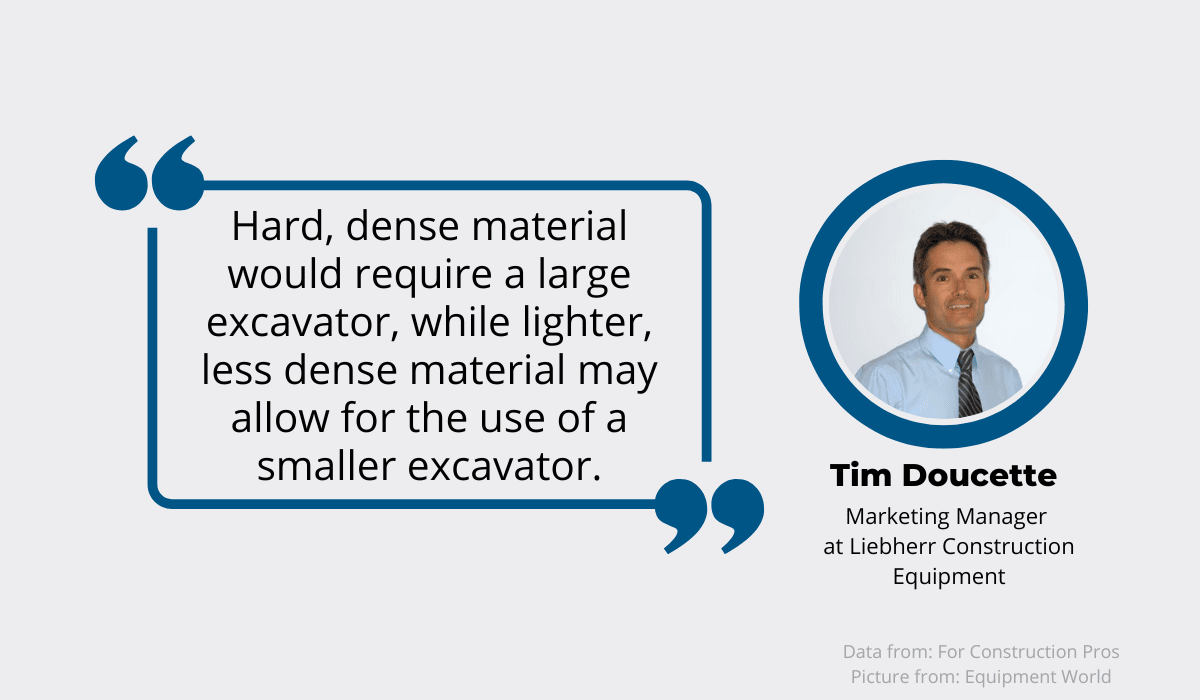

For instance, here’s how Tim Doucette, marketing manager at Liebherr Construction Equipment, describes the way in which the density of the material affects the choice of excavator in construction projects.

Apart from using an excavator, engineers also recommend using tractor scrapers and articulated trucks for moving material.

Tractor scrapers are well-suited for moving materials that are smooth and easy to spread, such as sandy loam soil, explains Fred Casten of Terex Construction.

And while scrapers are the cheapest way to move material under the right conditions, they don’t tend to do well if you’re dealing with wet, sticky clay or rocky soils. In that case, Casten advises opting for articulated trucks.

In short, being familiar with the material you’ll be moving and choosing the right machine to do so can help you avoid problems in the future.

Evaluate the Ground Surface

In addition to the size of the construction site and the materials you’ll be handling, consider the terrain you’ll be working on.

Taking the time to assess the ground surface plays an important role in making sure you don’t damage your equipment.

Is the ground flat and solid, or is it more on the soft and slippery side? Depending on what your answer is, you’re going to opt for earthmoving equipment with either tracks or tires.

The main difference between tracked equipment and equipment with tires is in the way that they distribute weight, which is particularly important when working on soft and slippery ground.

Given that tracked earthmoving machines have a lot more ground contact than their wheeled counterparts, they are the better choice for working on surfaces that aren’t solid and stable.

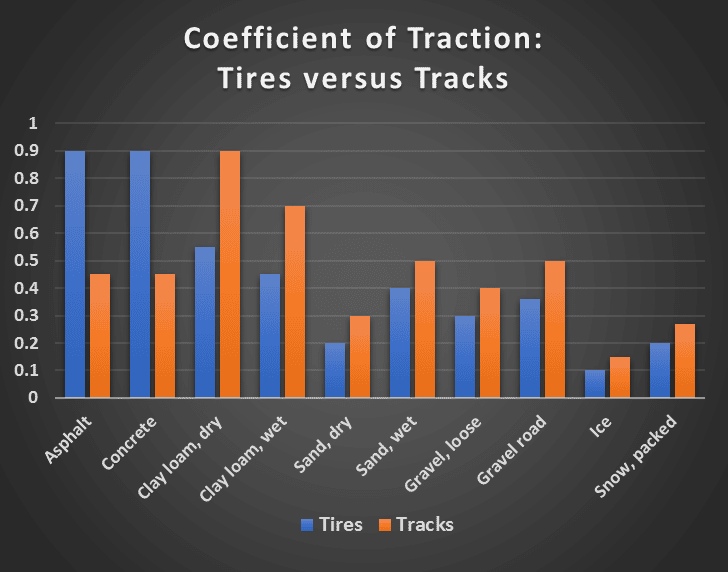

A study conducted by Final Drive Parts supports this statement.

As you can see, earthmoving equipment with tires performs better on solid surfaces such as asphalt and concrete, whereas equipment with tracks has better traction on loose and wet terrain.

Choosing earthmoving equipment based on the type of ground you’ll be working on is crucial for maintaining the mechanical health of your machines.

Regardless of which kind of earthmoving equipment you choose, make sure to inspect it for damage potentially caused by the ground conditions.

The GoCodes Asset Tracking tool tracking software can help with that.

It will allow you to scan asset tags you applied to your earthmoving machines in order to access their maintenance logs, as well as schedule them for routine maintenance.

Know the Types of Earthmoving Equipment

Apart from familiarizing yourself with the type of work you’ll be doing and the conditions you’ll be doing it in, you also need to invest time into learning about the different types of earthmoving equipment.

At first, that might seem like a daunting task, given that the market is saturated with so many types and models of equipment.

We’ll go over some of the most commonly used ones in order to provide you with a general overview.

An excavator primarily digs and removes soil and rocks. However, it also carries out other tasks with the help of attachments: material mixing, pipelaying, drilling, and more.

Next, a skid steer loader works well in tight urban spaces and on small lots due to its smaller size.

It has a front attachment that can be switched out for a bucket, a rotary hoe, a hammer, a pallet fork, and various other attachments.

Its functions include lifting materials, cleaning up the site, excavating, and breaking rocks.

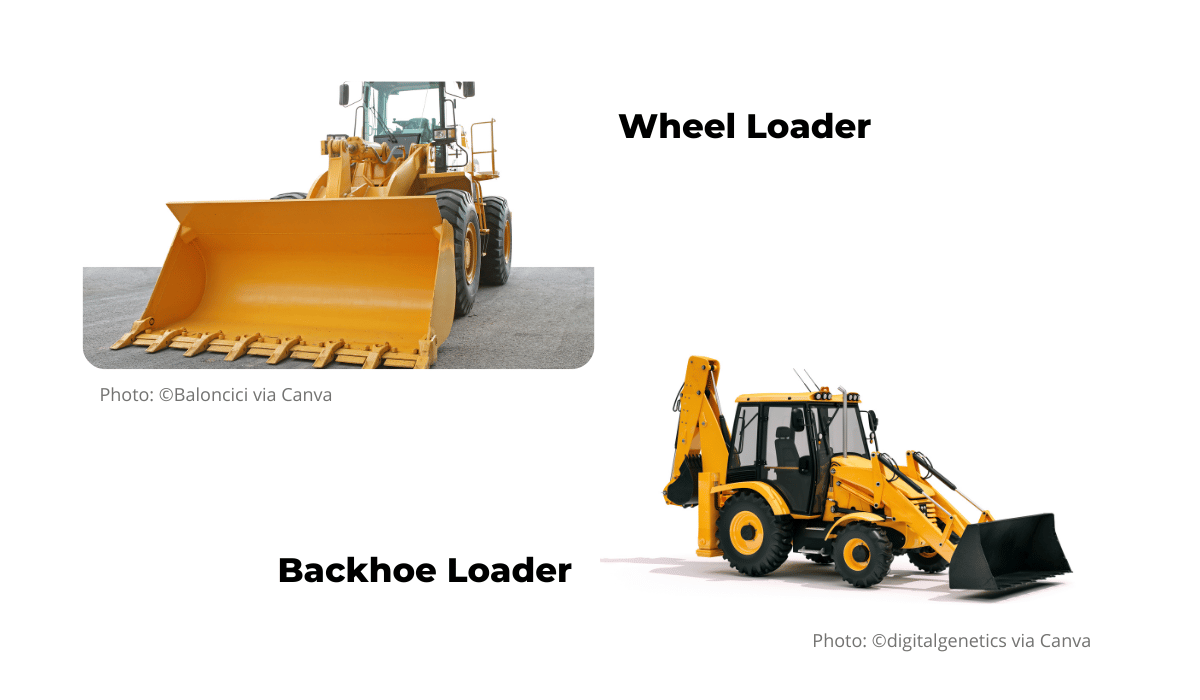

Another such versatile piece of equipment is the wheel loader.

Its main purpose is to transport heavy materials, such as dirt and rocks, with the help of its front bucket, but it can be adapted for other tasks like backfilling, material mixing, and soil stripping by removing the bucket and fitting a different attachment.

Similarly, a backhoe loader loads materials with the bucket in the front and excavates with the bucket in the back.

It also allows for the buckets to be removed in order to place attachments for tasks like landscaping, battering, lifting and breaking rocks.

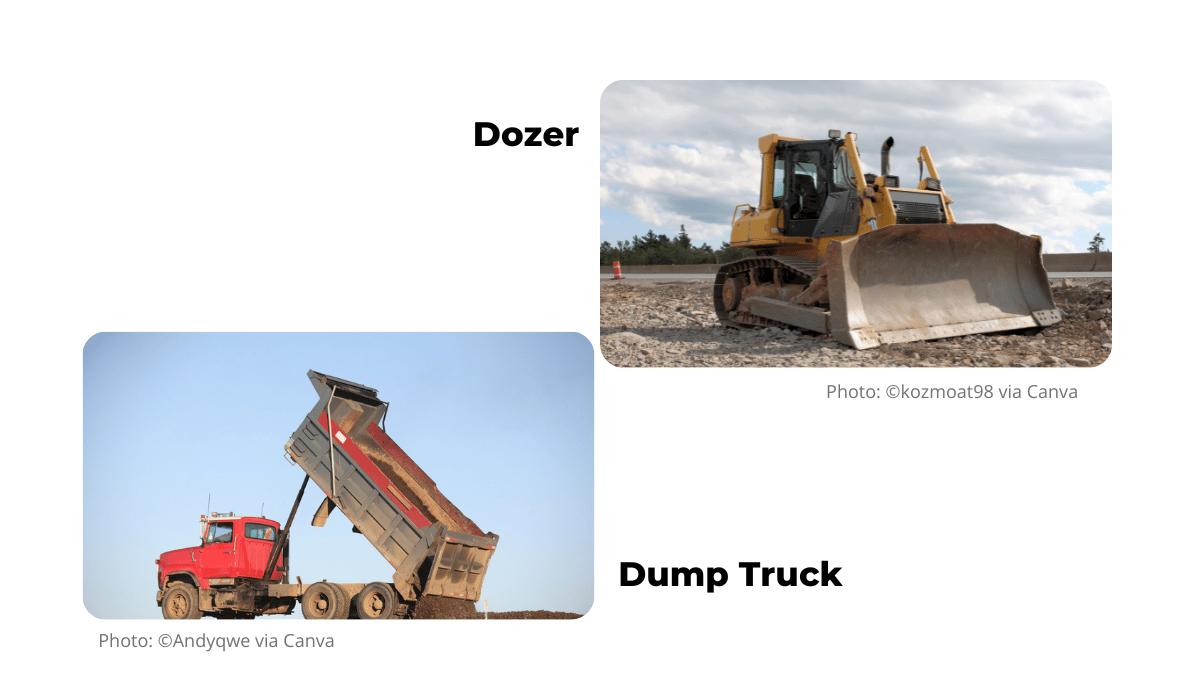

If you need a piece of equipment that can help with leveling and drain cutting, as well as clearing land and towing, a dozer (also known as a bulldozer or crawler) is the right choice for you.

The machine pushes materials such as dirt and rocks with the blade mounted in the front and has a ripper in the back that breaks hard materials into smaller pieces.

Finally, a dump truck is essential for transporting large amounts of material from point A to point B and, as the name implies, dumping them.

Being familiar with various types of earthmoving equipment and the types of tasks they can be used for is extremely helpful when choosing pieces of equipment that match the requirements of the project you’re working on.

Consider the Equipment’s Capacity

Once you start doing research into different types of earthmoving equipment, you’ll notice that the machines differ in size and capacity, too.

The amount of material you’ll be able to lift and transport will depend on the size of the machine you opt for.

So, how do you decide whether you need large or small earthmoving equipment?

According to Warren CAT, one of the biggest Caterpillar® dealerships in North America, “you should weigh your decision on the proper size of construction equipment based on the entirety of your needs and operating budget.”

As they sum it up:

Keep in mind, though, that larger machines won’t always be the better choice.

If you’re working on a project where the hauling distance and the material load are smaller, going for larger, more robust equipment may be a waste of money.

Larger equipment with bigger capacity is, however, the right choice if the hauling distance is longer and you need to move a large amount of material.

While it is the more expensive choice, you won’t have to worry that the large loads of material and long distances will push the machine too far and cause it to break down mid-project.

We recommend you take plenty of time to accurately assess the equipment size and capacity your project will require.

By doing so, you are helping prevent accidents and breakdowns that could occur due to mismatched machine size and material load.

Think About the Equipment’s Reach

Lastly, don’t forget to take the reach of earthmoving equipment into account when weighing your options.

What we mean by that is, ask yourself how high you’re going to need your equipment to lift the materials and how deep and wide you’ll need it to dig.

When it comes to making cuts of different depths and lengths, Scott Knoblauch, earthmoving consultant at Caterpillar Inc., goes for either a wheel tractor scraper or an articulated truck.

To sum up: if you need to dig deep, you should opt for earthmoving machines with longer articulated arms.

The second factor you should consider is how high you’re going to need to lift your materials.

If you are building, for instance, a skyscraper, you’re eventually going to need to lift your construction materials to the upper levels of the building.

In such a case, you are going to opt for an earthmoving machine with a long arm and a crane boom that is going to allow you to lift those materials effortlessly.

If, however, the construction materials don’t need to be lifted very high, smaller machines, such as skid steer loaders or dozers, will get the job done.

Conclusion

Choosing the earthmoving equipment that is the perfect fit for your project can be a challenging task, given that there are many factors you need to take into account.

We recommend you start by determining what kind of work you’ll be doing, how big the construction site is, and what kind of soil and materials you’ll be moving.

In order to make an informed decision about what earthmoving machines are right for you, make sure to do research into the various kinds available on the market.

Lastly, think about the size and capacity of the earthmoving equipment you’ll require, as well as how deep you’ll need to dig and how high you’ll need to lift your materials.