If you’re running a construction company, you’re probably dealing with complex logistical matters and managing your assets and jobsites, while also trying to grow your business.

Staying on top of all the work that entails takes a lot of energy.

However, there is a way to run your business smoothly and scale it up in a way that makes things easier for you, and it includes asset monitoring.

In this article, we’ll examine what asset monitoring is, why it’s important for the success of your business, the common technologies used, and how to choose the one that would best fit your company’s needs.

In this article...

What Is Asset Monitoring

Asset monitoring is the process of tracking physical assets remotely, using specialized hardware and software.

The practice, boosted by specialized equipment, helps companies keep track of all important movable assets and their location, ensuring they are secure and in good shape.

From tools, equipment, and computers to vehicles, machinery, and shipping containers, asset monitoring allows for accurate and efficient asset management.

It provides detailed information on an asset’s name, location, and status, notifies managers about asset damages or failures, and helps schedule maintenance.

Asset monitoring software can also help you track asset life cycles, maintenance records, and work orders.

Overseeing fleet vehicles, equipment, and heavy machinery is a daily task in construction management.

And one of the most effective ways to handle that and similar tasks is through asset monitoring.

Why Monitoring Your Assets Is Important

Your company’s physical assets provide great value to your business and are vital for its overall functioning and daily operations, especially in the construction industry.

It’s the leading reason companies turn towards solutions that will enable them to keep track of their assets and know their whereabouts and conditions.

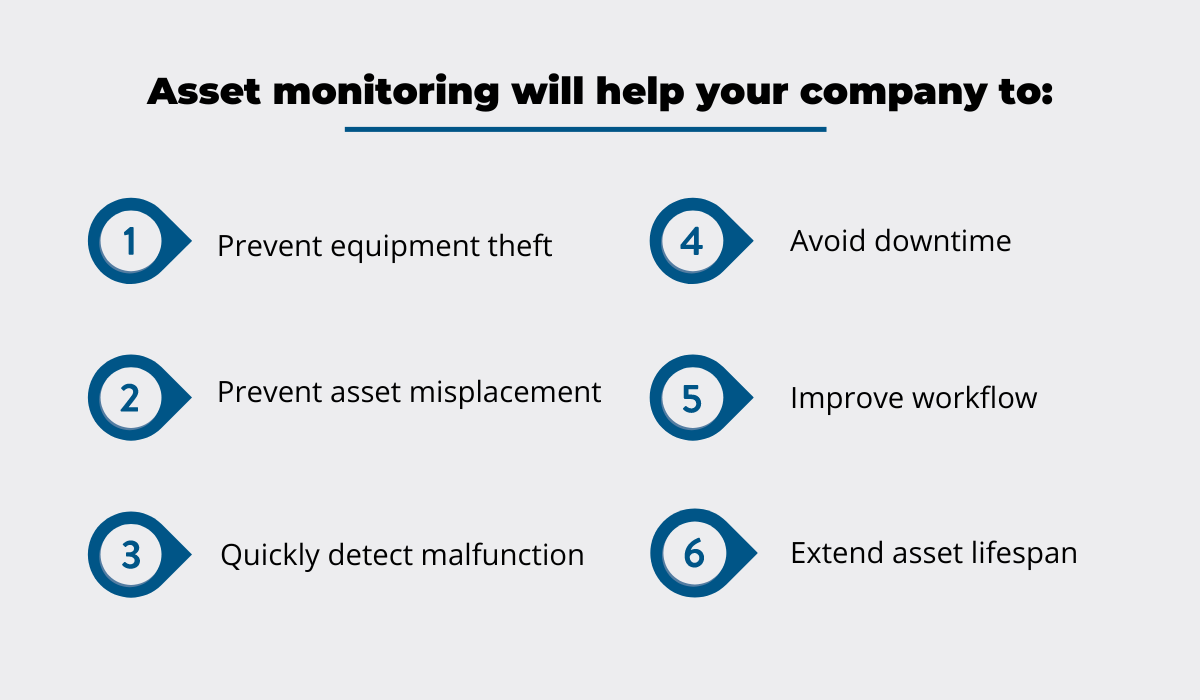

An effective asset monitoring solution prevents you from losing more assets to theft and misplacement or procuring needless duplicate equipment.

It can also help you avoid downtime by detecting maintenance and service needs as soon as they occur.

In other words, keeping your equipment and machinery in working order and knowing where they are, prevents losses and maximizes asset utilization.

Investing in an asset-tracking system will benefit your business on several levels.

It will help you cut costs, improve workflow and productivity, and introduce more efficient ways of doing things.

Let’s dive deeper into some of the key benefits of asset monitoring and tracking for your construction business, starting with improved asset utilization.

Maximizes Asset Utilization

Construction companies, by necessity, have considerable investments in equipment. To maintain productivity and profitability, they have to utilize their equipment optimally.

One major obstacle to efficient asset utilization is inadequate deployment.

Put simply, if a construction company doesn’t monitor its assets, some may end up overused while others are left idle.

Asset monitoring software would enable managers to establish the time, place, and condition of the assets put in use, allowing better planning and prioritization.

It can make a remarkable difference in ensuring that a piece of equipment is utilized precisely where and when it’s needed.

An even bigger problem when it comes to company assets is unscheduled downtime—the hours lost to unexpected or emergency repairs—typically due to poor preventive maintenance.

A solid preventive maintenance plan anchored by specialized asset monitoring software will give you the power to adjust quickly and efficiently to changing requirements.

This will change the equation and help your company maximize equipment utilization, complete construction projects on time and within budget, and meet profitability targets.

Compared to the traditional approach to asset monitoring, which involves a lot of manual work and administrative costs, modern software solutions are more time and cost-effective.

In conclusion, poor asset utilization costs construction companies money.

That is to say, if you allocate and use your assets most effectively, your company will make more profit.

Extends Asset Lifespans

Making the most of their physical assets is the ultimate goal of any enterprise for a simple reason—the longer the assets are functional, the longer they will bring in revenue.

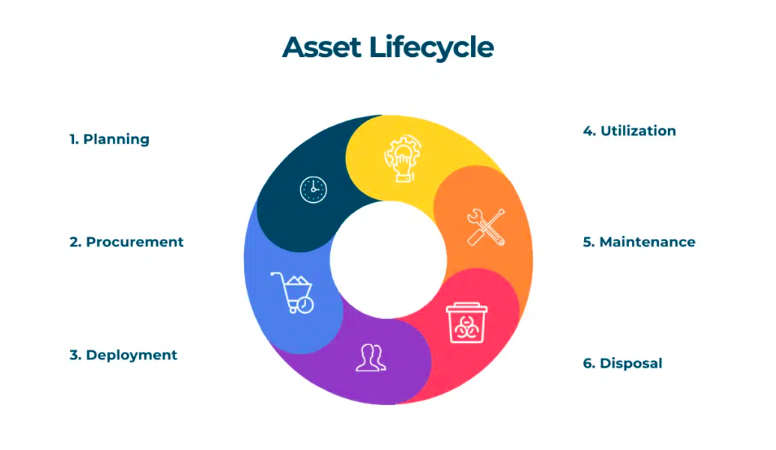

Every piece of equipment, machinery, or tool has a lifespan, which is basically the time between procurement and disposal.

If a construction company’s assets are poorly maintained, they are more likely to break down unexpectedly in the middle of a construction project.

That would not only cause costly repairs but also downtime, delays and financial losses.

To extend the functionality of critical assets, it’s important to follow a regular maintenance schedule.

Therefore, monitoring the life cycle of your assets is integral to a robust preventive maintenance strategy, which will help keep your company’s assets in good condition and extend their lifespan.

Asset monitoring software provides vital information about the asset’s usability in real time, increasing its potential to serve for as long as possible.

Namely, this software keeps records of each asset; it can inform you of the last maintenance date and when the next one needs to occur.

This way, you can schedule maintenance activities without interrupting daily work.

Another essential feature is that asset monitoring software allows you to almost simultaneously detect damage or malfunction of the equipment, cutting the time needed to schedule a repair.

Once you have all this data to back up your decisions and planning, you can certainly expand your assets’ lifespan and, by doing so, achieve better operational efficiency.

Minimizes the Risk of Theft

Preventing theft is the most crucial benefit of monitoring your high-value assets closely.

Equipment, tools, and building materials often get lost or stolen from worksites, damaging the company’s operations and productivity.

According to Kendall Jones, editor-in-chief at ConstructConnect, the replacement cost is just the start of a company’s problems if equipment gets stolen:

Additional costs associated with stolen construction equipment include renting replacement equipment, lost productivity, schedule delays, increased insurance premiums, and missed deadlines, which can result in hefty penalties.

Construction equipment, raw materials, and even brand-new appliances are not only highly valuable but also in high demand, which incites criminals to choose to go after them.

Most thefts are crimes of opportunity when assets are left unsupervised or in poorly secured on-site storage.

Therefore, investing in equipment tracking solutions will undoubtedly protect your assets and your business.

The theft prevention feature of the asset monitoring technology consists of attaching unique identifiers to the equipment and tools, like tags or labels, and tracking them via a cloud app installed on your smart device.

The thieves—whether the company’s own employees or external criminals who know the value of construction assets—are far less likely to try to steal them if they notice the attached monitoring technology.

In addition, when the equipment is protected by technology, say GPS trackers, the construction company has a higher chance of recovering their assets, and the thieves are less likely to get away with it.

In essence, an asset monitoring solution is cost-effective and easy to implement, and it will provide all the security you need.

Common Technologies Used for Monitoring Assets

Choosing the right asset monitoring technology can be a challenging task.

Nevertheless, you should focus on a few key aspects that could help you make an informed decision.

These include your current needs, the number and value of the assets, ease of installation and use, and purchasing and maintenance costs.

This article addresses four primary technology categories behind asset monitoring solutions, each with its distinct features, advantages, and shortcomings.

QR Codes

The Quick Response code is a type of two-dimensional scannable code, which, compared to its forerunner, the regular barcode, offers 300 times more data storage and enhanced functionality.

Each QR code comprises a unique pattern of black and white squares, which almost instantly turns into readable data when scanned with a smartphone or an app.

This technology’s usage has seen an epic revival and is still on the rise. Between 2018 and 2020 alone, QR interactions have increased by 94%, as cited by Blue Bite.

The implementation of QR codes is spreading rapidly in the construction industry because it enables managers and workers to easily track and manage construction materials, tools, equipment, and inventory.

For instance, the asset monitoring solution offered by GoCodes Asset Tracking works as follows:

QR code tags are attached to assets.

Scanning them with a smartphone lets you quickly access relevant information, including the asset’s location, availability, manufacturer data, maintenance history, etc.

From the mobile app, you can also view and input any updates and perform different actions, such as scheduling maintenance, assigning work orders, or performing audits.

These changes are instantly uploaded to a cloud database, which can be accessed anytime from any device, ensuring easier and regular information sharing for immediate action.

Using QR codes for tracking assets is an affordable, easy-to-use solution applicable to construction equipment of all shapes and sizes, significantly reducing the risk of lost or misplaced items.

If an asset is lost or stolen, it will pinpoint its last known location. However, on the downside, QR code technology can’t provide real-time tracking.

Another feature that limits their capabilities is that they require manual scanning, making them less efficient for large-scale asset monitoring and management.

GPS

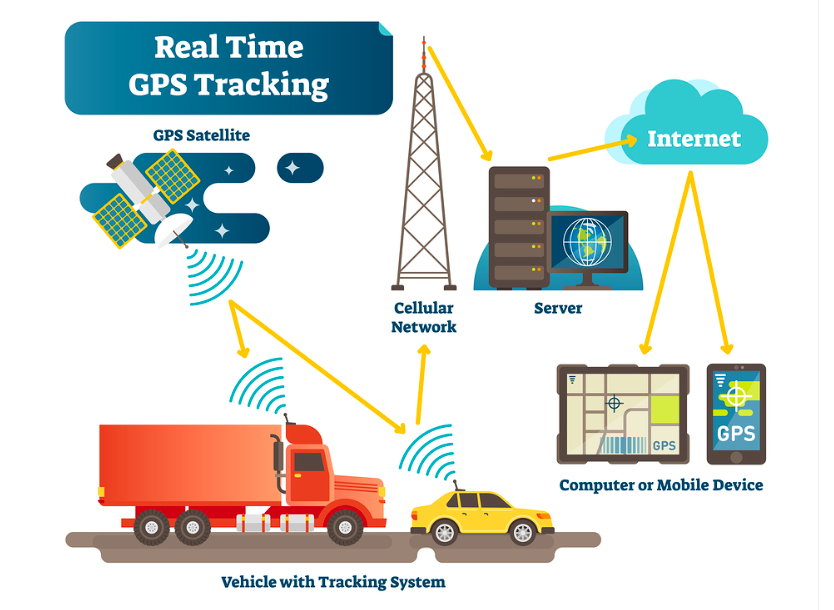

Global Positioning System (GPS) is used to determine the exact location of an object. It is ideal for outdoor tracking of movable assets worldwide.

GPS technology relies on satellites that send out signals with information about their current location to receivers on the ground.

The location data is then sent through a cellular network to the software, where it’s constantly updated, giving real-time information about an object’s location.

This same technology is applied in GPS trackers.

The main advantage of a GPS tracking system is its power to communicate across distances, providing precise real-time location data and enabling advanced monitoring of construction vehicles and machinery.

It also allows you to track other vehicle-related data, such as driving routes, speed, fuel consumption, and travel time.

GPS technology is beneficial for monitoring and tracking heavy equipment and machinery since the trackers can be powered directly by the vehicle’s main battery.

On the other hand, battery-powered GPS devices would need frequent recharges because they drain a battery fast to send signals over large distances.

Also, the GPS trackers are large, heavy and unsuitable for smaller equipment pieces.

Another shortcoming is that GPS requires line-of-sight with satellites.

Atmospheric conditions, radio interference, or obstacles such as mountains, buildings, or trees can inhibit signal strength and reduce the precision of the GPS.

BLE

Bluetooth Low Energy (BLE) is a type of wireless Bluetooth technology designed to transmit short-range signals.

A BLE beacon, or Bluetooth beacon, is a small battery-powered device that transmits radio signals to mobile devices within a given range, using Bluetooth technology.

The mobile device can detect their presence and determine their proximity.

Moreover, the leading advantages are their lower energy consumption, longer battery life, and greater range.

Also, their small size allows them to be easily attached to assets without causing damage or interference.

Another positive feature is that they do not require additional hardware to be read; any BLE-enabled devices, such as smartphones and laptops, can detect their signals.

Construction companies generally use beacons for real-time tracking of assets (equipment, tools, etc.), to manage inventory, optimize workflows, prevent theft, and ensure construction site security.

On the downside, BLE has lower data capacity, a limited range of 100-300 feet, and relies on battery power.

All in all, compared to other technologies, Bluetooth beacons provide high accuracy and scalability and are a cost-effective solution with a great price-to-value factor.

RFID

Radio-Frequency Identification (RFID) technology is an automated, real-time tracking system that uses radio waves to locate and identify objects through asset tagging.

Each RFID tag includes an antenna to transmit the signal and a rewritable chip that stores the data, all of which can be read by one handheld reader without a direct line of sight.

The construction industry has become one of the most reliant on RFID, employing the technology primarily for keeping track of tools and equipment and inventory management.

But how does it work exactly?

For example, tools are scanned before they’re shipped out of the company’s storage and then scanned again when they reach the construction site.

This produces a record of their whereabouts at any given time.

The RFID system also gives employees easy access to what material is on hand and helps avoid confusion regarding which equipment has been delivered to the construction site.

One of the main benefits of RFID tags is that they can be read from long distances, 26 feet or more, making them ideal for tracking large or high-value assets.

In doing so, these labels save time and increase tracking accuracy.

Regardless, RFID tags can be expensive to implement, as they require special infrastructure such as RFID readers and antennas.

So, it’s essential to set a budget and have a clear idea of what you need, so that you can find the RFID asset-tracking solution that’s right for you.

How Asset Monitoring Works

Now that we discussed the technologies used for asset monitoring, it’s important to understand that there is no one-size-fits-all solution.

Companies can adopt one or use a combination of two or more of the technologies described above.

Namely, it’s highly likely that you won’t need GPS transmitters on each tool in the warehouse.

Likewise, more than a QR code would be required to track valuable mobile assets like trucks or heavy machinery.

However, one common denominator is that contemporary asset tracking systems use the advantages offered by new technologies to streamline the process, making it more efficient and cost-effective.

Whether those technologies use labels and tags or specialized devices to scan them, they all transmit data to a cloud-based asset monitoring solution.

Ultimately, the software aims to help you keep all the assets in one system and update them when they need maintenance or replacement.

How to Choose an Asset Monitoring Solution

When choosing an asset monitoring system, one of the first things you should do is to analyze your requirements, priorities, and needs.

First, consider the number and types of assets you need to monitor so that you have a better understanding of the kind of approach you will need to take.

For example, GPS-based monitoring systems can give you a visualization of where some of your larger assets are.

They are perfect for tracking your outdoor equipment and construction fleet.

But, if you need more precise location tracking, especially indoors, Bluetooth beacons will do the job, seeing as they’re far more accurate than GPS.

Next, you should consider the size of your business.

Asset monitoring solutions can range from simple tracking systems designed for small businesses to complex enterprise-level solutions.

In addition, you should consider the limitations of different technologies.

For instance, Bluetooth beacons are suitable for environments that are wet, metal-rich, or otherwise challenging, that would be too demanding for RFID tags.

Another essential aspect to consider is which solution is most user-friendly and easiest to implement.

An asset tracking solution by GoCodes Asset Tracking has made it possible to keep it simple.

Clearly, there is no hardware like handheld scanners to purchase, no on-premises software to install, and no need to print or get labels and tags from external producers.

After all, as Einstein himself put it:

Everything should be as simple as it can be, but not simpler.

To that point, remember to look for a solution that provides training and ongoing customer support.

Finally, take into account your budget and the long-term benefits of this investment.

Conclusion

Monitoring your assets is another way to work smarter. Not only will you know of their location and condition, but you’ll make sure your assets are performing to their full capacity.

By tracking your assets, you’ll be able to quickly implement preventive maintenance, optimize the asset lifespan, increase efficiency, reduce costs, and achieve higher levels of profitability.

If your company isn’t investing in asset tracking, you may be losing both money and time.

Well-implemented asset tracking techniques will help you streamline your processes, improve your customer service, and allow you to scale your business upwards with ease.