Asset management is crucial for any company that deals with many pieces of equipment and wants to stay on top of them all.

If your company still relies on Excel to do all the necessary reporting, as well as track assets and maintenance, this article will make you think twice.

It will explain why Excel isn’t the right choice for anything other than basic tool management, pointing to all the risks associated with its limitations.

Keep reading if you want to find out more about the disadvantages of Excel and the advantages of other asset management solutions.

In this article...

Asset Management Is Not What Excel Is Designed For

Many companies use Excel to manage their equipment, but this is not the program’s primary purpose—which is why it’s not that good at it.

Excel is an option for storing and calculating data, as well as keeping time and task management.

It’s not suitable for keeping track of numerous assets and all related information.

It doesn’t have all the necessary features, it’s manual, and you cannot keep track of all the data required for successful and efficient asset management.

When you use Excel for something other than its original purpose, there’s a high risk of errors.

In fact, 9 out of 10 spreadsheets contain potentially costly mistakes.

Since Excel isn’t an asset management tool, you often won’t find the features or options you need, so you’ll be forced to create workarounds.

However, such workarounds are likely to be more complicated and less efficient than software designed for asset management.

Besides, you’re not getting the best out of your assets if you use a managing system not customized for that purpose.

Excel cannot offer many newer, more effective management options since its updates are not geared towards equipment management.

If you want to be efficient at asset management, opt for software explicitly designed to help you manage your equipment and track all the necessary data.

Questionable Reliability

Your problems with asset management tools start when you can’t depend on them to have the correct information, which is the case with Excel.

How reliable is Excel really? It’s hard to determine whether you can rely on the data in the file since many users have access to it, and they can all change it how they see fit.

Excel makes it almost impossible to understand who made the changes and why, so you have to believe that the change wasn’t an accidental entry or trust that the employees didn’t use the wrong line to enter their data.

Other than that, it’s also difficult to move certain items around in spreadsheets.

You might cut out a more significant section than you intended or paste it in the wrong spot. If you don’t notice it right away and save the document, the data is lost forever.

The more people use the file after you, the harder it will be to retrieve the data.

Another risk you can’t forget when using Excel is that it’s saved on a computer, which means that it can be affected by a virus, deleted, or destroyed easily, leaving you without your precious data.

Instead of relying on Excel to have all the necessary options to make your data accurate and reliable, use programs designed to let you update data effortlessly while leaving almost no place for errors.

Can’t Be Used on the Go

If you own lots of portable equipment that you move from site to site, you’ll understand the difficulty of staying on top of changes in Excel while using such equipment.

When you’re in the field, and an asset gets damaged, or you believe it needs repair, you must report this issue as soon as possible to solve it promptly.

However, it’s inconvenient to carry a laptop with you to log that information into a spreadsheet.

On the other hand, you will likely have a smartphone and log into Excel using it, but you’re risking too many errors when using a spreadsheet on your phone.

Not only are the boxes small, but so is the text. It’s not very convenient to write down changes in all the necessary boxes when you can’t have an accurate overview of the entire spreadsheet.

Maybe you’ll opt for taking a smartphone note or decide to memorize the changes so you can input them into the spreadsheet later.

This might seem easier than struggling to enter the data into Excel from the worksite.

However, you’re running the risk of forgetting to use spreadsheets that way while also being less productive and wasting more time on a task that you could have done on the spot, which would speed up the repair process if needed.

Possibly Outdated Information

Excel is not the best option for asset management as you cannot rely on the information to be updated or up-to-date.

You can’t guarantee that all the data in the spreadsheet is correct or that someone has updated recently. For all you know, the last update might have happened months ago.

Another problem with the outdated information is that you do not see the history of changes related to one tool.

If you keep all the maintenance dates for each device, your spreadsheet will get clogged very quickly.

If you opt to keep only the latest one, you deprive yourself of valuable information on maintenance, which can affect many asset-related decisions.

Also, if there’s anything wrong with a tool, the worker arranges a repair.

Requesting a repair or maintenance action is usually done through the asset management tool the company is using.

In the case of Excel, it’s easy to miss or skip the latest updates, meaning that you might not notice the information of a tool malfunctioning or breaking down until it’s time for someone else to use it again.

Such errors not only cause delays and downtime but negatively affect the asset’s life-cycle and cost you money in the long run.

No Way to Track Assets

You cannot track your assets using Excel, which means it’s difficult for you to understand where the tools are, where they have been, and who’s used them.

Since Excel’s primary purpose is not to track assets and let you have all equipment details in one place, you’ll find it hard to use it for equipment monitoring.

Employees can write their name down next to the item they are using, but it can still be challenging to understand who has used the tool, how often, and who is using it now.

If an employee picks an item up at the worksite, they can’t log into Excel right away to mark the change.

They might return the item to the original location without you ever knowing they’ve used it, which makes it easier for things to disappear.

Excel won’t even help you distinguish between your items if you have more than one of the same kind.

You can name them a certain way in the spreadsheet, but it’s pretty tricky to know which name refers to which item, confusing you and the employees using the assets.

The data might get associated with the wrong item, making you lose valuable insight once again.

It’s Single-User Oriented

A disadvantage of Excel for asset management is the fact that it suits a single user.

Multiple users can’t edit spreadsheets simultaneously, which means users have to wait for the other user to finish before logging in, leading to decreased productivity.

If your team was in the field the entire day and couldn’t update the spreadsheet using their phones, they will wait to come back to the office to do so.

However, they will have to go one by one, which wastes time and negatively affects productivity.

Also, the less tech-savvy employees might edit the spreadsheet while it’s being used and create a new version of the file, leaving you with two different versions.

By the time you notice, each file might have many new entries, and it will take a while for you to ensure that all entries are up to date.

Another problem that might arise is copying and pasting in spreadsheets, which can completely override data.

Suppose the person who incorrectly pasted information into the spreadsheet doesn’t notice the error on time.

In that case, it will be impossible to trace the error back to the person who made it or restore the last correct data.

No Audit Information

Advanced audits require detailed asset information, which you can rarely get from Excel.

Many companies have and still use Excel for basic auditing. Still, the tool simply isn’t up to par with more extensive audits since you need to analyze a lot of data from multiple sources to ensure you have the correct numbers and information.

When performing an audit, you will need a report from Excel with all the asset data to correctly perform the check and be sure your information is precise.

The reporting process is not as easy in Excel as it is in software designed to help you with audits.

Excel doesn’t give you the option to check multiple audits and compare them. Instead, you have to look at the entries one by one.

Once you do the audit on paper and upload all the relevant attachments into the system, you need to manually enter the data into the spreadsheet, which takes even more time and energy.

If you opt for software designed to perform audits, you can automate many of these steps.

On top of that, you can communicate through comments with your team when performing audits, which helps you understand potential errors or miscalculations.

No Attachments

An Excel downside is the inability to attach pictures or documents related to an asset, making it difficult for people to spot it right away.

If you get a new tool and input it into the tool management spreadsheet, you will organize training on using the latest equipment.

You will also upload the manual, so your team can access it whenever they have to use the tool. However, you won’t be able to do this in Excel.

You have to save manuals, pictures of the item, and detailed documentation in a different folder.

Using other files to check out and view data on a single asset isn’t user-friendly, so your team won’t use these additional folders as often as you’d like.

Such data is necessary when trying to perform an audit or determine new maintenance dates or servicing efficiency.

If you want to get more information on the tool, you will have to look for it in other folders, increasing the chance of overlooking something.

If attachments are crucial to your company’s asset management, opt for software that allows you to upload all the materials related to the asset and have it available next to its name and specifications.

Lack of Automatization

Excel makes you manually input all the information you need, leaving room for errors and data loss.

When you input all the data manually, it’s hard to vouch for their accuracy since many people can use the file, accidents can happen, and specific information can be overridden, deleted, or replaced with information that doesn’t belong to the asset at hand.

Automation could fix this problem by eliminating the risk of human error in most cases while speeding you up.

Also, if an employee wants to check a piece of equipment out, they need to access the file—provided that nobody else is using it at the time—and write down the details.

If they cannot access the file or are in the field, they can’t upload the changes until they can use the company laptop or until the file is accessible.

You can automate this entire process so all your employees can quickly check equipment in and out without depending on the company PCs or document’s availability.

On top of all that, automatization helps you leave an audit trail that is easily accessible and reliable, thus eliminating the risk of taking incomplete or incorrect data as factual.

Automatization not only helps prevent errors but saves your employees time and increases productivity.

What’s the Alternative?

Since Excel doesn’t have all the options you need for quality asset management, opt for software and applications that do.

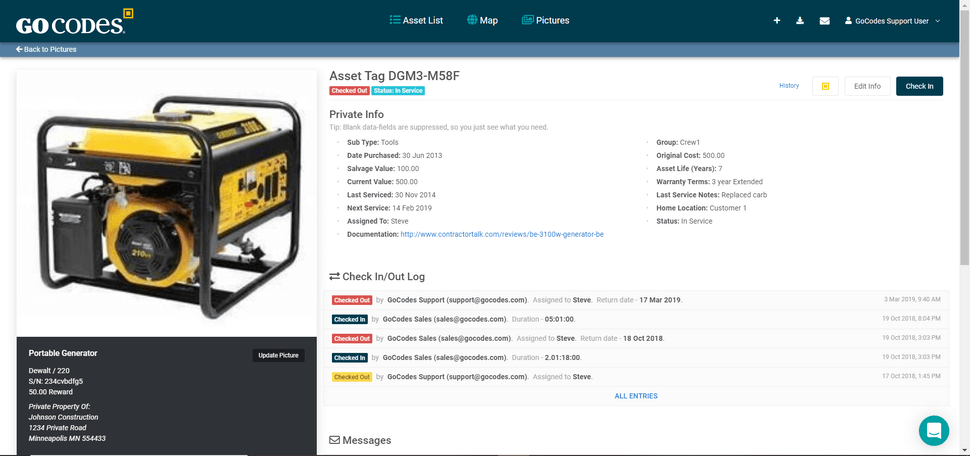

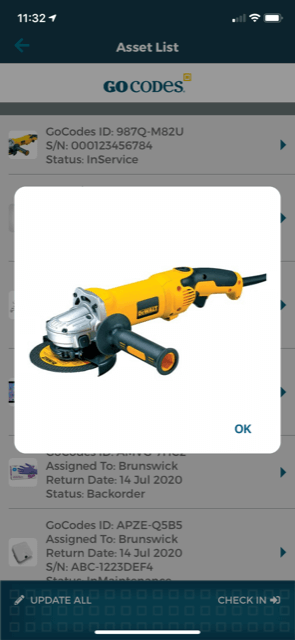

Asset management software like GoCodes Asset Tracking has all the benefits that Excel lacks, even though it isn’t free.

However, it lets you pay only for what you use, eliminating excessive payments for the space you won’t use.

Such cloud-based solutions that let you track your items and their usage by scanning the tags on the item or by searching for the equipment in the cloud will make your life easier.

GoCodes Asset Tracking lets you update all the relevant data and attachments on the asset’s page, so anyone who clicks on the item or scans its tag has a complete overview of the necessary information.

They can easily understand who is using the item, when they’re returning it, and what comments others left.

You can even set up a reminder for scheduled maintenance, letting everyone know when the tool won’t be available to use.

This option allows you and your team to plan around the servicing to ensure there is no downtime.

Cloud-based software will let you have all the asset data, including attachments and maintenance history, in one place while letting your team check equipment in and out and leave comments about the equipment.

Conclusion

Excel’s original purpose is not tool management. Because of this, it’s single-user oriented, unreliable, and makes it more difficult to upload information and use it when out and about, posing a risk of outdated data.

This tool doesn’t provide you with an option of tracking your assets and having all the related data and attachments in a click or two.

The lack of automation costs you accuracy, money, and time while making it more difficult to audit your equipment.

If you want to track your equipment and have all the data at hand, opt for automatized, cloud-based software like GoCodes Asset Tracking.