Equipment maintenance means repairing and tweaking your assets that allows you to continue using them safely.

If you work for a company that owns and handles tools and equipment, you definitely have some experience with the maintenance process and procedures.

But, do you know what the main upkeep goals are?

This article will explain some of the most vital maintenance goals and their importance for your business.

In this article...

Assuring Equipment Safety

The most important maintenance goal is equipment safety assurance.

For many, this aspect of the upkeep process is vital since it helps you protect your workers.

It’s no wonder that planned maintenance was first used to prevent locomotive boiler explosions that led to death and injuries—companies invested in regular equipment inspections to protect the workers.

This remains true today.

By investing in planned or preventive maintenance, you lower the risk of unexpected breakdowns or malfunctions that can harm the operators, other field employees, or bystanders.

Preventive maintenance ensures that the equipment is safe to use and eliminates any potential safety hazards.

Your maintenance team has to carefully inspect each piece of equipment to ensure it is up to par and functions correctly.

If you opt for reactive upkeep, on the other hand, you are risking not only equipment failure but severe safety hazards.

You can never predict what can happen when a part of the asset breaks off or if a tool short-circuits.

Because of this, it’s wiser to invest in planned maintenance and ensure the inspection of each asset component.

A vital maintenance goal is to ensure that your equipment is safe to use.

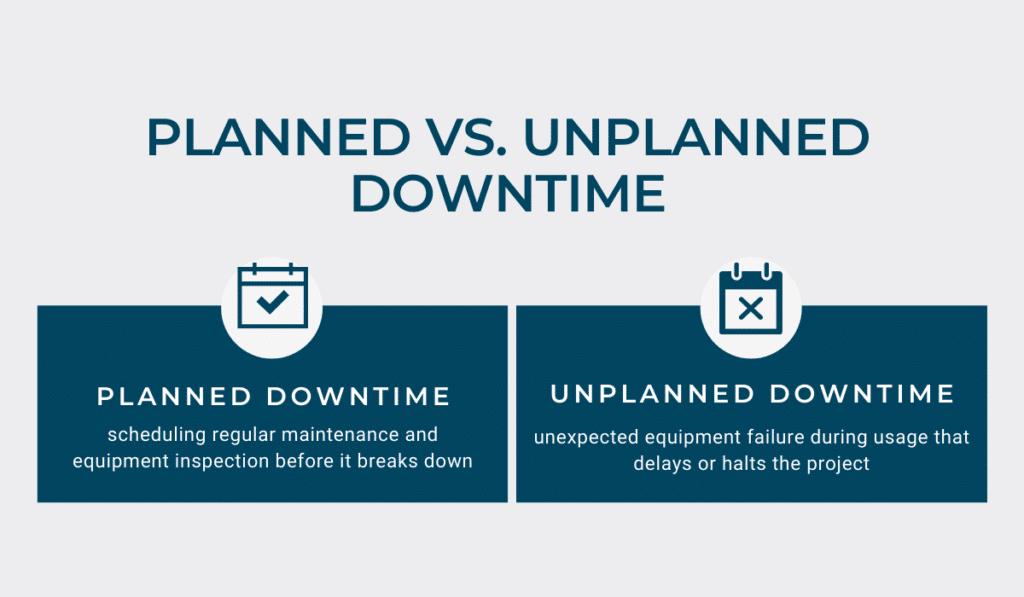

Less Unexpected Downtime

One of the most critical maintenance goals is to lower the amount of unexpected downtime.

Downtime happens when there’s an equipment malfunction or an issue that you need to fix before using the tool.

Therefore, downtime is the period during which you can’t use your equipment due to a breakdown or potential hazards.

However, you can plan for downtime if you need to perform regular, scheduled maintenance. In this case, when the downtime is not unexpected, there is no need to work on eliminating it.

On the other hand, unplanned downtime is the type that causes you problems as it means that the equipment broke down while you were trying to use it.

Sometimes it can even halt your entire project.

The goal of your maintenance team is to eliminate unplanned downtime as much as possible.

That goal will never be entirely achievable—after all, the upkeep team cannot control the weather conditions, improper use, or anything that happens in the field.

However, what the maintenance team can do is inspect the equipment regularly and fix any minor problems.

They can tweak the equipment, determine when to use a replacement part for better performance, and periodically change oil, add water, or perform any similar tasks that help the equipment run smoothly.

Maintenance decreases the risk of equipment breakdowns, thus eliminating unexpected downtime.

Minimize Downtime Duration

Your maintenance should strive to minimize the duration of equipment downtime.

Even if you can’t eliminate downtime, you can at least control how long it lasts since it stops you from performing the task at hand.

The maintenance team can’t handle the issue on the spot most of the time. Instead, they need to inspect the asset, understand the problem and how to approach it, fix, and test it.

Only then can you use the tool safely.

The key to a good maintenance process is performing the tasks mentioned above as quickly as possible while still staying safe and effective.

After all, quick upkeep that won’t actually fix the issue isn’t worth much if you will deal with the same problem in a week or two or, even worse, if it causes an accident.

If you’re wondering how you can minimize the duration of downtime, try to optimize each part of the process, starting from reporting the issue.

The longer each separate task lasts, the longer the downtime. Therefore, first, think of an effective way for your team to report a problem.

For example, if you use tool tracking software, you can update the asset’s status to “needs repair” so your maintenance team can get notified right away.

Optimize each part of the maintenance process to minimize the duration of tool downtime.

Longer Equipment Useful Life

Your maintenance should prolong your equipment’s useful life.

A tool’s useful life is the period during which you can use the tool for its original purpose and get satisfactory results.

Of course, equipment slows down, and the quality levels often go down with time. If you care about your results, replace an asset when its performance becomes sub-standard.

Until then, invest in maintenance as it prolongs the useful life, allowing you to get more out of the asset.

Regularly check the equipment and its parts to spot any issues or notice weak points that could cause problems in the future. You can fix the issues on the spot and examine the vulnerable areas to determine whether to replace a part right away.

Either way, you’re getting to know the piece of equipment and what you can expect of it.

When you handle these issues early on, you eliminate unnecessary downtime and breakdowns that can hinder your equipment even after you fix it.

Unfortunately, some breakdowns result in complete failure, after which you cannot resolve the issue, so regular upkeep is vital.

Prolonging your equipment’s useful life is one of the key maintenance goals.

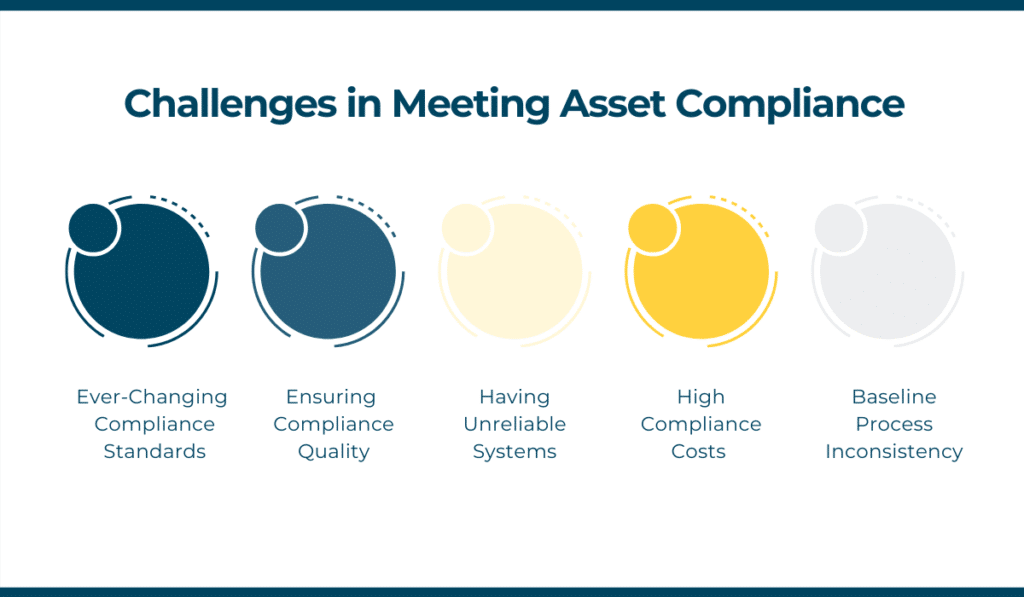

Rules and Regulations Compliance

Your maintenance should ensure that you’re complying with rules and regulations.

Otherwise, you’re not operating according to standards, and you’re risking fines, penalties, and lawsuits.

For example, if someone gets hurt using your tools or products, you can use regular maintenance logs as evidence that you’ve tried your best to take care of the equipment and remove all potential hazards.

Therefore, you aren’t liable for the injury.

Of course, if you can’t provide such logs because you didn’t keep them or didn’t even invest in maintenance, you’ll be held liable.

The country, state, or local government put specific regulations in place to ensure a standard across the industry to protect the workers.

When it comes to maintenance, the rules and regulations refer to equipment safety, among other things. The biggest issue when it comes to regulatory compliance is that the relevant legislation often changes.

You have to adjust to the changes and modify your current maintenance processes to reflect the changes. If you don’t do this, you’ll stay behind and eventually be below standard. On top of that, your company can get penalized or shut down.

Invest in maintenance to be confident of your regulatory compliance.

Saving Money

Your maintenance process should save you money. If it doesn’t, something’s not right.

On top of all the benefits mentioned above, a quality maintenance plan will save you money in more ways than one.

First, upkeep prolongs the equipment’s lifetime, allowing you to use the asset for a longer time, thus saving money on buying a new asset to perform the same duties.

When you invest in regular maintenance, you ensure that you’re getting the most out of your investment.

Secondly, planned upkeep helps you avoid reactive maintenance.

If you don’t schedule maintenance in advance to discover issues early on, you only hear about problems when assets break down, injure someone, or stop working correctly.

Then, you have to repair the equipment ASAP, since you usually discover such faults when the assets are in the field.

Thirdly, maintenance ensures that the equipment runs in optimal condition, allowing you to save money on energy and resources.

The closer the asset is to such a condition, the less power it will waste to get the job done. You’ll not only save money on those costs but help the environment as well.

Saving money is one of the most vital maintenance goals.

Creating High-Quality Products

A goal of your maintenance process is to create high-quality products.

While not every company uses its equipment to create a product, many do. Others use their assets to work in construction, elevate buildings, or provide service.

Regardless of the final product, the goal of your maintenance is to guarantee that your equipment is in optimal condition and that it can perform its intended purpose well.

Creating quality products or doing quality work is not just a maintenance goal—it’s a general company goal.

If it’s not, you’re not putting your end customers or clients first, which isn’t a good approach to business and will inevitably lead to failure down the line.

If your tools don’t produce the necessary results, you may have to start from scratch or invest in repairs or do more to simply get the job done.

These options cost you time, energy, and money. However, maybe most importantly, they can also affect your reputation.

Think of it like this: if your clients aren’t happy with the final product, quality of work, or the amount of time needed to finish the job, they won’t return.

They might even leave a bad review—and word of mouth travels fast.

Therefore, your maintenance should guarantee that the final product or work is excellent.

Providing Accurate Maintenance Records

Providing accurate maintenance records is vital for your company.

Maintenance itself often seems to be the core of upkeep procedures, but you shouldn’t forget to detail and write down the methods and results.

As already explained, if you are ever sued because of a faulty product or service, having maintenance records can help you prove the fault didn’t happen because of your negligence.

Quite the opposite, it shows your full intent to make the product or service as high-quality as possible.

On top of that, such records help you save money.

They demonstrate what kind of repairs you’ve already done, preventing you from repeating the same procedures on the same asset unnecessarily.

Keeping maintenance records shouldn’t be an afterthought—you can implement it in your maintenance procedures and treat it as an obligatory step for your team.

They will quickly get used to following a maintenance checklist and writing down any potential problems they notice.

If you have lots of equipment and think it’s impossible to record and save the maintenance data of each asset, look into software that lets you upload these documents into the cloud.

Such software allows you to have the upkeep stats and records connected to the tool itself, so when you look for the asset in the software, you easily find this information.

Create and save detailed maintenance records.

Conclusion

Maintenance is a vital part of prolonging the equipment’s life cycle. If you want to stay safe and get the most out of your assets, you need to invest in scheduled upkeep.

The main goals of having a maintenance program in place are to ensure that your tools are safe to use, eliminate downtime, and guarantee the lowest possible downtime duration.

On top of that, maintenance helps you prolong your equipment’s useful life and create high-quality products or provide excellent services.

Finally, it helps you be cost-effective in multiple ways, including maximizing your regulatory compliance.

However, you need to provide accurate maintenance records to be able to prove your compliance.