Key takeaways:

- Centralized digital asset records help prevent theft, reduce misplacement, and boost productivity.

- Effective asset management relies on the right tools: software, QR or RFID tags, and GPS or Bluetooth trackers for high-value assets.

- Preventive maintenance can reduce unplanned downtime by over 30%, with predictive maintenance delivering even greater gains.

- Managing the full asset lifecycle with clear procedures and regular audits ensures long-term performance and accountability.

Managing physical assets the right way helps keep your operations running smoothly, cuts downtime, and saves money.

Whether you’re managing vehicles, heavy equipment, tools, office furniture, IT gear, or inventory, there are proven ways to make asset management more effective.

In this article, we’ll walk you through six best practices that help businesses of all sizes take control of their assets.

In this article...

Keep Detailed Asset Records

Accurate asset records are the backbone of any effective asset management strategy.

To illustrate this and the other best practices in this article, we’ll use the construction industry as a leading example since contractors typically manage physical assets of all types and sizes.

Of course, these principles apply just as well to other sectors like manufacturing, healthcare, and facilities management, as well as office and IT equipment tracking.

Clear, up-to-date records are the foundation for everything that follows.

They help you understand what assets you have, where they are, and what they’re worth.

Charlotte Ellarby, Director at itemit, adds another important point:

Illustration: GoCodes Asset Tracking / Quote: itemit

Conversely, inaccurate or incomplete asset records can lead to lost equipment, reduced productivity, unexpected downtime, or insurance claims that don’t hold up.

So, what’s the solution?

A centralized system where all asset details are stored and easily updated.

In the past, many businesses relied on spreadsheets, but these aren’t ideal for presenting information or allowing multiple users to update records centrally.

That’s why dedicated asset management software is far more efficient.

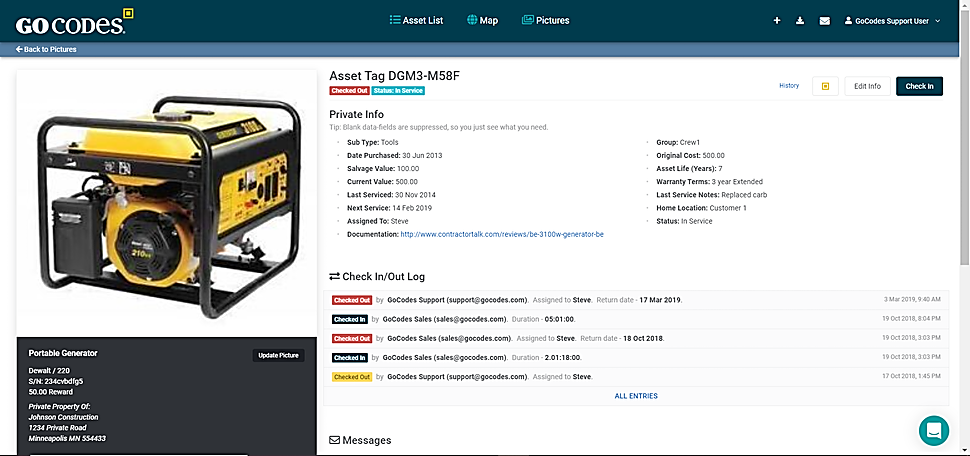

It lets you create a central database where each asset has a unique ID and its own info page with key details like purchase date, value, warranty, location, maintenance history, images, attachments, and more.

Source: GoCodes Asset Tracking

Today, most asset management solutions are cloud-based. You can access them from any internet-connected device like a desktop, laptop, tablet, or smartphone.

This makes updating asset records much easier, reducing manual input and errors. Plus, all updates are instantly visible to every authorized user.

Another advantage is the digital audit trail, which records who made changes and when.

This is crucial for accountability, meeting warranty requirements, supporting insurance investigations, and ensuring regulatory compliance.

Alongside regular audits (covered separately), establishing a centralized, cloud-based asset database is key to keeping your records accurate and up-to-date.

Track Your Assets’ Location and Condition

Tracking your assets helps ensure they’re locatable, their condition is known, and the risk of theft, loss, or unauthorized use is minimized.

That doesn’t mean every asset needs a real-time GPS tracker.

In most cases, live tracking is reserved for high-value, mobile assets like vehicles and heavy equipment.

For everything else, simple tracking methods like barcodes, QR codes, or RFID tags are more practical and cost-effective.

Just as each asset should have a unique ID in your database, it also needs a physical label or tag that links back to that record.

For example, a QR code printed on a durable label and attached to a tool or machine lets users scan it with a smartphone to instantly access the asset’s info.

Source: GoCodes Asset Tracking

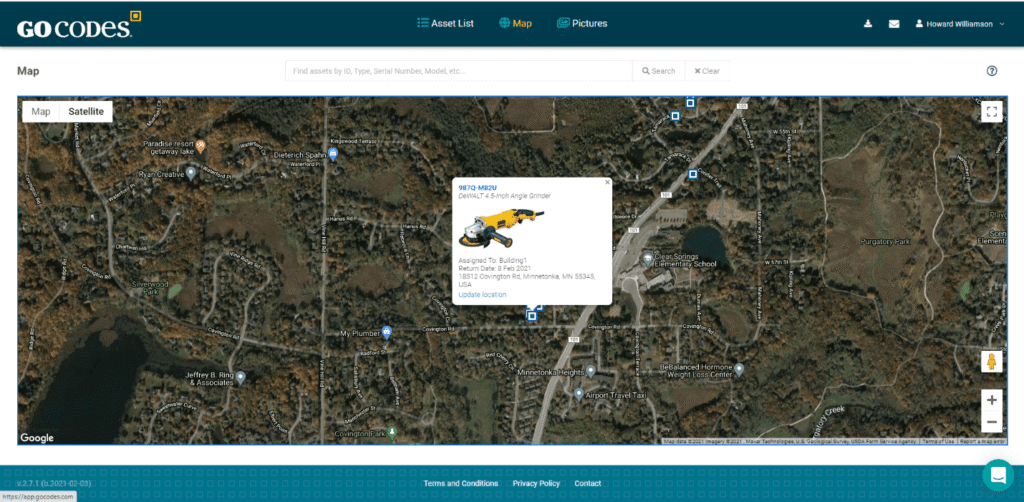

Some asset management solutions offer GPS-enabled QR codes, where each scan with a smartphone or tablet automatically captures the device’s GPS location.

Over time, regular scans create a near real-time digital trail of asset movements.

This makes it easy for users to find where an asset was last seen, track its location across job sites, or recover items left behind.

All they need to do is open the tracking app, search for the asset, and view its most recent location on a map.

Source: GoCodes Asset Tracking

Whether you choose QR codes or RFID tags, these affordable methods should be applied to all assets as part of your primary tracking system.

For critical, high-value assets that move between sites, you can add real-time GPS trackers.

These devices use satellites to pinpoint location and send updates directly to your asset management app.

To illustrate, here’s a GPS tracker attached to a trailer.

Source: GoCodes Asset Tracking

Another option is Bluetooth trackers—small devices placed on assets that provide live location data within a limited area, such as a job site.

Whichever tools you choose, start by categorizing your assets based on value, mobility, and operational importance.

This is where accurate asset records are essential.

Once you’ve mapped your needs, you’ll know exactly how many QR code labels, RFID tags, GPS trackers, or Bluetooth beacons are required.

Then it’s time to choose a tracking provider.

While some companies piece together tools from multiple sources, many prefer a single solution that offers all tracking options in one place.

GoCodes Asset Tracking is one such all-in-one provider.

Here’s an overview of the tracking solutions we offer:

Source: GoCodes Asset Tracking

By combining affordable tags like GPS-enabled QR codes with more advanced trackers, you gain real-time visibility across all your assets.

With a mobile app, employees can quickly check where assets are located at any time.

But tracking isn’t just about location.

As we’ll discuss next, it also helps you monitor asset condition and stay on top of maintenance needs.

Conduct Proactive Maintenance

When an asset breaks down, the consequences often include work delays, rising costs, and reduced equipment lifespan.

That’s why proactive maintenance is one of the most valuable strategies you can implement.

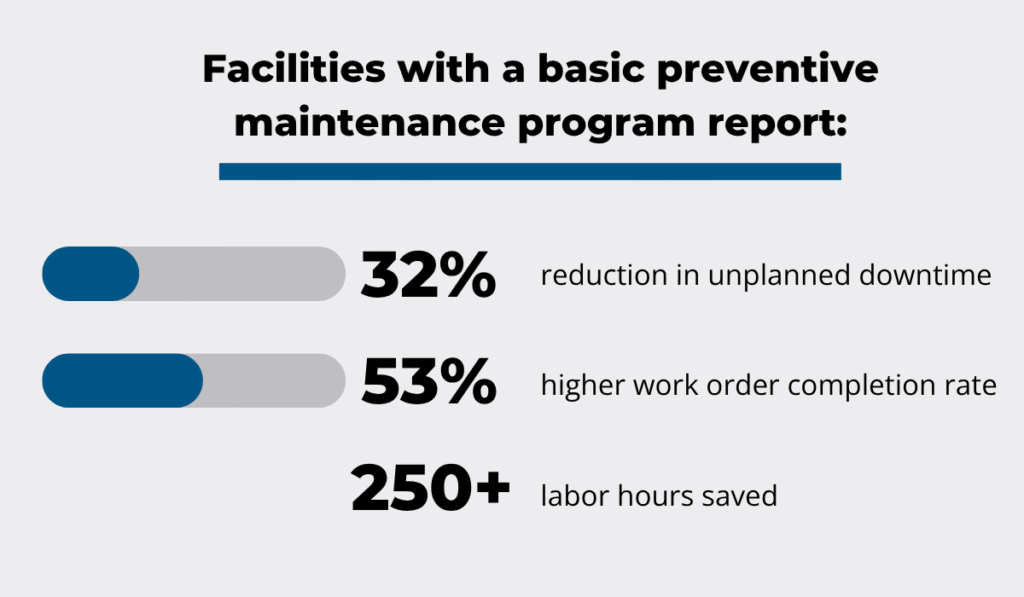

According to a 2024 survey, even moving from a fully reactive to a partially preventive maintenance program can make a significant difference.

Facilities that made this shift reported fewer unexpected failures, smoother workflows, and major time savings, as you can see below:

Illustration: GoCodes Asset Tracking / Data: MaintainX

Of course, you shouldn’t just stick to a service schedule. Proactive maintenance is all about making smarter decisions based on real data.

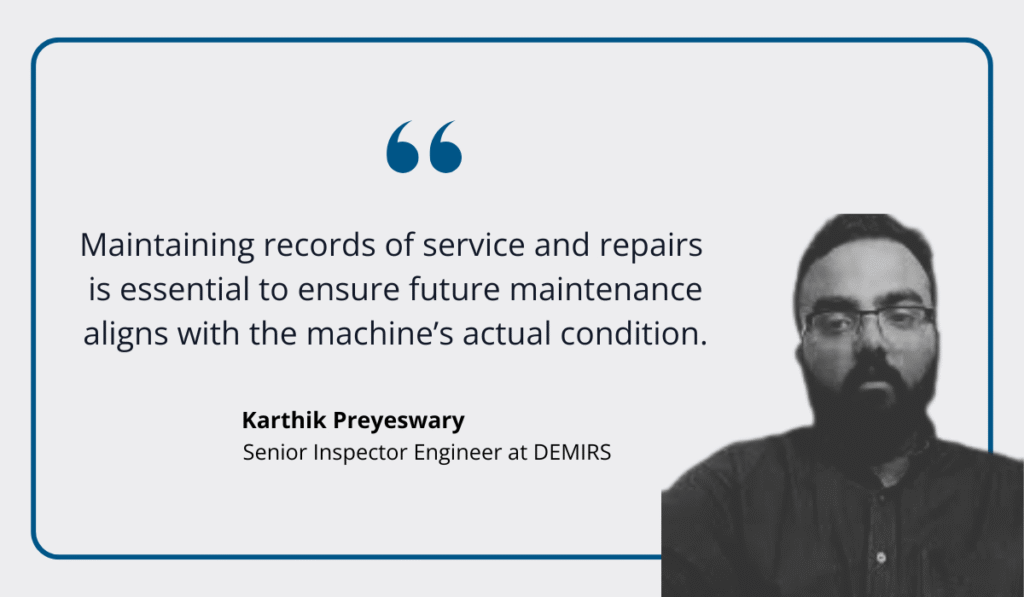

Accurate records of inspections, repairs, and part replacements, linked to each asset’s info page in your asset management solution, help maintenance teams fine-tune schedules, catch early warning signs, and avoid unnecessary work.

That way, teams can focus on preventing issues before they happen, rather than constantly reacting to breakdowns.

Karthik Preyeswary, Senior Inspector Engineer at DEMIRS, agrees:

Illustration: GoCodes Asset Tracking / Quote: LinkedIn

With primary tracking methods like QR codes or RFID tags, technicians can instantly access asset maintenance history, inspection reports, manuals, or service checklists using their smartphone.

This keeps everything centralized and ensures that no detail is missed during scheduling, inspections, or repairs.

For fleets and other high-value equipment, companies can also integrate various sensors, typically paired with GPS trackers.

These devices monitor usage patterns, engine hours, or fluid levels and automatically trigger alerts when maintenance is due or anomalies are detected.

Combined with data analytics, this approach can take your maintenance strategy from preventive to predictive.

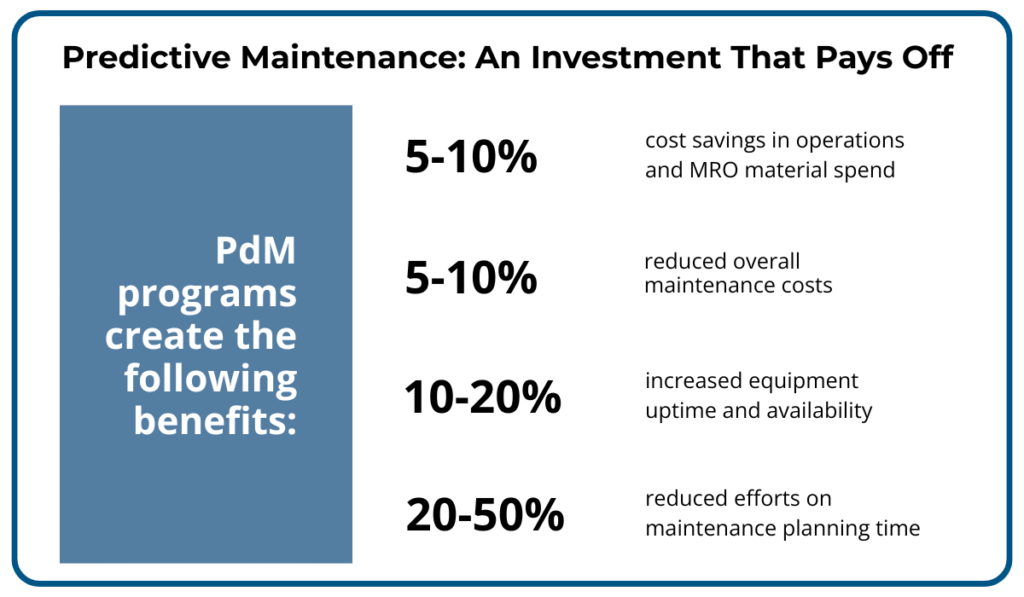

According to a 2024 Deloitte study, here’s what organizations can gain when making that shift:

Illustration: GoCodes Asset Tracking / Data: Deloitte

In short, the best proactive maintenance usually combines centralized service records and smart tracking technologies, all depending on your needs and budget.

The benefits are clear:

- Fewer unexpected breakdowns

- Lower emergency repair costs

- Longer asset lifespans

And the more data you collect on how each asset is used and maintained, the easier it becomes to plan not just for the next service, but for the asset’s entire lifecycle.

Leverage Asset Lifecycle Management

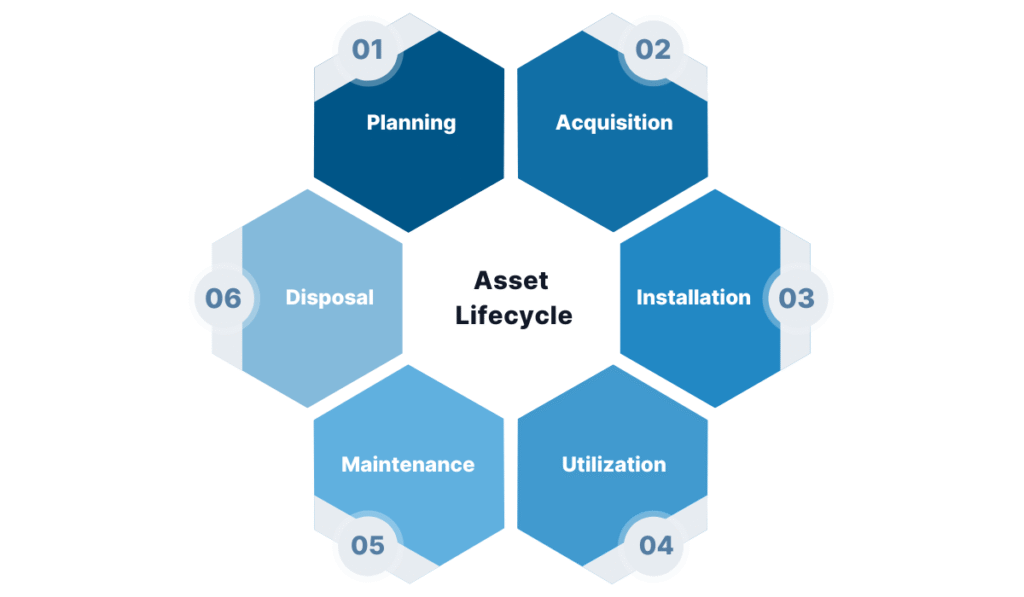

To get the most value from your assets, it’s essential to manage them across their entire lifecycle—from initial planning and acquisition to final disposal.

This approach, known as asset lifecycle management, helps organizations extend asset lifespan, control costs, and plan upgrades or replacements with confidence.

Each stage plays a role in ensuring assets remain productive, compliant, and cost-effective throughout their use.

Here’s a quick look at the typical stages an asset goes through:

Source: GoCodes Asset Tracking

Optimizing each lifecycle stage can lead to significant savings and improved asset performance.

For example, during the utilization stage, tracking how often an asset is used and how well it performs can help inform smarter maintenance schedules or indicate when it’s time for a replacement.

Since utilization runs alongside maintenance, combining usage data with service history can extend the asset’s lifespan.

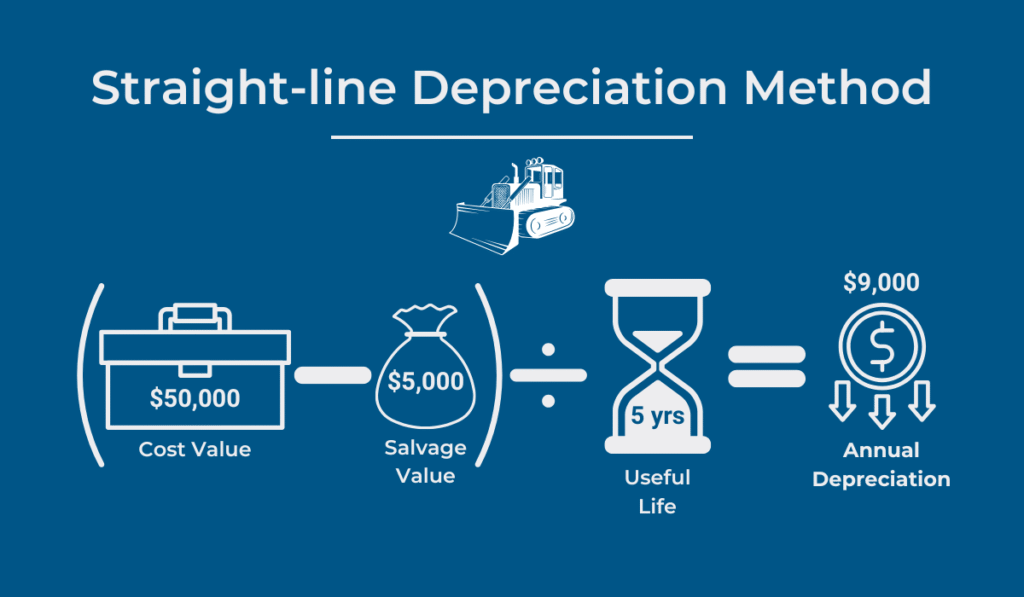

Lifecycle management also enables accurate depreciation tracking, which is essential for budgeting and compliance.

Here’s a simple example using the straight-line depreciation method for a bulldozer:

Source: GoCodes Asset Tracking

Long story short, this best practice involves actively managing each asset from planning to disposal.

Benefits include maximizing asset value, reducing avoidable costs, and ensuring compliance with financial and environmental standards.

Whether it’s scheduling timely replacements or tracking depreciation, a lifecycle-focused approach helps you make informed decisions that support long-term operational efficiency and sustainability of your assets.

Establish Clear Asset Management Procedures

Establishing clear, standardized procedures for how assets are used, stored, moved, and retired helps reduce loss, misuse, and confusion, especially in environments where equipment changes hands frequently.

These procedures should define responsibilities across the entire asset lifecycle, from acquisition and assignment to return and disposal.

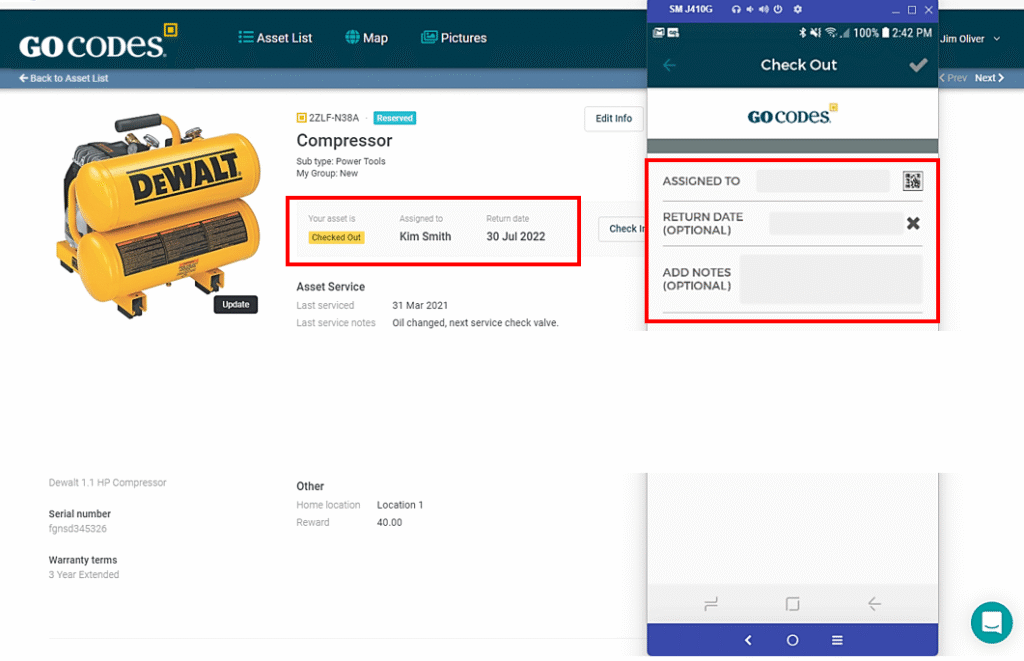

One essential practice is requiring users to check assets in and out, so there’s always a record of who has what asset and when it’s due back.

Asset management software reinforces this policy by making the process fast, trackable, and consistent.

Typically, workers scan an asset’s tag when checking it out and again when returning it.

The software automatically records each check-in/out action, creating a real-time audit trail.

Source: GoCodes Asset Tracking

This helps maintain accountability and makes it easier to follow up on missing, late, or misused items.

SOPs should also cover how to handle asset theft, including who to report it to, how to document the incident, and what steps to take next.

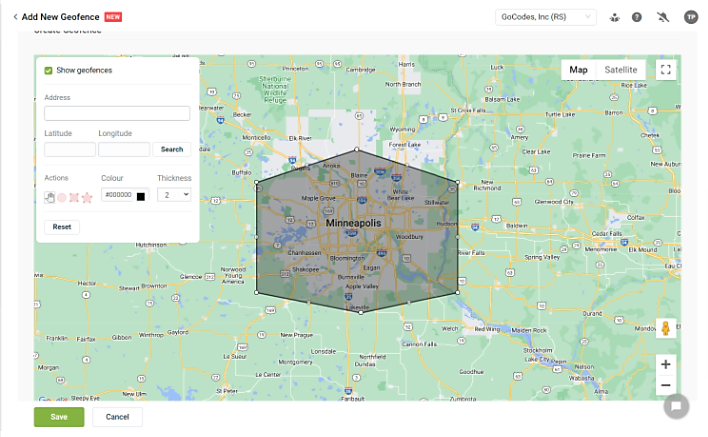

Again, asset management tools coupled with the right trackers (GPS or Bluetooth) can support these policies by enabling real-time theft prevention features like geofencing.

With this setup, managers can define invisible digital boundaries around job sites or storage areas.

Source: GoCodes Asset Tracking

If an asset leaves the designated area outside of approved hours or without being checked out, the system sends an automatic alert, giving managers a head start in responding to potential theft or misuse.

The same principle—establishing SOPs and leveraging software features to support them—can be applied to other asset-related actions as well.

These include:

- Assigning new equipment

- Reporting damage

- Requesting maintenance

- Conducting inspections

- Performing audits

- Retiring assets in a compliant and responsible way

Overall, clear asset management procedures enable workers to be more consistent, accountable, and efficient in how they handle assets across their lifecycle.

Perform Regular Asset Audits

The final best practice we’ll cover is performing regular audits to ensure assets are accounted for, properly maintained, and compliant with regulations.

Audits help verify the location, status, and condition of your assets, allowing your team to identify discrepancies, eliminate ghost assets, and maintain accurate records.

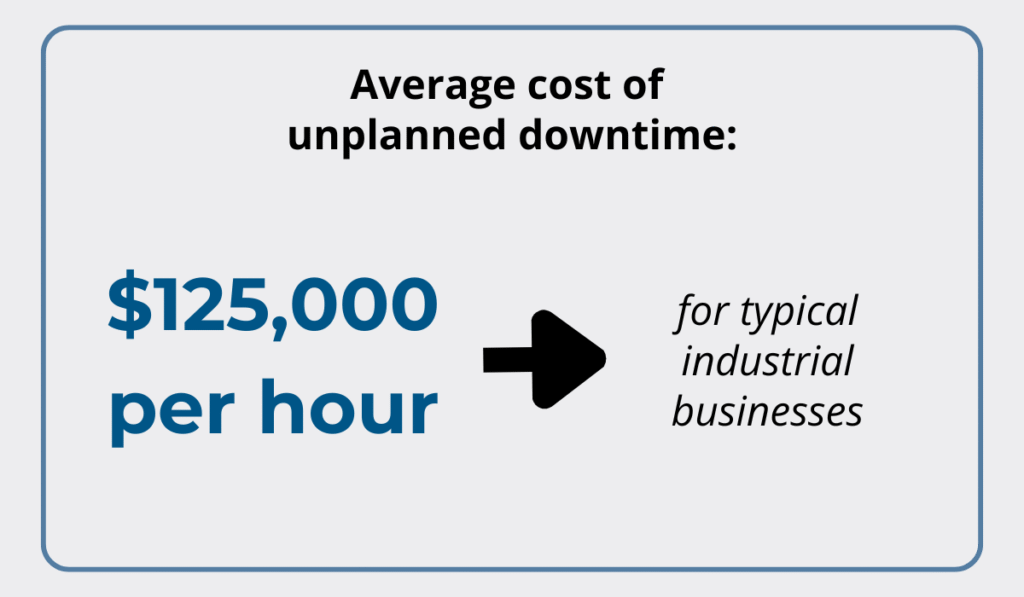

When done consistently, audits also reduce the risk of unexpected operational disruptions that lead to costly downtime.

On that note, ABB’s 2023 survey of over 3,000 maintenance leaders found that unplanned outages can cost a typical industrial business as much as $125,000 per hour.

Illustration: GoCodes / Data: ABB

To prevent such costly disruptions, many organizations build asset audits into their regular workflows.

They don’t have to be complex as long as they’re consistent, well-documented, and adapted to the specific asset type.

A great example comes from Superior Paving Corp, where every employee, regardless of department, is assigned equipment to audit each month.

Walkarounds are performed with the help of operators or mechanics, using tailored checklists based on the asset’s usage and maintenance history.

As Tyler Mitchell, equipment manager, explains, their asset management software allows for immediate access to audit results:

Illustration: GoCodes Asset Tracking / Quote: Construction Equipment

This means managers are regularly informed of the condition of equipment, so they can spot issues early, prioritize repairs, and make informed decisions about replacements or retirements.

Audits also improve compliance with internal policies and external regulations by ensuring documentation is always current and easily accessible.

Over time, regular audits create a strong feedback loop, delivering accurate data that informs your asset management planning, budgeting, and forecasting.

Ultimately, this best practice strengthens accountability across teams and keeps operations running smoothly with fewer unexpected setbacks.

Conclusion

If anything, these six best practices show that effective asset management depends on combining smart technology with clear procedures.

Only then can your asset management support data-driven decisions across the asset lifecycle.

Whether you manage a fleet, tools, or facilities, putting clear systems in place today leads to better performance and cost savings tomorrow.