Key Takeaways:

- The construction industry faces high theft losses and low recovery rates.

- Jobsite security like fencing, surveillance, and access control reduce theft risks.

- GPS trackers and scannable QR codes can help locate stolen assets and provide proof of ownership.

Did you know that if your construction equipment is stolen, there’s less than a 25% chance it’ll ever be recovered?

That’s a huge risk for construction companies of any size, especially individual contractors who rely on every piece of equipment to keep projects moving.

The good news?

With the right preventive measures, you can protect your assets and reduce the chances of theft.

And if the worst happens, knowing how to respond quickly can make all the difference.

Here’s what you need to know.

In this article...

Four Preventive Measures for Preventing Equipment Theft

Thieves look for easy targets, and unsecured jobsites or unprotected equipment are exactly that.

The National Equipment Register (NER) estimates that the construction industry in the U.S. alone loses between $300 million and $1 billion annually due to theft.

NER’s studies also suggest that under 25% of stolen equipment is recovered, with some other research showing even lower recovery rates.

What is the best way to avoid becoming part of these statistics?

Make stealing as difficult as possible.

That means securing your jobsite, protecting your equipment, setting clear expectations for employees, and keeping detailed records.

Here’s how each of these measures helps safeguard your assets.

#1 Securing Your Jobsite

Securing your construction site typically requires a mix of low- and high-tech preventive measures.

The specific measures you take will depend on factors like your budget, site surroundings, and how complex they are to implement.

However, a well-secured jobsite always starts with clear boundaries.

This means installing sturdy fencing and gates to control access.

Cost-effective temporary fencing solutions come in many forms, including options that don’t require drilling.

For example, this security fencing uses weighted ballasts of up to 200 kg (440 pounds), providing a strong and reliable barrier without the need for ground penetration.

Source: CLD Systems

Next, gates should have heavy-duty locks and tamper-proof fasteners to prevent unauthorized entry during off-hours.

Of course, even during work hours, not everyone should have unrestricted access.

Using keycards, PIN codes, or biometric scanners ensures that only approved workers enter the site.

A sign-in/sign-out log for visitors and temporary workers adds another layer of accountability.

Without strict enforcement of these measures, theft can happen right under your nose—even in broad daylight.

That’s exactly what’s been reported on jobsites in Durham, North Carolina:

“Police said a lot of these thefts are happening in broad daylight, even sometimes when workers are on the site. The thieves are coming in, acting quickly, and getting away with sometimes thousands of dollars of important tools.”

In addition to physical barriers and access control, security cameras and alarms remain essential theft deterrents—continuously evolving to be more effective and accessible.

CCTV cameras placed at entry points, high-traffic areas, and near valuable equipment not only deter thieves but also provide crucial evidence if a theft occurs.

For maximum effectiveness, cameras should have high resolution, night vision, and motion-activated recording.

Here’s an example of one such camera:

Source: Resideo

This camera is part of a battery-powered, wireless video surveillance system.

When it detects motion, it instantly records a video and sends it to your monitoring station or smartphone, allowing you to quickly assess whether it’s a real threat or a false alarm.

Generally, these systems are now more affordable, portable, and easy to relocate as jobsites change.

Paired with an alarm system that triggers upon unauthorized entry after hours, they can significantly reduce theft risks.

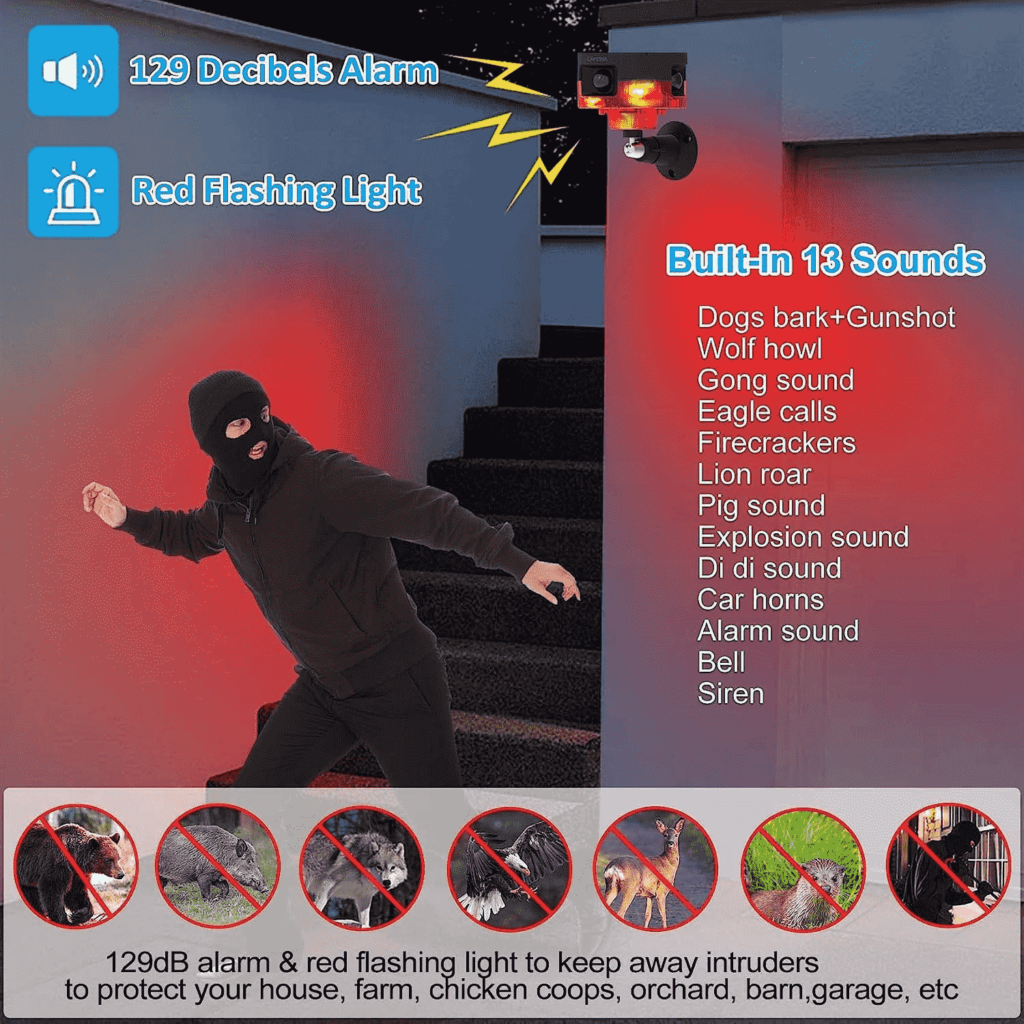

Loud sirens and flashing lights can startle intruders and drive them away before they take anything.

Source: Amazon

Finally, good jobsite lighting remains one of the simplest yet most effective deterrents.

Well-lit perimeters, pathways, and storage areas eliminate hiding spots, making it far riskier for thieves to operate undetected.

Next, let’s look at how to secure your equipment.

#2 Securing Your Equipment

Securing your jobsite is only half the battle—protecting individual pieces of equipment is just as critical.

Why?

Because heavy machinery and vehicles are prime targets for thieves, especially when left unattended overnight.

To prevent unauthorized use or theft, consider installing heavy-duty locks and immobilizers on machinery and vehicles.

Source: CALIFORNIA IMMOBILIZER

Ignition locks, hydraulic locks, and wheel locks make it significantly harder for thieves to start or move equipment.

Some manufacturers also offer built-in security features, such as keypad entry systems or operator-specific PIN codes, adding an extra layer of protection.

Of course, installing GPS trackers on your valuable mobile equipment is another key measure for added security and recovery in case of theft.

Source: GoCodes Asset Tracking

As shown, these trackers allow you to monitor your fleet in real-time and quickly locate stolen assets.

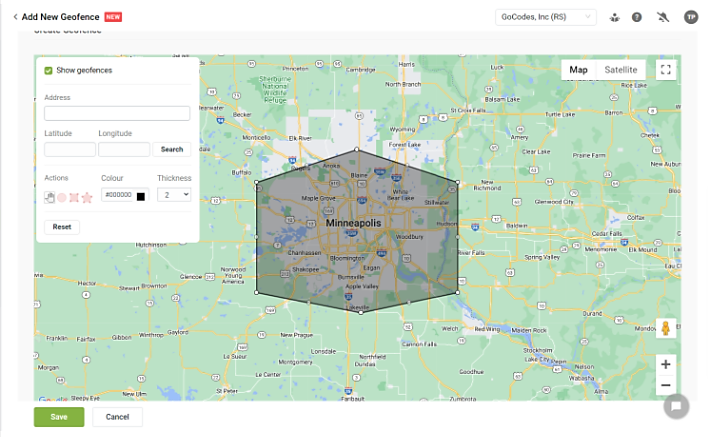

Advanced GPS systems can also send alerts if a machine moves outside your predefined security zone, known as a geofence.

Source: GoCodes Asset Tracking

Geofences can be as large or small as needed and can take any shape, such as covering transport routes from storage to site.

When you receive a geofence alert, you can immediately check whether an operator made an honest mistake—or if a theft is in progress.

Smaller tools and portable equipment are easier to steal, making secure storage essential.

As for smaller tools and portable equipment, they’re easier to steal, so secure storage is essential.

Lockable storage boxes, secure tool chests, and mobile storage units can protect handheld tools from theft.

Source: Amazon

Additionally, requiring workers to return tools to designated storage areas after each shift helps keep inventory organized and accounted for.

Of course, this relies on employee cooperation, so let’s explore how clear instructions for your team can further enhance security.

#3 Having Clear Instructions for Employees

Even with strong physical security measures, your jobsite remains vulnerable if employees don’t have clear instructions and protocols to follow.

Well-defined security procedures help ensure that every worker understands their responsibility and role in preventing theft.

Of course, having honest, well-paid, and loyal workers is probably the best theft deterrent—but clear guidelines and tracking systems further reduce risks.

Instructions typically start with establishing site access rules and communicating them during onboarding and daily briefings.

Employees should know:

- Who is allowed on-site

- How to report suspicious activity

- Proper procedures for securing equipment after each shift

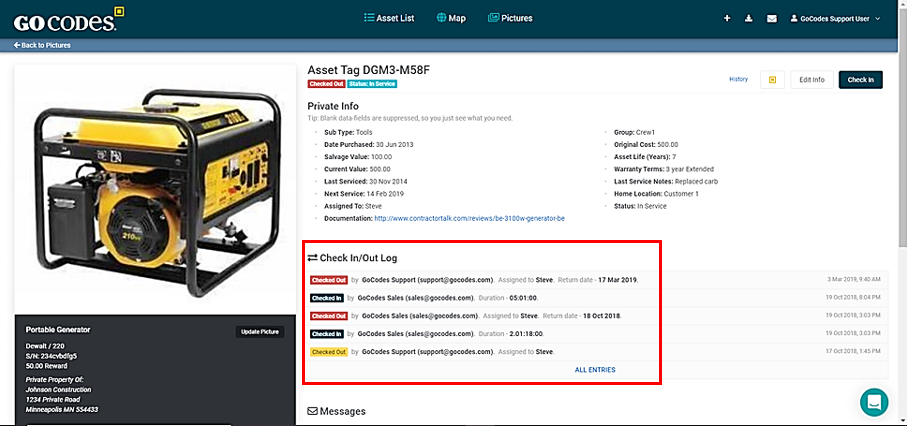

To improve accountability for tools and portable equipment, consider using an automated check-in/check-out system, creating a real-time record of usage.

Source: GoCodes Asset Tracking

In this system, workers are required to scan a tool or piece of equipment when checking it out and scan it again upon return.

This functionality improves worker accountability, thereby preventing negligent operation, unauthorized borrowing, and internal theft.

If an item goes missing, supervisors can quickly determine who last used it and take appropriate action.

Additionally, implementing end-of-day security protocols ensures that nothing is left vulnerable after work hours.

A designated team member should be instructed to lock gates, verify that lights are on, and confirm that all equipment is secured.

Ultimately, clear instructions help foster a culture of accountability, where every worker understands that theft prevention is a shared responsibility.

#4 Keeping Detailed And Accurate Equipment Records

To effectively manage equipment and prevent theft, keeping detailed and accurate records is essential.

Why?

Because if you don’t know what you have, you won’t even realize when it’s gone—especially for smaller, less critical tools and other inventory items.

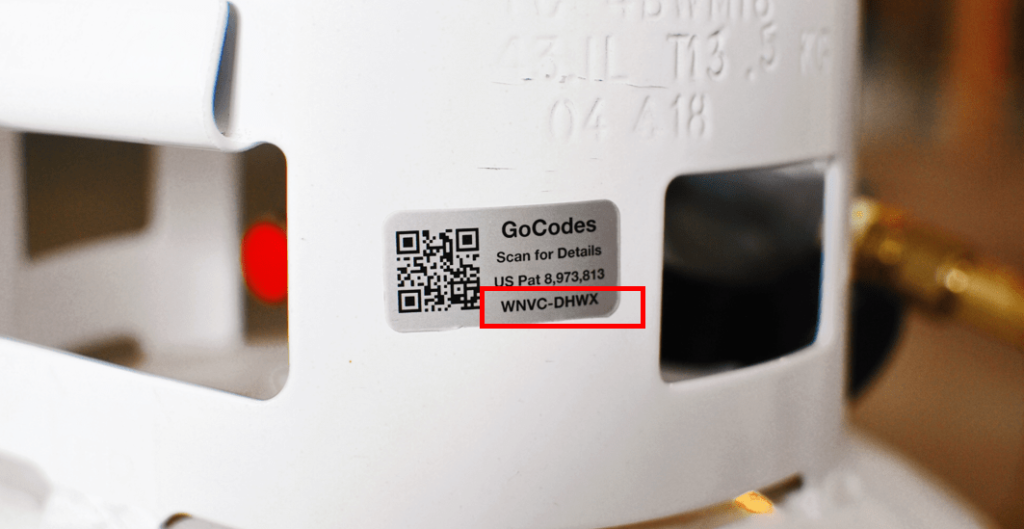

One of the most efficient ways to keep records up to date is by using scannable QR codes in combination with in-app scanners and asset-tracking software.

With QR code tags attached to equipment, tools, and other items, workers can use their smartphones or tablets to easily scan the tag and view or update asset records in real-time.

Here’s how this simple process works:

Source: GoCodes Asset Tracking

Additionally, each scan automatically captures crucial information—namely the worker’s ID, time, and location—creating an audit trail that can be reviewed at any time.

Although QR code tags are not real-time trackers, they use the scanning device’s GPS locator to record the asset’s location.

This minimizes the need for manual data entry, reducing human error and increasing accuracy.

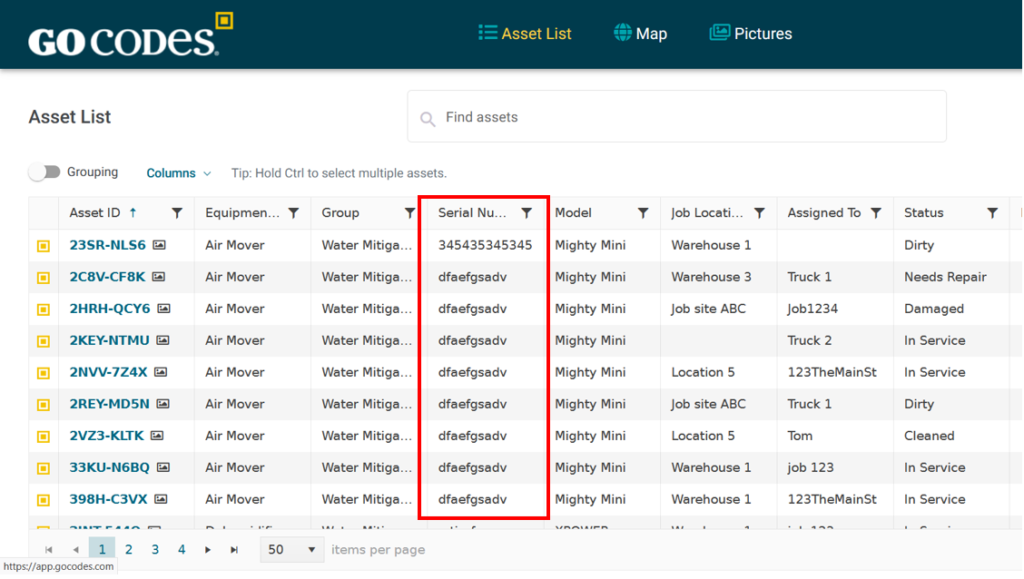

Along with the check-in/check-out function described earlier, this system allows you to keep a central database of tracked tools and equipment accurate and up to date.

Better yet, this digital database allows you to store other asset data that may prove critical in case of theft, such as equipment serial numbers.

Source: GoCodes Asset Tracking

If you’re also using GPS trackers, asset-tracking software like GoCodes Asset Tracking ties these elements together, syncing the data from QR scans and GPS into a centralized system.

All the above functions of asset-tracking software enable you to maintain accurate, real-time records, ensuring you can identify missing equipment right away and take action.

What If Your Equipment Gets Stolen Anyway?

Although we’ve covered key preventive measures to help protect your equipment, theft can still happen.

In such cases, quick action is essential to recover stolen assets and minimize losses.

The following steps outline the critical actions you should take if your equipment goes missing.

1. Report the Theft Immediately

Once you’re certain that a piece of equipment has been stolen rather than lost or misplaced, the first thing to do is contact local law enforcement and file a police report.

When filing the report, be sure to provide detailed information, including serial numbers, photos, and any other identifying features of the stolen item.

These details can be stored in your central asset database, along with attached photos of the equipment and its unique identifiers.

Typically, such identifiers include the nameplate with the serial number and the QR code tag with the asset ID assigned to it in your digital asset list.

Source: GoCodes Asset Tracking

Since these tags can be made from tamper-proof or hard-to-remove materials, providing photos of them can help authorities identify and recover the stolen asset.

Additionally, they serve as proof of ownership if the equipment is found.

While reporting theft is the first step, a parallel move is to review your tracking and security systems for additional data that can aid authorities in the recovery process.

2. Review Your Tracking and Security Systems

Other than acting as deterrents, your tracking and security systems can provide crucial leads about the location of the stolen equipment and the perpetrator(s).

So, the next step is to analyze the data these systems have recorded.

If the missing equipment has a real-time GPS tracker, check your tracking app to see if it’s still transmitting a location.

If the tracker remains active, law enforcement may be able to recover the equipment quickly.

Some trackers can be discreetly hidden to avoid detection, while decoy trackers can mislead thieves into thinking they removed them.

Cases like this frequently make the news, often leading to the discovery of additional stolen assets—sometimes worth millions.

That’s exactly what recently happened in Alberta, Canada.

Source: Edmonton Journal

As Constable Corey Riggs explained, a victim of theft had a GPS tracker installed on their equipment.

Since it remained active, they reported the location to the police, which led to a major recovery operation.

“It popped up on their GPS tracking app, and then we were able to go from there.”

While real-time GPS tracking is ideal for locating high-value assets, it’s often too expensive or impractical for smaller equipment, tools, and other items.

However, if these assets are tagged with scan-based GPS QR codes, as described earlier, you’ll be able to check where the stolen item was last scanned and by whom.

Source: GoCodes Asset Tracking

This can help narrow down when and where the asset was last seen, determine who was responsible for it, and identify potential witnesses.

Of course, you should also check security camera footage for any suspicious activity or unauthorized access around the time of the theft.

Any relevant data, including GPS records and video evidence, should be shared with law enforcement to support the investigation.

3. Notify Nearby Job Sites and Equipment Dealers

If your equipment is stolen, spreading the word can increase the chances of recovery.

Start by notifying nearby construction sites and competitors so they can be on the lookout.

Providing photos, descriptions, and serial numbers of stolen equipment will make identification easier.

It might just happen that thieves offer to sell your items to your fellow contractors, or they turn up on their site as part of a worker’s or subcontractor’s personal gear.

Next, alert equipment dealers, rental companies, and other potential resale points, depending on the type of stolen asset.

Remember, the more people who are watching, the better your chances are of getting equipment back.

4. File an Insurance Claim

If your equipment is insured against theft, filing a claim as soon as possible can help you recover your losses more quickly.

Depending on your coverage, you may also be compensated for project delays or lost income due to the theft.

Start by gathering all necessary documents, including the police report, proof of ownership, purchase receipts, and an estimate of the asset’s value.

Again, having a centralized asset database with digital records can significantly streamline this process.

Source: GoCodes Asset Tracking

With all relevant details stored in one place, you can quickly retrieve ownership documents, maintenance logs, inspection reports, and depreciation calculations.

These records are essential for determining the value of stolen equipment and may be required by your insurer for verification.

Of course, photos and serial numbers are crucial to your claim, and a digital database ensures they’re readily accessible.

With these documents in order, contact your insurance provider and follow their claims process carefully.

Be ready to respond promptly to any requests for additional information to avoid delays.

Ultimately, a well-documented claim increases the likelihood of a swift payout, allowing you to replace stolen equipment and minimize losses.

Conclusion

Preventing equipment theft requires a proactive approach, from securing jobsites and equipment to maintaining accurate records and enforcing clear security protocols.

While theft can still occur, the right tracking tools and quick actions can improve your chances of recovery.

Don’t wait until it’s too late—invest in smart security measures today to protect your assets and keep your projects on track.